Simple Stresses

Simple stresses are expressed as the ratio of the applied force divided by the resisting

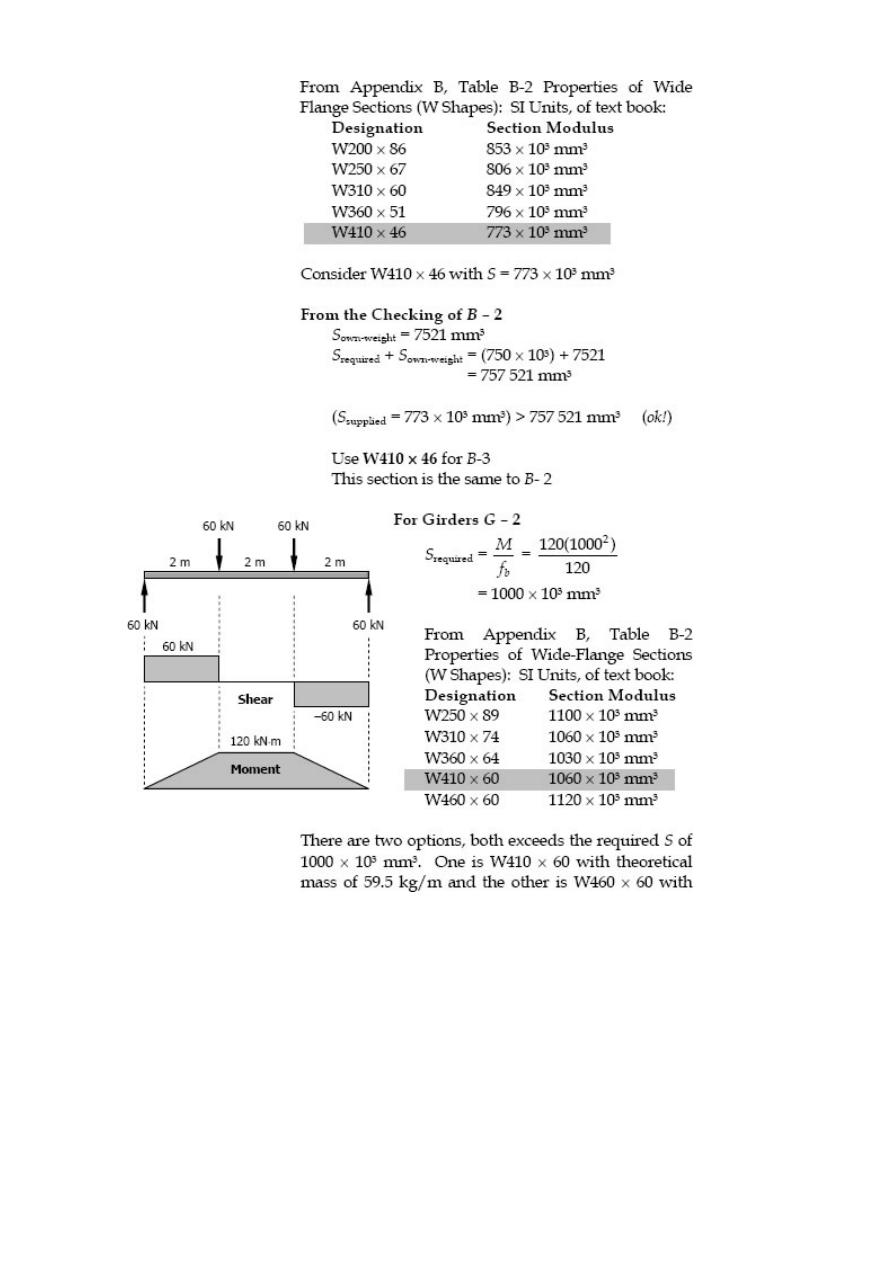

area or

σ = Force / Area.

It is the expression of force per unit area to structural members that are subjected to

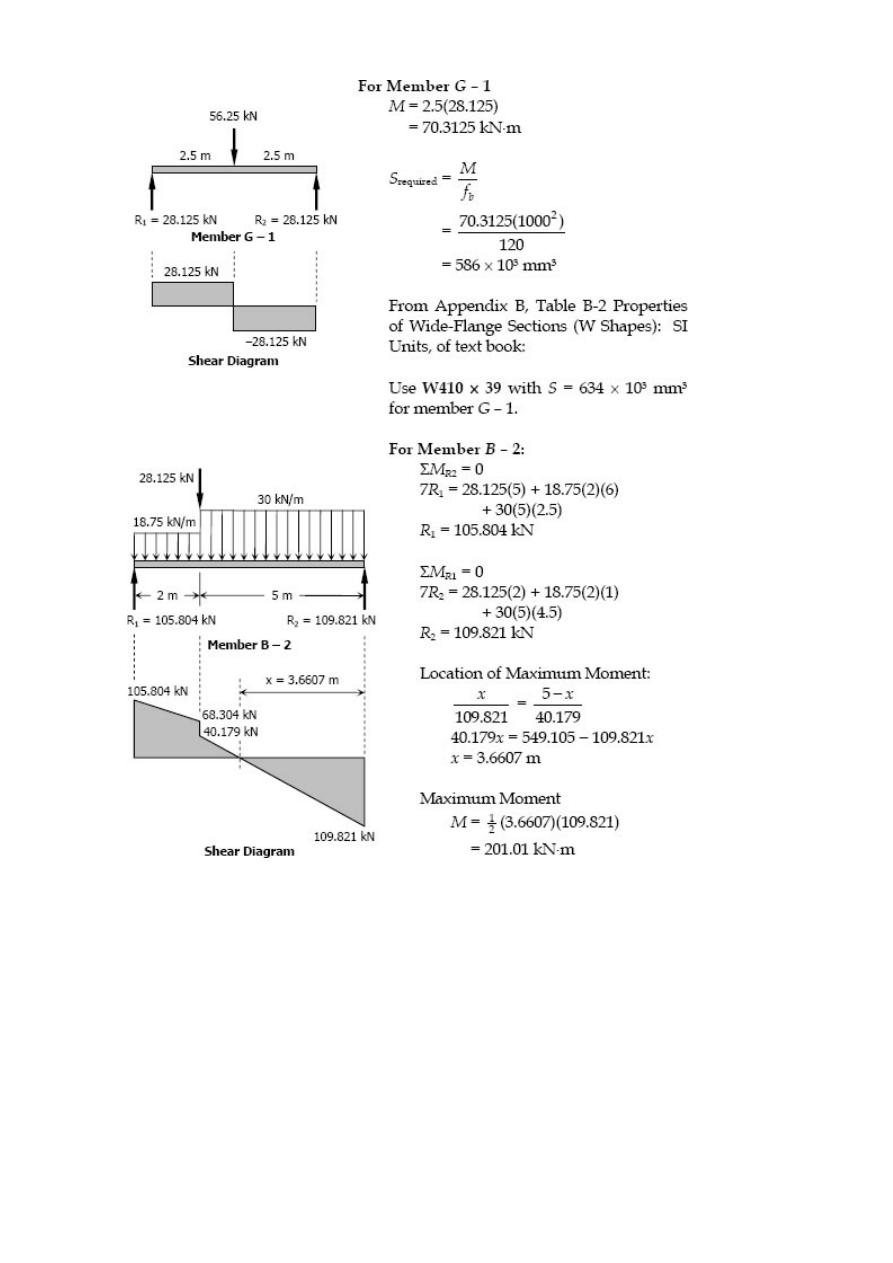

external forces and/or induced forces. Stress is the lead to accurately describe and

predict the elastic deformation of a body.

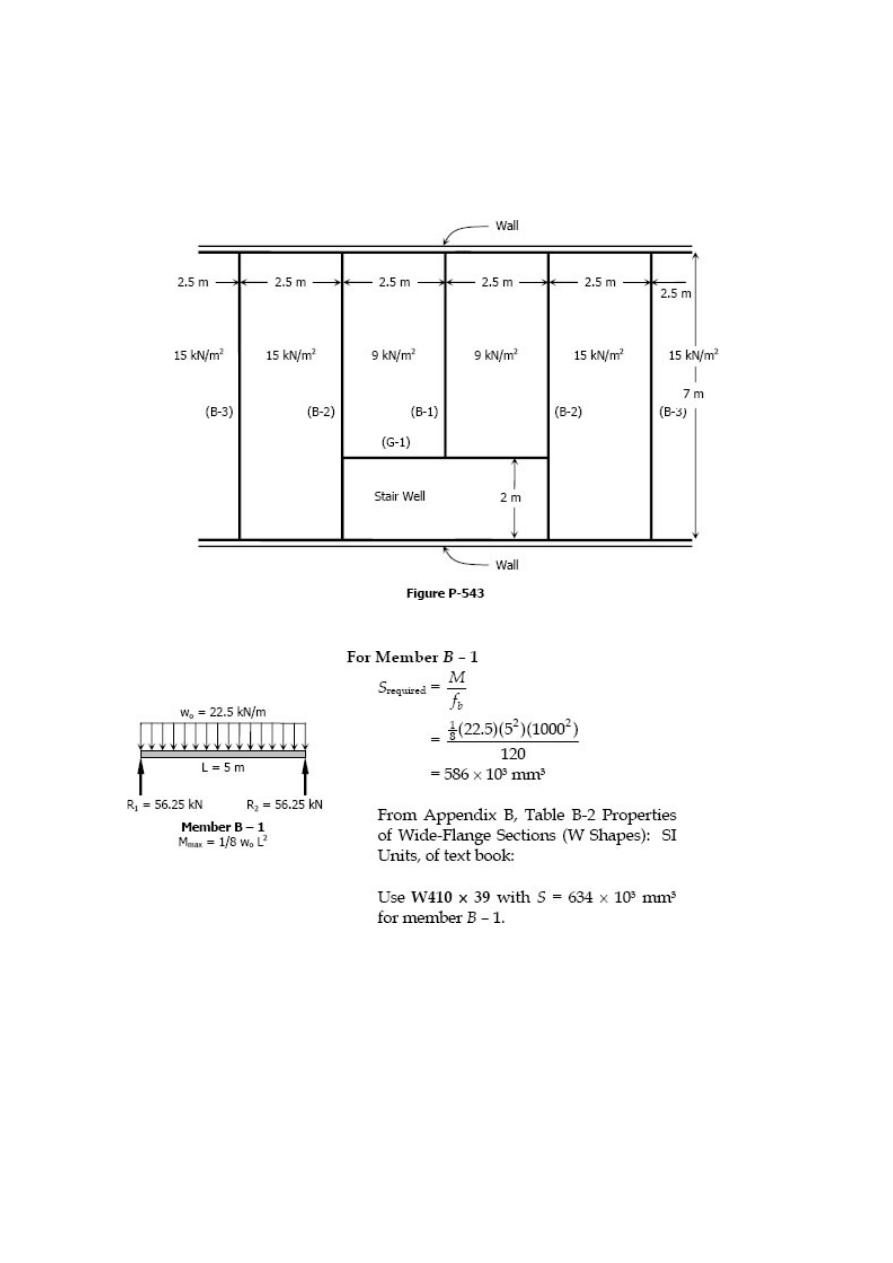

Simple stress can be classified as normal stress, shear stress, and bearing stress.

Normal stress develops when a force is applied perpendicular to the cross-sectional

area of the material. If the force is going to pull the material, the stress is said to be

tensile stress and compressive stress develops when the material is being

compressed by two opposing forces. Shear stress is developed if the applied force is

parallel to the resisting area. Example is the bolt that holds the tension rod in its

anchor. Another condition of shearing is when we twist a bar along its longitudinal axis.

This type of shearing is called torsion and covered in Chapter 3. Another type of simple

stress is the bearing stress, it is the contact pressure between two bodies.

Suspension bridges are good example of structures that carry these stresses. The

weight of the vehicle is carried by the bridge deck and passes the force to the stringers

(vertical cables), which in turn, supported by the main suspension cables. The

suspension cables then transferred the force into bridge towers.

Normal Stress

Stress

Stress is the expression of force applied to a unit area of surface. It is measured in psi

(English unit) or in MPa (SI unit). Another unit of stress which is not commonly used is

the dynes (cgs unit). Stress is the ratio of force over area.

stress = force / area

Simple Stresses

There are three types of simple stress namely; normal stress, shearing stress, and

bearing stress.

Normal Stress

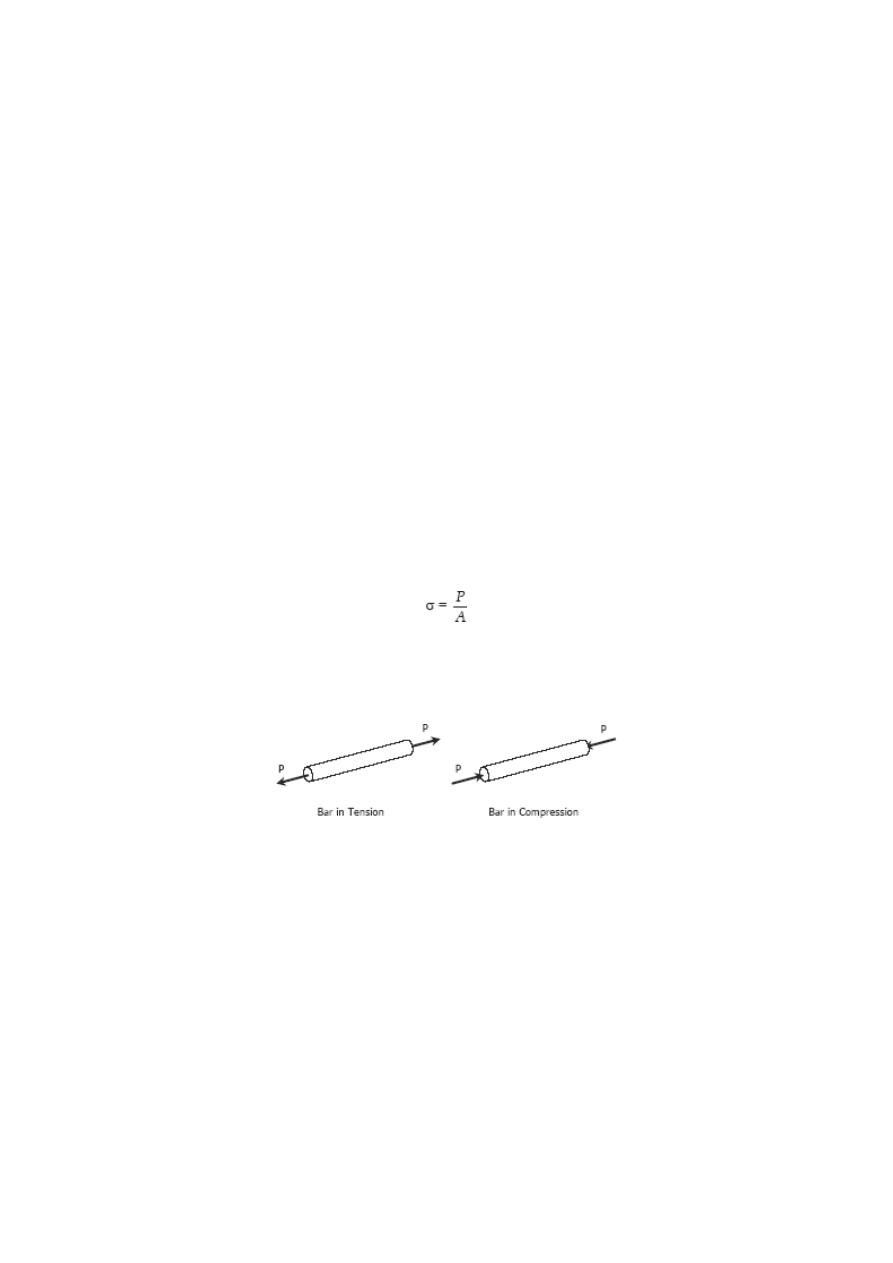

The resisting area is perpendicular to the applied force, thus normal. There are two

types of normal stresses; tensile stress and compressive stress. Tensile stress applied

to bar tends the bar to elongate while compressive stress tend to shorten the bar.

where P is the applied normal load in Newton and A is the area in mm

2

. The maximum

stress in tension or compression occurs over a section normal to the load.

SOLVED PROBLEMS IN NORMAL STRESS

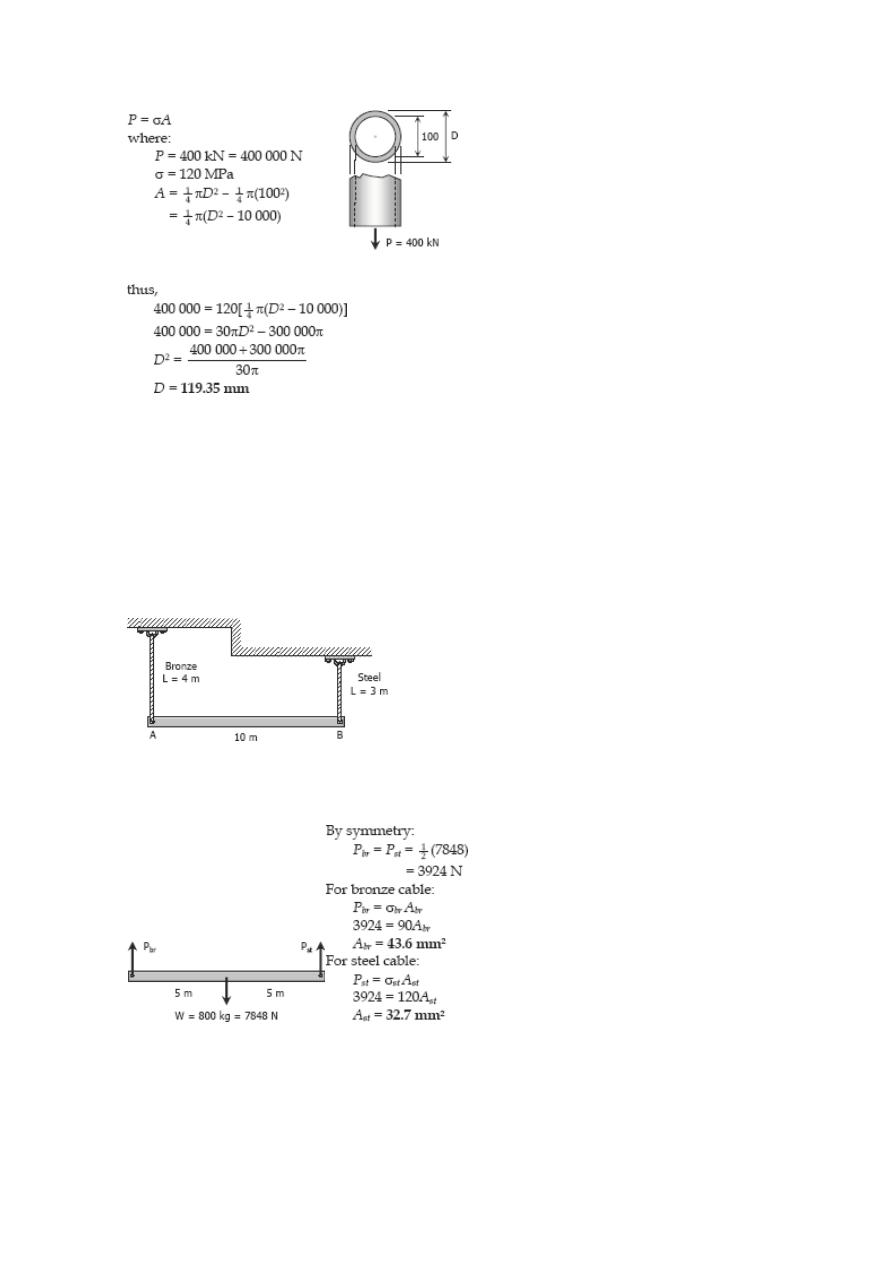

Problem 104

A hollow steel tube with an inside diameter of 100

mm must carry a tensile load of 400 kN. Determine

the outside diameter of the tube if the stress is limited

to 120 MN/m

2

.

Solution 104

Problem 105

A homogeneous 800 kg bar AB is supported at either

end by a cable as shown in Fig. P-105. Calculate the

smallest area of each cable if the stress is not to exceed

90 MPa in bronze and 120 MPa in steel.

Figure P-105

Solution 105

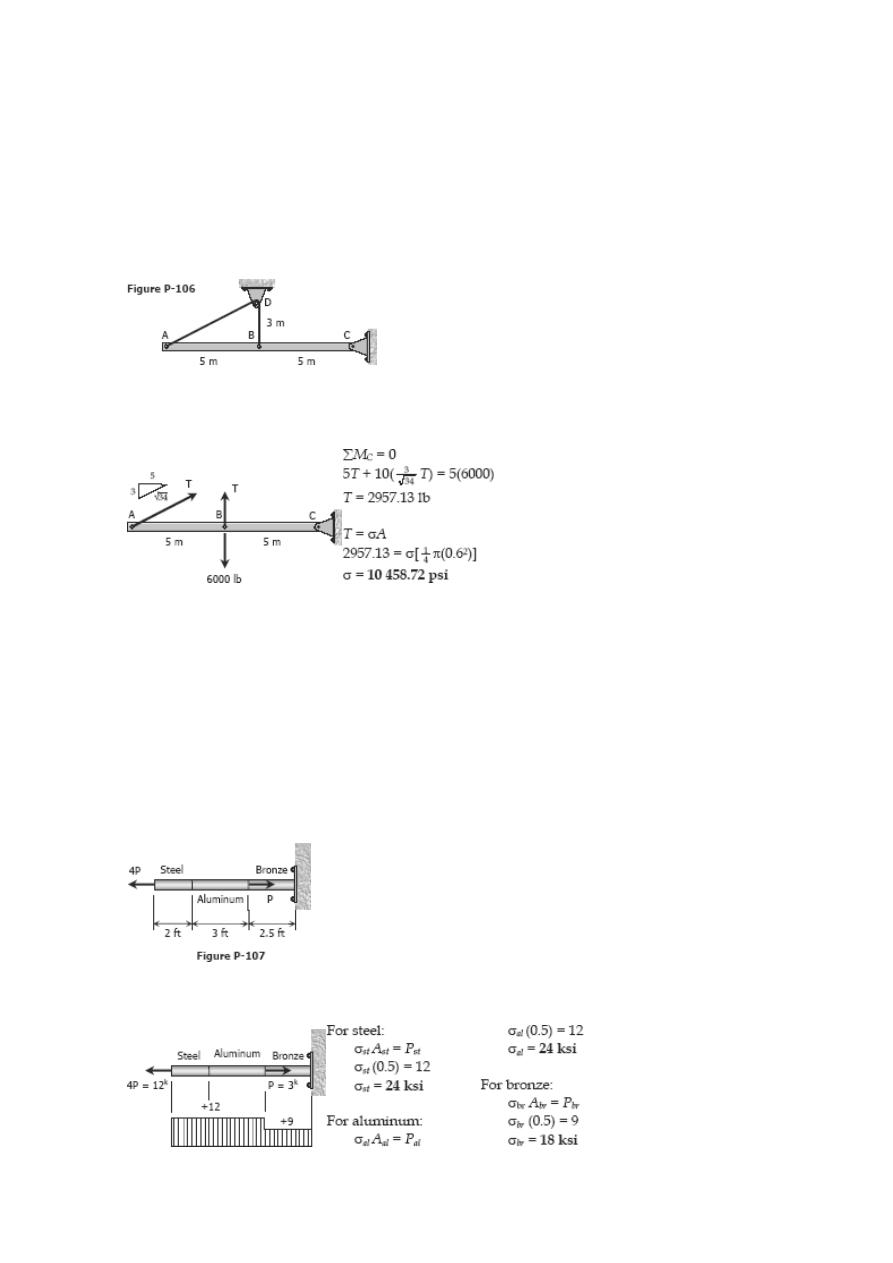

Problem 106

The homogeneous bar shown in Fig. P-106 is

supported by a smooth pin at C and a cable that runs

from A to B around the smooth peg at D. Find the

stress in the cable if its diameter is 0.6 inch and the

bar weighs 6000 lb.

Solution 106

Problem 107

A rod is composed of an aluminum section rigidly

attached between steel and bronze sections, as shown

in Fig. P-107. Axial loads are applied at the positions

indicated. If P = 3000 lb and the cross sectional area

of the rod is 0.5 in

2

, determine the stress in each

section.

Solution 107

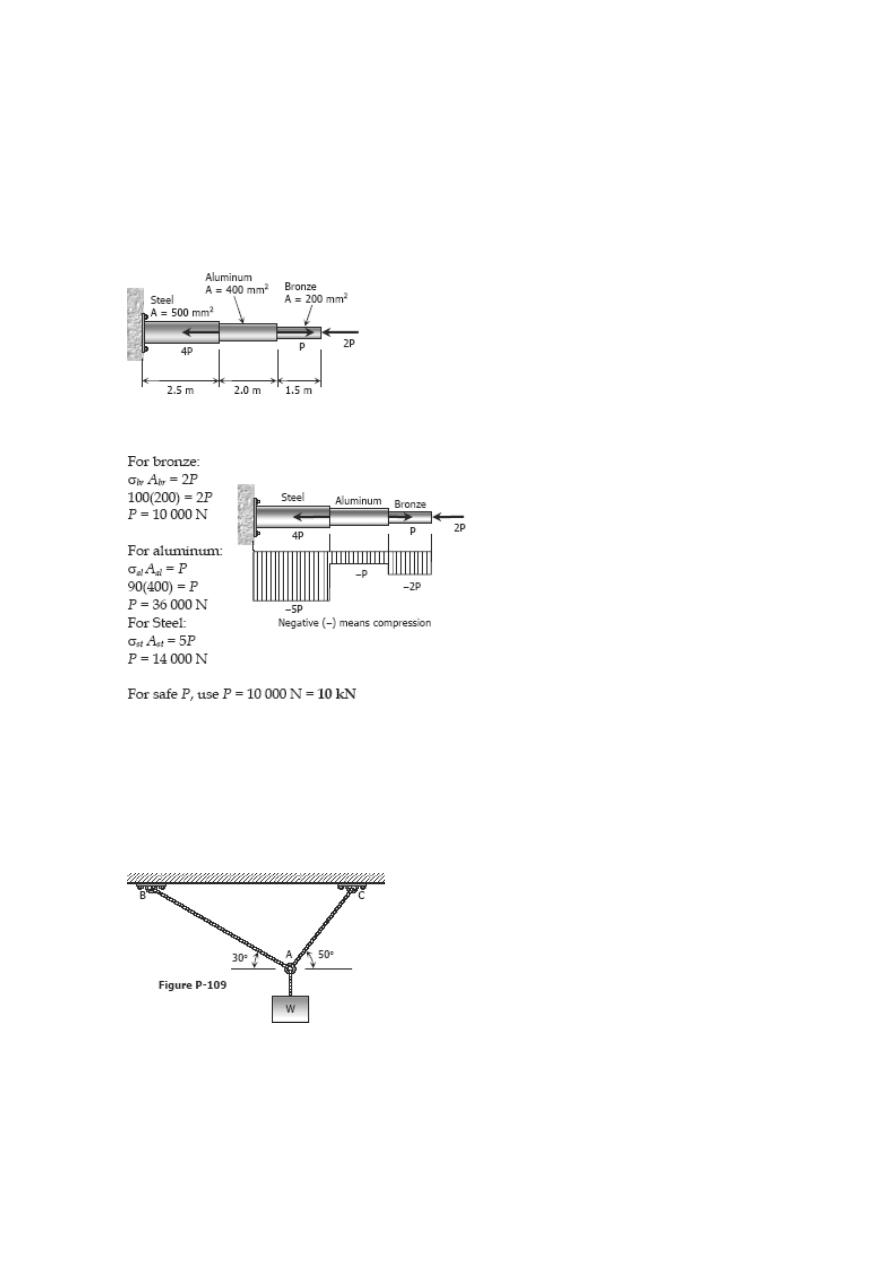

Problem 108

An aluminum rod is rigidly attached between a steel rod and a bronze rod as shown in

Fig. P-108. Axial loads are applied at the positions indicated. Find the maximum value of

P that will not exceed a stress in steel of 140 MPa, in aluminum of 90 MPa, or in bronze

of 100 MPa.

Figure P-108

Solution 108

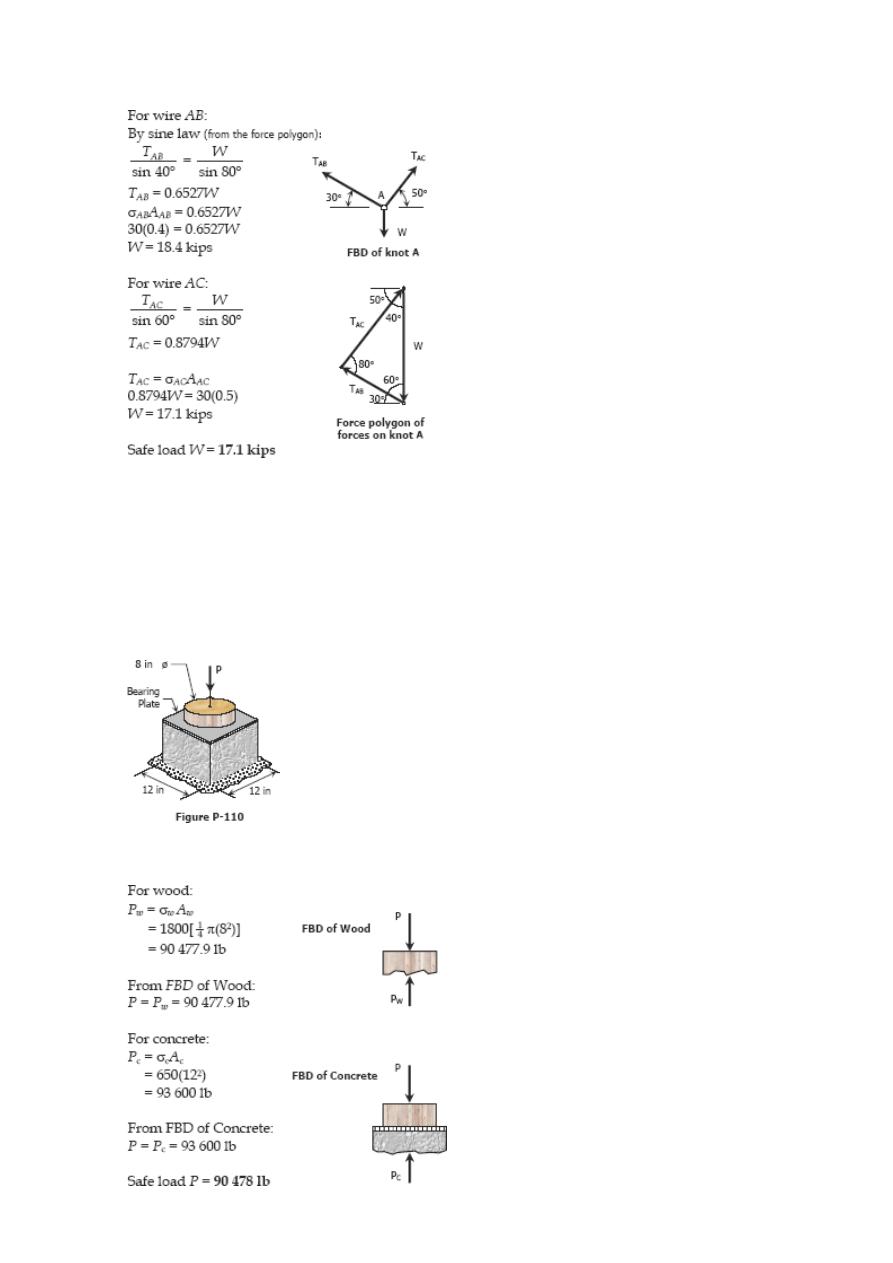

Problem 109

Determine the largest weight W that can be supported by two wires shown in Fig. P-

109. The stress in either wire is not to exceed 30 ksi. The cross-sectional areas of wires

AB and AC are 0.4 in

2

and 0.5 in

2

, respectively.

Solution 109

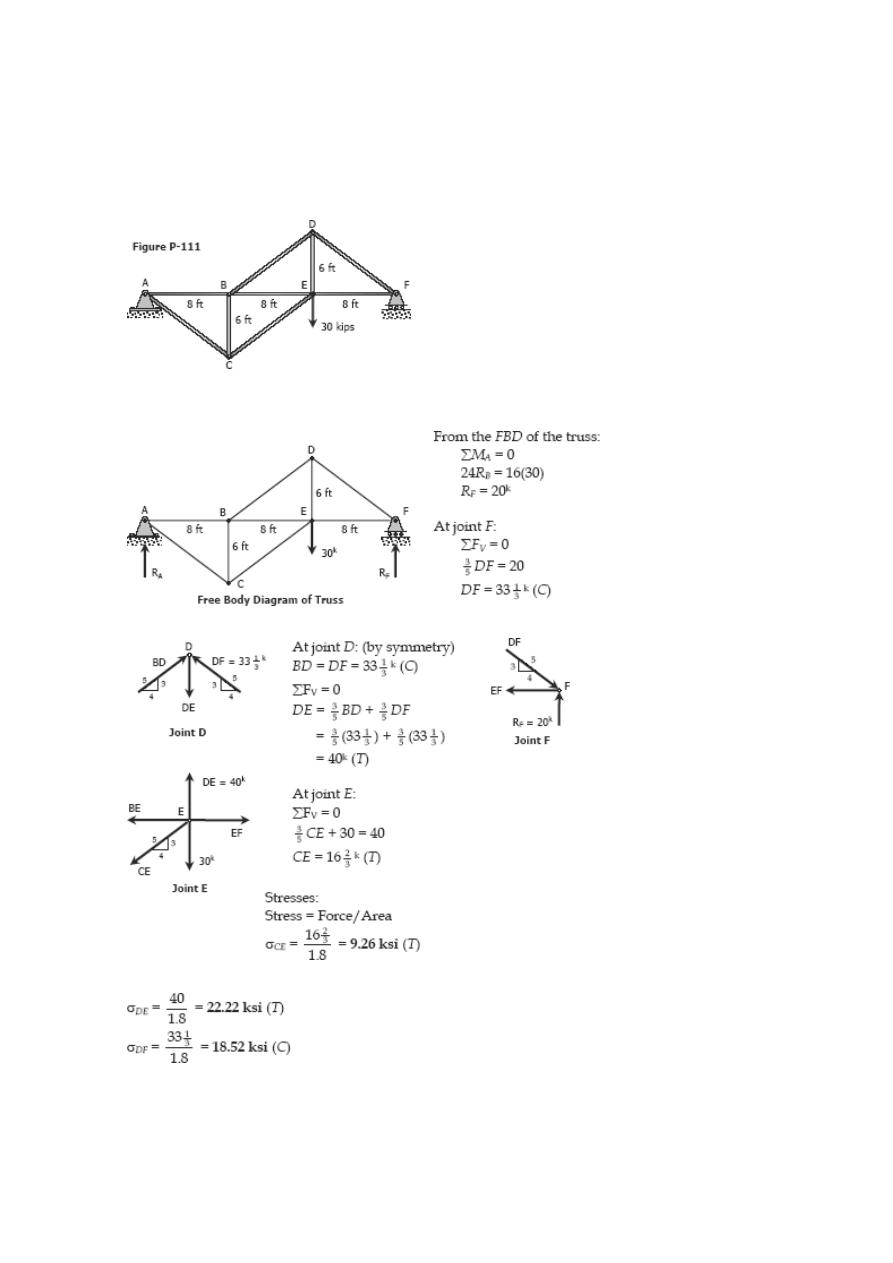

Problem 110

A 12-inches square steel bearing plate lies between an 8-inches diameter

wooden post and a concrete footing as shown in Fig. P-110. Determine

the maximum value of the load P if the stress in wood is limited to 1800

psi and that in concrete to 650 psi.

Solution 110

Problem 111

For the truss shown in Fig. P-111, calculate the stresses in members CE, DE, and DF.

The crosssectional area of each member is 1.8 in

2

. Indicate tension (T) or compression

(C).

Solution 111

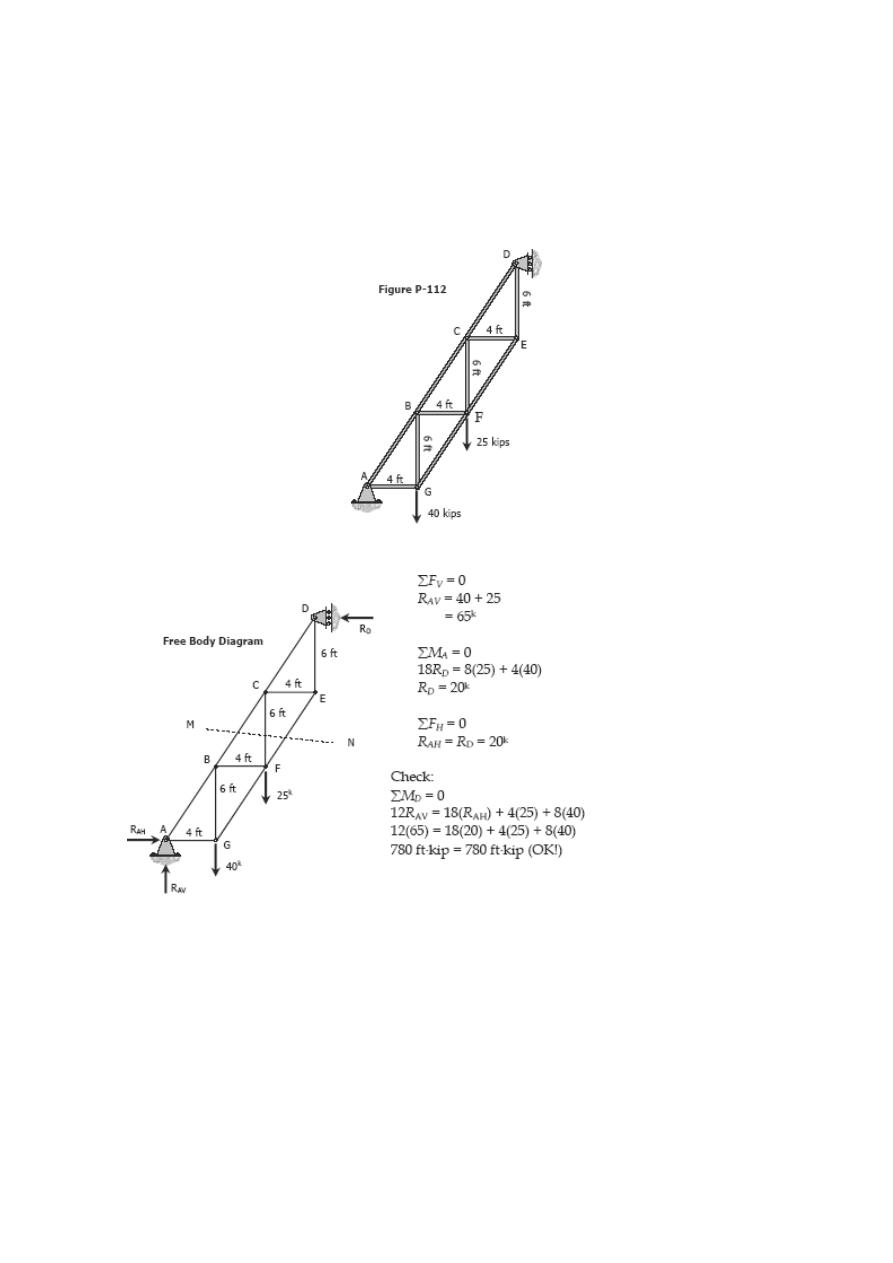

Problem 112

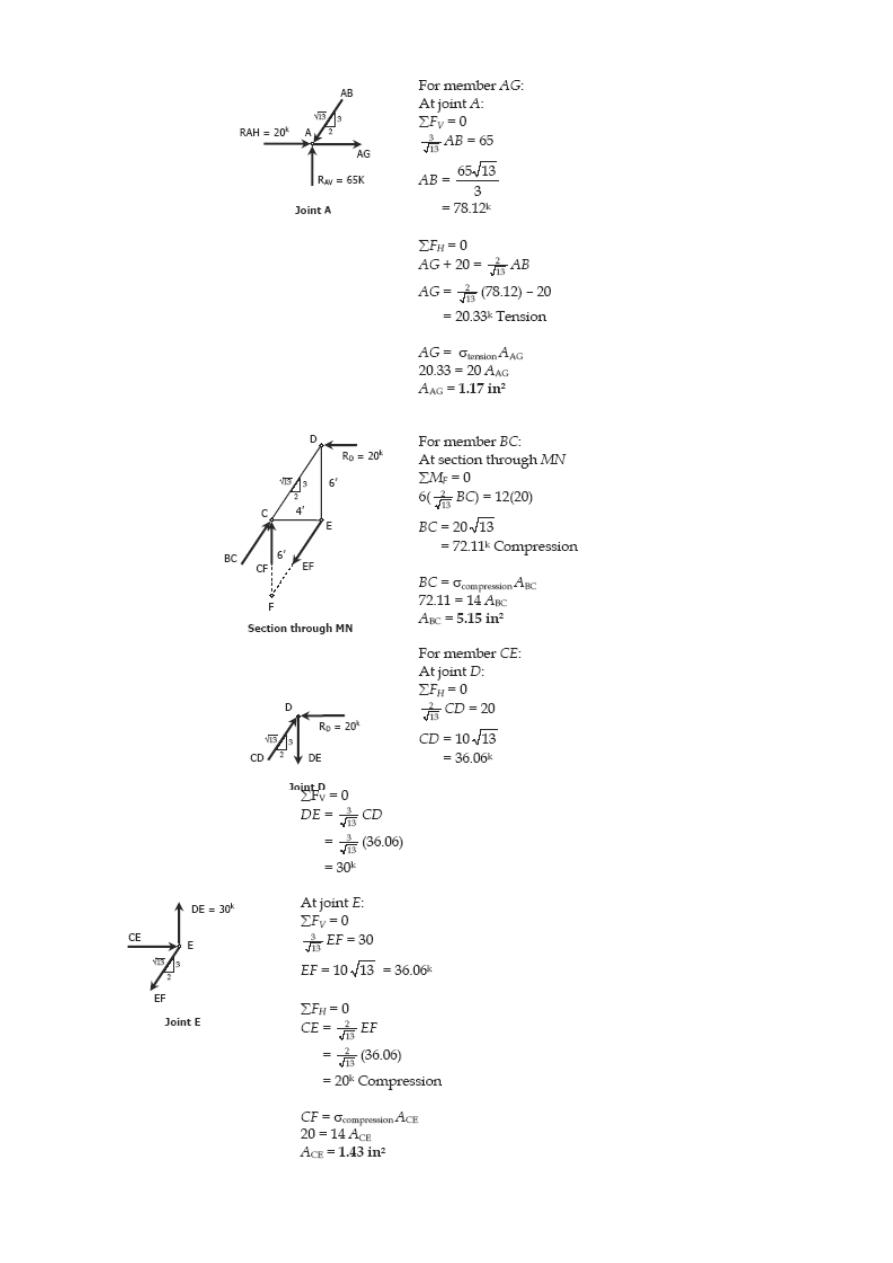

Determine the crosssectional areas of members AG, BC, and CE for the truss shown in

Fig. P-112 above. The stresses are not to exceed 20 ksi in tension and 14 ksi in

compression. A reduced stress in compression is specified to reduce the danger of

buckling.

Solution 112

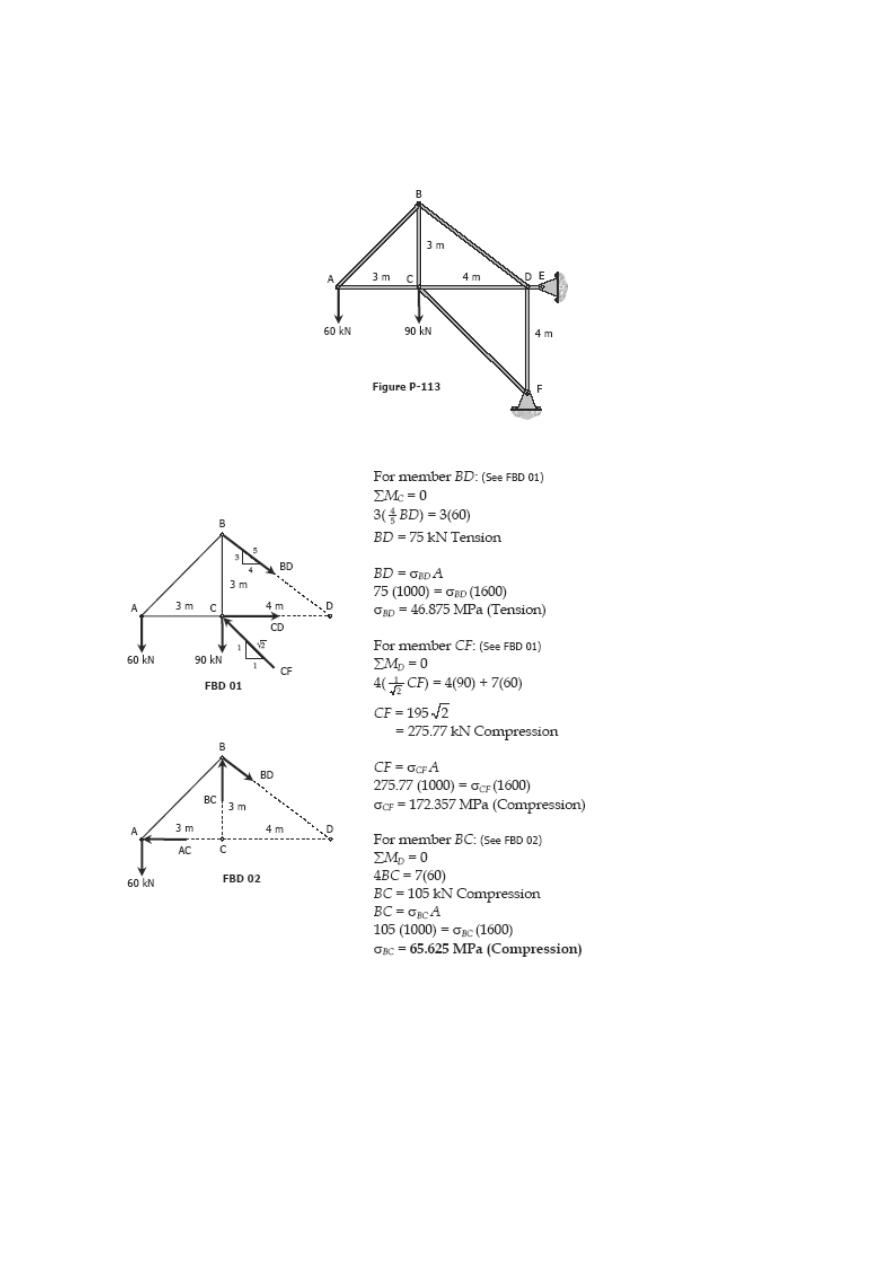

Problem 113

Find the stresses in members BC, BD, and CF for the truss shown in Fig. P-113. Indicate

the tension or compression. The cross sectional area of each member is 1600 mm

2

.

Solution 113

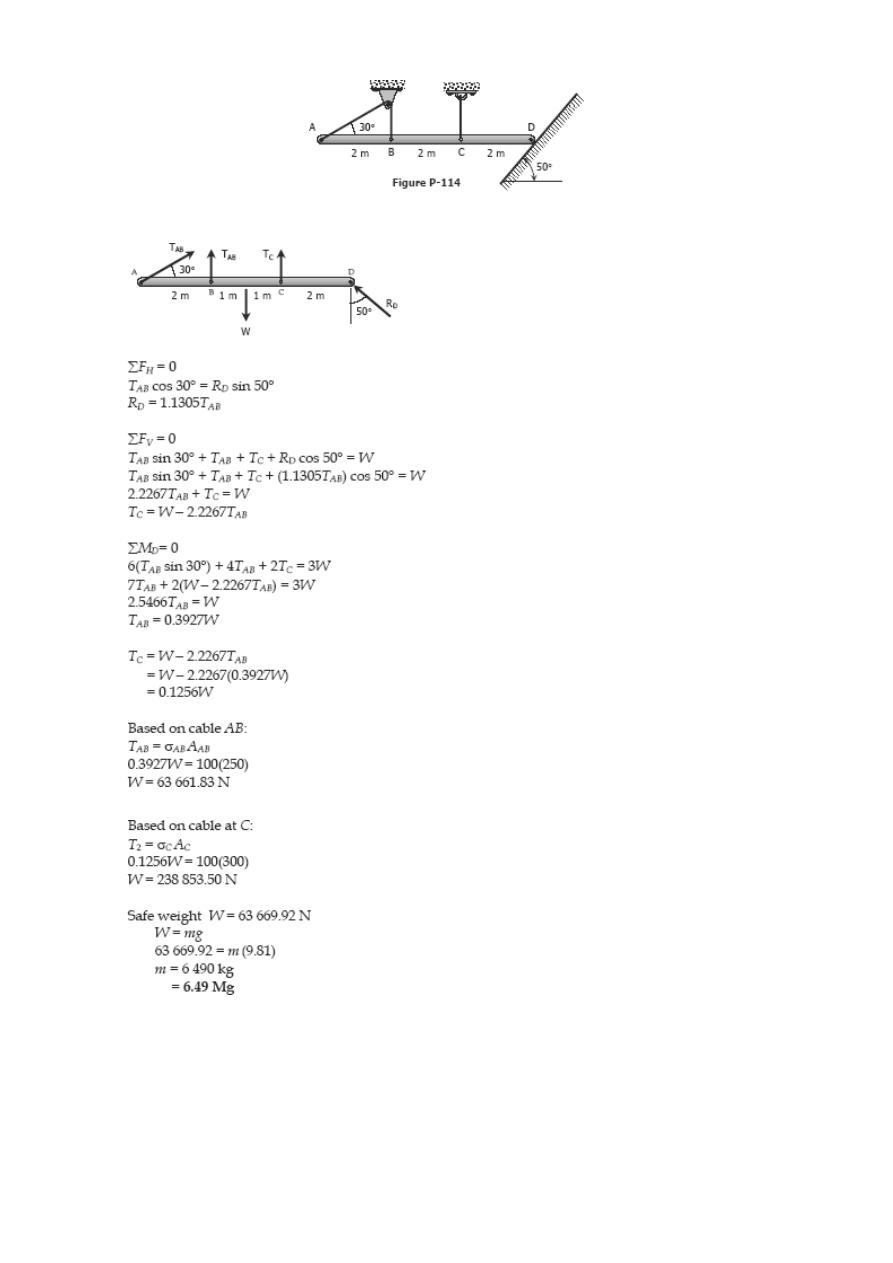

Problem 114

The homogeneous bar ABCD shown in Fig. P-114 is supported by a cable that runs from

A to B around the smooth peg at E, a vertical cable at C, and a smooth inclined surface

at D. Determine the mass of the heaviest bar that can be supported if the stress in each

cable is limited to 100 MPa. The area of the cable AB is 250 mm

2

and that of the cable

at C is 300 mm

2

.

Solution 114

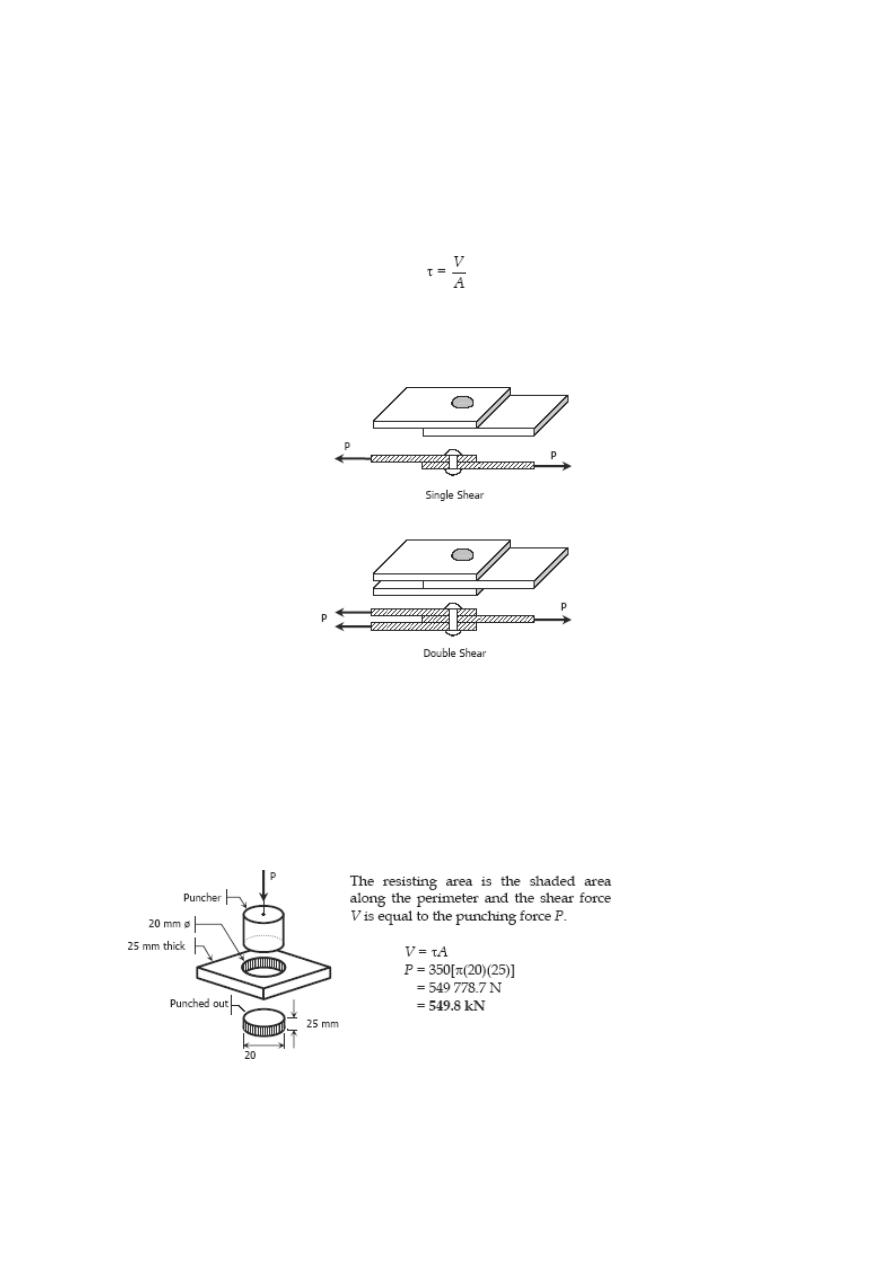

Shearing Stress

Forces parallel to the area resisting the force cause shearing stress. It differs to tensile

and compressive stresses, which are caused by forces perpendicular to the area on

which they act. Shearing stress is also known as tangential stress.

where V is the resultant shearing force which passes which passes through the centroid

of the area A being sheared.

SOLVED PROBLEMS IN SHEARING STRESS

Problem 115

What force is required to punch a 20-mm-diameter hole in a plate that is 25 mm thick?

The shear strength is 350 MN/m

2

.

Solution 115

Problem 116

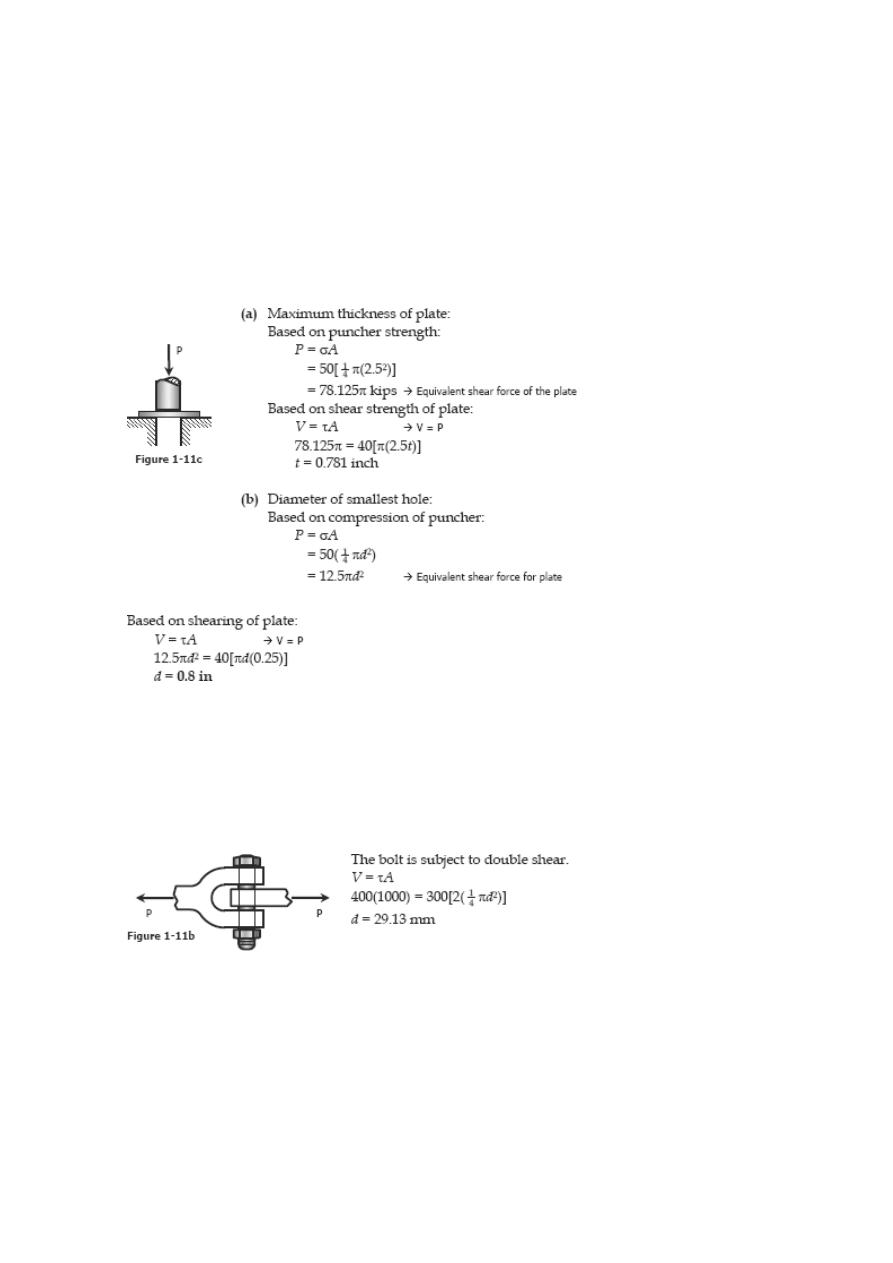

As in Fig. 1-11c, a hole is to be punched out of a plate having a shearing strength of 40

ksi. The compressive stress in the punch is limited to 50 ksi. (a) Compute the maximum

thickness of plate in which a hole 2.5 inches in diameter can be punched. (b) If the

plate is 0.25 inch thick, determine the diameter of the smallest hole that can be

punched.

Solution 116

Problem 117

Find the smallest diameter bolt that can be used in the clevis shown in Fig. 1-11b if P =

400 kN. The shearing strength of the bolt is 300 MPa.

Solution 117

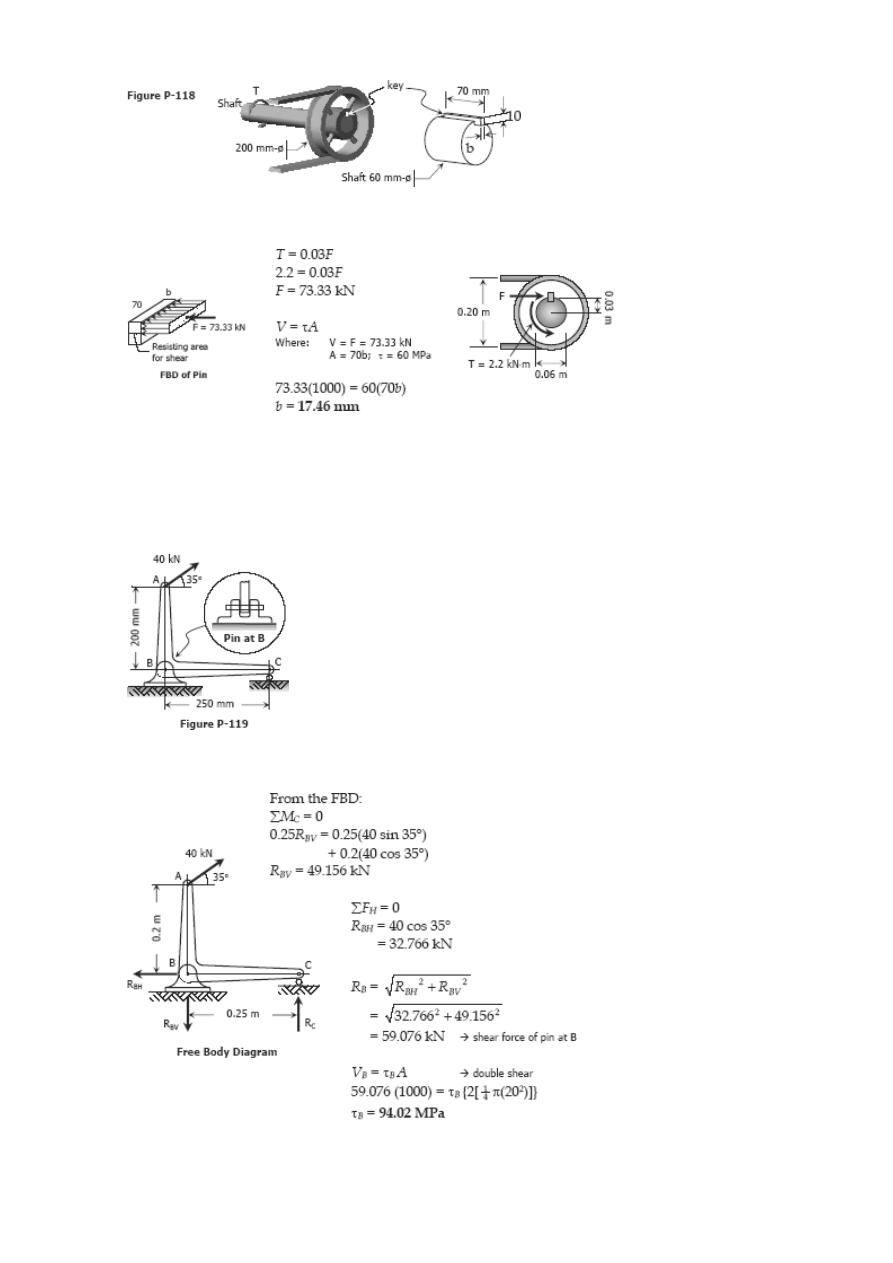

Problem 118

A 200-mm-diameter pulley is prevented from rotating relative to 60-mm-diameter shaft

by a 70-mm-long key, as shown in Fig. P-118. If a torque T = 2.2 kN·m is applied to the

shaft, determine the width b if the

allowable shearing stress in the key is 60 MPa.

Solution 118

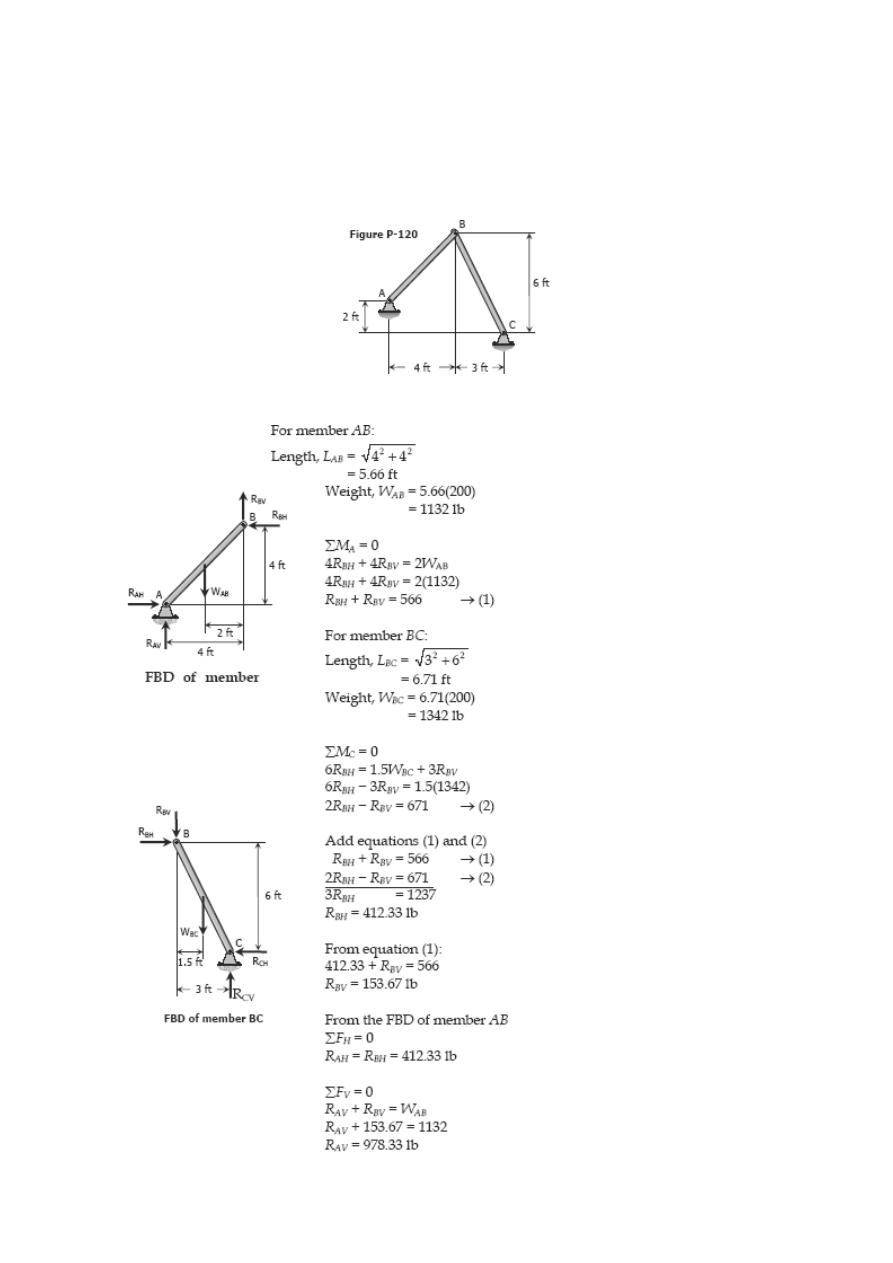

Problem 119

Compute the shearing stress in the pin at B for the member supported as

shown in Fig. P-119. The pin diameter is 20 mm.

Solution 119

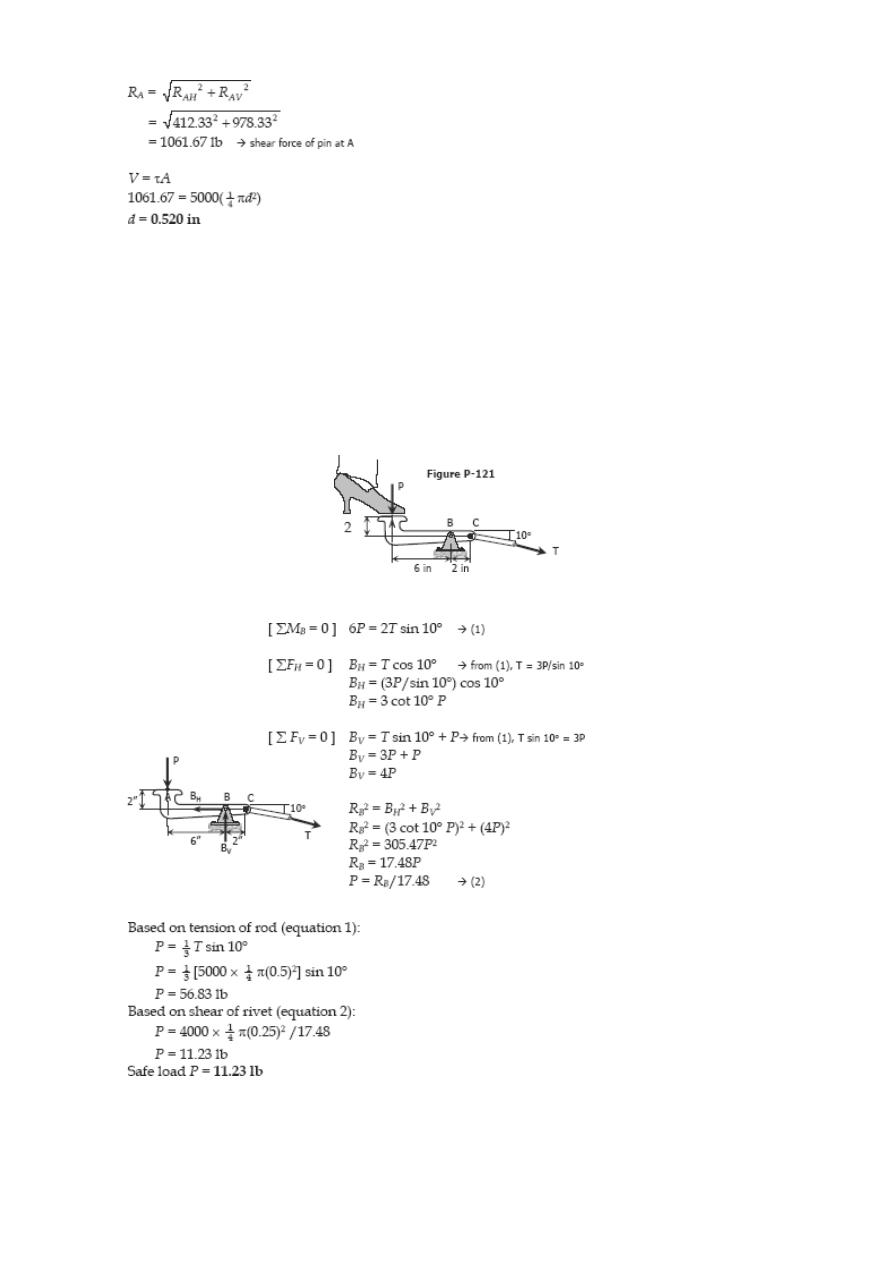

Problem 120

The members of the structure in Fig. P-120 weigh 200 lb/ft. Determine the smallest

diameter pin that can be used at A if the shearing stress is limited to 5000 psi. Assume

single shear.

Solution 120

Problem 121

Referring to Fig. P-121, compute the maximum force P that can be applied by the

machine operator, if the shearing stress in the pin at B and the axial stress in the

control rod at C are limited to 4000 psi and 5000 psi, respectively. The diameters are

0.25 inch for the pin, and 0.5 inch for the control rod. Assume single shear for the pin

at B.

Solution 121

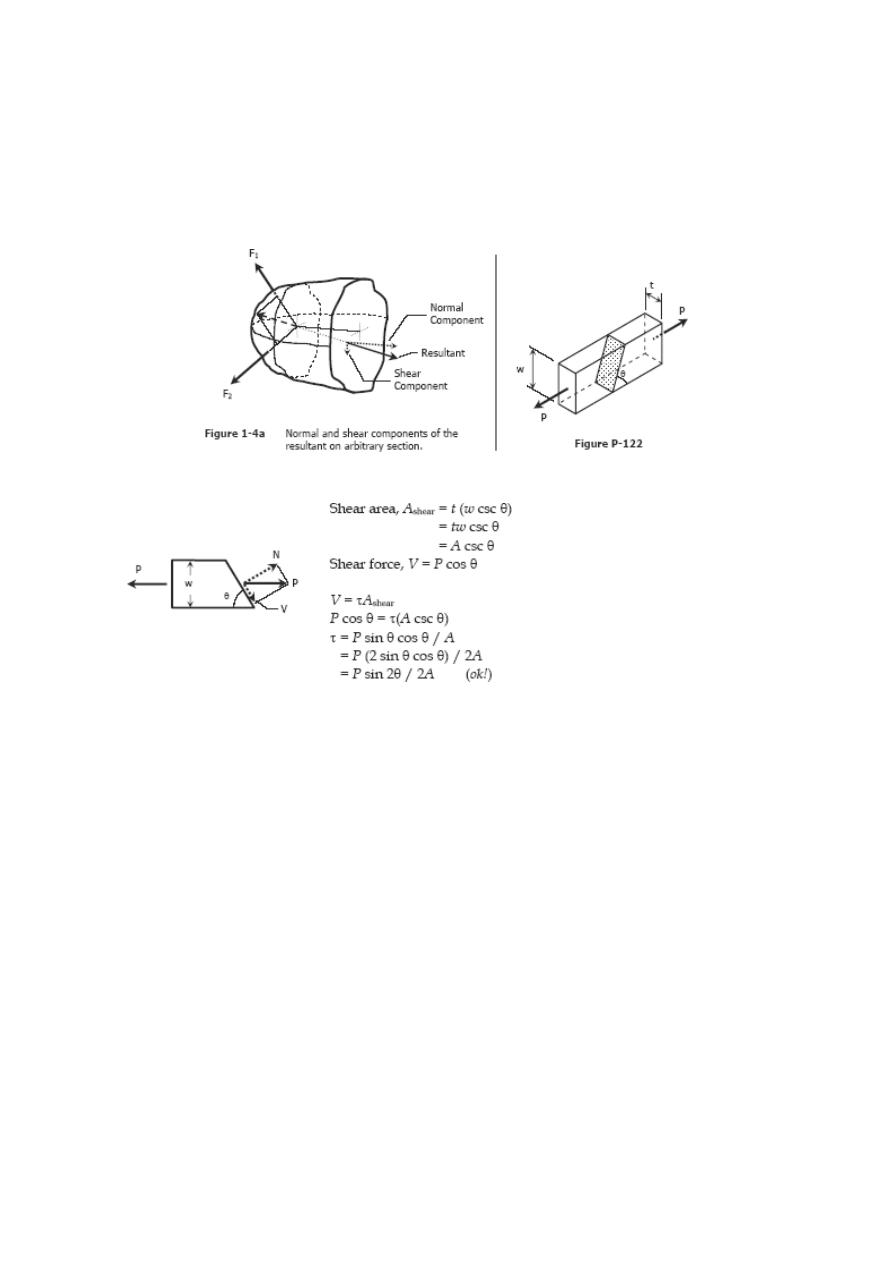

Problem 122

Two blocks of wood, width w and thickness t, are glued together along the joint inclined

at the angle θ as shown in Fig. P-122. Using the free-body diagram concept in Fig. 1-4a,

show that the shearing stress on the glued joint is τ = P sin 2θ/2A, where A is the cross-

sectional area.

Solution 122

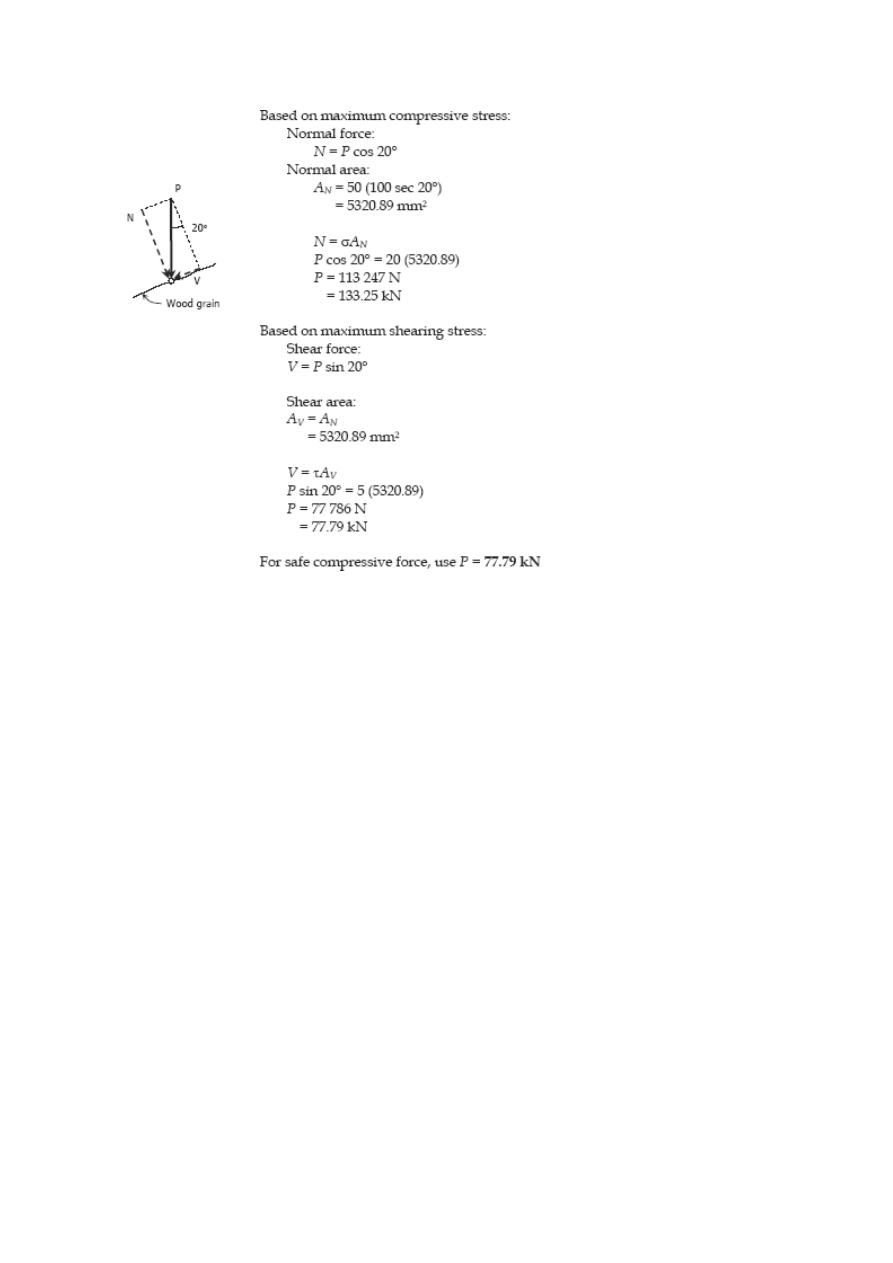

Problem 123

A rectangular piece of wood, 50 mm by 100 mm in cross section, is used as a

compression block shown in Fig. P-123. Determine the axial force P that can be safely

applied to the block if the compressive stress in wood is limited to 20 MN/m

2

and the

shearing stress parallel to the grain is limited to 5 MN/m

2

. The grain makes an angle of

20° with the horizontal, as shown. (Hint: Use the results in Problem 122.)

Solution 123

Bearing Stress

Bearing stress is the contact pressure between the separate bodies. It differs from

compressive stress, as it is an internal stress caused by compressive forces.

SOLVED PROBLEMS IN BEARING STRESS

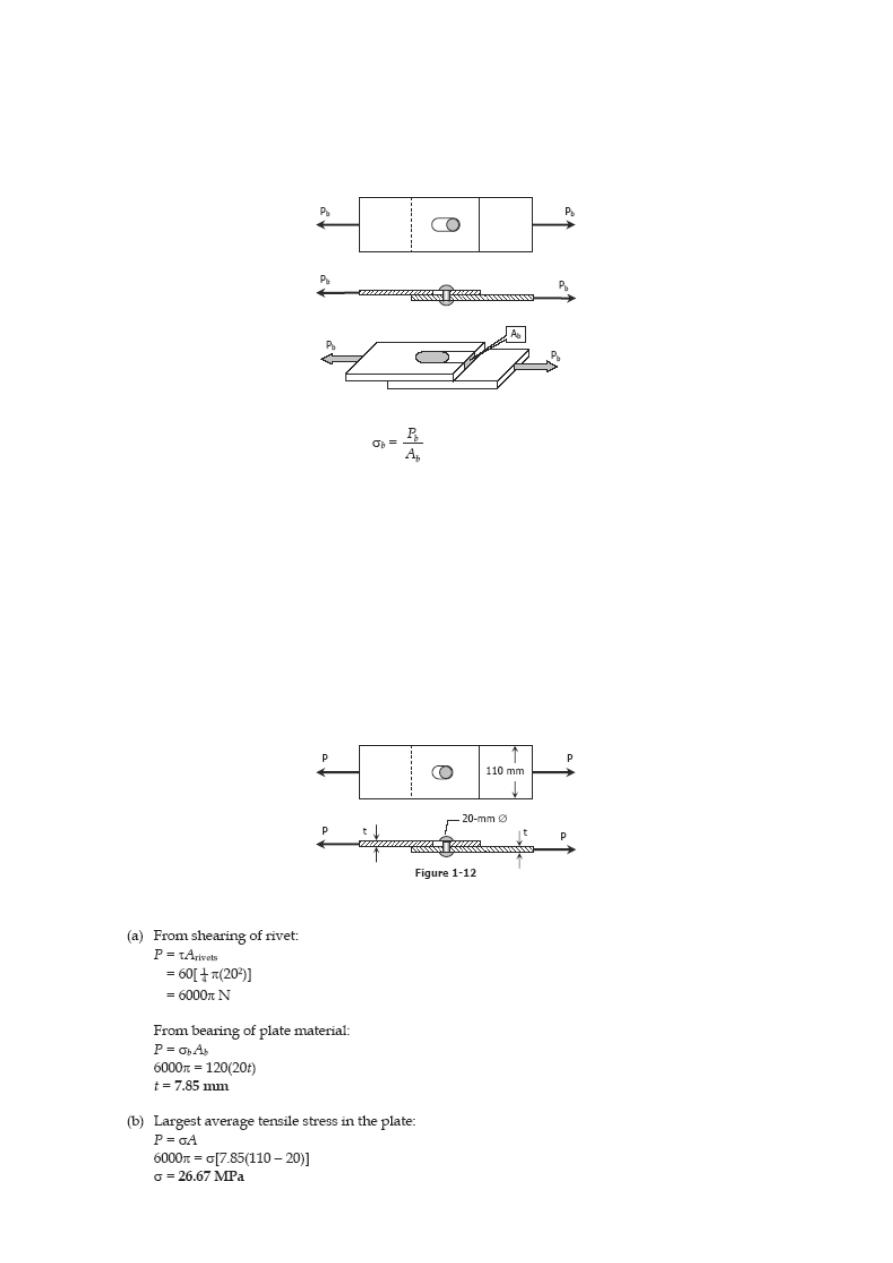

Problem 125

In Fig. 1-12, assume that a 20-mm-diameter rivet joins the plates that are each 110

mm wide. The allowable stresses are 120 MPa for bearing in the plate material and 60

MPa for shearing of rivet. Determine (a) the minimum thickness of each plate; and (b)

the largest average tensile stress in the plates.

Solution 125

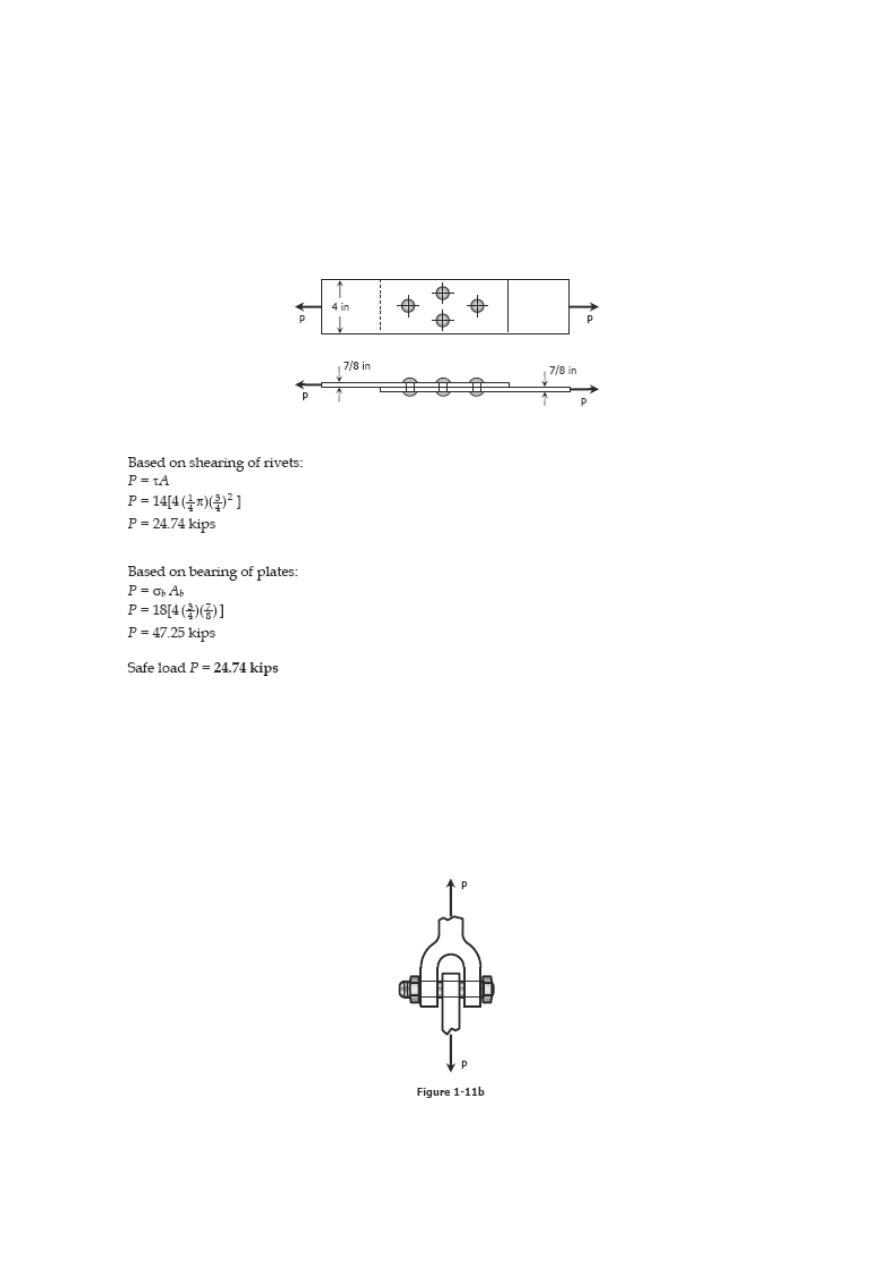

Problem 126

The lap joint shown in Fig. P-126 is fastened by four ¾-in.-diameter rivets. Calculate

the maximum safe load P that can be applied if the shearing stress in the rivets is

limited to 14 ksi and the bearing stress in the plates is limited to 18 ksi. Assume the

applied load is uniformly distributed among the four rivets.

Solution 126

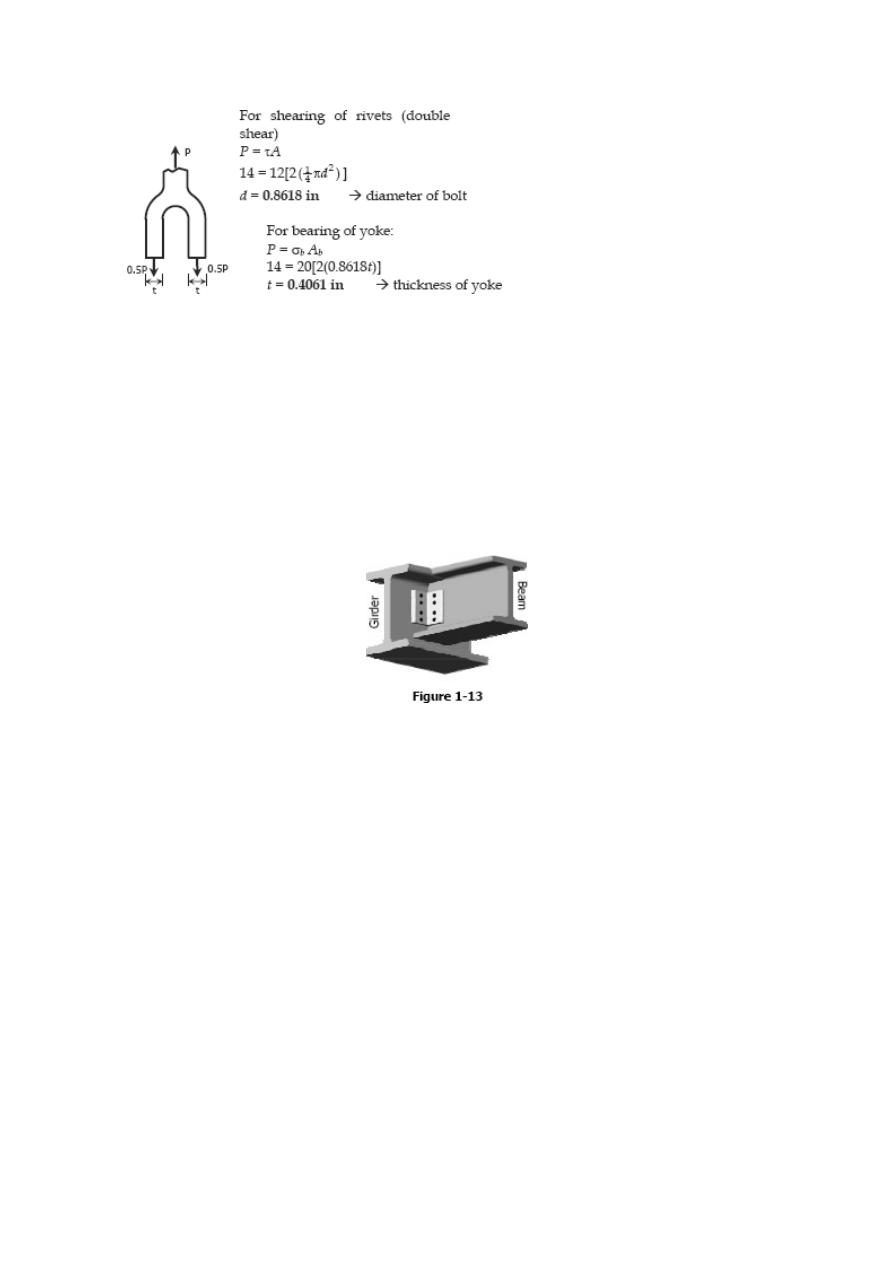

Problem 127

In the clevis shown in Fig. 1-11b, find the minimum bolt diameter and the minimum

thickness of each yoke that will support a load P = 14 kips without exceeding a shearing

stress of 12 ksi and a bearing stress of 20 ksi.

Solution 127

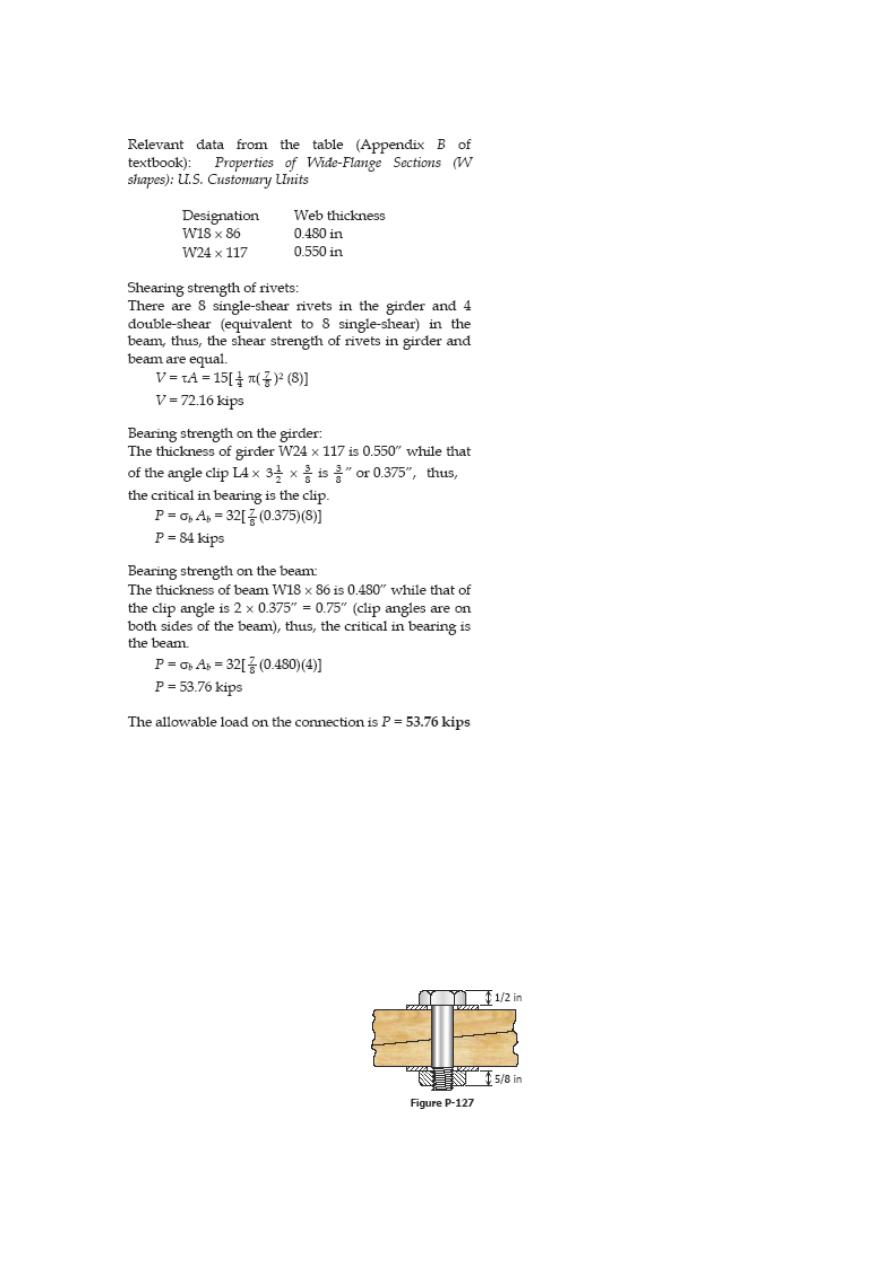

Problem 128

A W18 × 86 beam is riveted to a W24 × 117 girder by a connection similar to that in

Fig. 1-13. The diameter of the rivets is 7/8 in., and the angles are each 4 × 31/2 × 3/8

in. For each rivet, assume that the allowable stresses are τ = 15 ksi and σ

b

= 32 ksi.

Find the allowable

load on the connection.

Solution 128

Note: Textbook is Strength of Materials 4th edition by Pytel and Singer

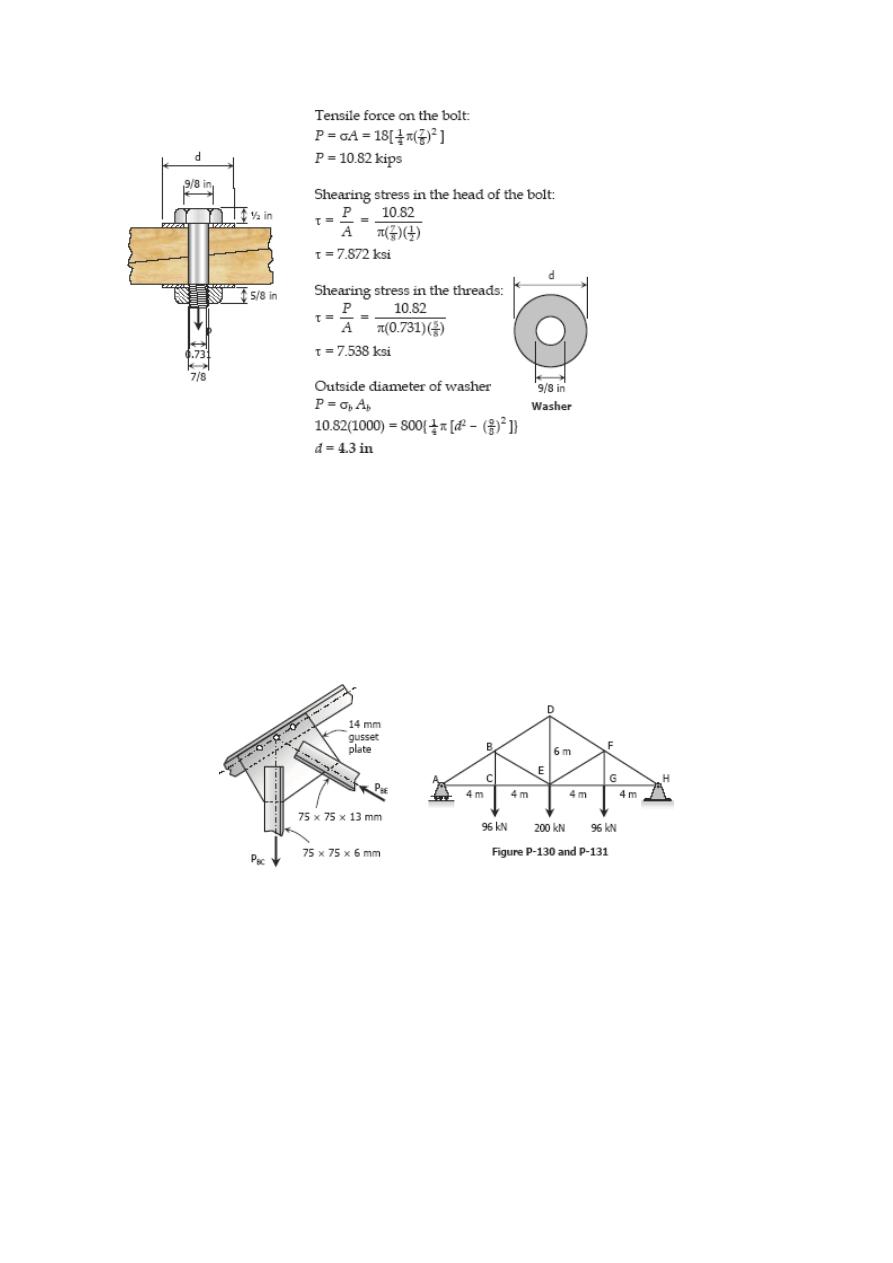

Problem 129

A 7/8-in.-diameter bolt, having a diameter at the root of the threads of 0.731 in., is

used to fasten two timbers together as shown in Fig. P-129. The nut is tightened to

cause a tensile stress of 18 ksi in the bolt. Compute the shearing stress in the head of

the bolt and in the threads. Also, determine the outside diameter of the washers if their

inside diameter is 9/8 in. and the bearing stress is limited to 800 psi.

Solution 129

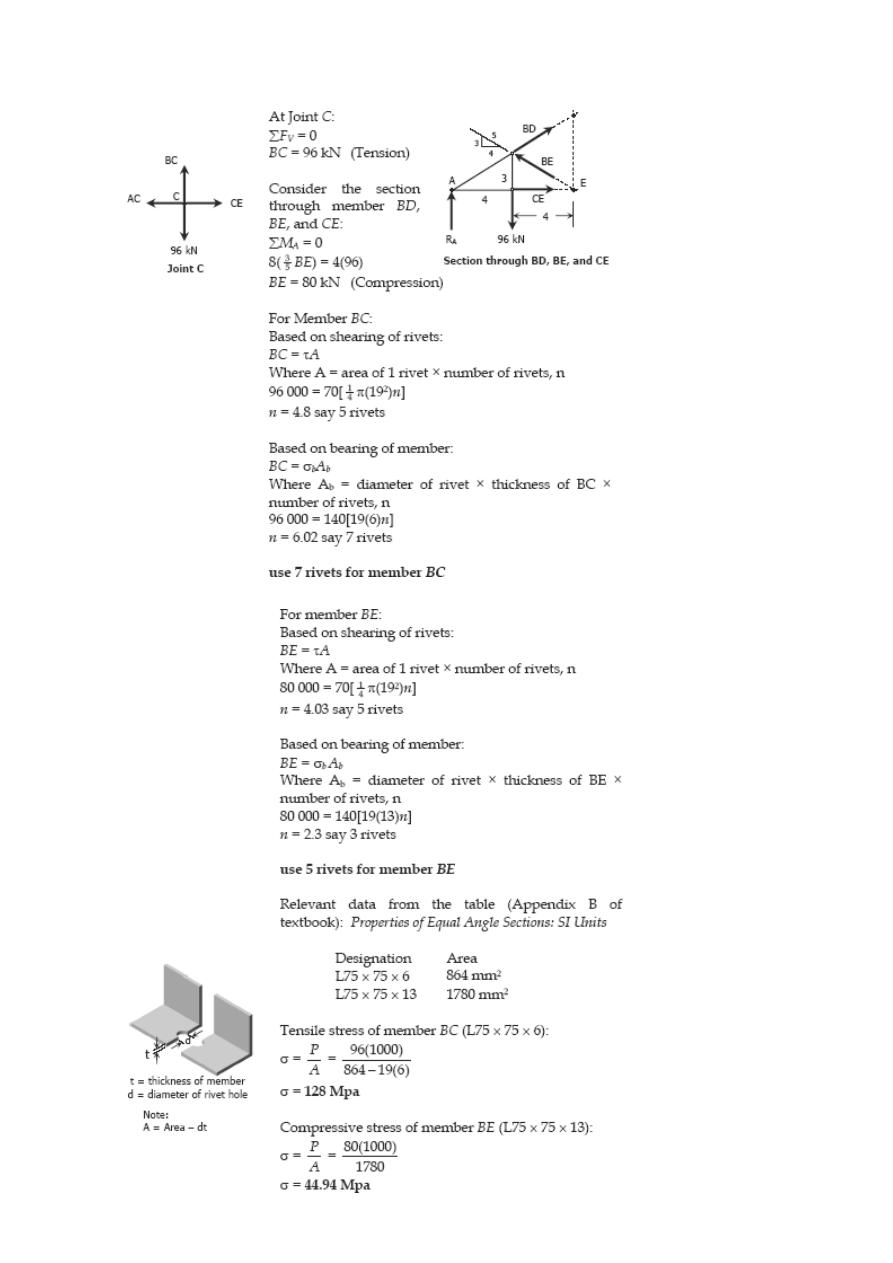

Problem 130

Figure P-130 shows a roof truss and the detail of the riveted connection at joint B. Using

allowable stresses of τ = 70 MPa and σ

b

= 140 MPa, how many 19-mm diameter rivets

are required to fasten member BC to the gusset plate? Member BE? What is the largest

average tensile or compressive stress in BC and BE?

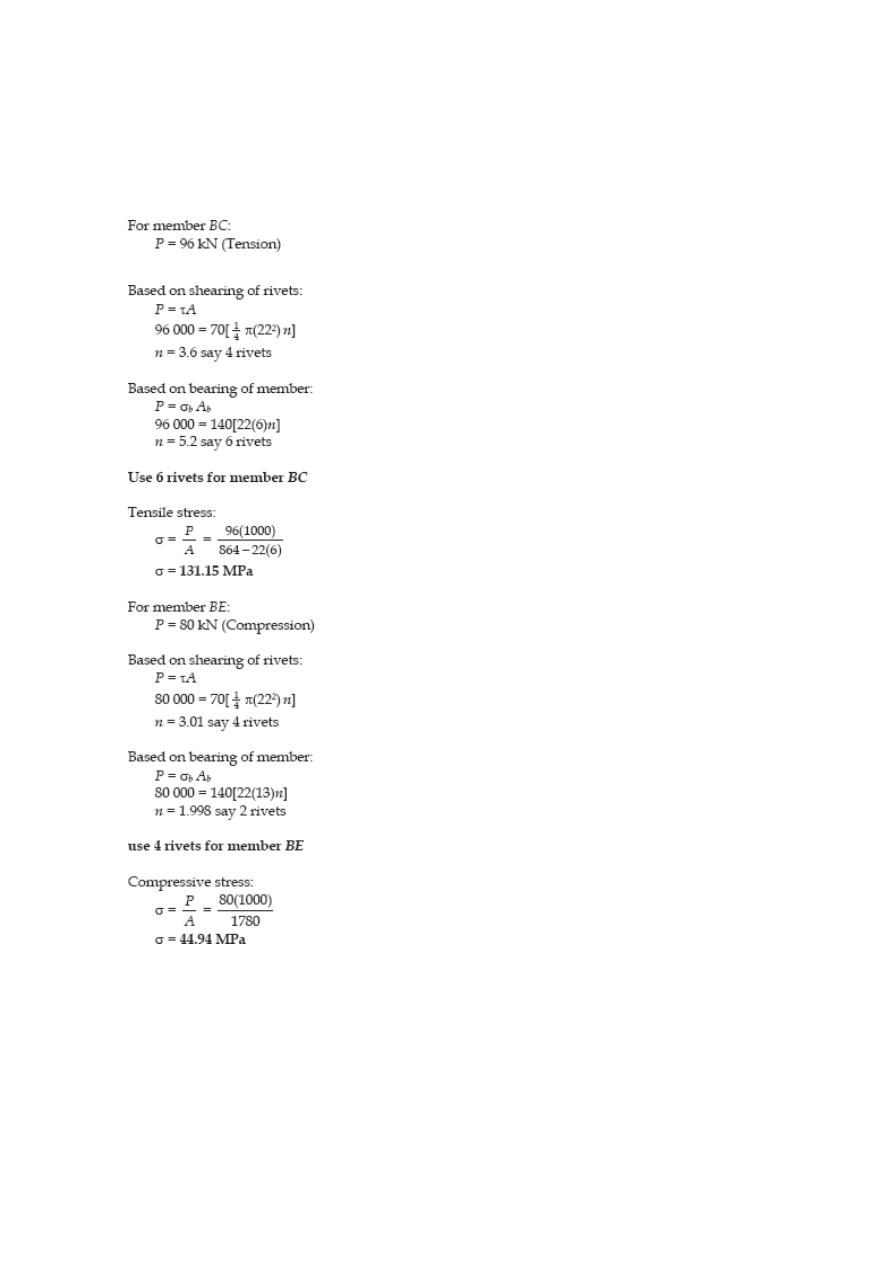

Solution 130

Problem 131

Repeat Problem 130 if the rivet diameter is 22 mm and all other data remain

unchanged.

Solution 131

Thin-Walled Pressure Vessels

A tank or pipe carrying a fluid or gas under a pressure is subjected to tensile forces,

which resist bursting, developed across longitudinal and transverse sections.

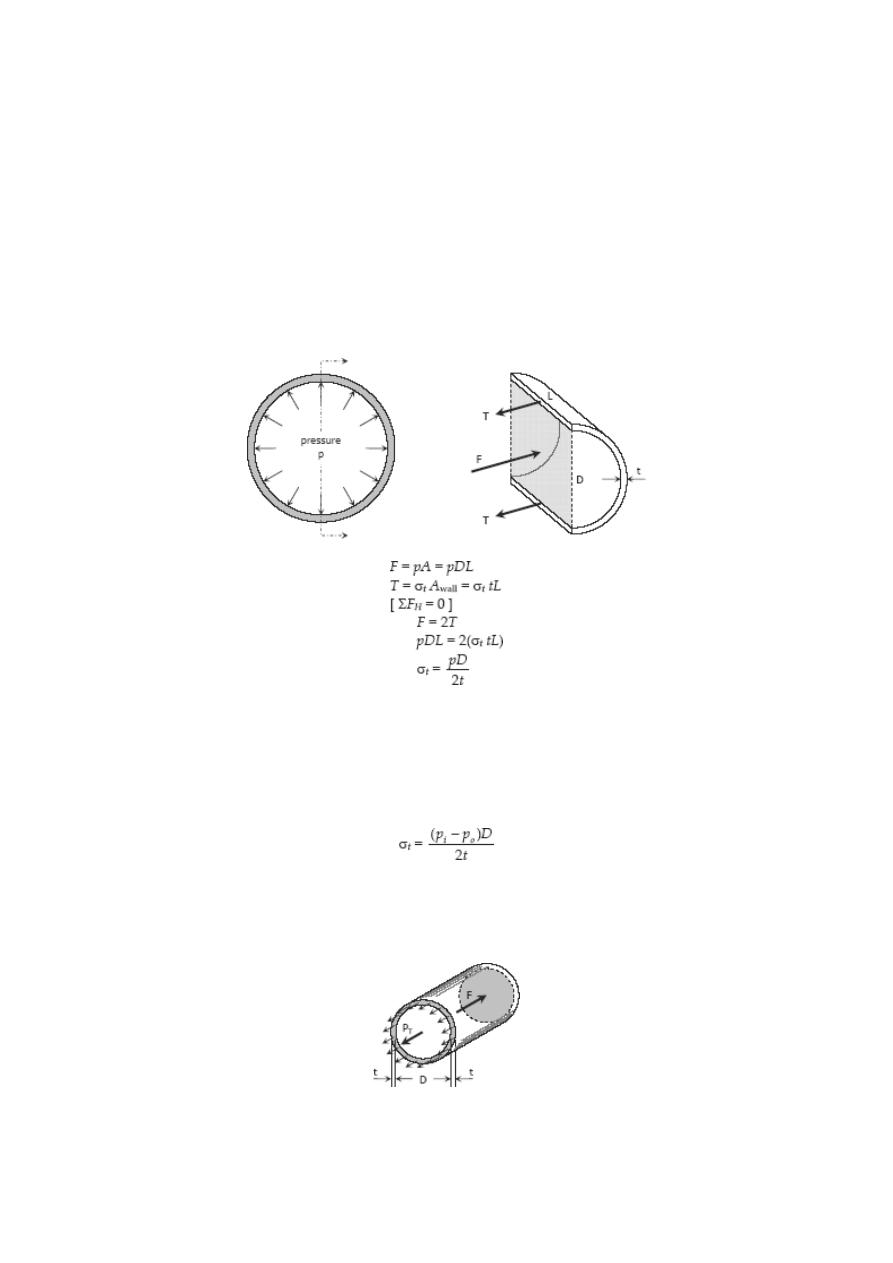

TANGENTIAL STRESS

(Circumferential Stress)

Consider the tank shown being subjected to an internal pressure p. The length of the

tank is L and the wall thickness is t. Isolating the right half of the tank:

If there exist an external pressure p

o

and an internal pressure p

i

, the formula may be

expressed as:

LONGITUDINAL STRESS, σ

L

Consider the free body diagram in the transverse section of the tank:

The total force acting at the rear of the tank F must equal to the total longitudinal stress

on the wall P

T

= σ

L

A

wall

. Since t is so small compared to D, the area of the wall is close

to πDt

If there exist an external pressure p

o

and an internal pressure p

i

, the formula may be

expressed as:

It can be observed that the tangential stress is twice that of the longitudinal stress.

σ

t

= 2 σ

L

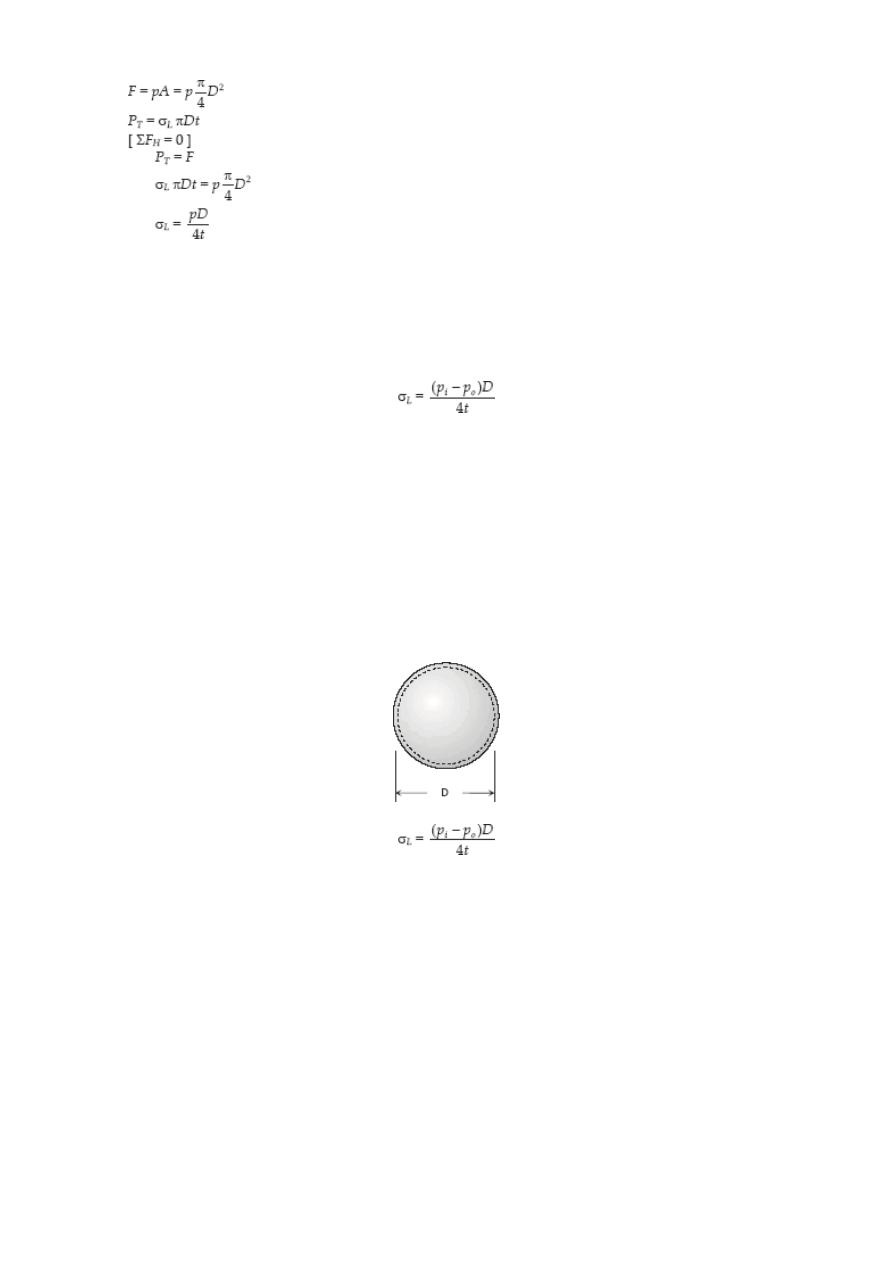

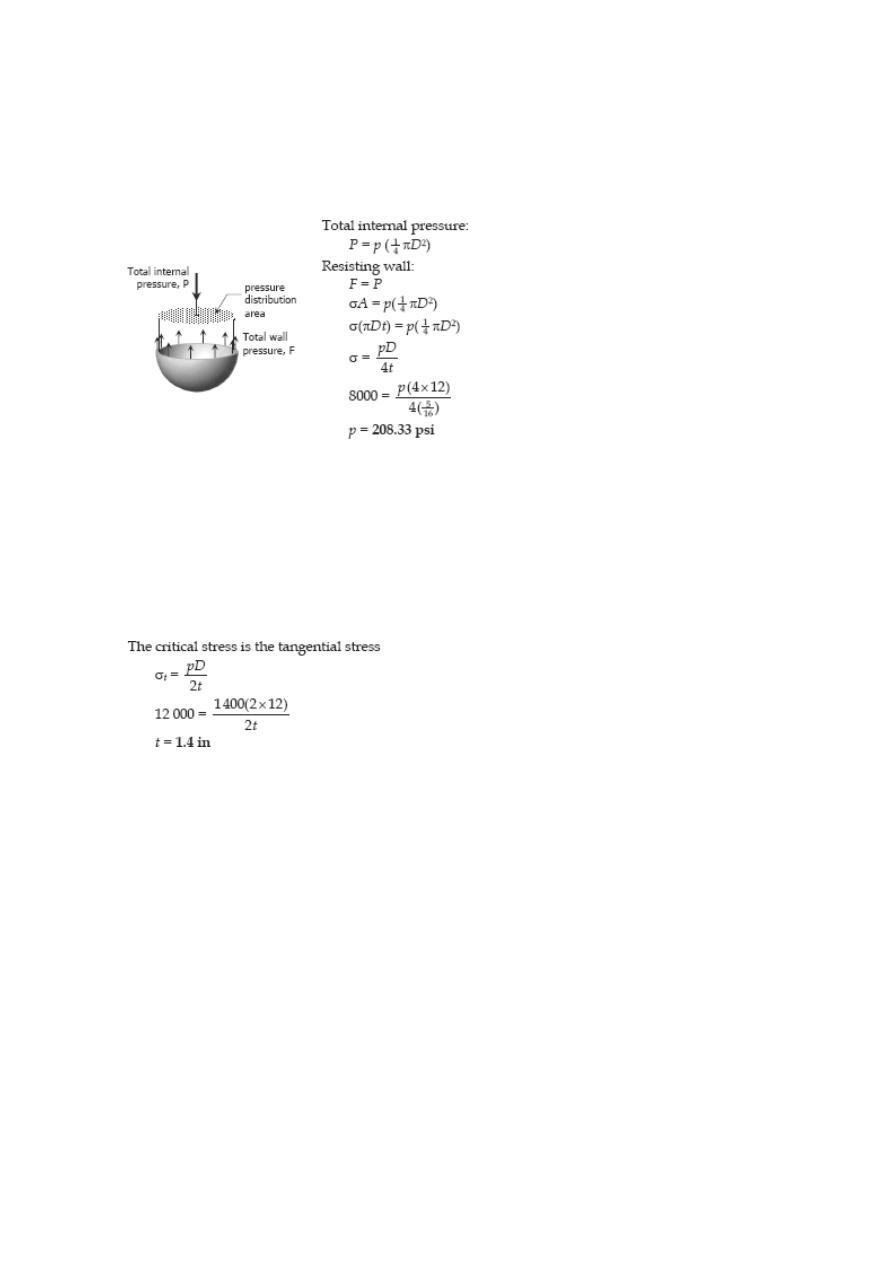

SPHERICAL SHELL

If a spherical tank of diameter D and thickness t contains gas under

a pressure of p, the stress at the wall can be expressed as:

SOLVED PROBLEMS IN THIN WALLED PREASSURE VESSELS

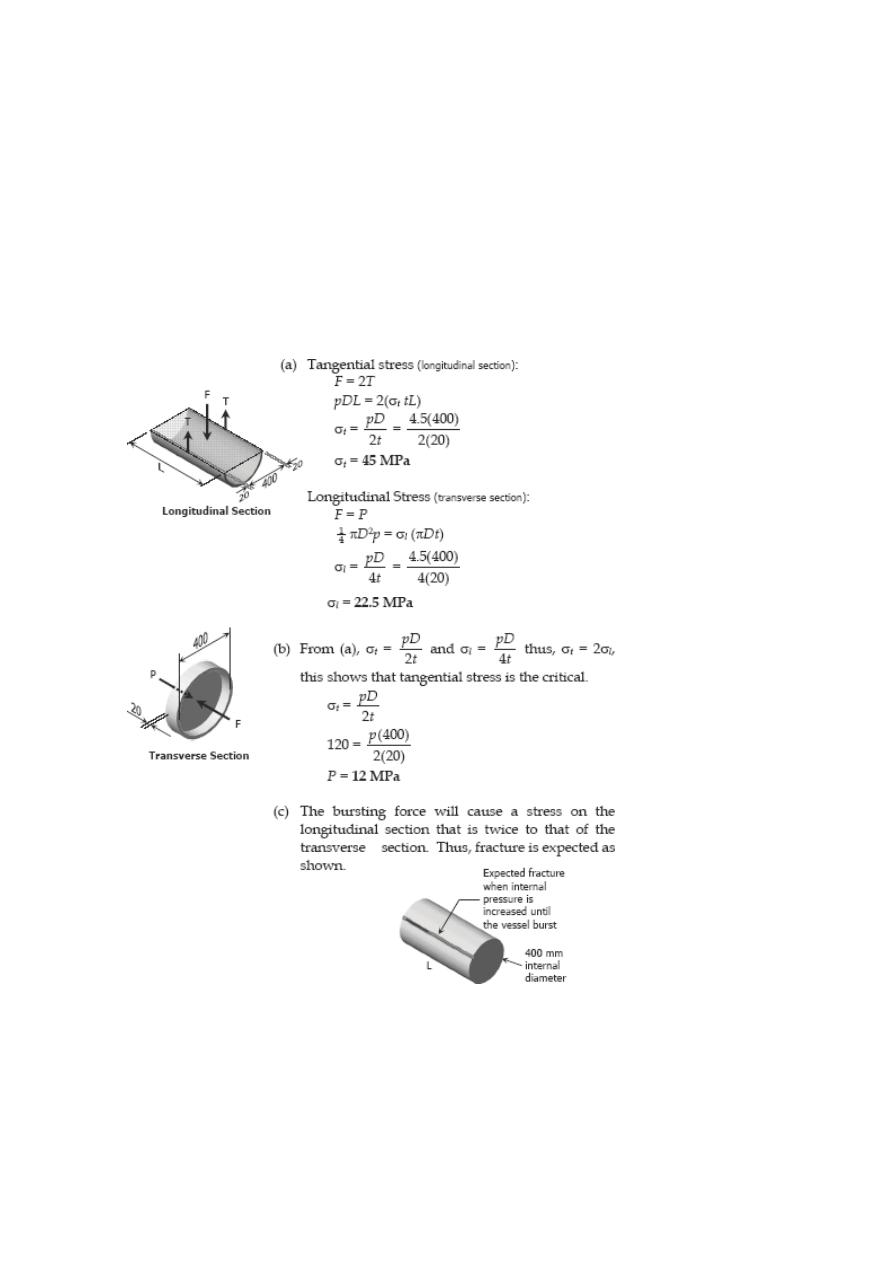

Problem 133

A cylindrical steel pressure vessel 400 mm in diameter with a wall thickness of 20 mm,

is subjected to an internal pressure of 4.5 MN/m

2

. (a) Calculate the tangential and

longitudinal stresses in the steel. (b) To what value may the internal pressure be

increased if the stress in the steel is limited to 120 MN/m

2

? (c) If the internal pressure

were increased until the vessel burst, sketch the type of fracture that would occur.

Solution 133

Problem 134

The wall thickness of a 4-ft-diameter spherical tank is 5/16 in. Calculate the allowable

internal pressure if the stress is limited to 8000 psi.

Solution 134

Problem 135

Calculate the minimum wall thickness for a cylindrical vessel that is to carry a gas at a

pressure of 1400 psi. The diameter of the vessel is 2 ft, and the stress is limited to 12

ksi.

Solution 135

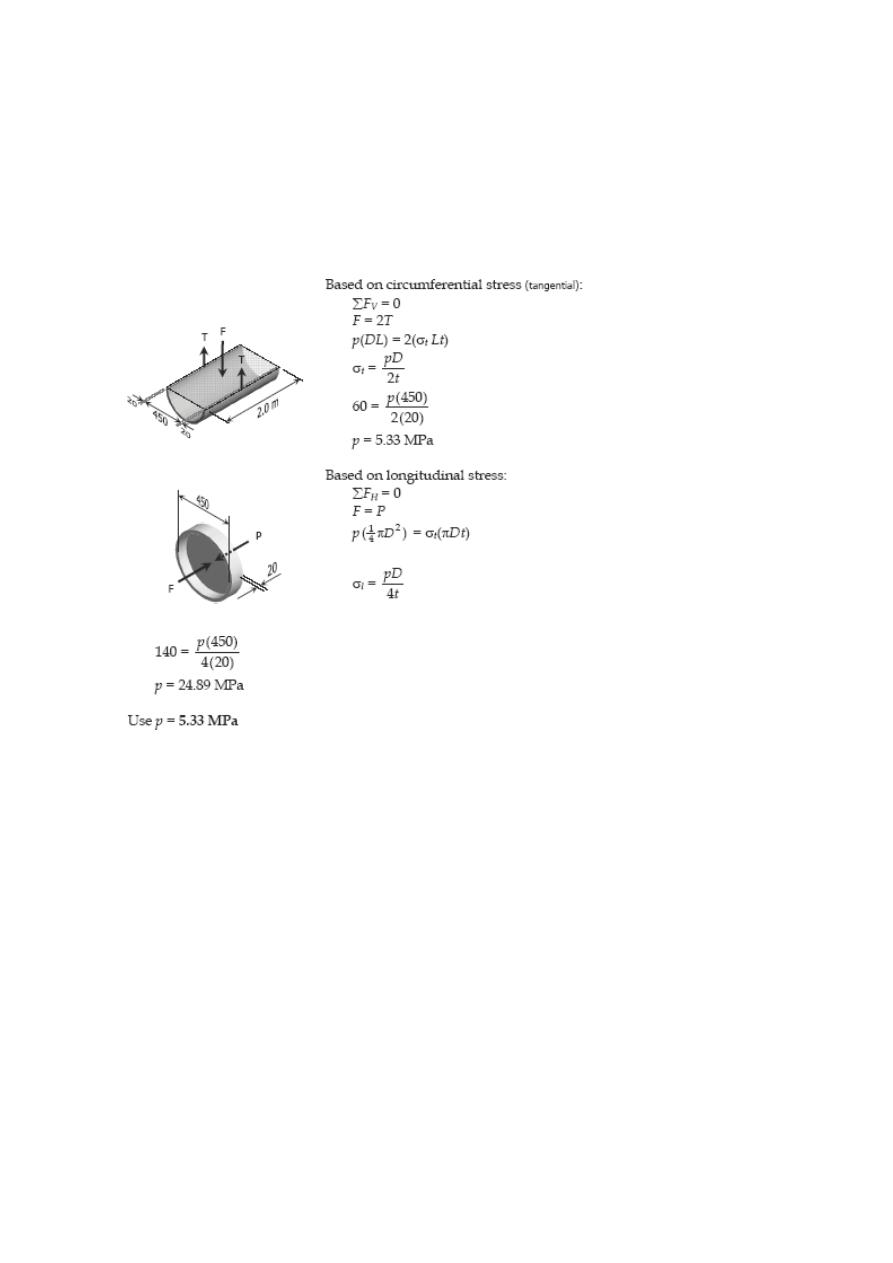

Problem 136

A cylindrical pressure vessel is fabricated from steel plating that has a thickness of 20

mm. The diameter of the pressure vessel is 450 mm and its length is 2.0 m. Determine

the maximum internal pressure that can be applied if the longitudinal stress is limited to

140 MPa, and the circumferential stress is limited to 60 MPa.

Solution 136

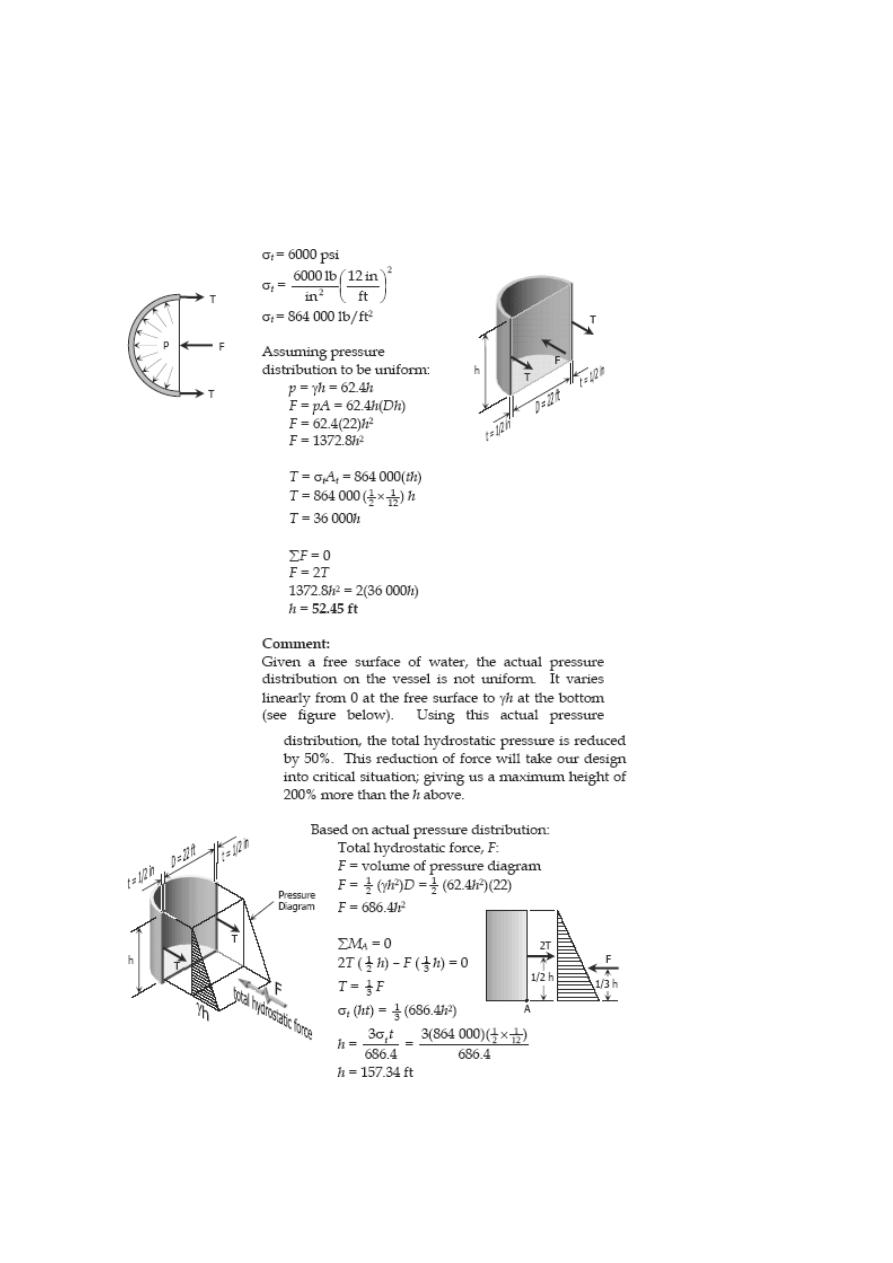

Problem 137

A water tank, 22 ft in diameter, is made from steel plates that are ½ in. thick. Find the

maximum height to which the tank may be filled if the circumferential stress is limited

to 6000 psi. The specific weight of water is 62.4 lb/ft

3

.

Solution 137

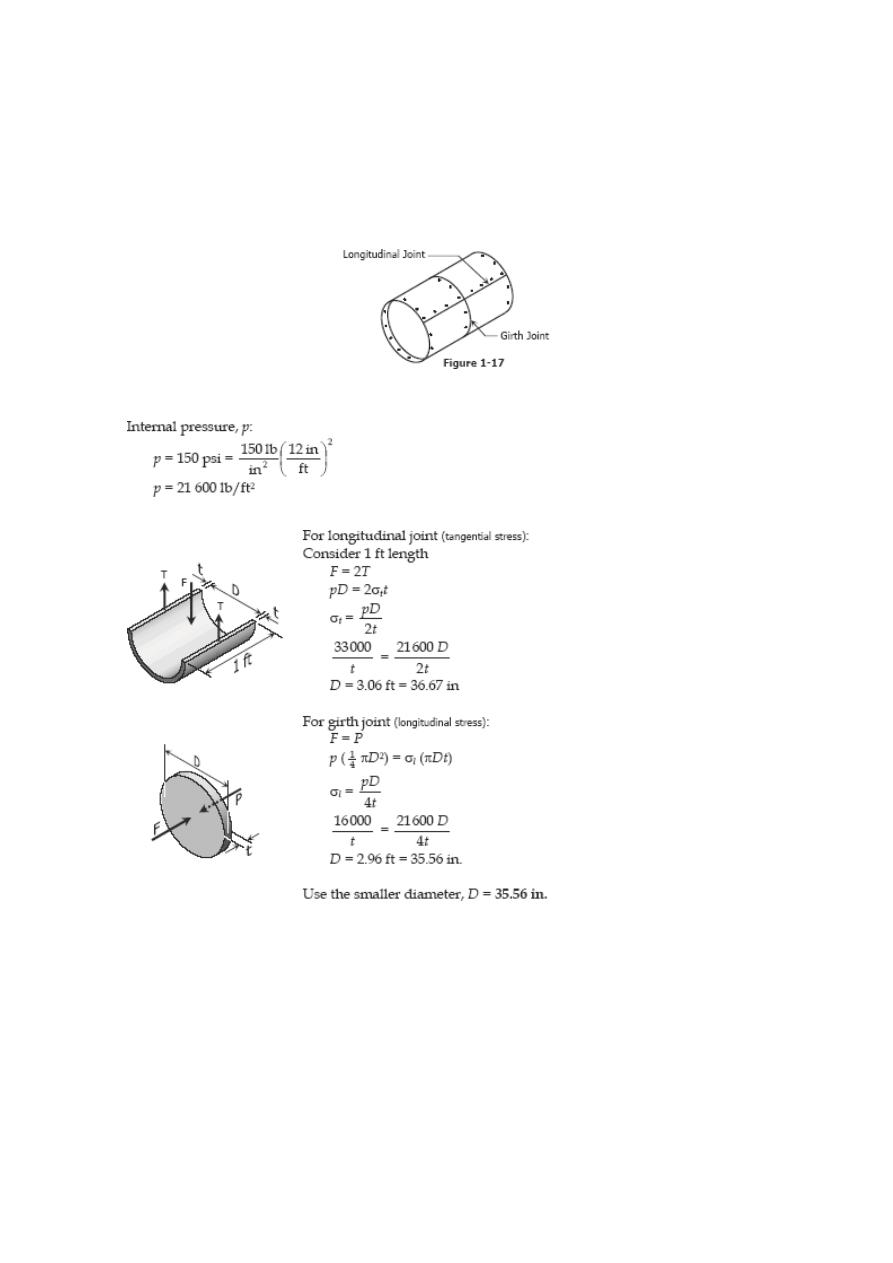

Problem 138

The strength of longitudinal joint in Fig. 1-17 is 33 kips/ft, whereas for the girth is 16

kips/ft. Calculate the maximum diameter of the cylinder tank if the internal pressure is

150 psi.

Solution 138

Problem 139

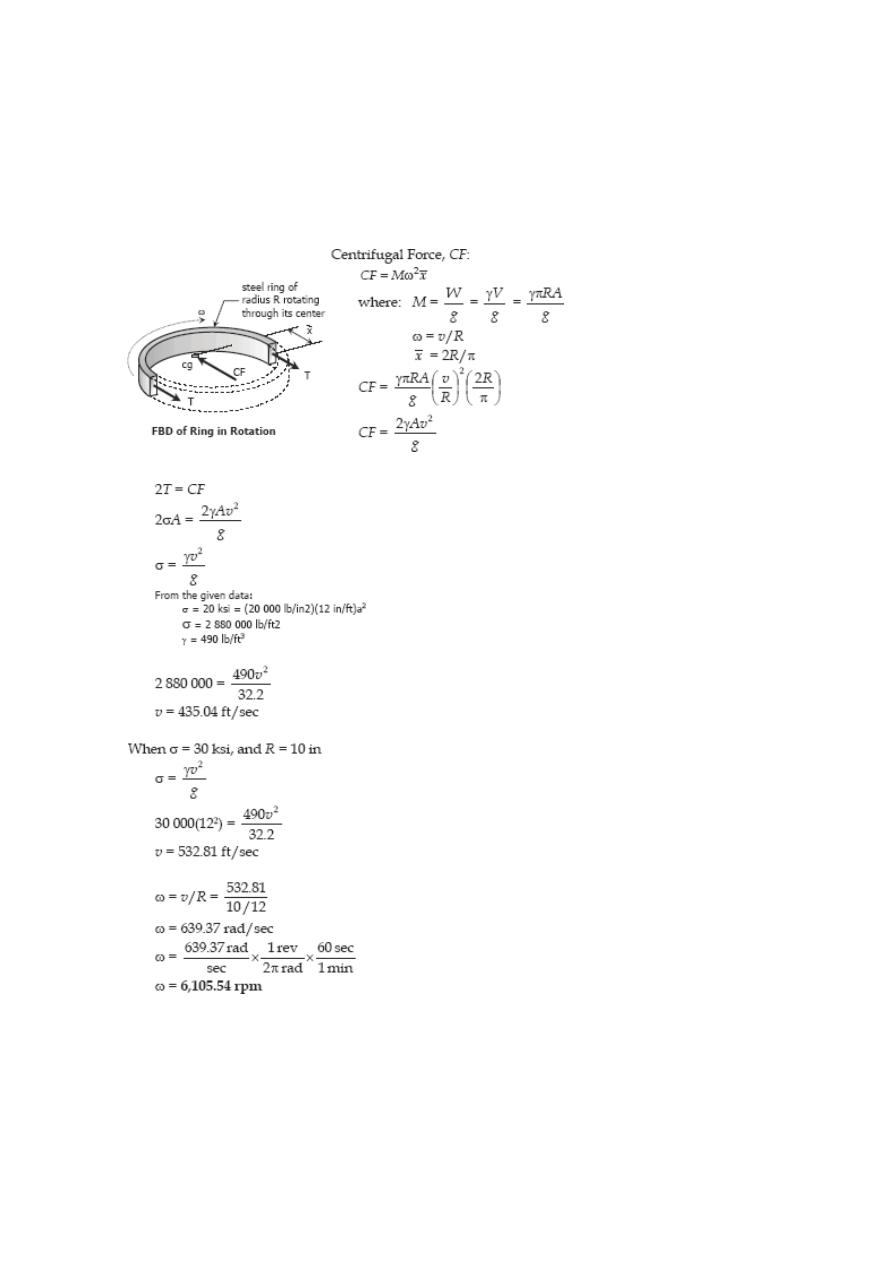

Find the limiting peripheral velocity of a rotating steel ring if the allowable stress is 20

ksi and steel weighs 490 lb/ft

3

. At what revolutions per minute (rpm) will the stress

reach 30 ksi if the mean radius is 10 in.?

Solution 139

Problem 140

At what angular velocity will the stress of the rotating steel ring equal 150 MPa if its

mean radius is 220 mm? The density of steel 7.85 Mg/m

3

.

Solution 140

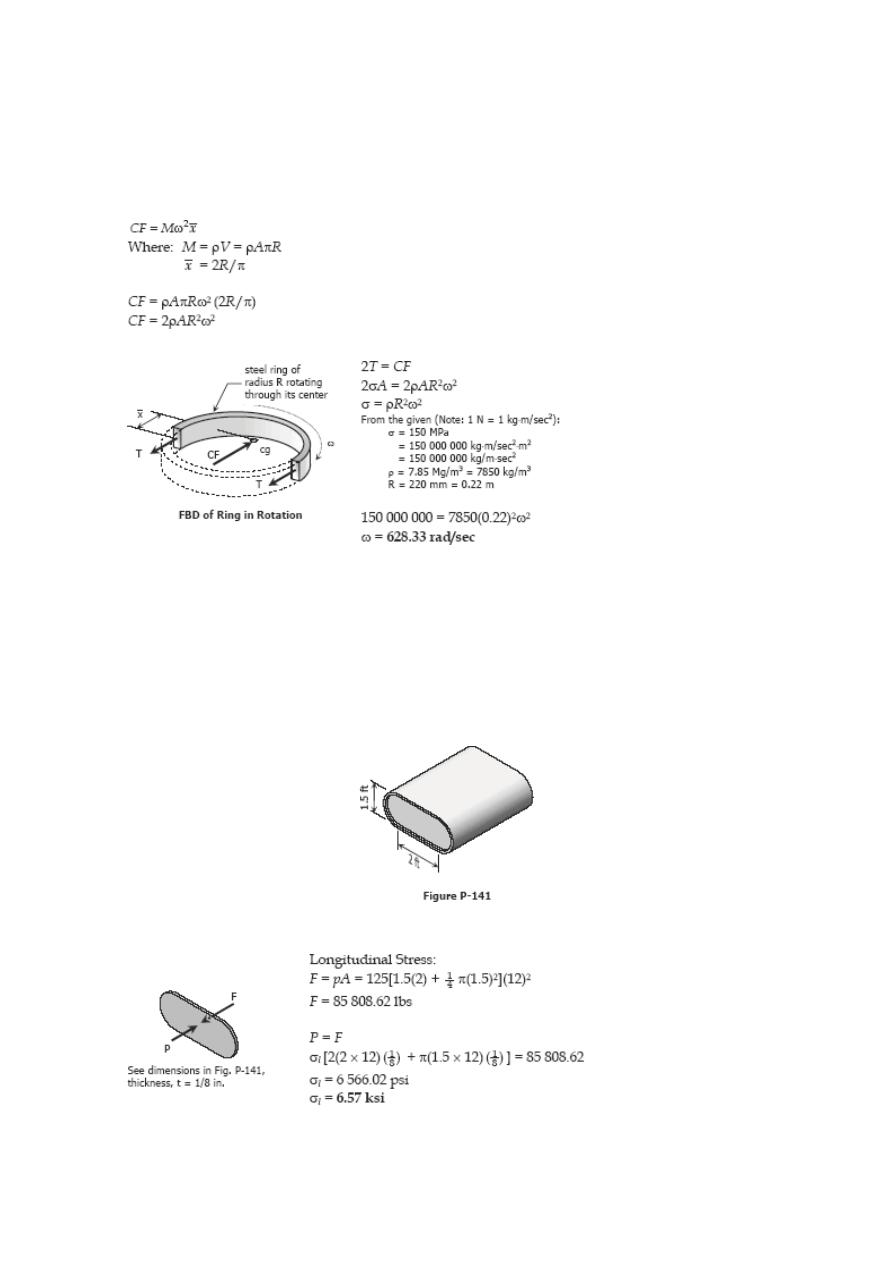

Problem 141

The tank shown in Fig. P-141 is fabricated from 1/8-in steel plate. Calculate the

maximum longitudinal and circumferential stress caused by an internal pressure of 125

psi.

Solution 141

Problem 142

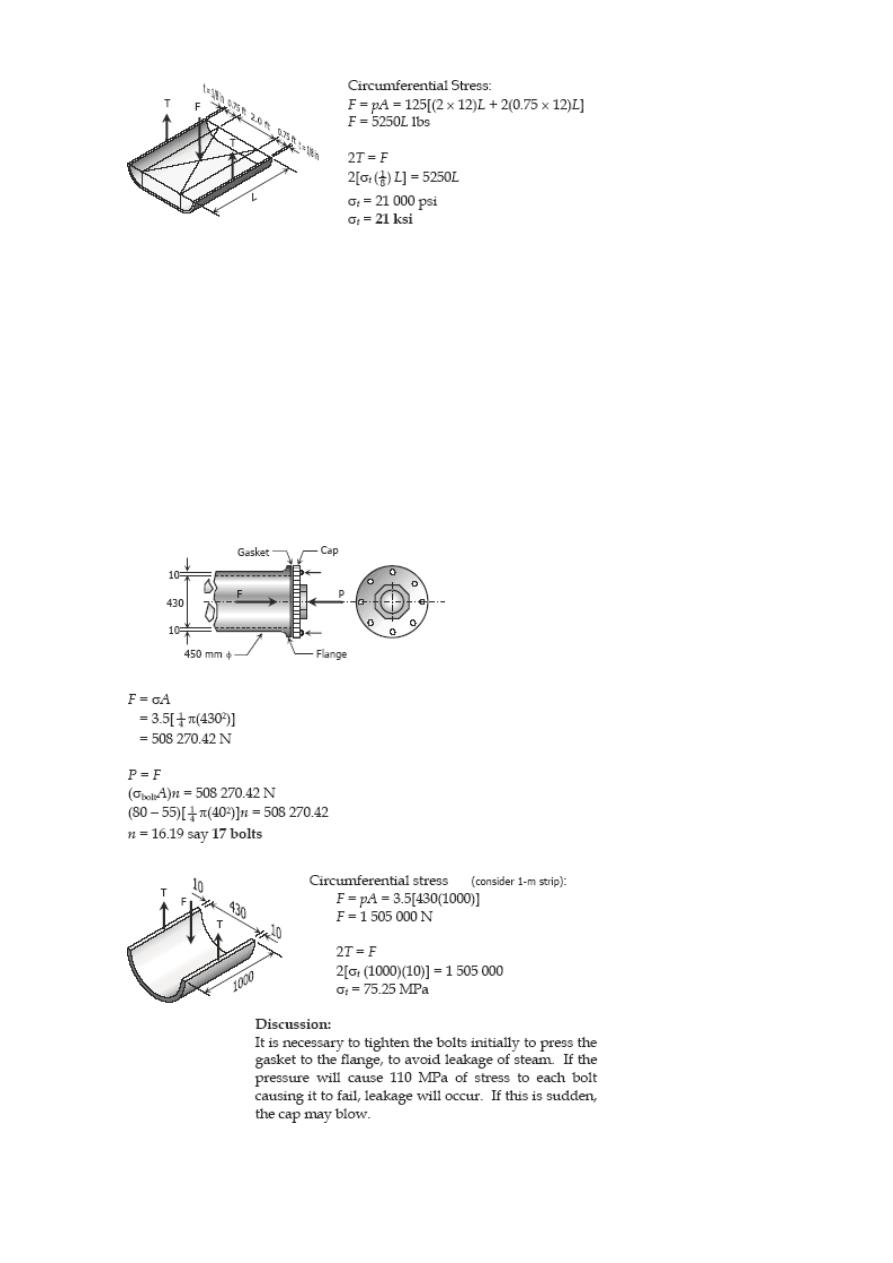

A pipe carrying steam at 3.5 MPa has an outside diameter of 450 mm and a wall

thickness of 10 mm. A gasket is inserted between the flange at one end of the pipe and

a flat plate used to cap the end. How many 40-mm-diameter bolts must be used to hold

the cap on if the allowable stress in the bolts is 80 MPa, of which 55 MPa is the initial

stress? What circumferential stress is developed in the pipe? Why is it necessary to

tighten the bolt initially, and what will happen if the steam pressure should cause the

stress in the bolts to be twice the value of the initial stress?

Solution 142

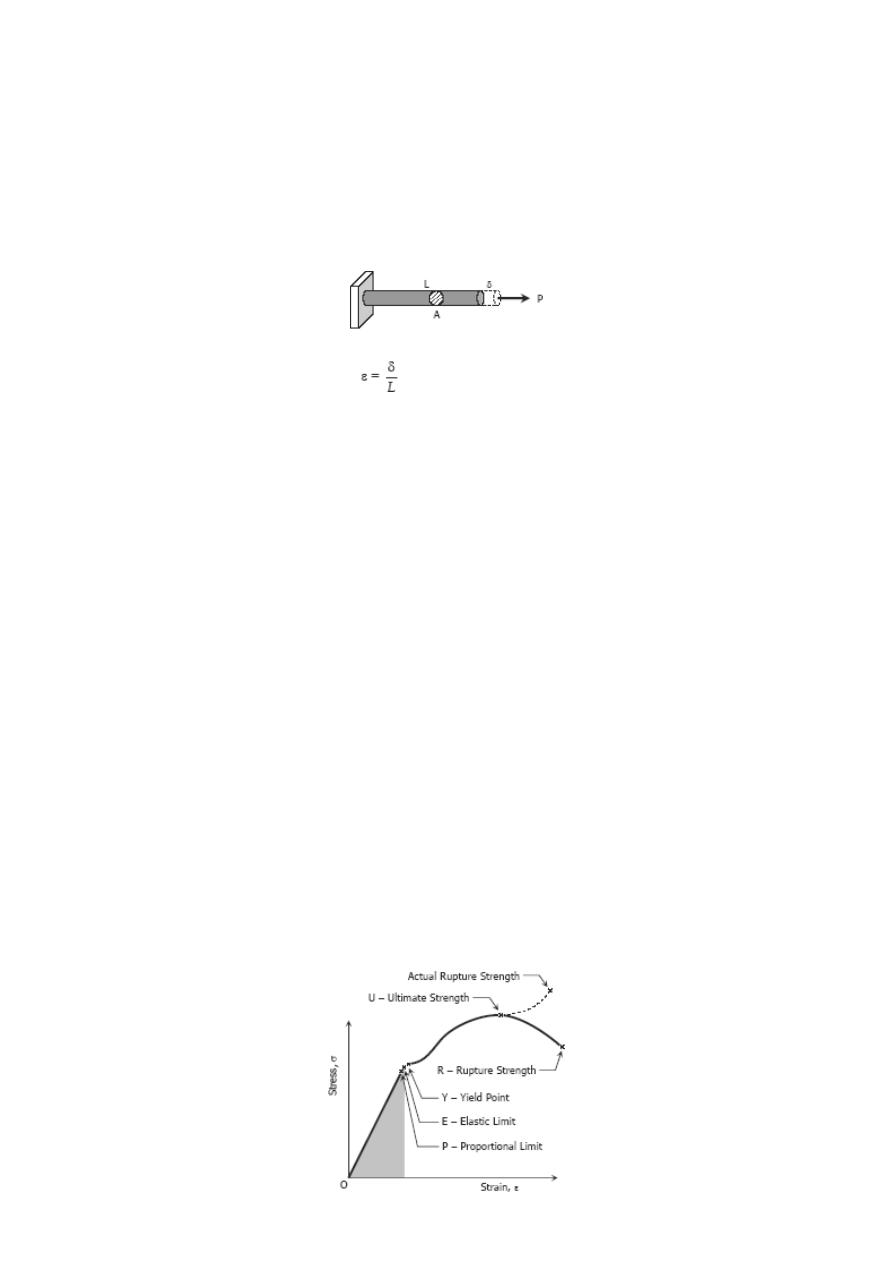

Strain

Simple Strain

Also known as unit deformation, strain is the ratio of the change in length caused by the

applied force, to the original length.

where δ is the deformation and L is the original length, thus ε is dimensionless.

Stress-Strain Diagram

Suppose that a metal specimen be placed in tension-compression testing machine. As

the axial load is gradually increased in increments, the total elongation over the gage

length is measured at each increment of the load and this is continued until failure of

the specimen takes place. Knowing the original cross-sectional area and length of the

specimen, the normal stress σ and the strain ε can be obtained. The graph of these

quantities with the stress σ along the y-axis and the strain ε along the x-axis is called

the stress-strain diagram. The stress-strain diagram differs in form for various

materials. The diagram shown below is that for a medium carbon structural steel.

Metallic engineering materials are classified as either ductile or brittle materials. A

ductile material is one having relatively large tensile strains up to the point of rupture

like structural steel and aluminum, whereas brittle materials has a relatively small strain

up to the point of rupture like cast iron and concrete. An arbitrary strain of 0.05

mm/mm is frequently taken as the dividing line between these two classes.

PROPORTIONAL LIMIT (HOOKE'S LAW)

From the origin O to the point called proportional limit, the stress-strain

curve is a straight line. This linear relation between elongation and the

axial force causing was first noticed by Sir Robert Hooke in 1678 and is

called Hooke's Law that within the proportional limit, the stress is directly

proportional to strain or

The constant of proportionality k is called the Modulus of Elasticity E or Young's Modulus

and is equal to the slope of the stress-strain diagram from O to P. Then

ELASTIC LIMIT

The elastic limit is the limit beyond which the material will no longer go back to its

original shape when the load is removed, or it is the maximum stress that may e

developed such that there is no permanent or residual deformation when the load is

entirely removed.

ELASTIC AND PLASTIC RANGES

The region in stress-strain diagram from O to P is called the elastic range. The region

from P to R is called the plastic range.

YIELD POINT

Yield point is the point at which the material will have an appreciable elongation or

yielding without any increase in load.

ULTIMATE STRENGTH

The maximum ordinate in the stress-strain diagram is the ultimate strength or tensile

strength.

RAPTURE STRENGTH

Rapture strength is the strength of the material at rupture. This is also known as the

breaking strength.

MODULUS OF RESILIENCE

Modulus of resilience is the work done on a unit volume of material as the force is

gradually increased from O to P, in Nm/m

3

. This may be calculated as the area under

the stress-strain curve from the origin O to up to the elastic limit E (the shaded area in

the figure). The resilience of the material is its ability to absorb energy without creating

a permanent distortion.

MODULUS OF TOUGHNESS

Modulus of toughness is the work done on a unit volume of material as the force is

gradually increased from O to R, in Nm/m

3

. This may be calculated as the area under

the entire stress-strain curve (from O to R). The toughness of a material is its ability to

absorb energy without causing it to break.

WORKING STRESS, ALLOWABLE STRESS, AND FACTOR OF SAFETY

Working stress is defined as the actual stress of a material under a given loading. The

maximum safe stress that a material can carry is termed as the allowable stress. The

allowable stress should be limited to values not exceeding the proportional limit.

However, since proportional limit is difficult to determine accurately, the allowable tress

is taken as either the yield point or ultimate strength divided by a factor of safety. The

ratio of this strength (ultimate or yield strength) to allowable strength is called the

factor of safety.

AXIAL DEFORMATION

In the linear portion of the stress-strain diagram, the tress is proportional to strain and

is given by

σ = Eε

since σ = P / A and εe = δ / L, then P / A = E δ / L. Solving for δ,

To use this formula, the load must be axial, the bar must have a uniform cross-sectional

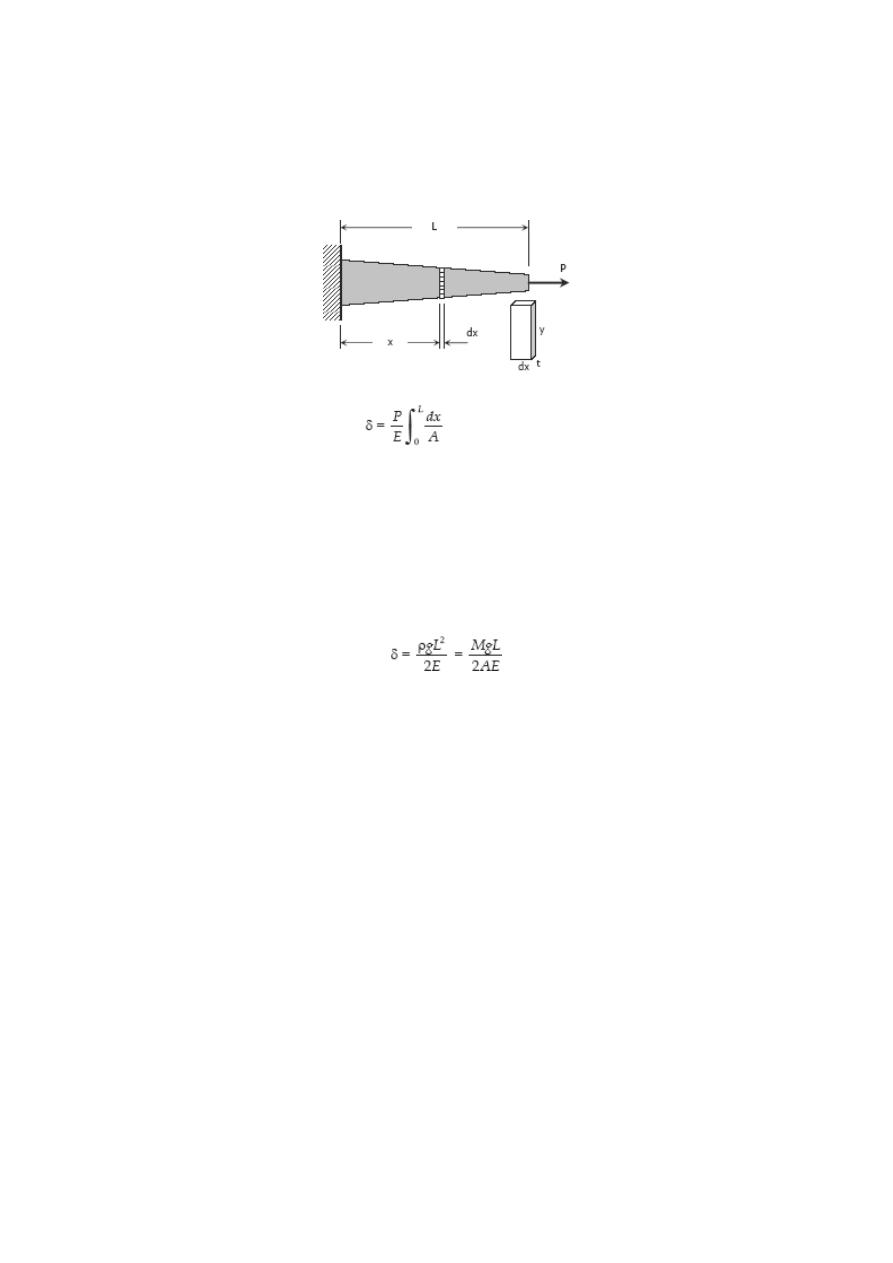

area, and the stress must not exceed the proportional limit. If however, the cross-

sectional area is not uniform, the axial deformation can be determined by considering a

differential length and applying integration.

If however, the cross-sectional area is not uniform, the axial deformation can be

determined by considering a differential length and applying

integration.

where A = ty and y and t, if variable, must be expressed in terms of x.

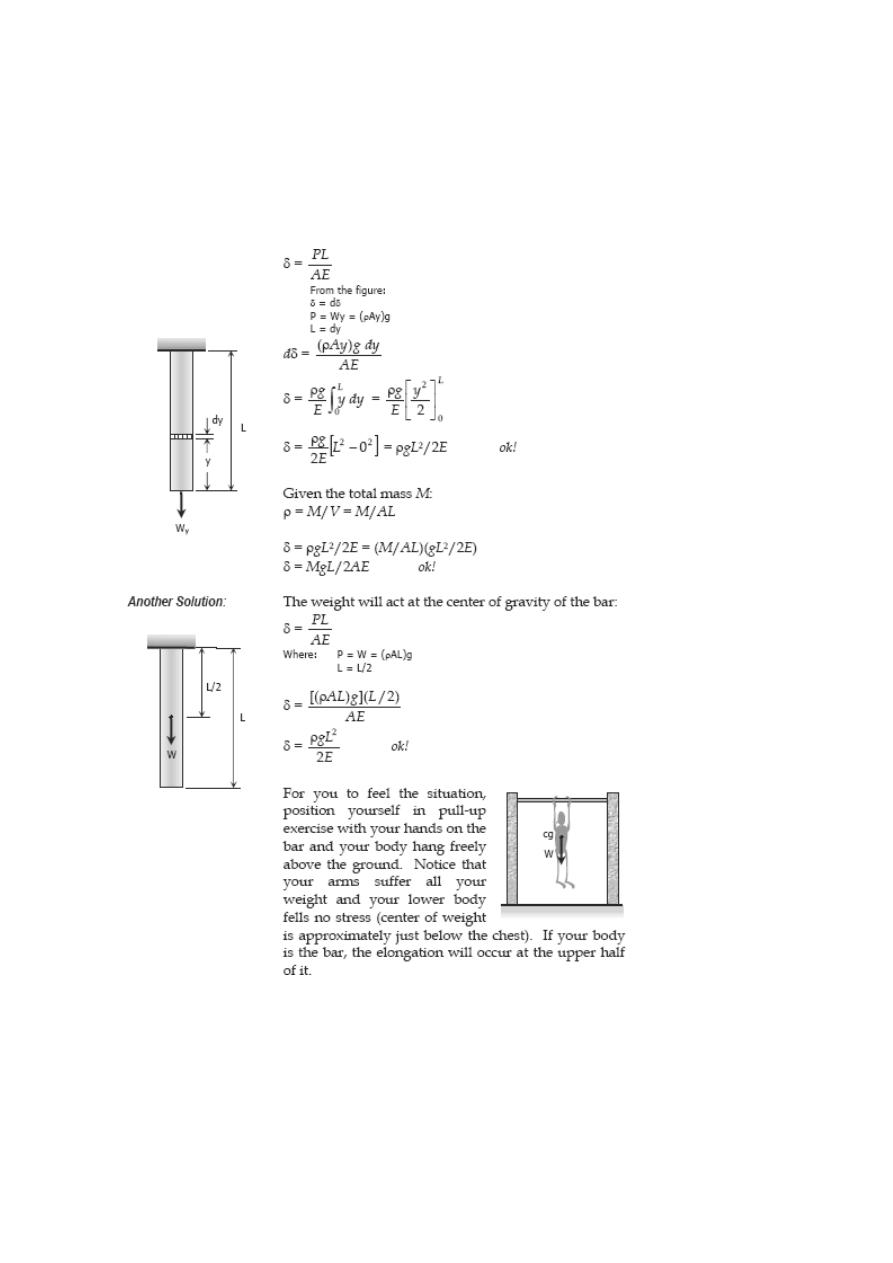

For a rod of unit mass ρ suspended vertically from one end, the total elongation due to

its own weight is

where ρ is in kg/m

3

, L is the length of the rod in mm, M is the total mass of the rod in

kg, A is the cross-sectional area of the rod in mm

2

, and g = 9.81 m/s

2

.

STIFFNESS, k

Stiffness is the ratio of the steady force acting on an elastic body to the resulting

displacement. It has the unit of N/mm.

k = P / δ

SOLVED PROBLEMS IN AXIAL DEFORMATION

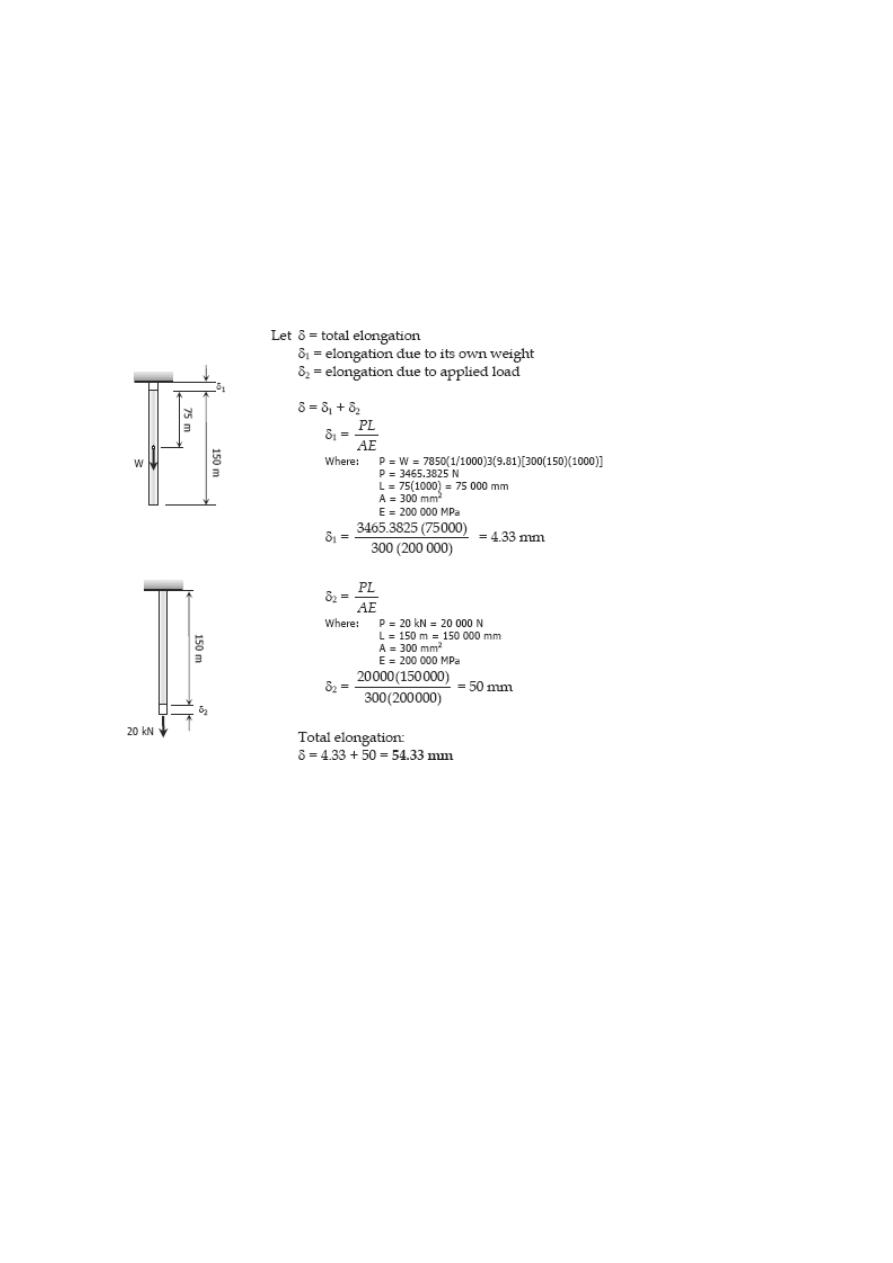

Problem 206

A steel rod having a cross-sectional area of 300 mm

2

and a length of 150 m is

suspended vertically from one end. It supports a tensile load of 20 kN at the lower end.

If the unit mass of steel is 7850 kg/m

3

and E = 200 × 10

3

MN/m

2

, find the total

elongation of the rod.

Solution 206

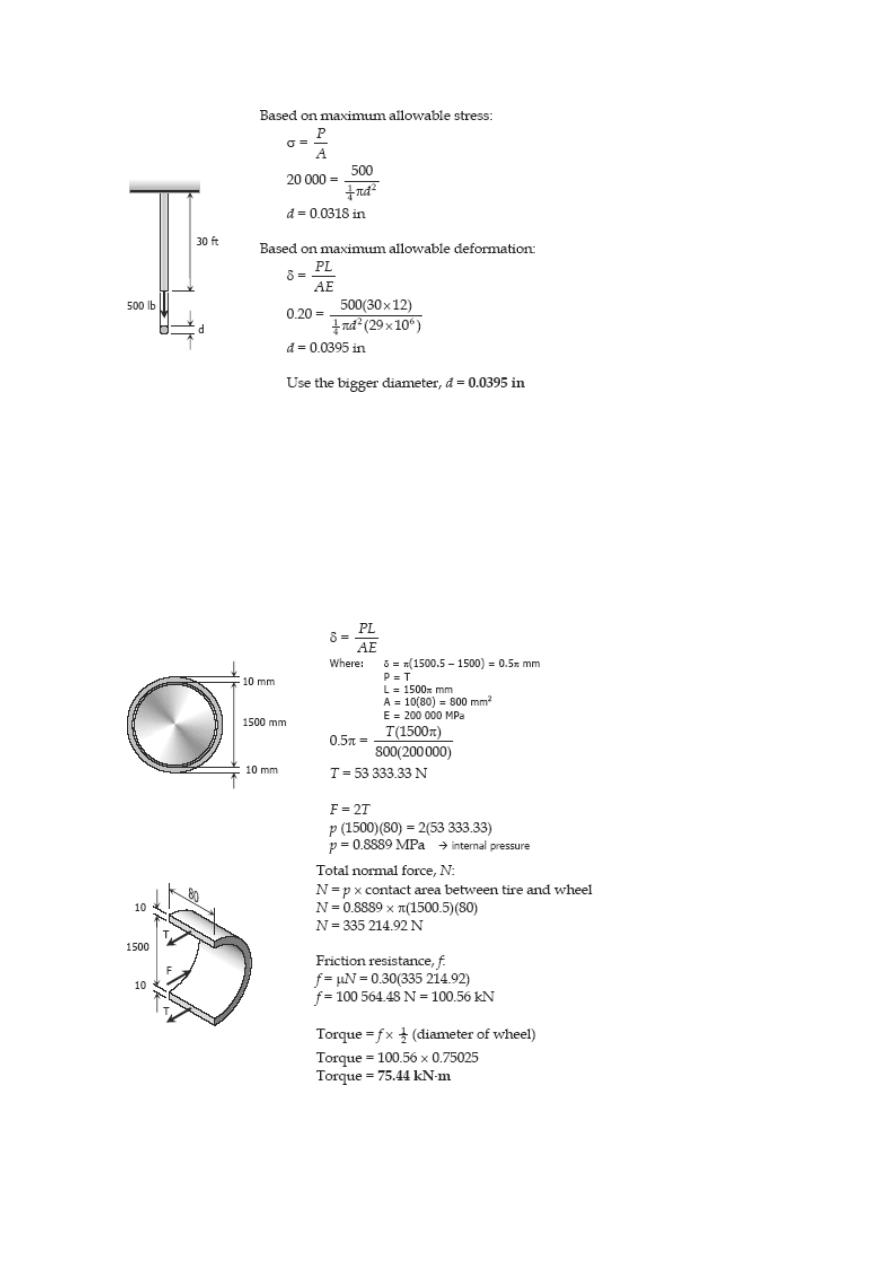

Problem 207

A steel wire 30 ft long, hanging vertically, supports a load of 500 lb. Neglecting the

weight of the wire, determine the required diameter if the stress is not to exceed 20 ksi

and the total elongation is not to exceed 0.20 in. Assume E = 29 × 10

6

psi.

Solution 207

Problem 208

A steel tire, 10 mm thick, 80 mm wide, and 1500.0 mm inside diameter, is heated and

shrunk onto a steel wheel 1500.5 mm in diameter. If the coefficient of static friction is

0.30, what torque is required to twist the tire relative to the wheel? Neglect the

deformation of the wheel. Use E = 200 GPa.

Solution 208

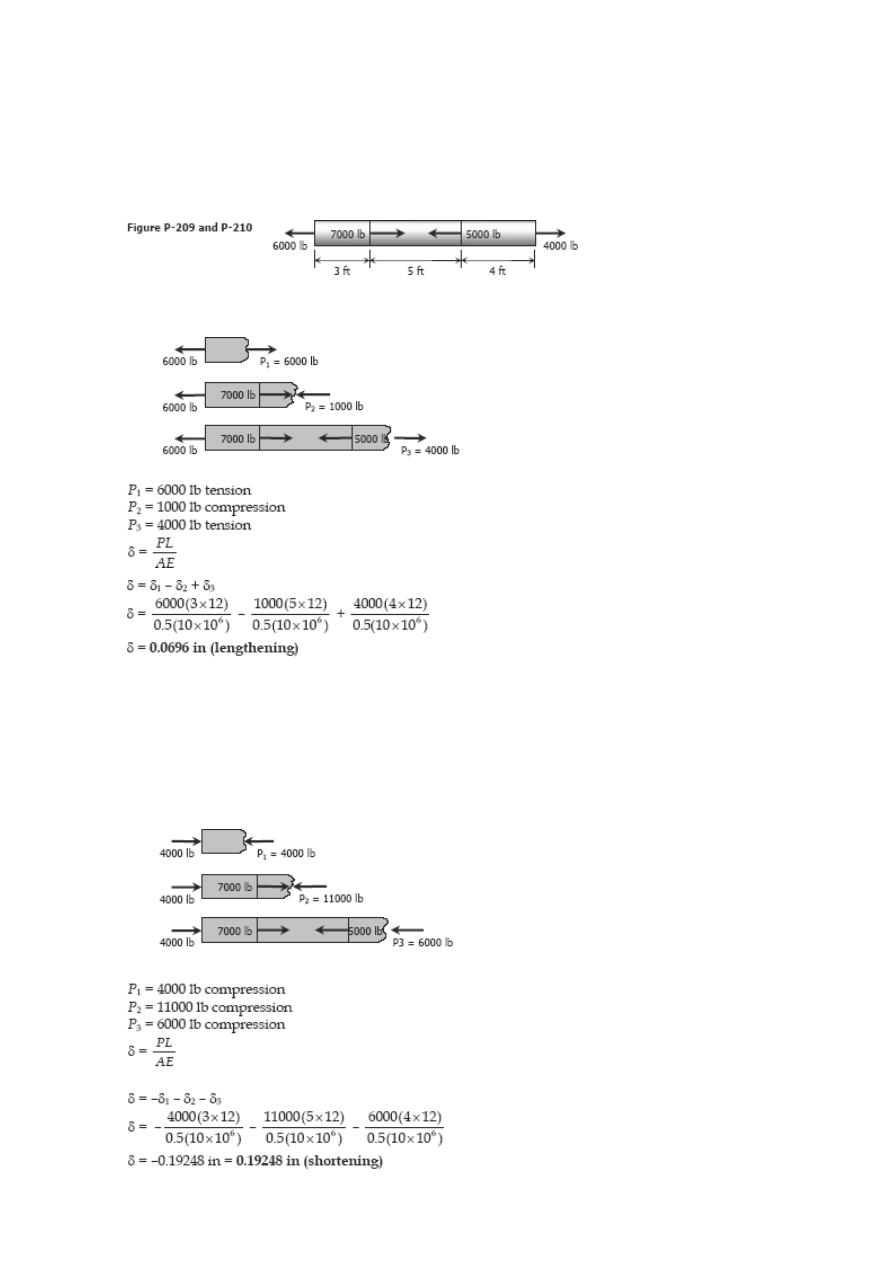

Problem 209

An aluminum bar having a cross-sectional area of 0.5 in

2

carries the axial loads applied

at the positions shown in Fig. P-209. Compute the total change in length of the bar if E

= 10 × 10

6

psi. Assume the bar is suitably braced to prevent lateral buckling.

Solution 209

Problem 210

Solve Prob. 209 if the points of application of the 6000-lb and the 4000-lb forces are

interchanged.

Solution 210

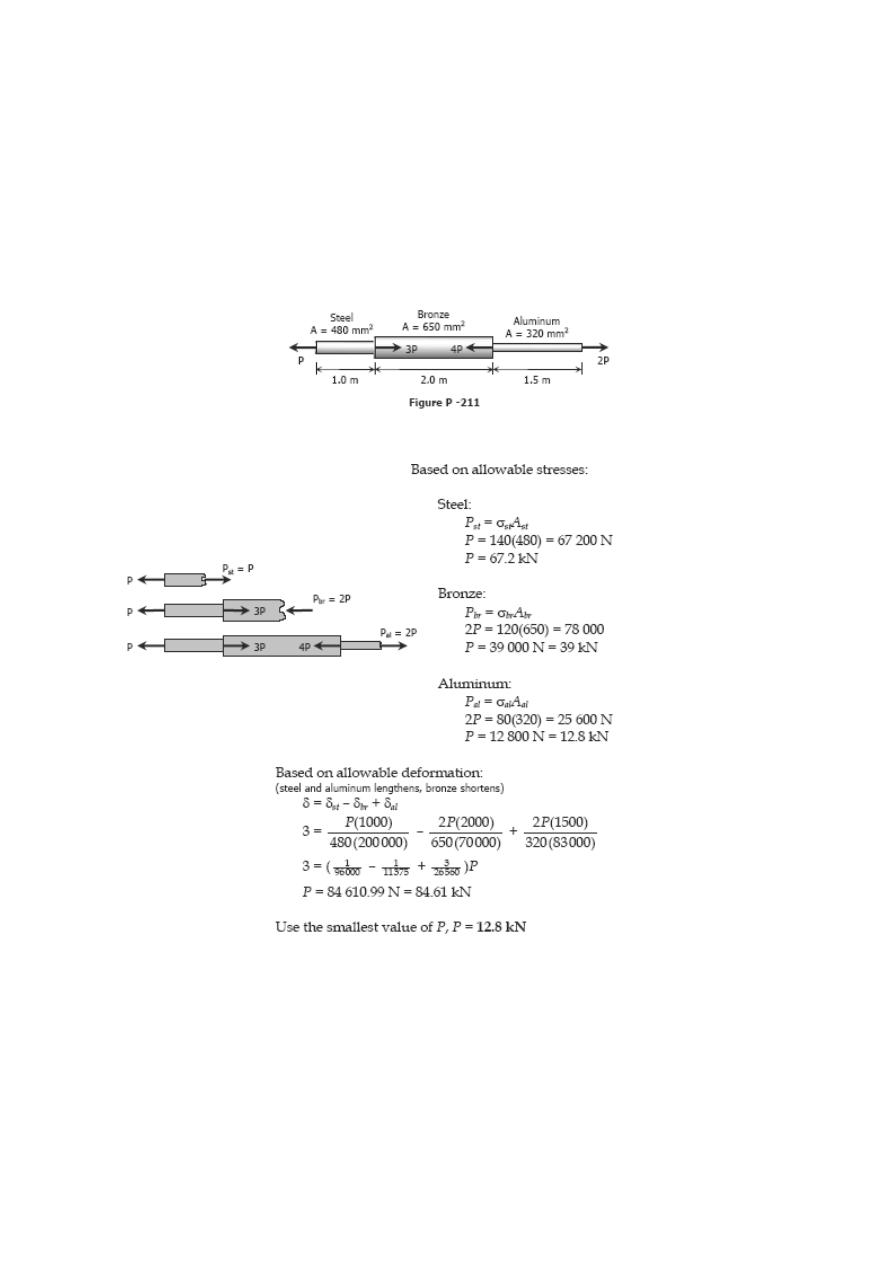

Problem 211

A bronze bar is fastened between a steel bar and an aluminum bar as shown in Fig. P-

211. Axial loads are applied at the positions indicated. Find the largest value of P that

will not exceed an overall deformation of 3.0 mm, or the following stresses: 140 MPa in

the steel, 120 MPa in the bronze, and 80 MPa in the aluminum. Assume that the

assembly is suitably braced to prevent buckling. Use E

st

= 200 GPa, E

al

= 70 GPa, and

E

br

= 83 GPa.

Solution 211

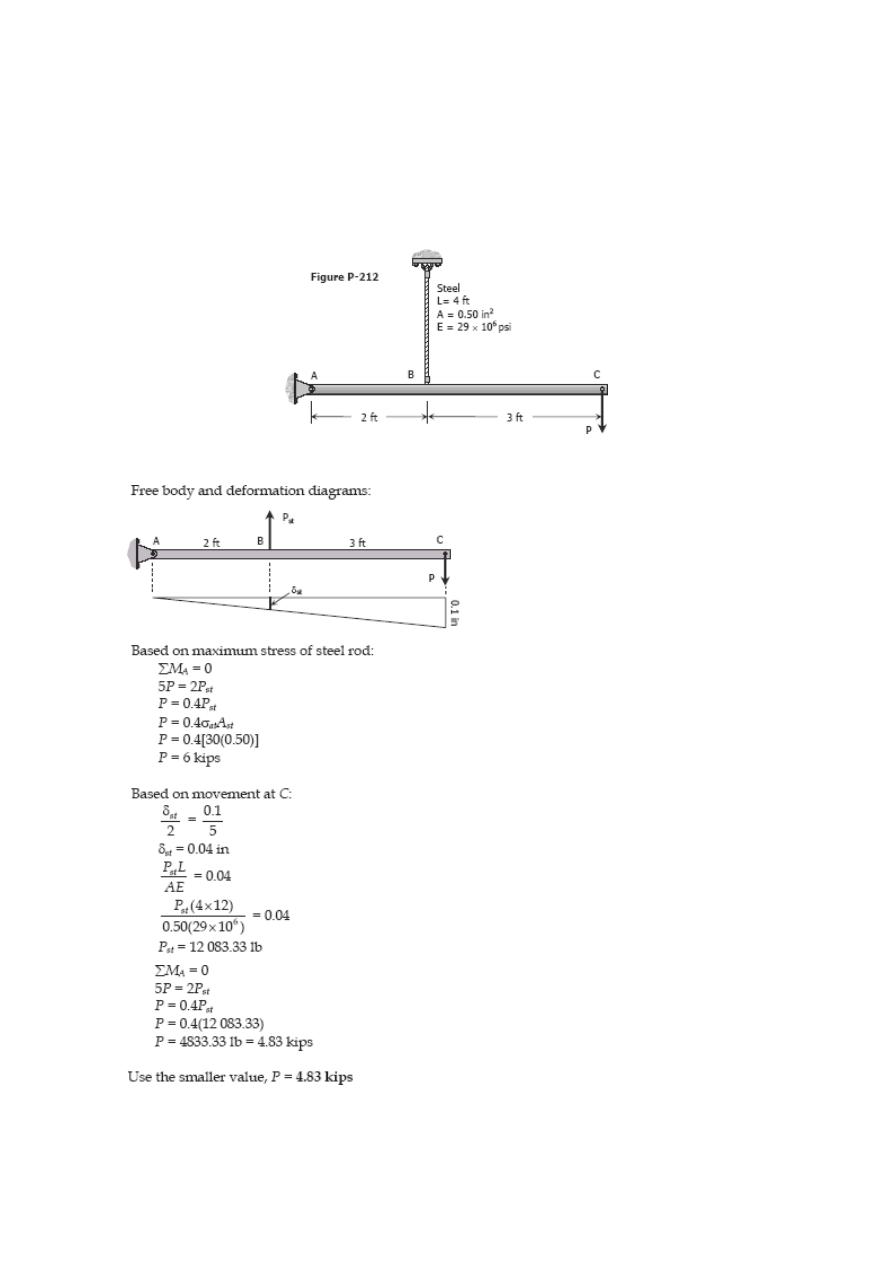

Problem 212

The rigid bar ABC shown in Fig. P-212 is hinged at A and supported by a steel rod at B.

Determine the largest load P that can be applied at C if the stress in the steel rod is

limited to 30 ksi and the vertical movement of end C must not exceed 0.10 in.

Solution 212

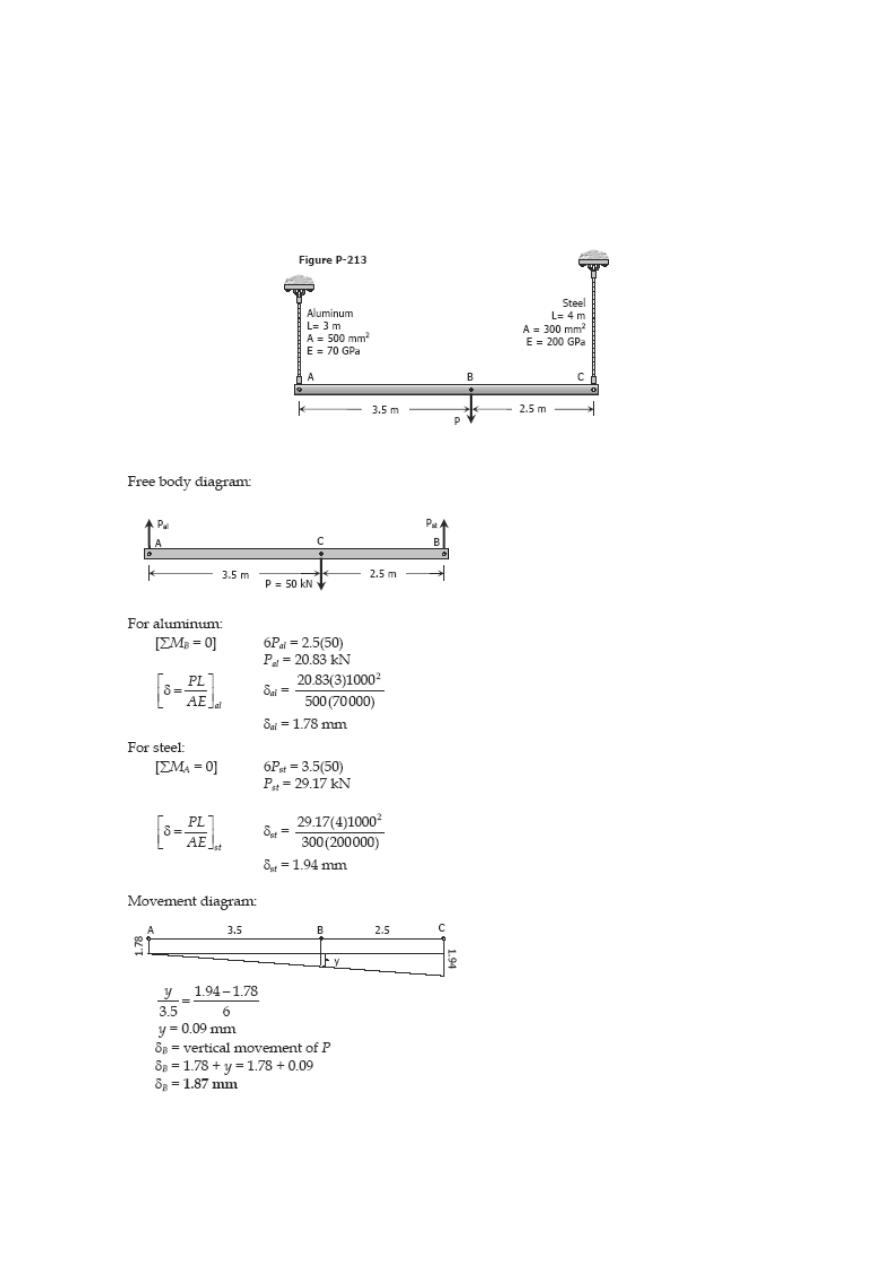

Problem 213

The rigid bar AB, attached to two vertical rods as shown in Fig. P-213, is horizontal

before the load P is applied. Determine the vertical movement of P if its magnitude is 50

kN.

Solution 213

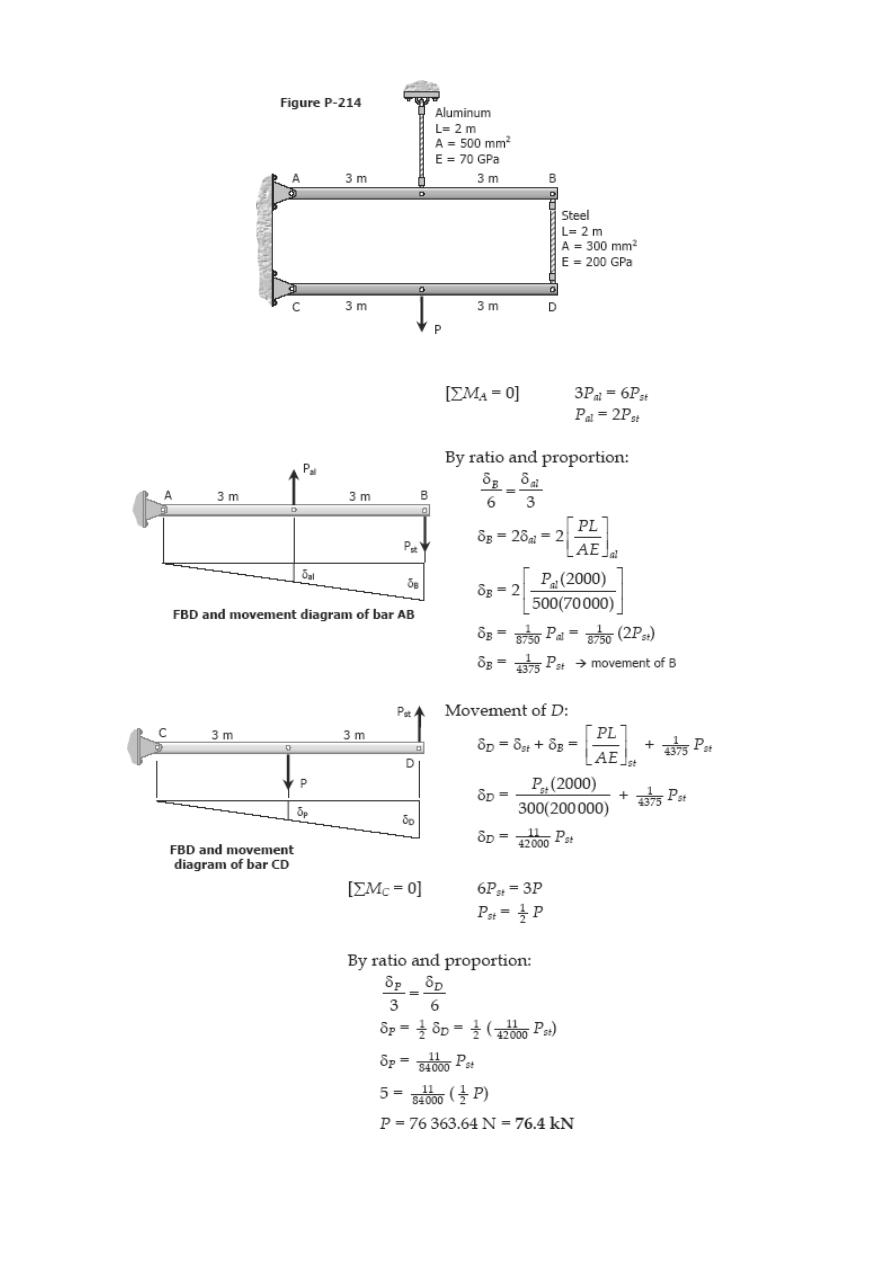

Problem 214

The rigid bars AB and CD shown in Fig. P-214 are supported by pins at A and C and the

two rods. Determine the maximum force P that can be applied as shown if its vertical

movement is limited to 5 mm. Neglect the weights of all members.

Solution 214

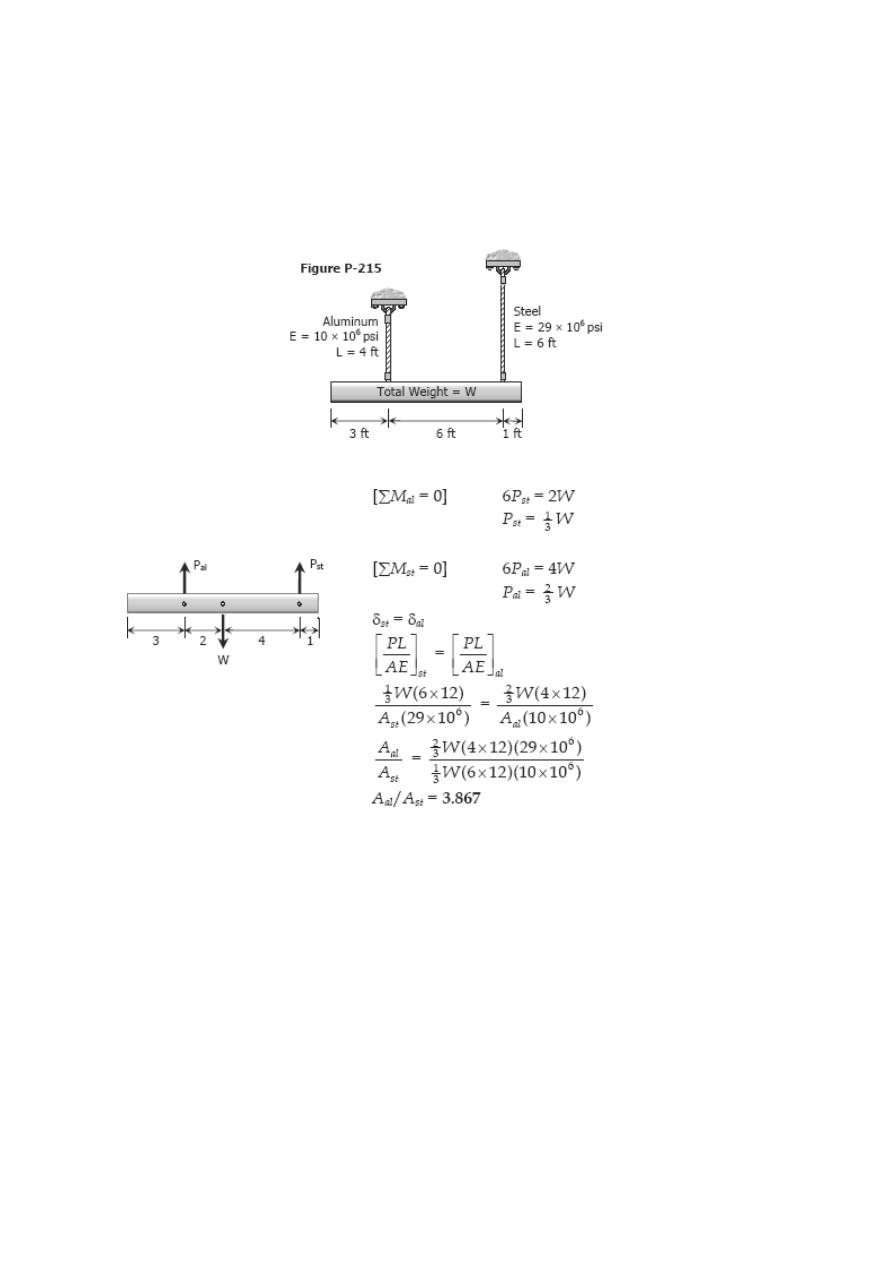

Problem 215

A uniform concrete slab of total weight W is to be attached, as shown in Fig. P-215, to

two rods whose lower ends are on the same level. Determine the ratio of the areas of

the rods so that the slab will remain level.

Solution 215

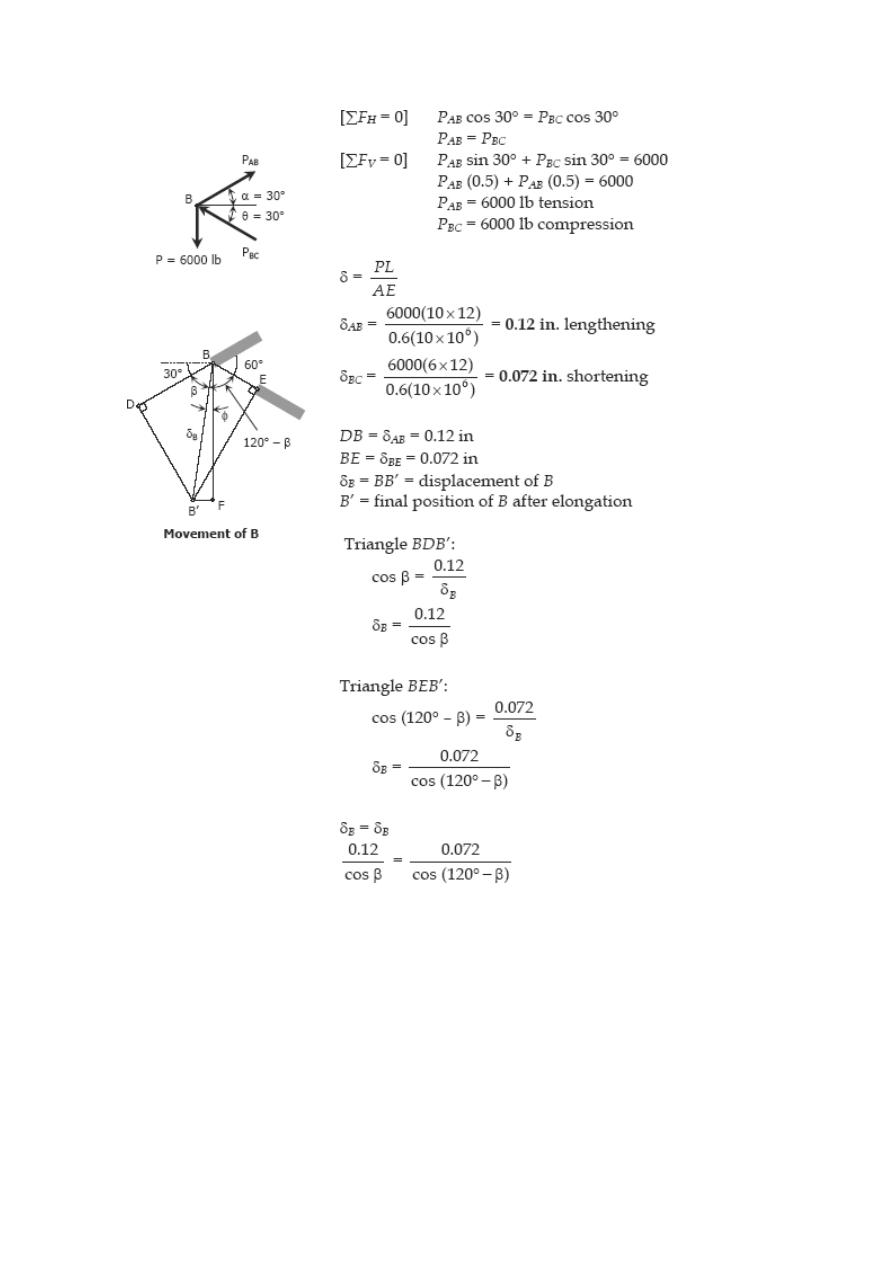

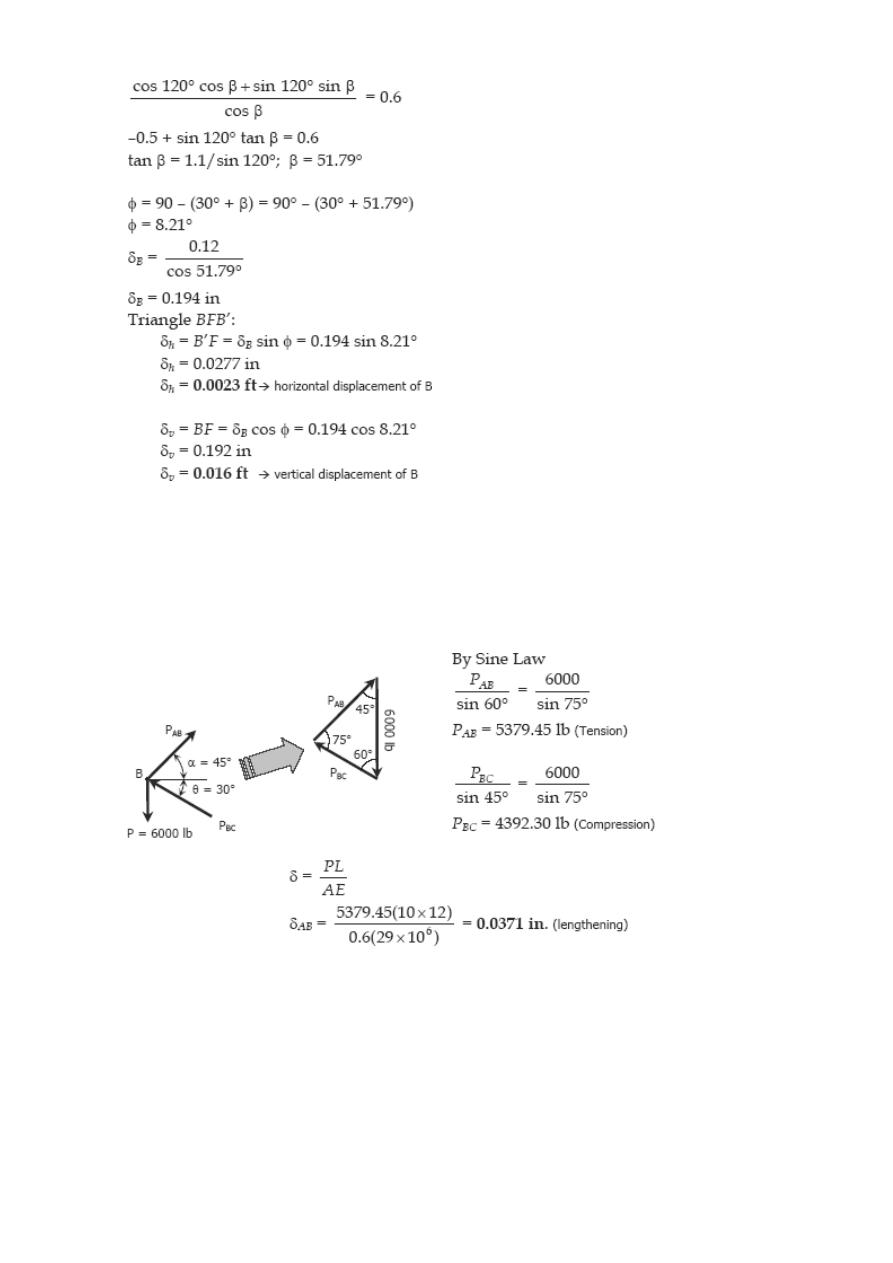

Problem 216

As shown in Fig. P-216, two aluminum rods AB and BC, hinged to rigid supports, are

pinned together at B to carry a vertical load P = 6000 lb. If each rod has a

crosssectional area of 0.60 in

2

and E = 10 × 10

6

psi, compute the elongation of each

rod and the horizontal and vertical displacements of point B. Assume α = 30° and θ =

30°.

Solution 216

Problem 217

Solve Prob. 216 if rod AB is of steel, with E = 29 × 10

6

psi. Assume α = 45° and θ =

30°; all other data remain unchanged.

Solution 217

Problem 218

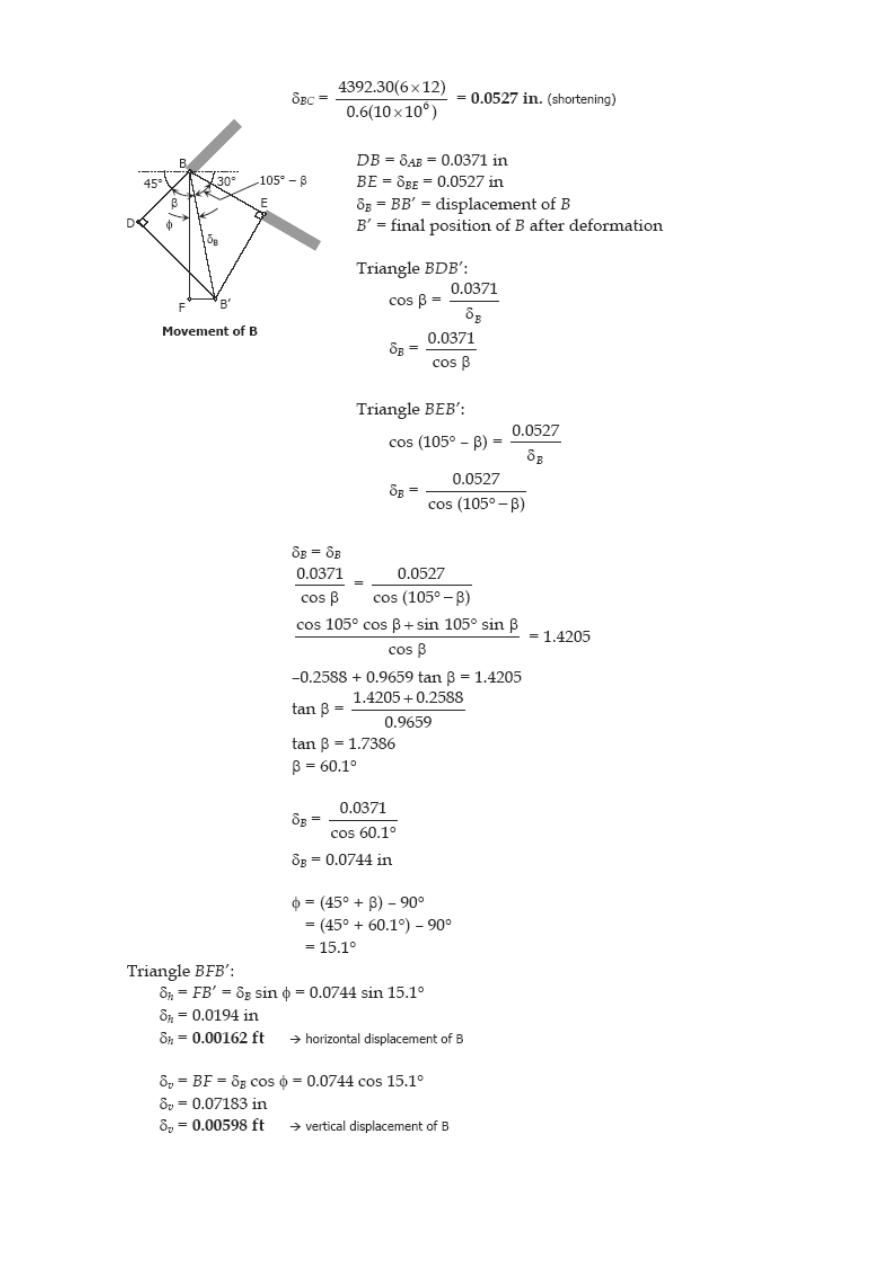

A uniform slender rod of length L and cross sectional area A is rotating in a horizontal

ertical axis through one end. If the unit mass of the

al

plane about a v

rod is ρ, and it is rotating at a constant angular velocity of ω rad/sec, show that the tot

elongation of the rod is ρω

2

L

3

/3E.

Solution 218

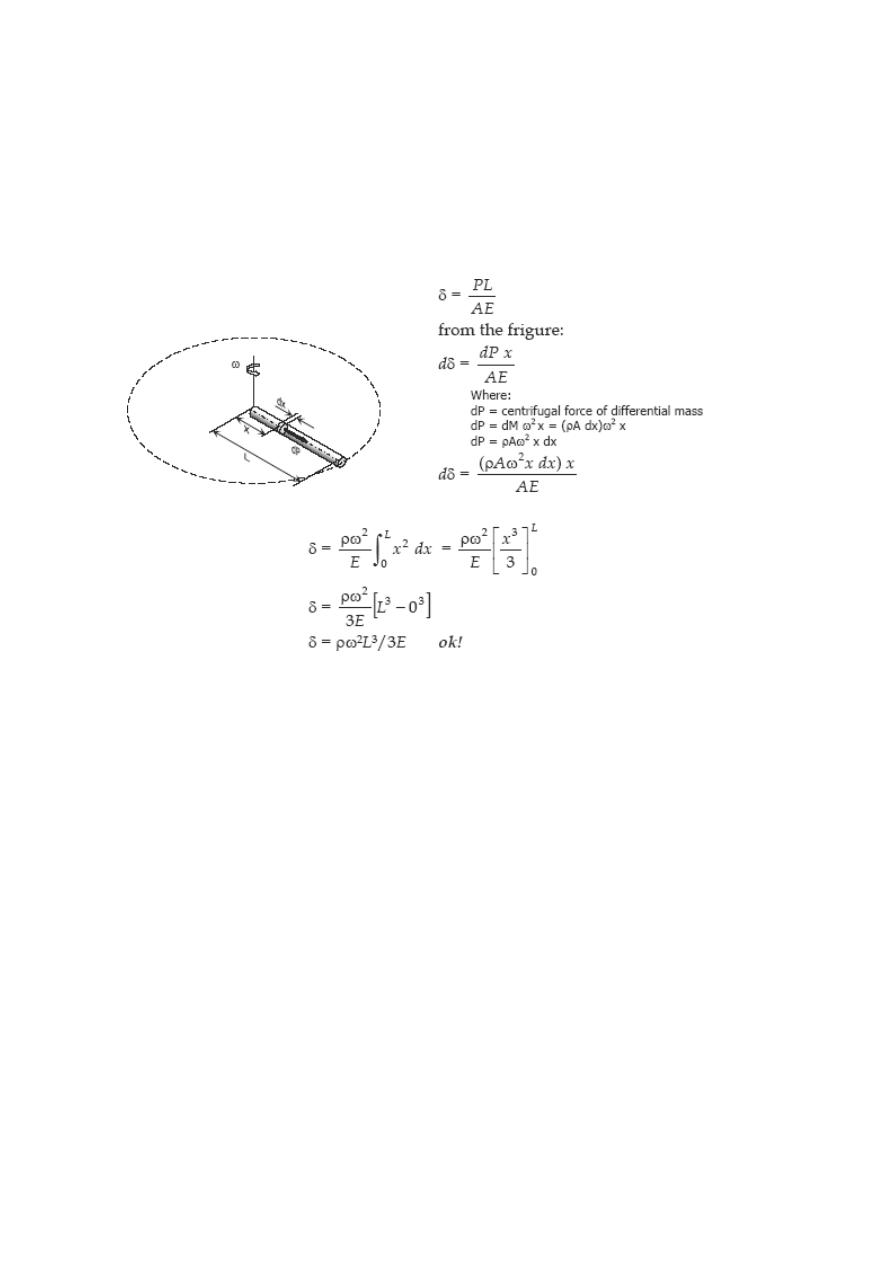

Problem 219

A round bar of length L, which tapers uniformly from a diameter D at one end to a

r d at the other, is suspended vertically from the large end. If w is the

e

smaller diamete

weight per unit volume, find the elongation of the rod caused by its own weight. Us

this result to determine the elongation of a cone suspended from its base.

Solution 219

SOLVED PROBLEMS IN STRAIN AND AXIAL DEFORMATION

Problem 203

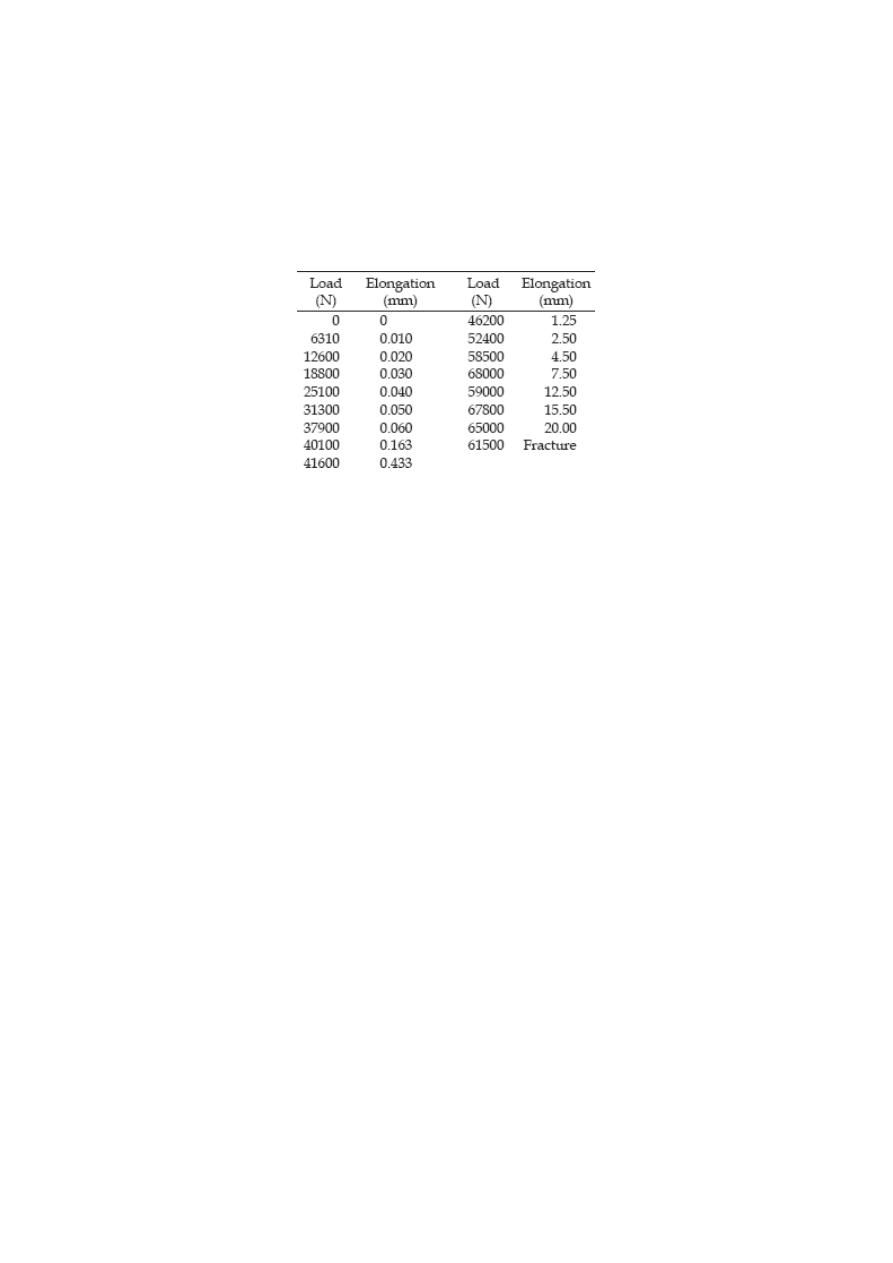

The following data were recorded during the tensile test of a 14-mm-diameter mild steel

rod. The gage length was 50 mm.

Plot the stress-strain diagram and determine the following mechanical properties: (a)

proportional limits; (b) modulus of elasticity; (c) yield point; (d) ultimate strength; and

(e) rupture strength.

Solution 203

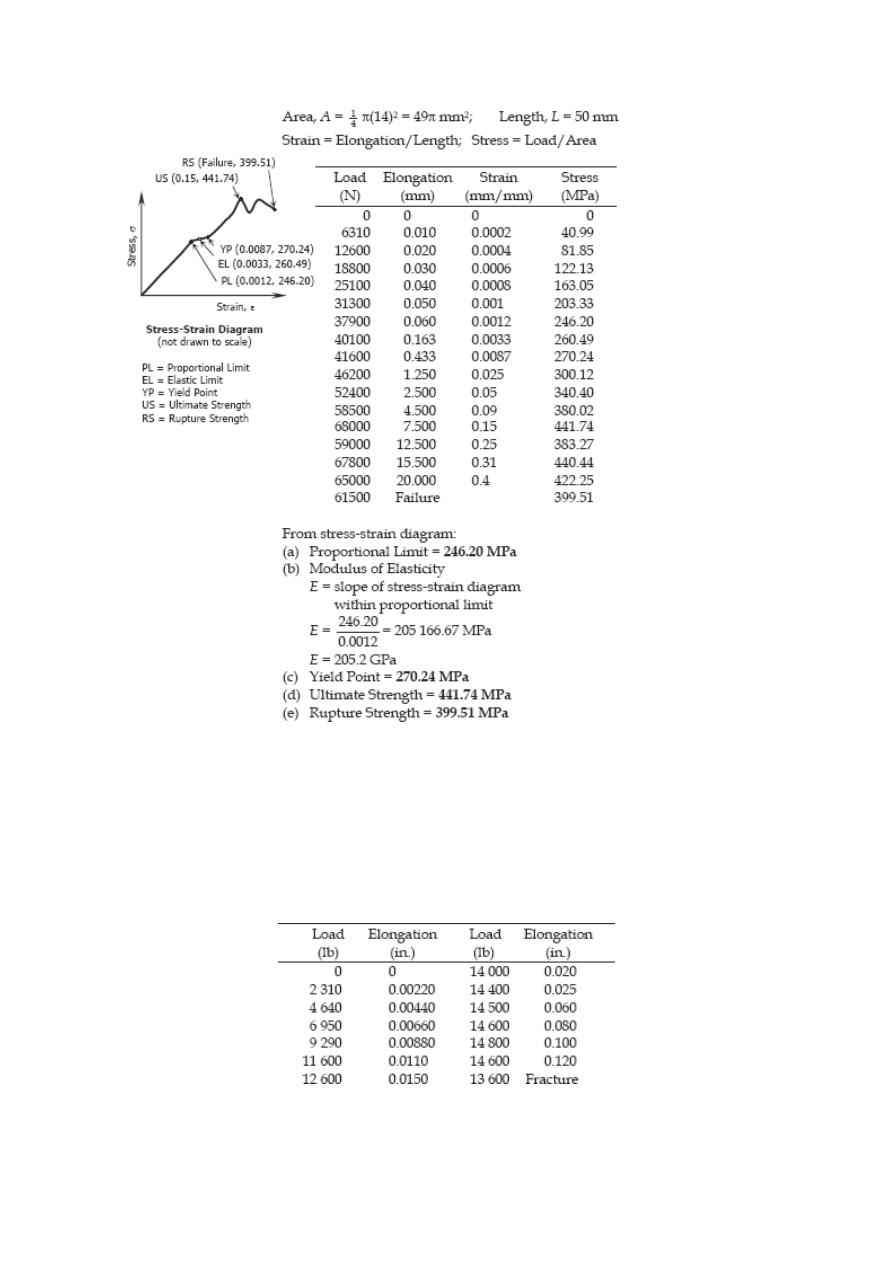

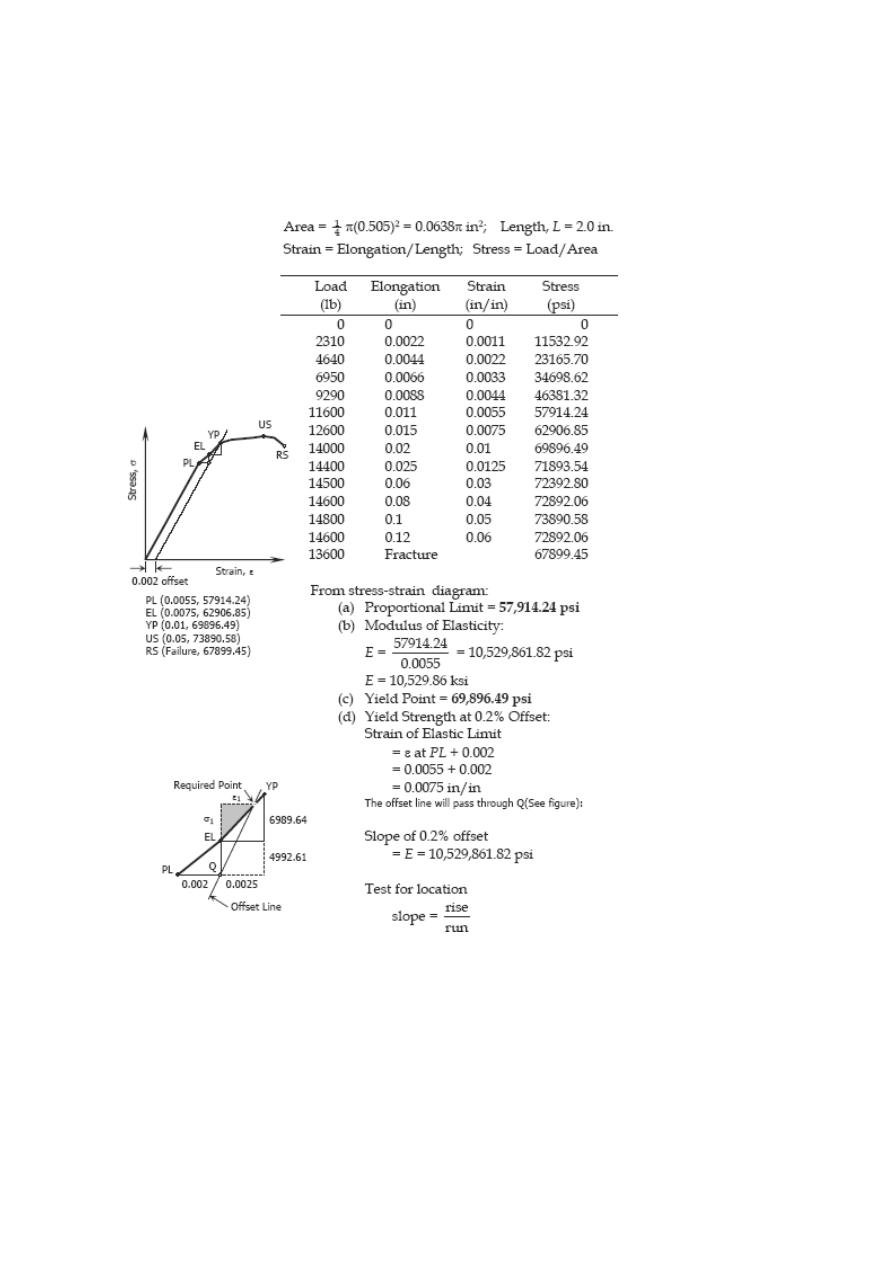

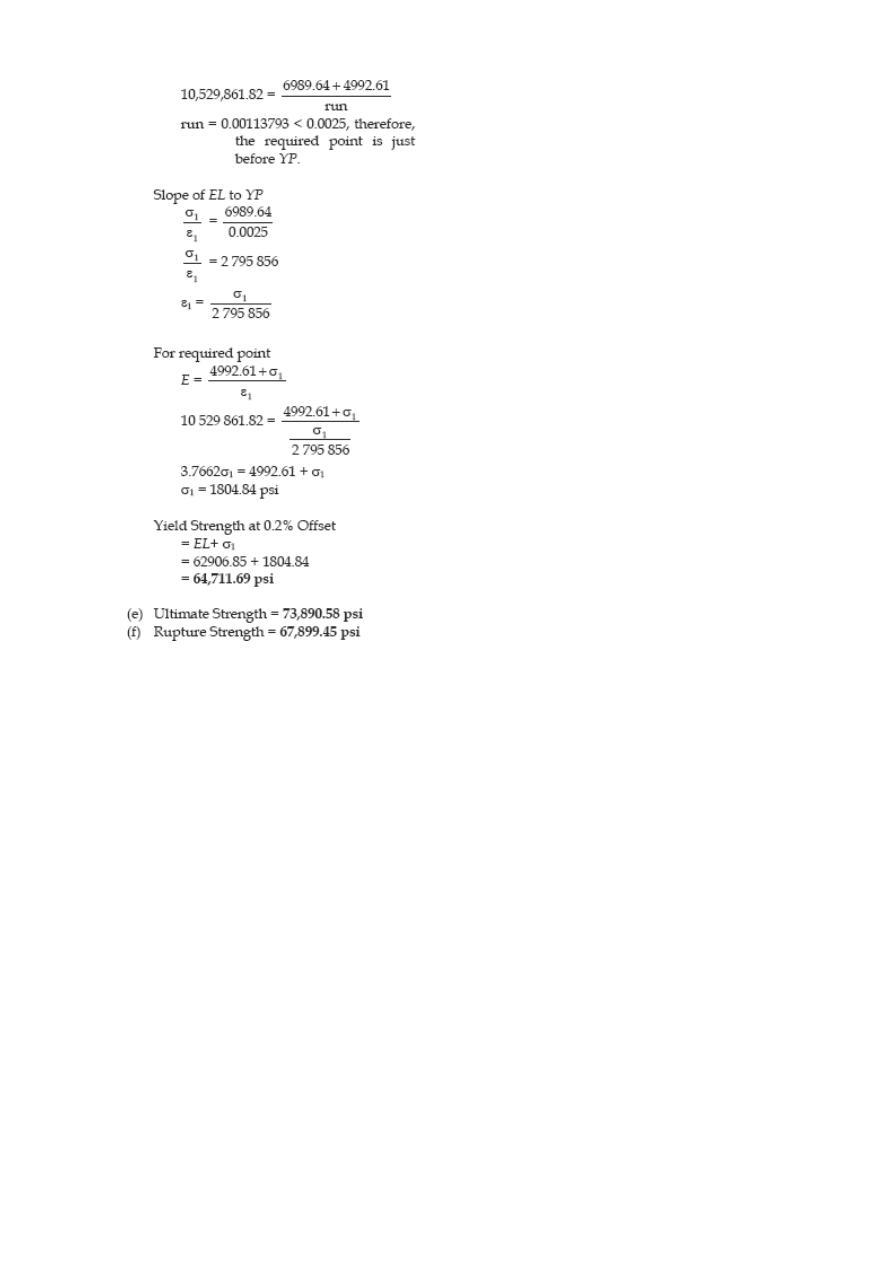

Problem 204

The following data were obtained during a tension test of an aluminum alloy. The initial

diameter of the test specimen was 0.505 in. and the gage length was

2.0 in.

Plot the stress-strain diagram and determine the following mechanical properties: (a)

proportional limit; (b) modulus of elasticity; (c) yield point; (d) yield strength at 0.2%

offset; (e) ultimate strength; and (f) rupture strength.

Solution 204

Problem 205

A uniform bar of length L, cross-sectional area A, and unit mass ρ is suspended

vertically from one end. Show that its total elongation is δ = ρgL

2

/ 2E. If the total mass

of the bar is M, show also that δ = MgL/2AE.

Solution 205

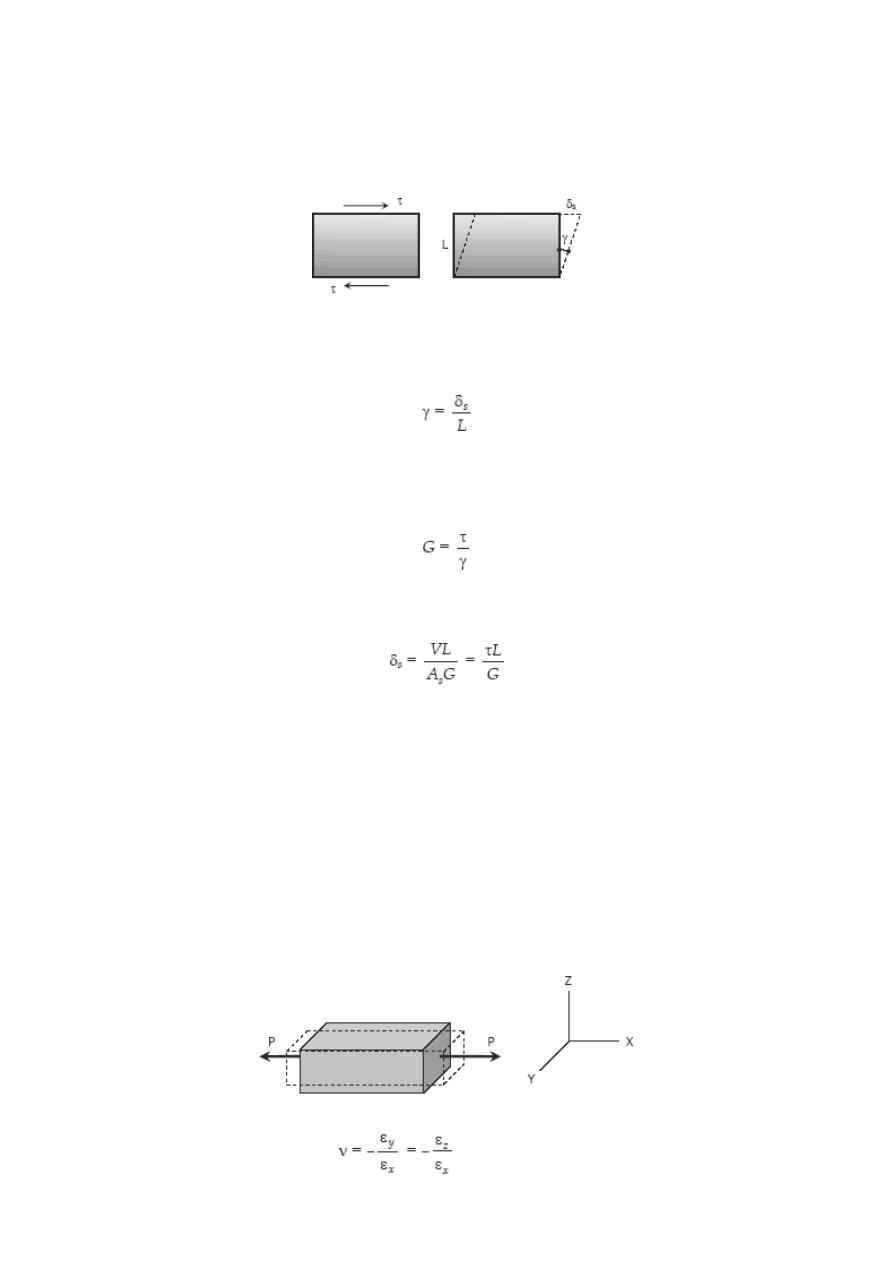

Shearing Deformation

Shearing forces cause shearing deformation. An element subject to shear does not

change in length but undergoes a change in shape.

The change in angle at the corner of an original rectangular element is called the shear

strain and is expressed as

The ratio of the shear stress τ and the shear strain γ is called the modulus of elasticity

in shear or modulus of rigidity and is denoted as G, in MPa.

The relationship between the shearing deformation and the applied shearing force is

where V is the shearing force acting over an area A

s

.

Poisson's Ratio

When a bar is subjected to a tensile loading there is an increase in length of the bar in

the direction of the applied load, but there is also a decrease in a lateral dimension

perpendicular to the load. The ratio of the sidewise deformation (or strain) to the

longitudinal deformation (or strain) is called the Poisson's ratio and is denoted by ν. For

most steel, it lies in the range of 0.25 to 0.3, and 0.20 for concrete.

where ε

x

is strain in the x-direction and ε

y

and ε

z

are the strains in the perpendicular

direction. The negative sign indicates a decrease in the transverse dimension when ε

x

is

positive.

BIAXIAL DEFORMATION

If an element is subjected simultaneously by ensile stresses, σ

x

and σ

y

, in the x and y

directions, the strain in the x-direction is σ

x

/ E and the strain in the y direction is σ

y

/ E.

Simultaneously, the stress in the y direction will produce a lateral contraction on the x

x

direction of the amount -ν ε

y

or -ν σ

y

/E. The resulting strain in the x direction will be

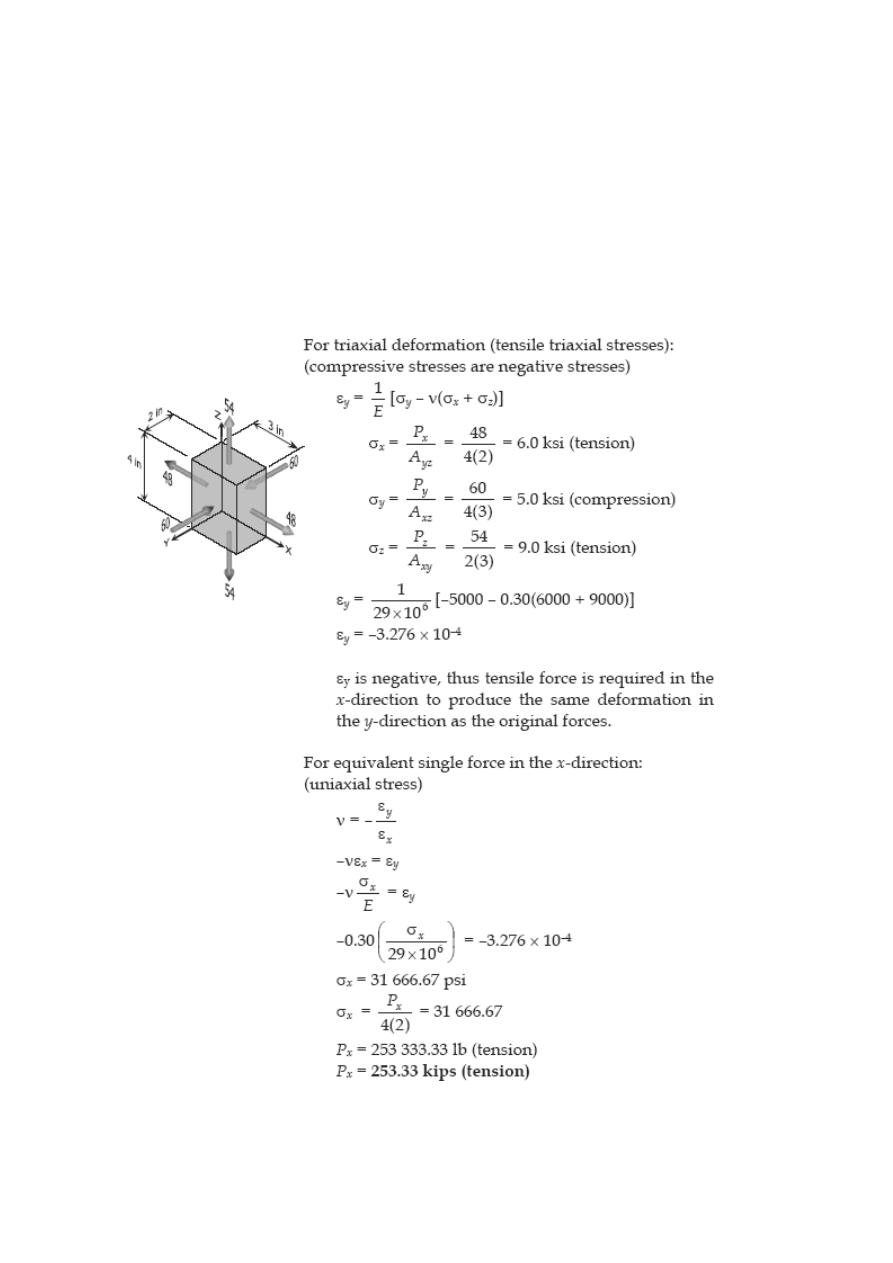

TRIAXIAL DEFORMATION

If an element is subjected simultaneously by three mutually perpendicular normal

stresses σ

x

, σ

y

, and σ

z

, which are accompanied by strains ε

x

, ε

y

, and ε

z

, respectively,

Tensile stresses and elongation are taken as positive. Compressive stresses and

contraction are taken as negative.

Relationship Between E, G, and

ν

The relationship between modulus of elasticity E, shear modulus G and Poisson's ratio ν

is:

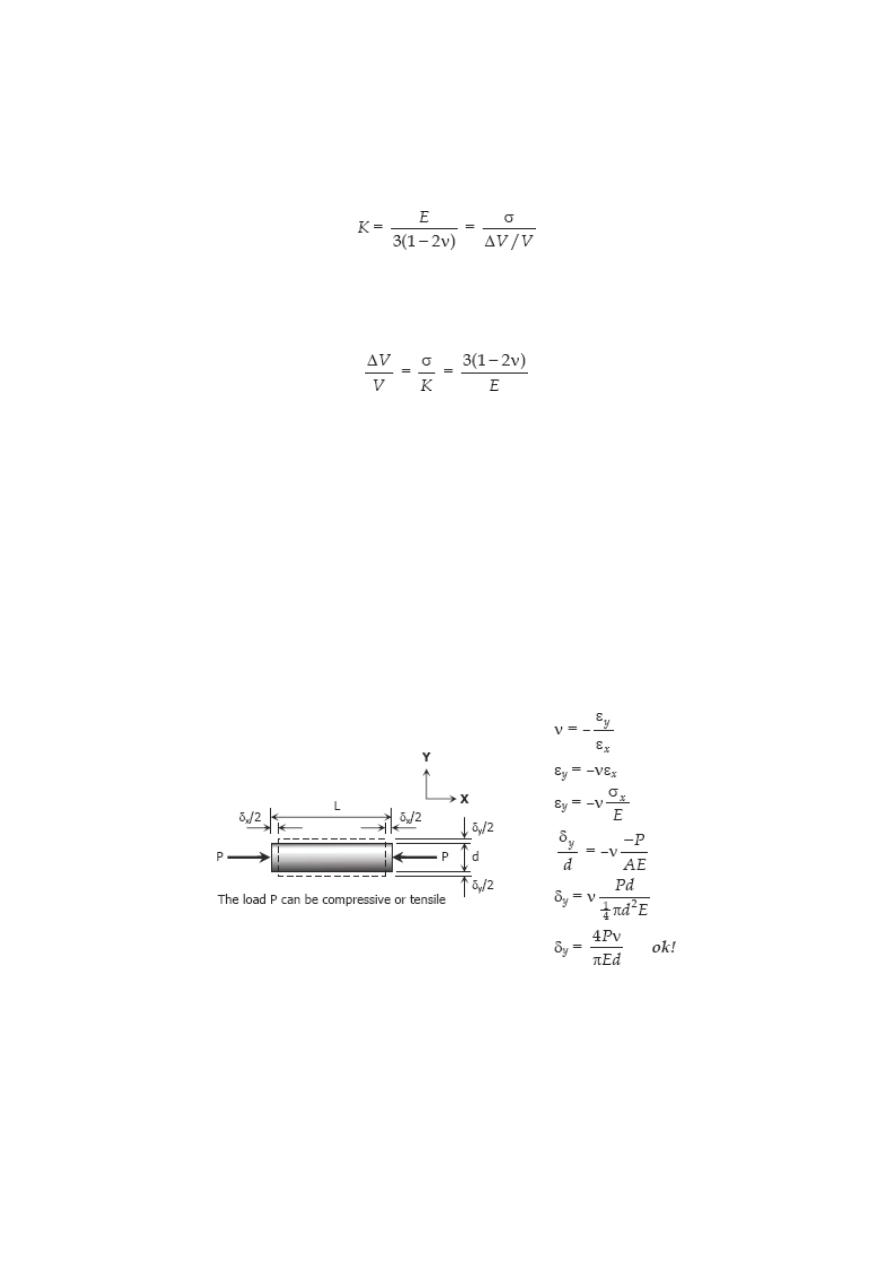

Bulk Modulus of Elasticity or Modulus of Volume Expansion, K

The bulk modulus of elasticity K is a measure of a resistance of a material to change in

volume without change in shape or form. It is given as

where V is the volume and ΔV is change in volume. The ratio ΔV / V is called volumetric

strain and can be expressed as

Solved Problems in Shearing Deformation

Problem 222

A solid cylinder of diameter d carries an axial load P. Show that its change in diameter is

4Pν / πEd.

Solution 222

Problem 223

A rectangular steel block is 3 inches long in the x direction, 2 inches long in the y

direction, and 4 inches long in the z direction. The block is subjected to a triaxial loading

of three uniformly distributed forces as follows: 48 kips tension in the x direction, 60

kips compression in the y direction, and 54 kips tension in the z direction. If ν = 0.30

and E = 29 × 10

6

psi, determine the single uniformly distributed load in the x direction

that would produce the same deformation in the y direction as the original loading.

Solution 223

Problem 224

For the block loaded triaxially as described in Prob. 223, find the uniformly distributed

load that must be added in the x direction to produce no deformation in the z direction.

Solution 224

Problem 225

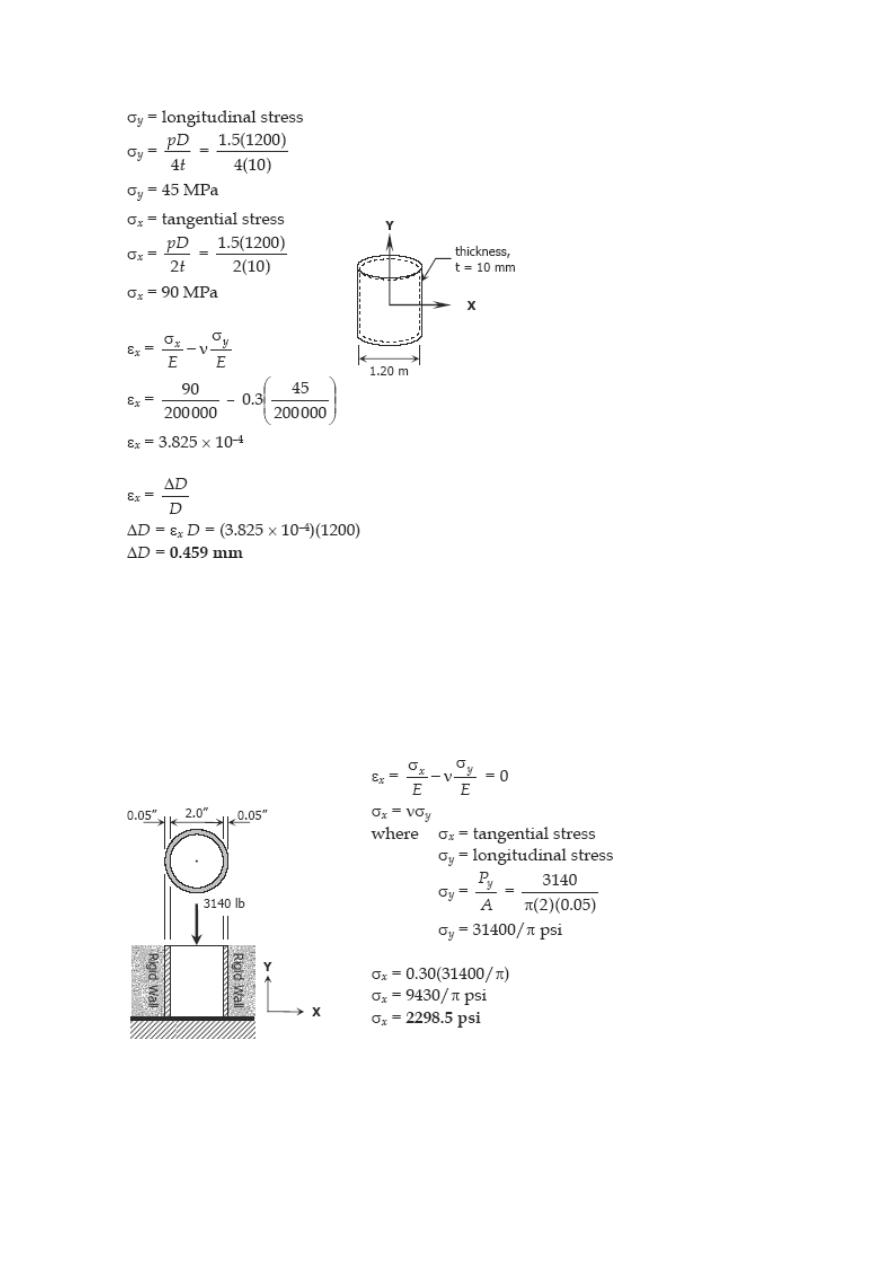

A welded steel cylindrical drum made of a 10-mm plate has an internal diameter of 1.20

m. Compute the change in diameter that would be caused by an internal pressure of 1.5

MPa. Assume that Poisson's ratio is 0.30 and E = 200 GPa.

Solution 225

Problem 226

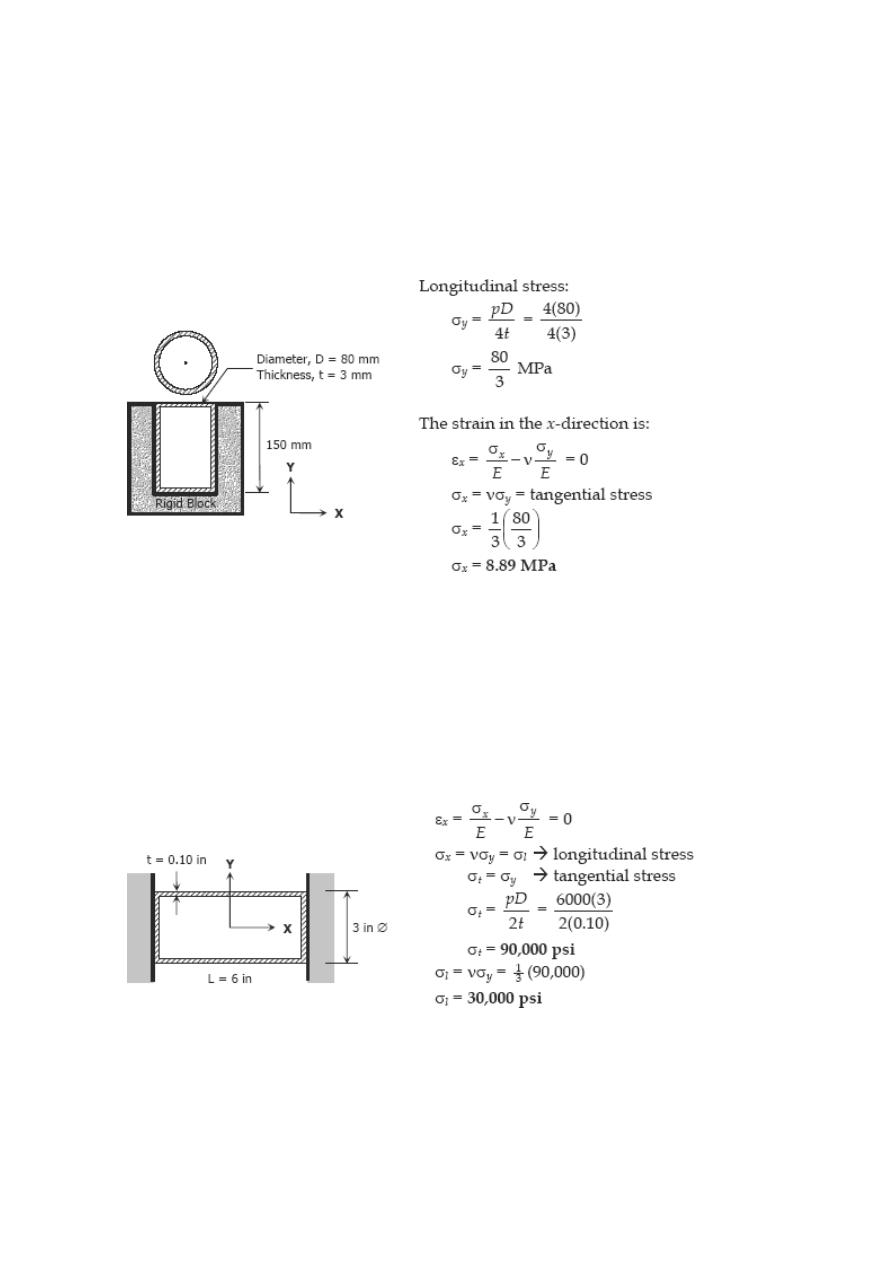

A 2-in.-diameter steel tube with a wall thickness of 0.05 inch just fits in a rigid hole.

Find the tangential stress if an axial compressive load of 3140 lb is applied. Assume ν =

0.30 and neglect the possibility of buckling.

Solution 226

Problem 227

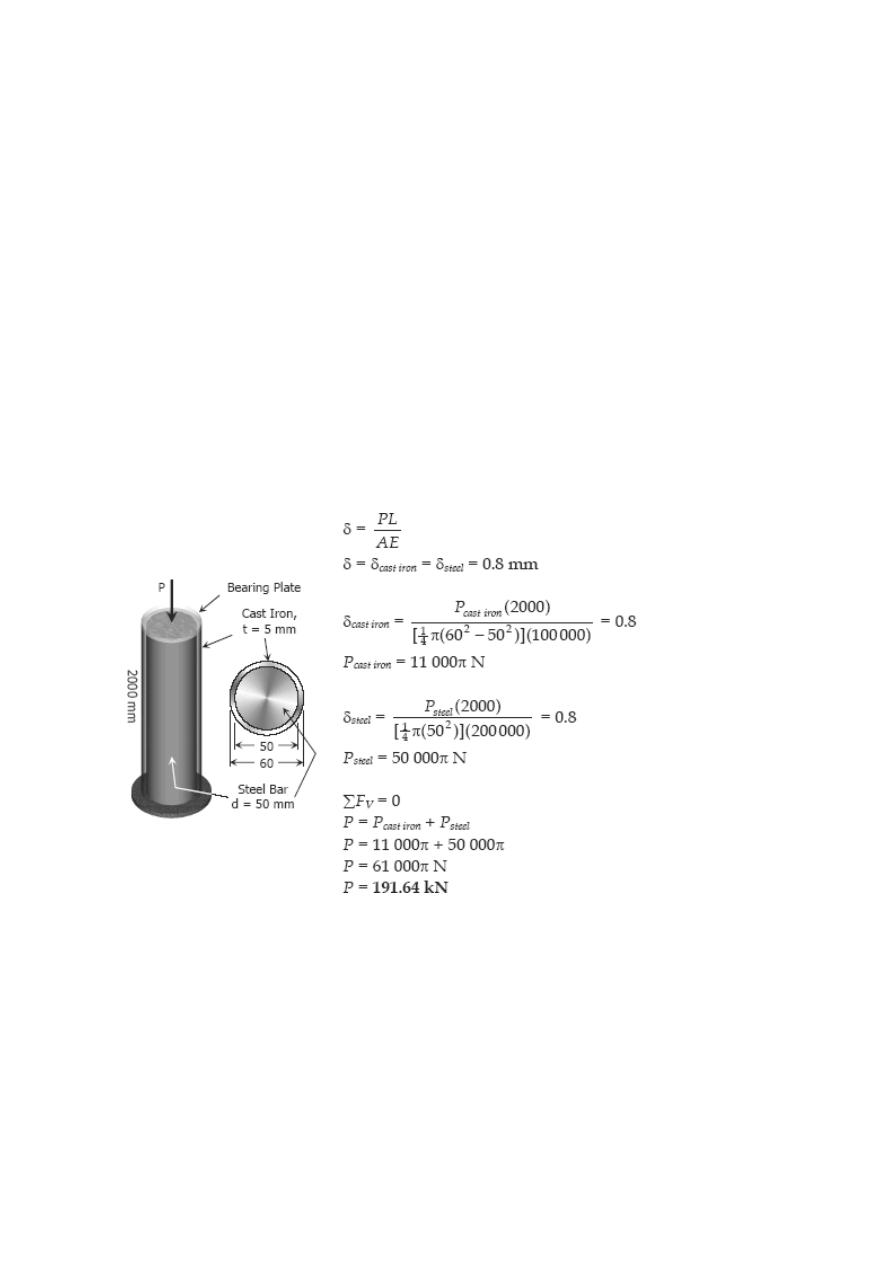

A 150-mm-long bronze tube, closed at its ends, is 80 mm in diameter and has a wall

thickness of 3 mm. It fits without clearance in an 80-mm hole in a rigid

block. The tube is then subjected to an internal pressure of 4.00 MPa. Assuming ν = 1/3

and E = 83 GPa, determine the tangential stress in the tube.

Solution 227

Problem 228

A 6-in.-long bronze tube, with closed ends, is 3 in. in diameter with a wall thickness of

0.10 in. With no internal pressure, the tube just fits between two rigid end walls.

Calculate the longitudinal and tangential stresses for an internal pressure of 6000 psi.

Assume ν = 1/3 and E = 12 × 10

6

psi.

Solution 228

Statically Indeterminate Members

When the reactive forces or the internal resisting forces over a cross section exceed the

number of independent equations of equilibrium, the structure is called statically

indeterminate. These cases require the use of additional relations that depend on the

elastic deformations in the members.

Solved Problems in Statically Indeterminate Members

Problem 233

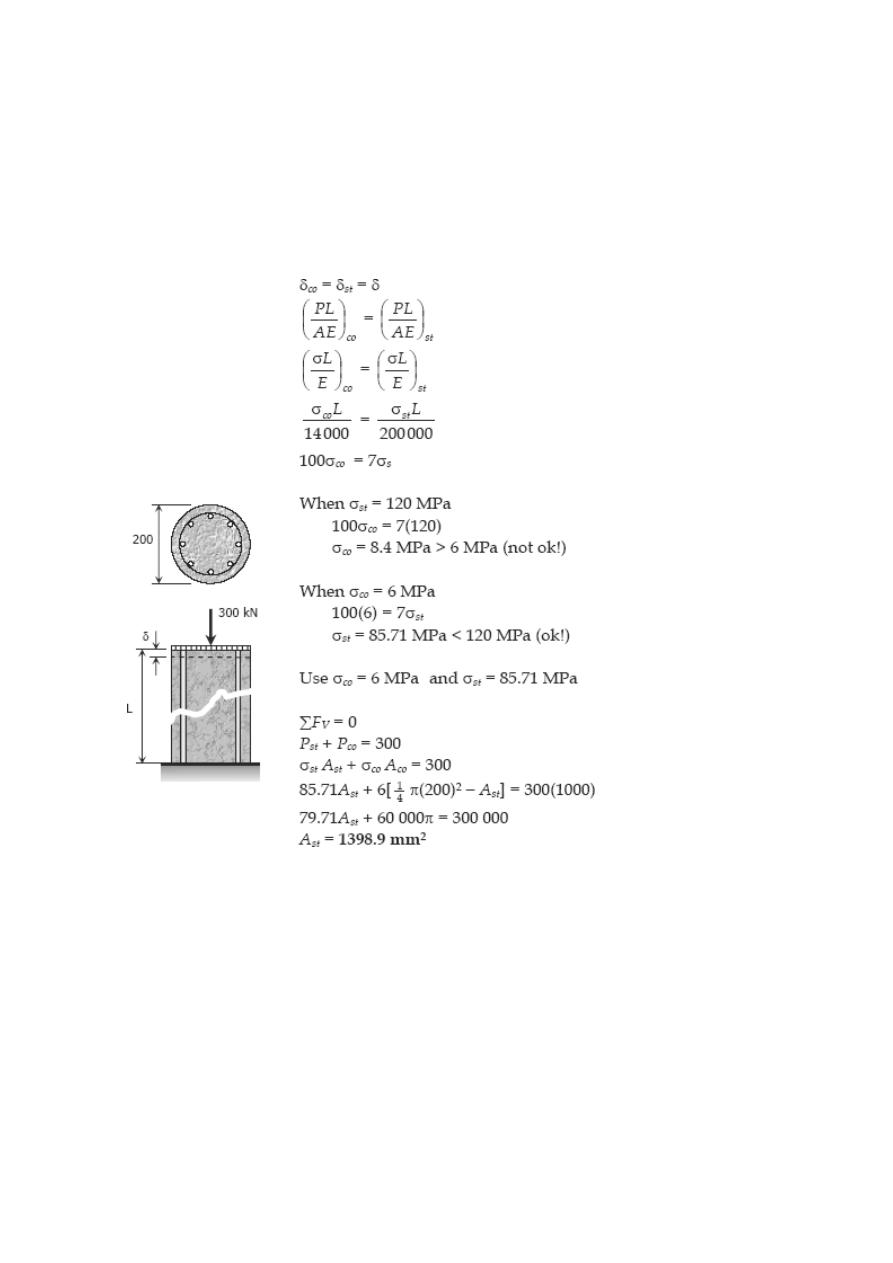

A steel bar 50 mm in diameter and 2 m long is surrounded by a shell of a cast iron 5

mm thick. Compute the load that will compress the combined bar a total of 0.8 mm in

the length of 2 m. For steel, E = 200 GPa, and for cast iron, E = 100 GPa.

Solution 233

Problem 234

A reinforced concrete column 200 mm in diameter is designed to carry an axial

compressive load of 300 kN. Determine the required area of the reinforcing steel if the

allowable stresses are 6 MPa and 120 MPa for the concrete and steel, respectively. Use

E

co

= 14 GPa and E

st

= 200 GPa.

Solution 234

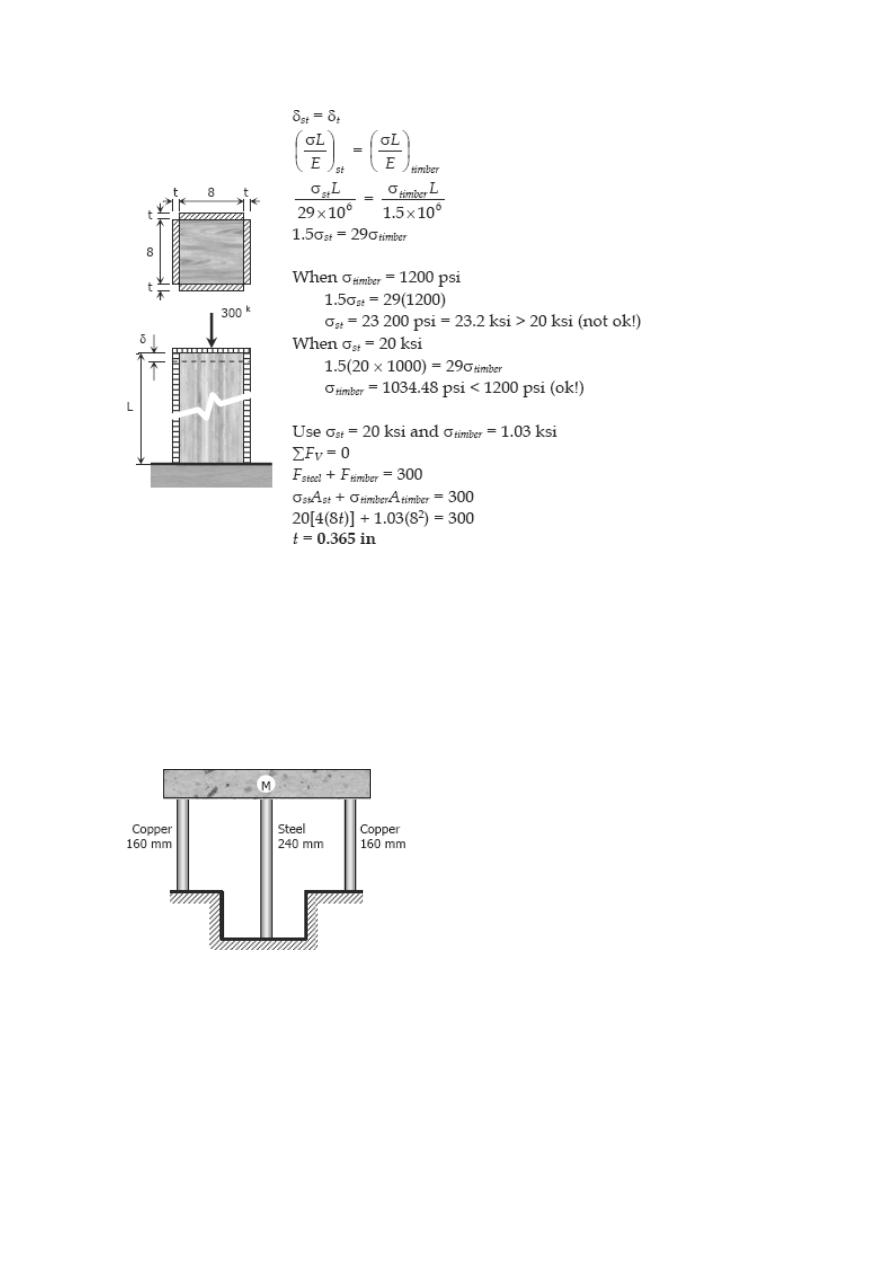

Problem 235

A timber column, 8 in. × 8 in. in cross section, is reinforced on each side by a steel

plate 8 in. wide and t in. thick. Determine the thickness t so that the column will

support an axial load of 300 kips without exceeding a maximum timber stress of 1200

psi or a maximum steel stress of 20 ksi. The moduli of elasticity are 1.5 × 10

6

psi for

timber, and 29 × 10

6

psi for steel.

Solution 235

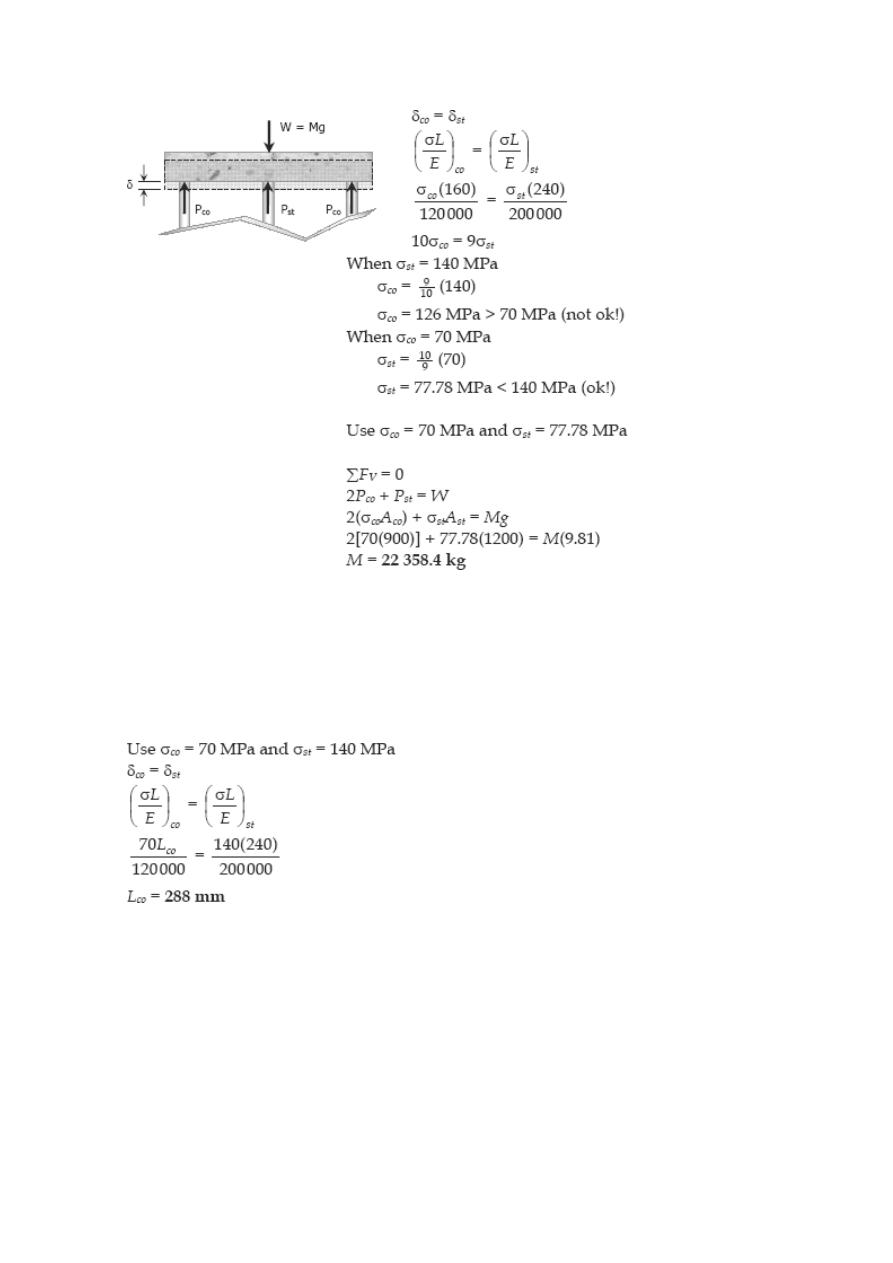

Problem 236

A rigid block of mass M is supported by three symmetrically spaced rods as shown in fig

P-236. Each copper rod has an area of 900 mm

2

; E = 120 GPa; and the allowable stress

is 70 MPa. The steel rod has an area of 1200 mm

2

; E = 200 GPa; and the allowable

stress is 140 MPa. Determine the largest mass M which can be supported.

Figure P-236 and P-237

Solution 236

Problem 237

In Prob. 236, how should the lengths of the two identical copper rods be changed so

that each material will be stressed to its allowable limit?

Solution 237

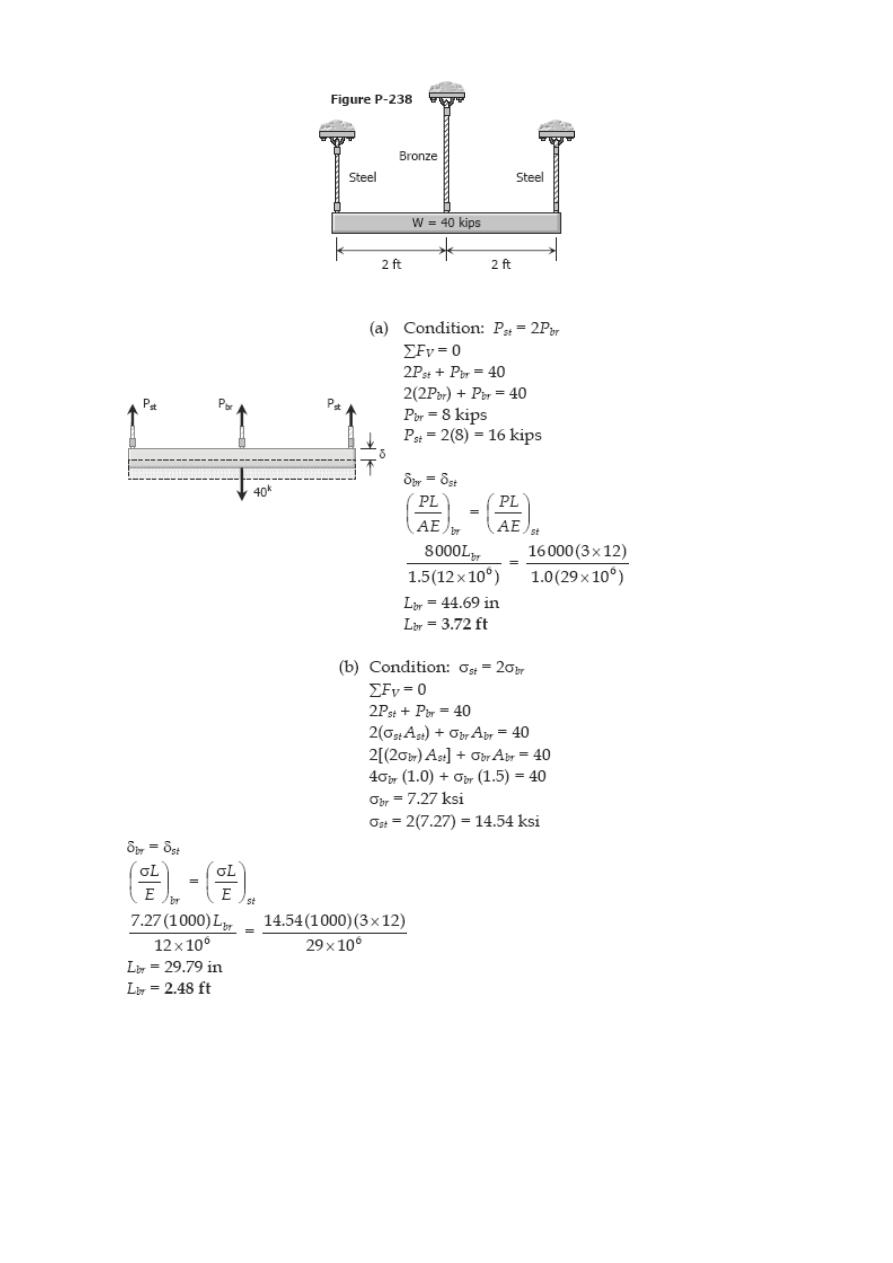

Problem 238

The lower ends of the three bars in Fig. P-238 are at the same level before the uniform

rigid block weighing 40 kips is attached. Each steel bar has a length of 3 ft, and area of

1.0 in.

2

, and E = 29 × 10

6

psi. For the bronze bar, the area is 1.5 in.

2

and E = 12 × 10

6

psi. Determine (a) the length of the bronze bar so that the load on each steel bar is

twice the load on the bronze bar, and (b) the length of the bronze that will make the

steel stress twice the bronze stress.

Solution 238

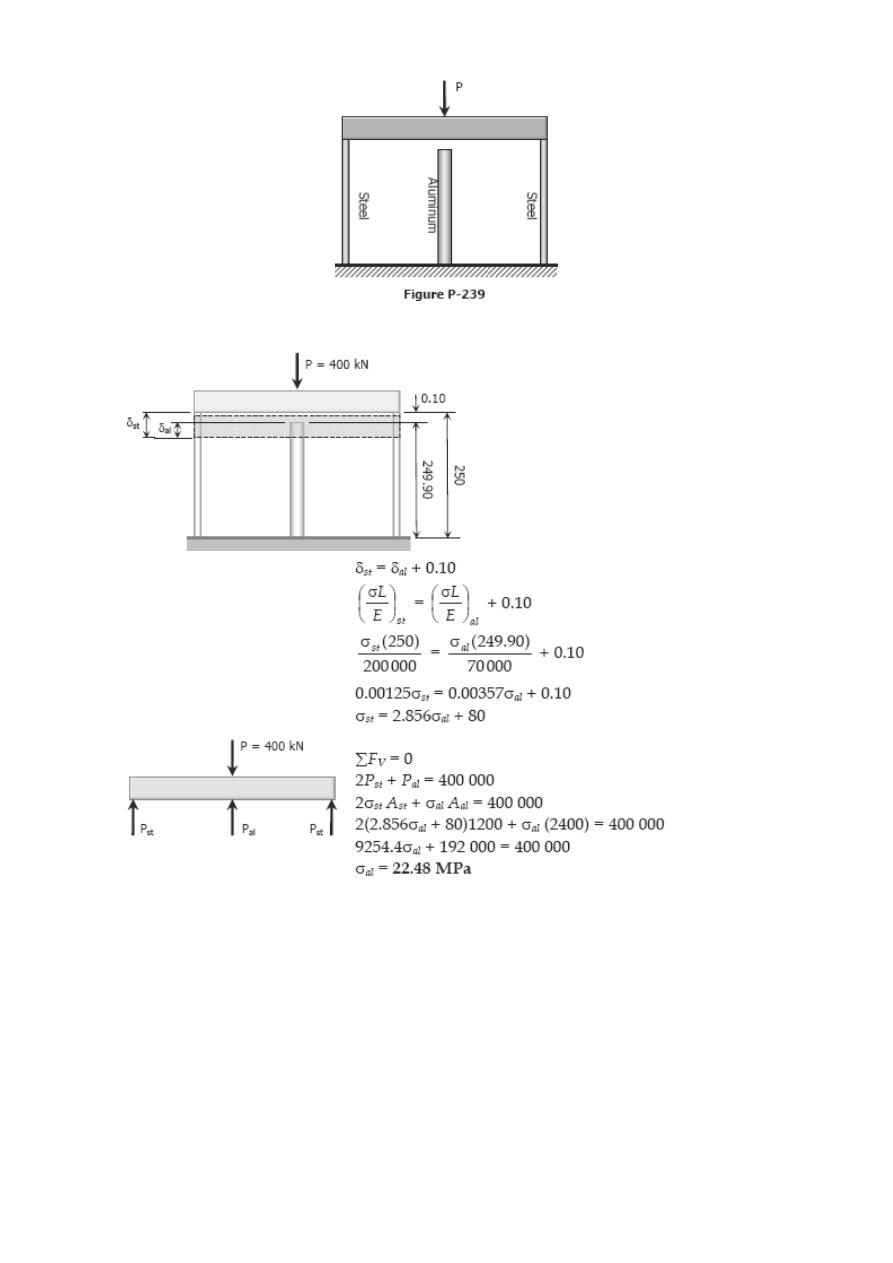

Problem 239

The rigid platform in Fig. P-239 has negligible mass and rests on two steel bars, each

250.00 mm long. The center bar is aluminum and 249.90 mm long. Compute the stress

in the aluminum bar after the center load P = 400 kN has been applied. For each steel

bar, the area is 1200 mm

2

and E = 200 GPa. For the aluminum bar, the area is 2400

mm

2

and E = 70 GPa.

Solution 239

Problem 240

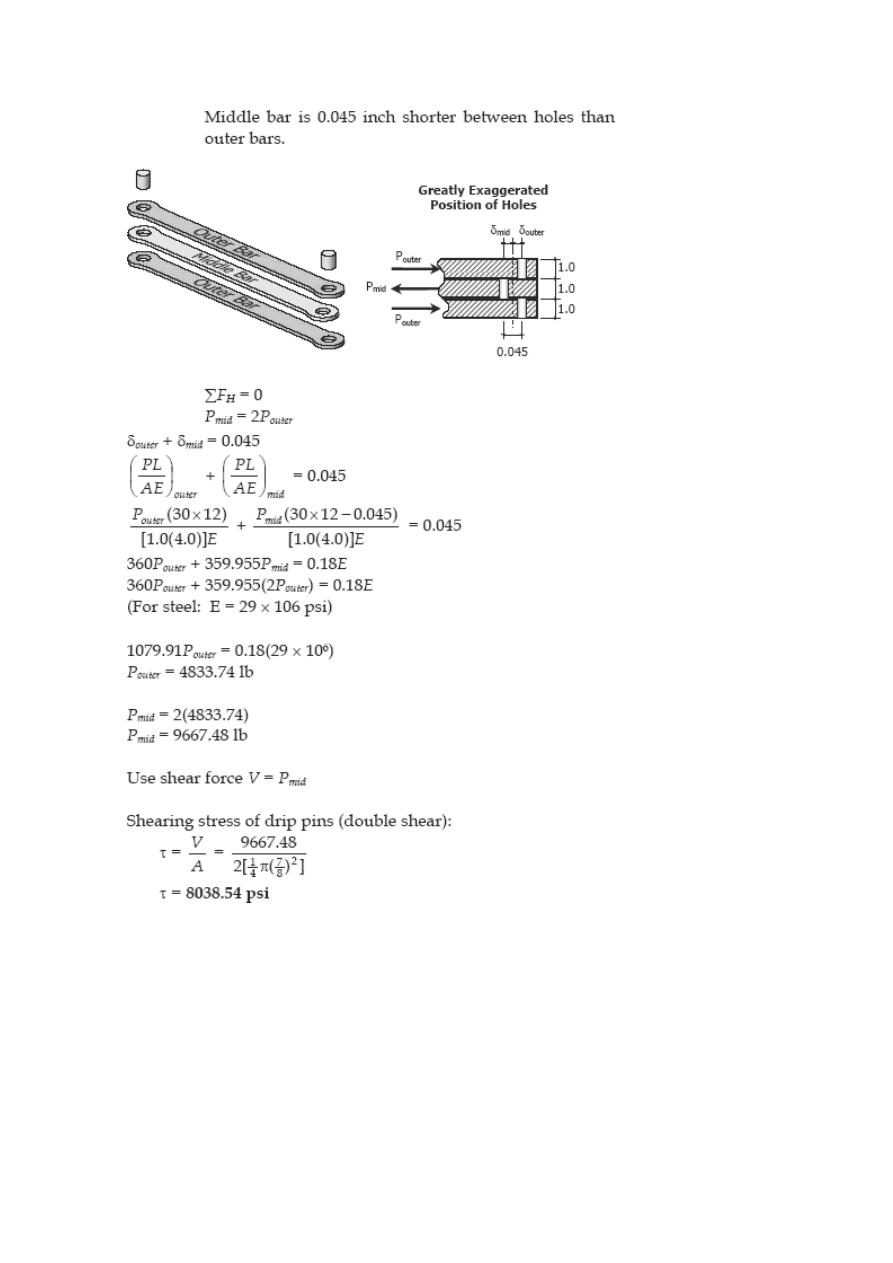

Three steel eye-bars, each 4 in. by 1 in. in section, are to be assembled by driving rigid

7/8-in.-diameter drift pins through holes drilled in the ends of the bars. The center-line

spacing between the holes is 30 ft in the two outer bars, but 0.045 in. shorter in the

middle bar. Find the shearing stress developed in the drip pins. Neglect local

deformation at the holes.

Solution 240

Problem 241

As shown in Fig. P-241, three steel wires, each 0.05 in.

2

in area, are used to lift a load

W = 1500 lb. Their unstressed lengths are 74.98 ft, 74.99 ft, and 75.00 ft. (a) What

stress exists in the longest wire? (b) Determine the stress in the shortest wire if W =

500 lb.

Solution 241

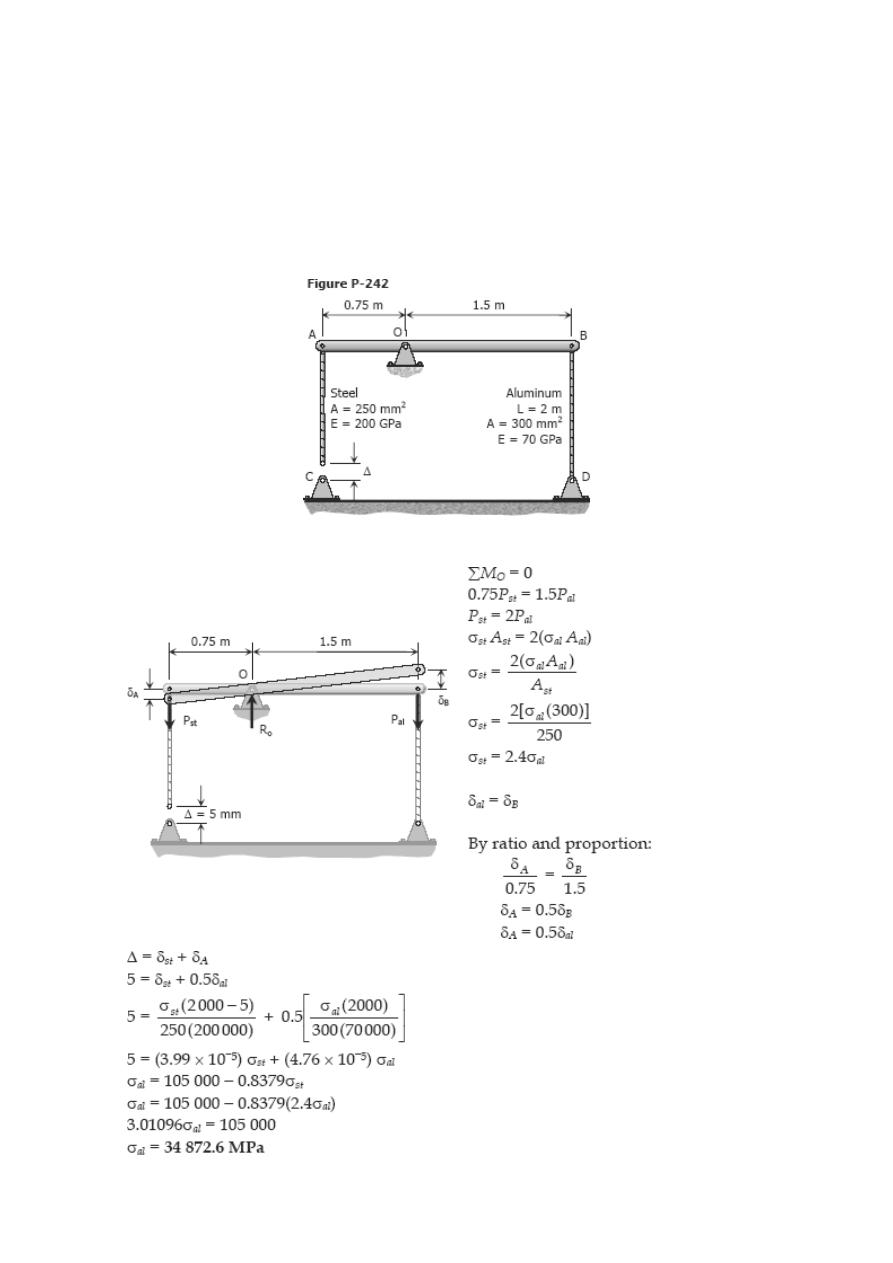

Problem 242

The assembly in Fig. P-242 consists of a light rigid bar AB, pinned at O, that is attached

to the steel and aluminum rods. In the position shown, bar AB is horizontal and there is

a gap, Δ = 5 mm, between the lower end of the steel rod and its pin support at C.

Compute the stress in the aluminum rod when the lower end of the steel rod is attached

to its support.

Solution 242

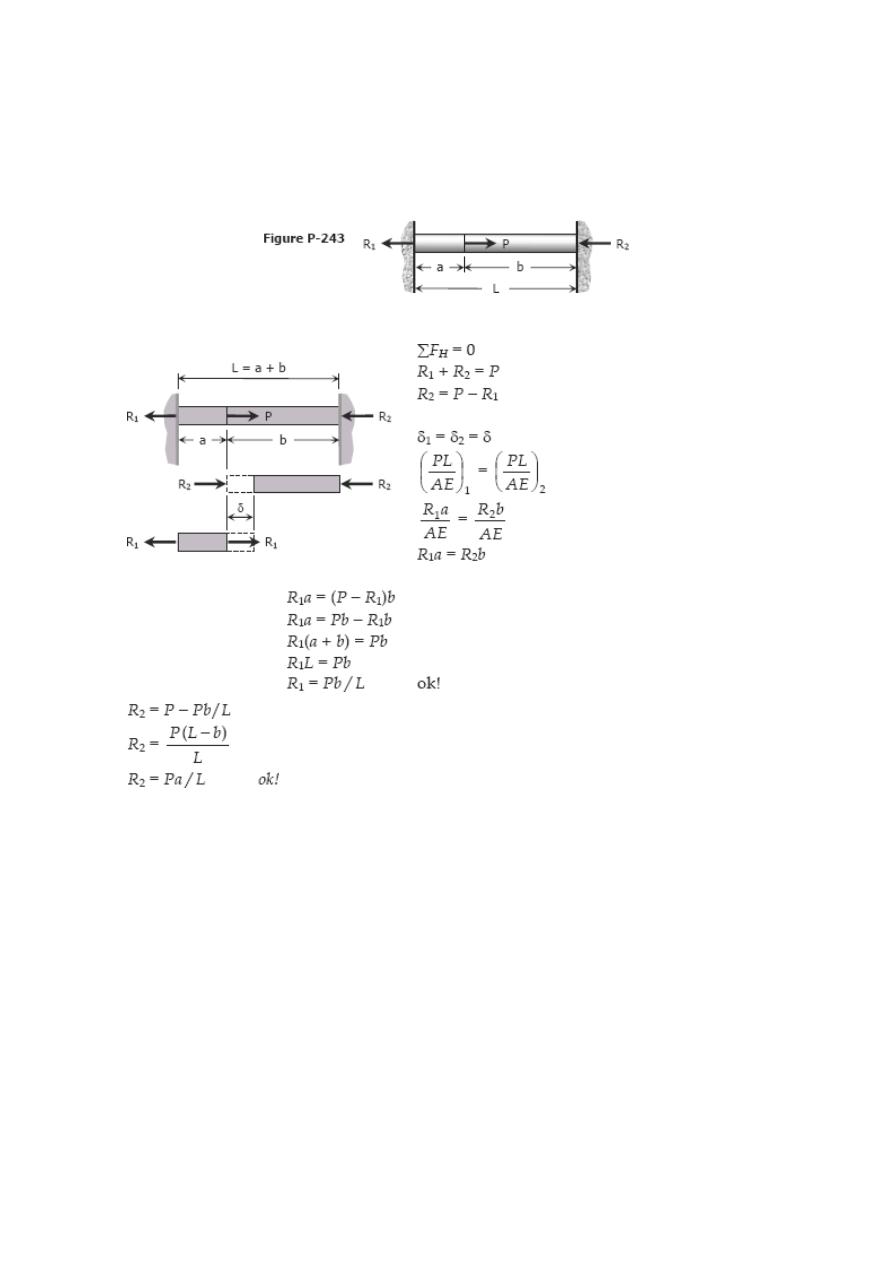

Problem 243

A homogeneous rod of constant cross section is attached to unyielding supports. It

carries an axial load P applied as shown in Fig. P-243. Prove that the reactions are given

by R

1

= Pb/L and R

2

= Pa/L.

Solution 243

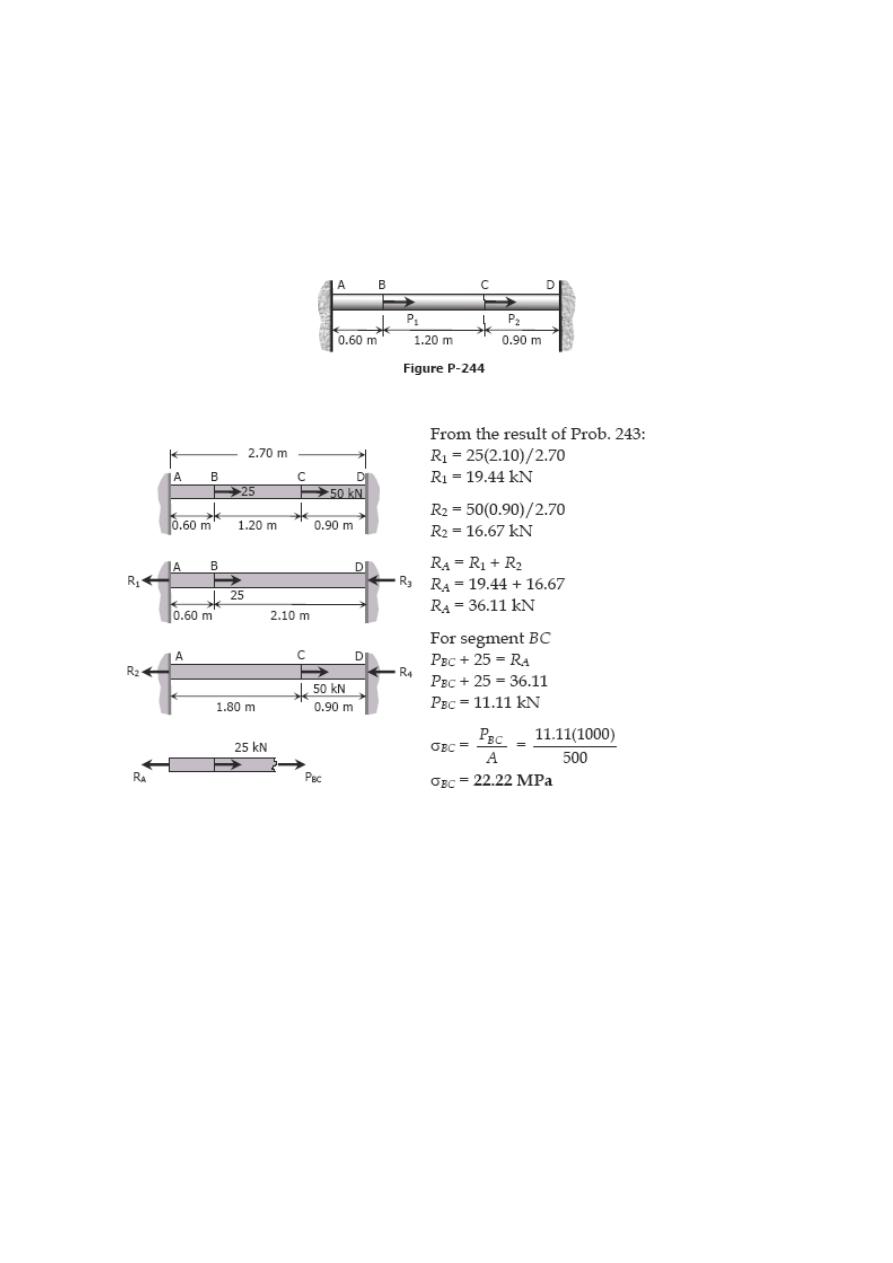

Problem 244

A homogeneous bar with a cross sectional area of 500 mm

2

is attached to rigid

supports. It carries the axial loads P1 = 25 kN and P2 = 50 kN, applied as shown in Fig.

P-244. Determine the stress in segment BC. (Hint: Use the results of Prob. 243, and

compute the reactions caused by P

1

and P

2

acting separately. Then use the principle of

superposition to compute the reactions when both loads are applied.)

Solution 244

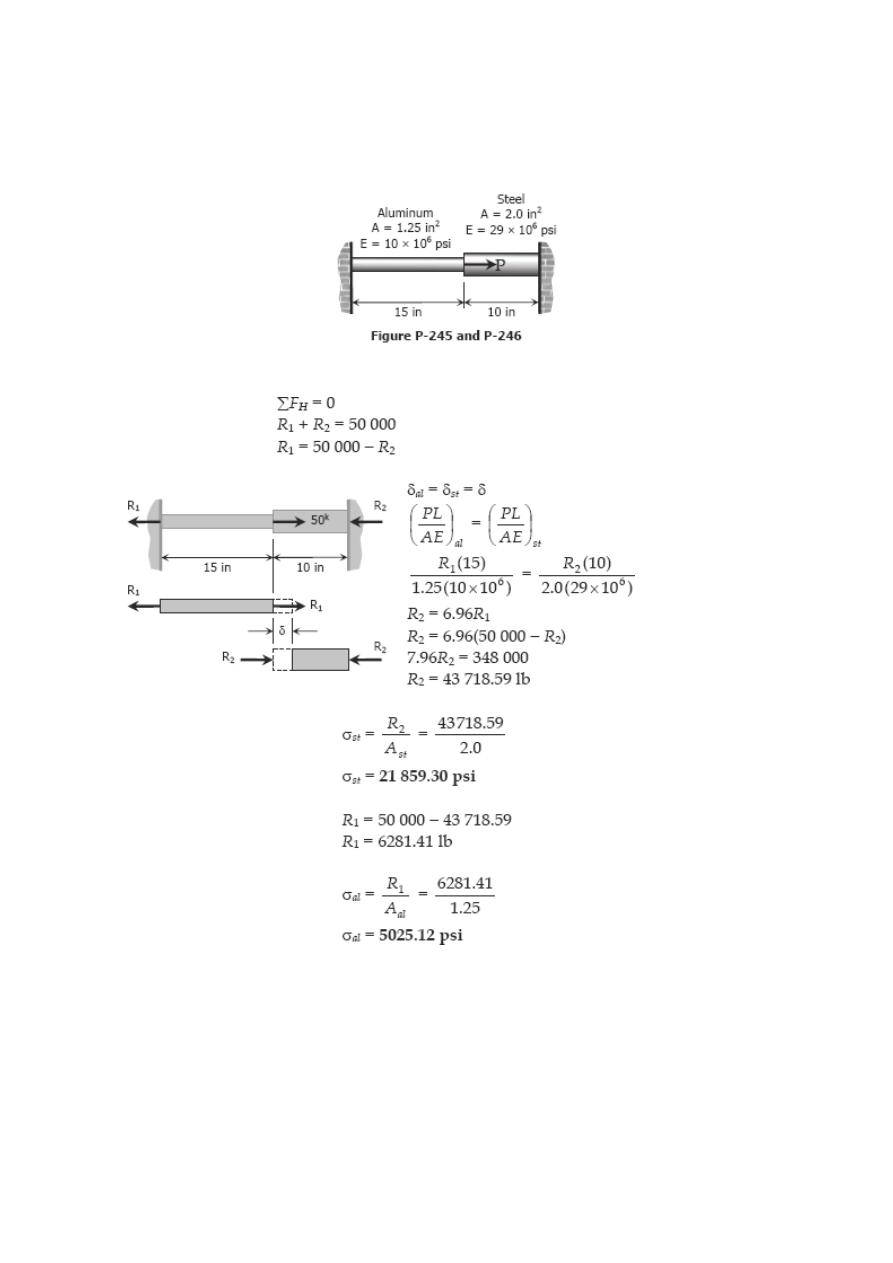

Problem 245

The composite bar in Fig. P-245 is firmly attached to unyielding supports. Compute the

stress in each material caused by the application of the axial load P = 50 kips.

Solution 245

Problem 246

Referring to the composite bar in Prob. 245, what maximum axial load P can be applied

if the allowable stresses are 10 ksi for aluminum and 18 ksi for steel.

Solution 246

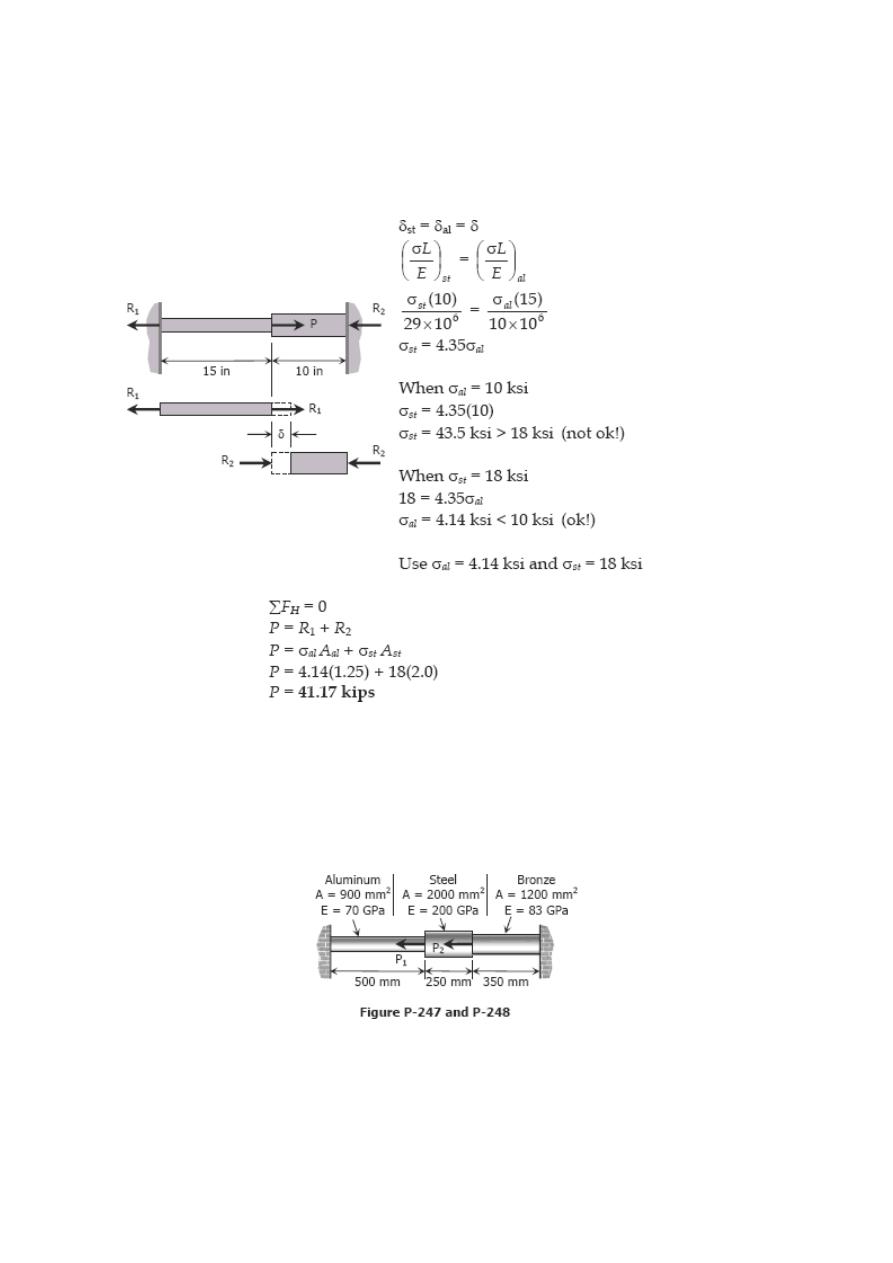

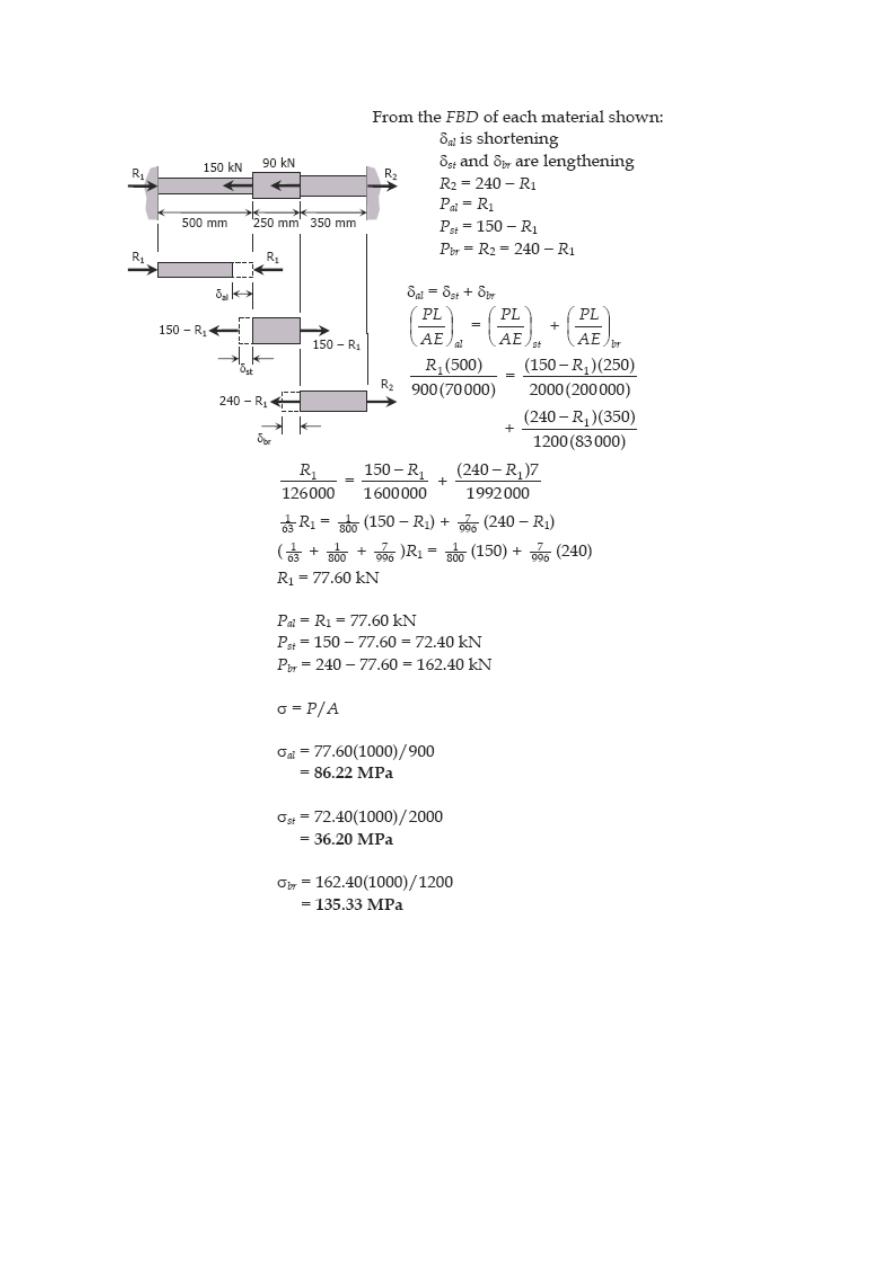

Problem 247

The composite bar in Fig. P-247 is stress-free before the axial loads P1 and P2 are

applied. Assuming that the walls are rigid, calculate the stress in each material if P

1

=

150 kN and P

2

= 90 kN.

Solution 247

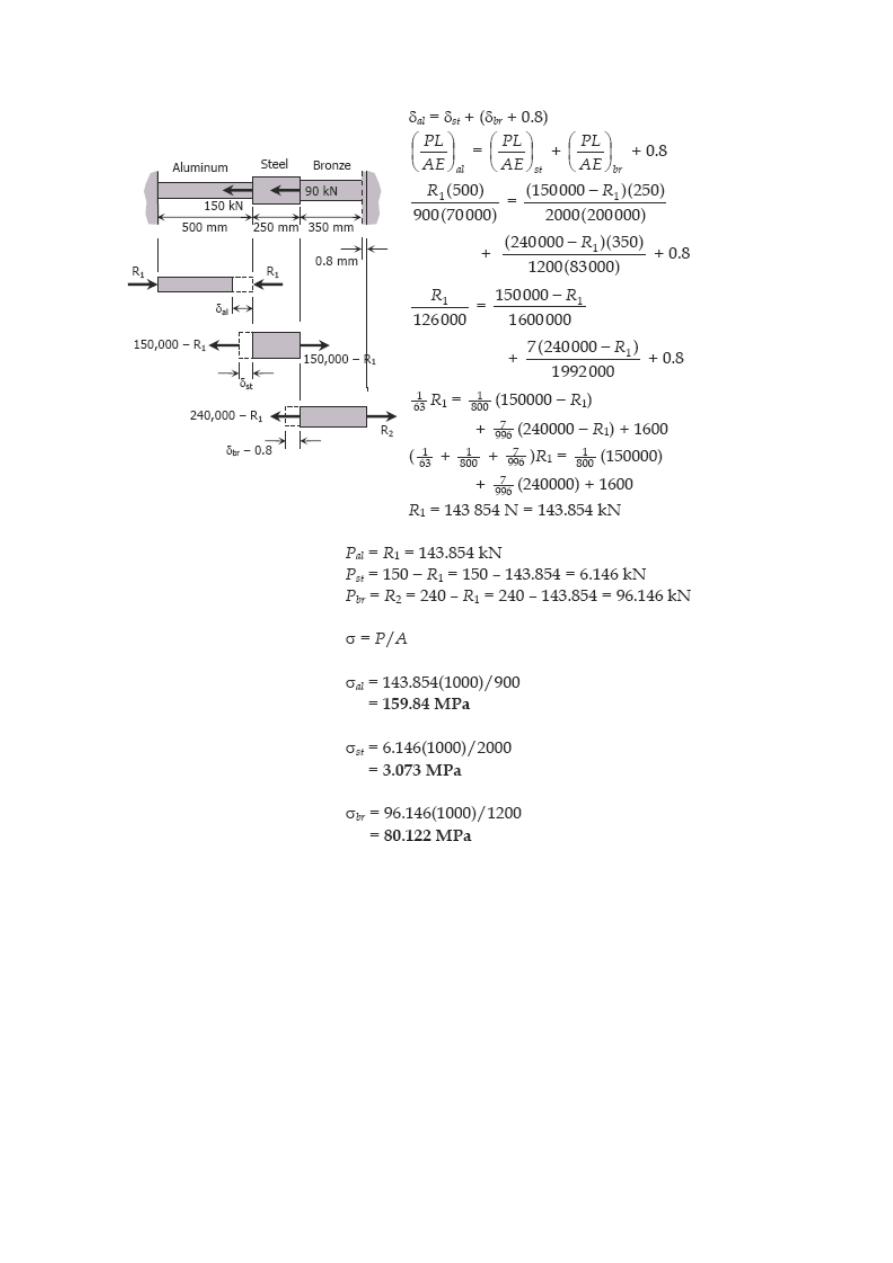

Problem 248

Solve Prob. 247 if the right wall yields 0.80 mm.

Solution 248

Problem 249

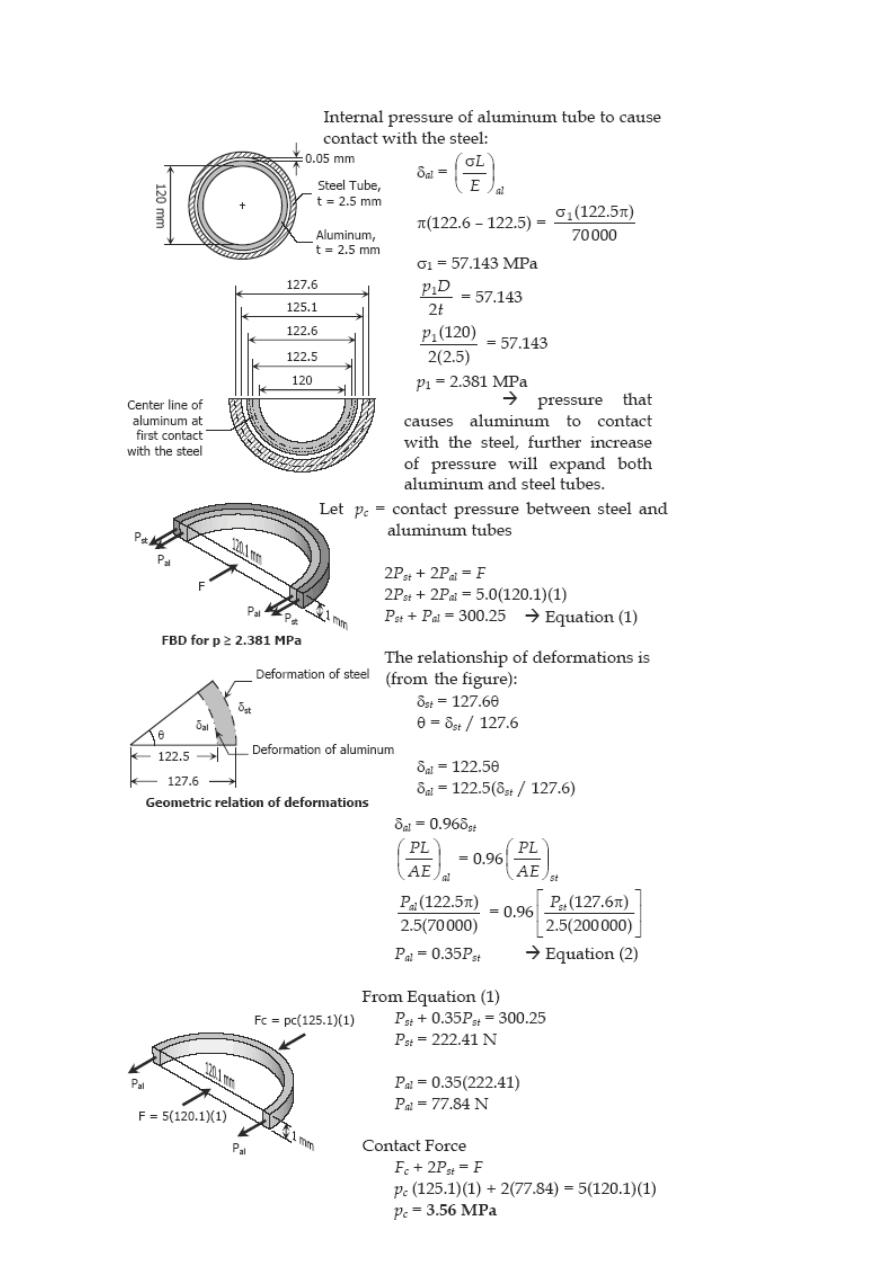

There is a radial clearance of 0.05 mm when a steel tube is placed over an aluminum

tube. The inside diameter of the aluminum tube is 120 mm, and the wall thickness of

each tube is 2.5 mm. Compute the contact pressure and tangential stress in each tube

when the aluminum tube is subjected to an internal pressure of 5.0 MPa.

Solution 249

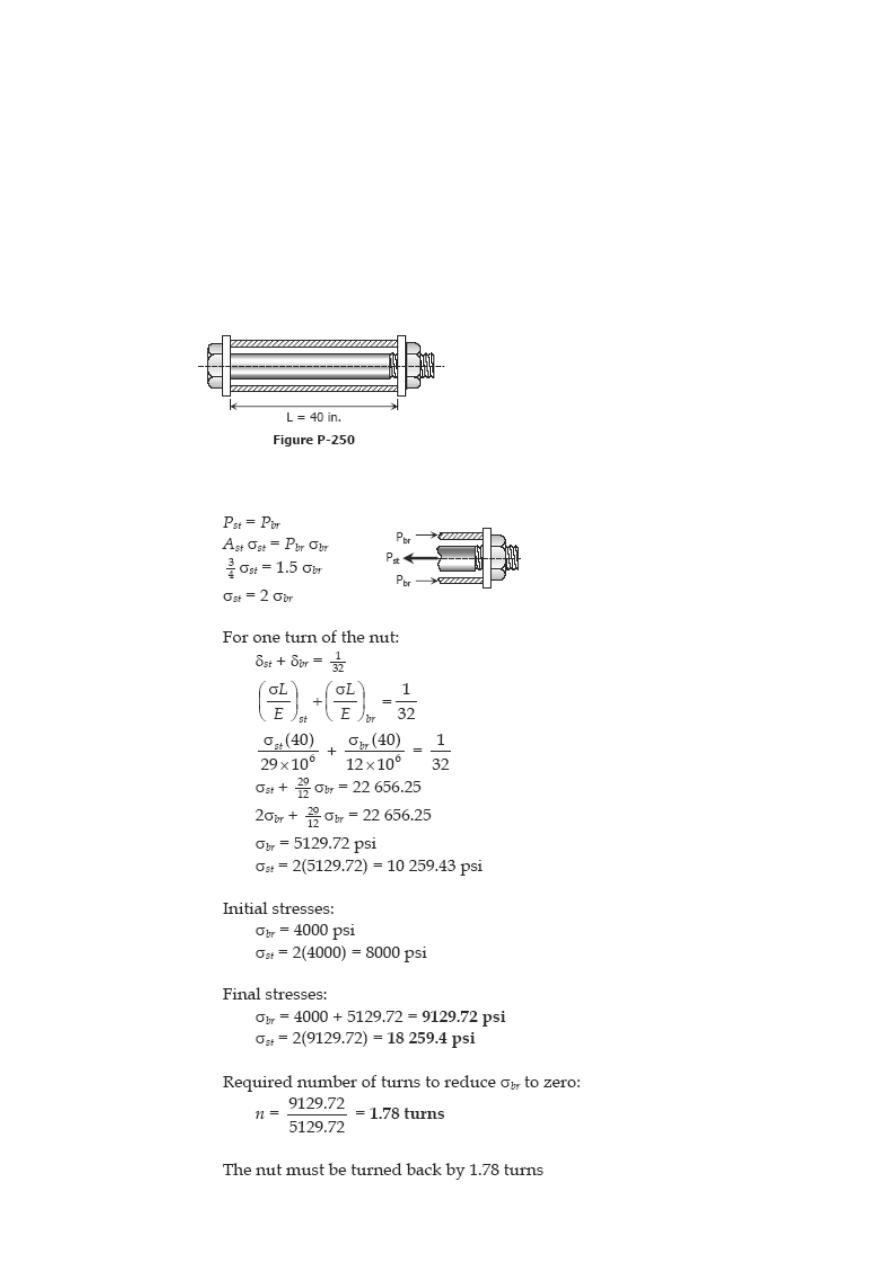

Problem 250

In the assembly of the bronze tube and steel bolt shown in Fig. P-250, the pitch of the

bolt thread is p = 1/32 in.; the cross-sectional area of the bronze tube is 1.5 in.

2

and of

steel bolt is ¾ in.

2

The nut is turned until there is a compressive stress of 4000 psi in

the bronze tube. Find the stresses if the nut is given one additional turn. How many

turns of the nut will reduce these stresses to zero? Use Ebr = 12 × 10

6

psi and Est = 29

× 10

6

psi.

Solution 250

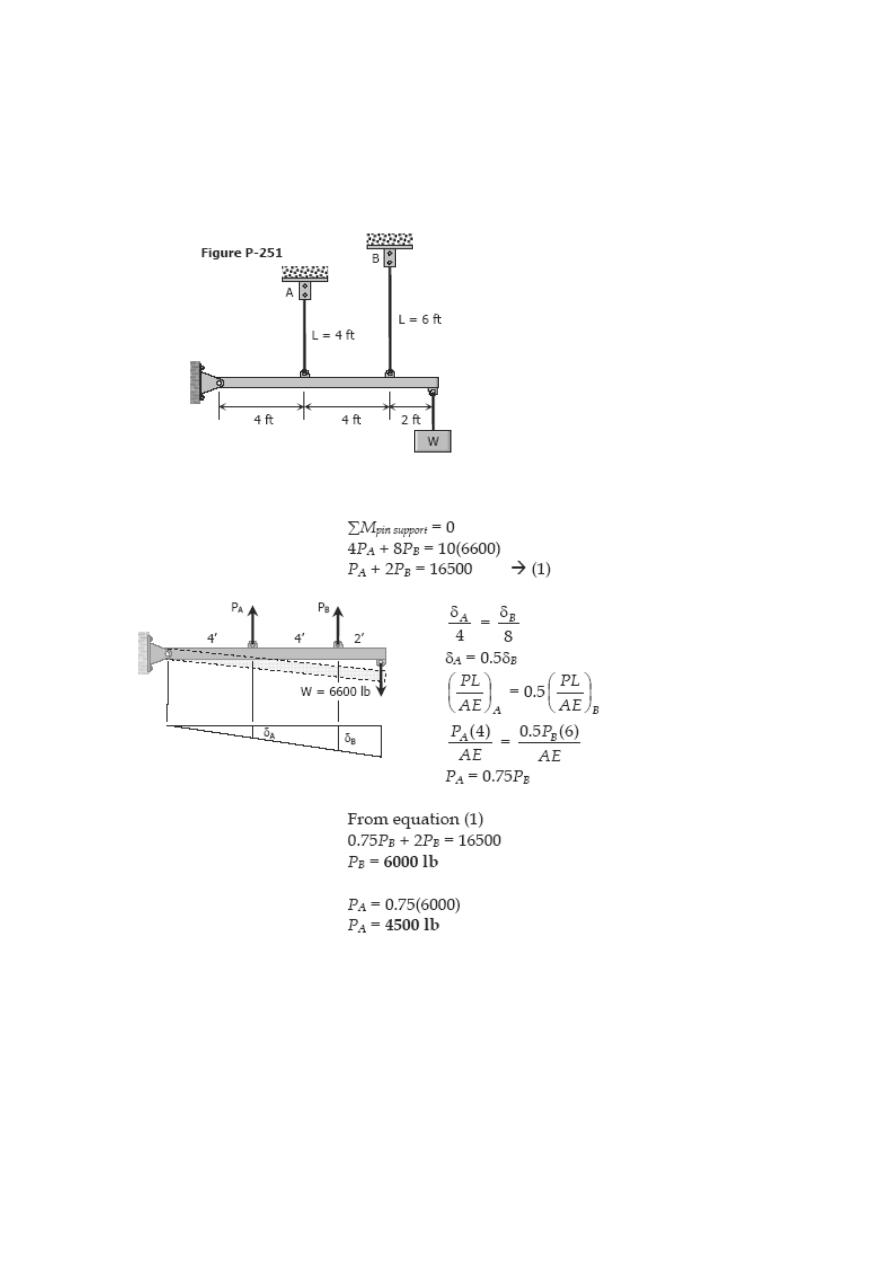

Problem 251

The two vertical rods attached to the light rigid bar in Fig. P-251 are identical except for

length. Before the load W was attached, the bar was horizontal and the rods were

stress-free. Determine the load in each rod if W = 6600 lb.

Solution 251

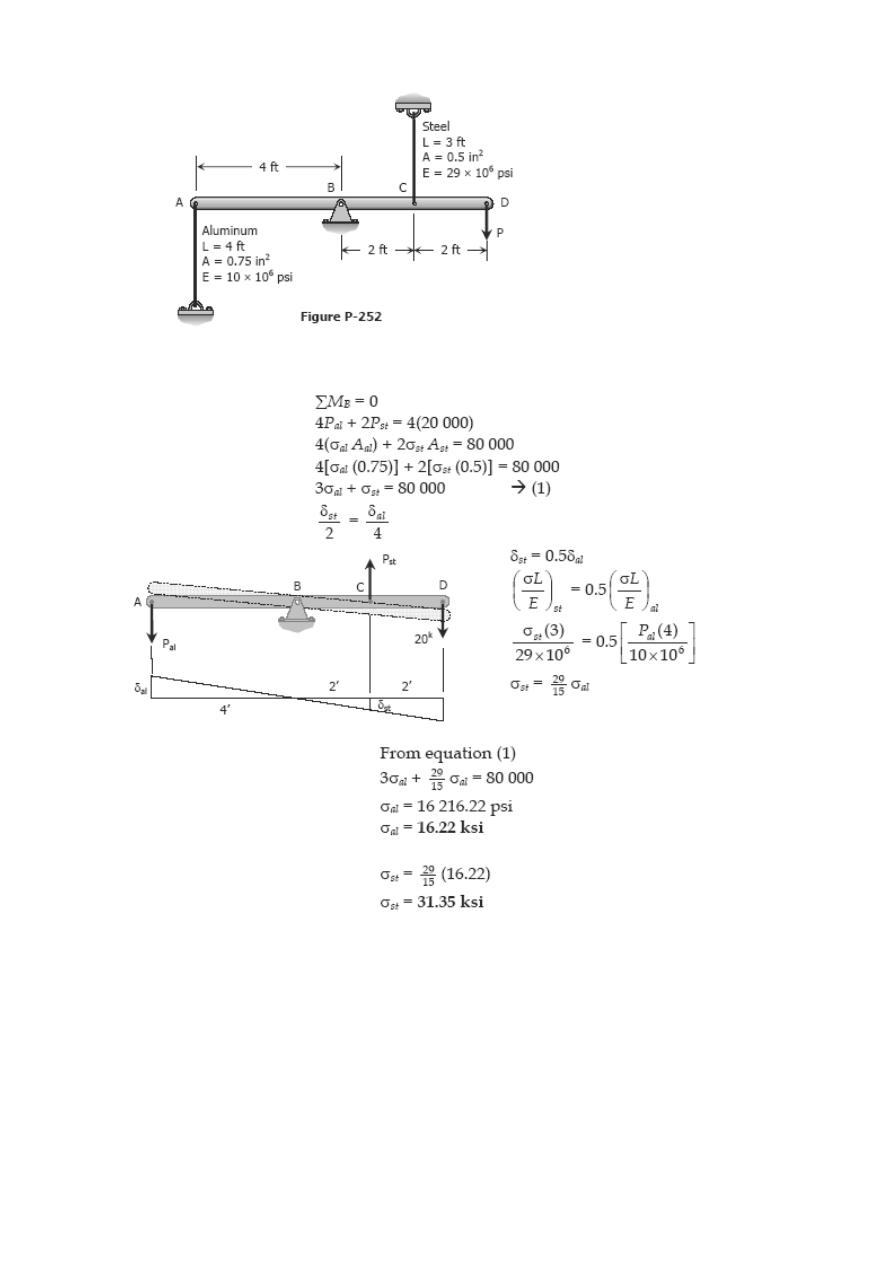

Problem 252

The light rigid bar ABCD shown in Fig. P-252 is pinned at B and connected to two

vertical rods. Assuming that the bar was initially horizontal and the rods stress-free,

determine the stress in each rod after the load after the load P = 20 kips is applied.

Solution 252

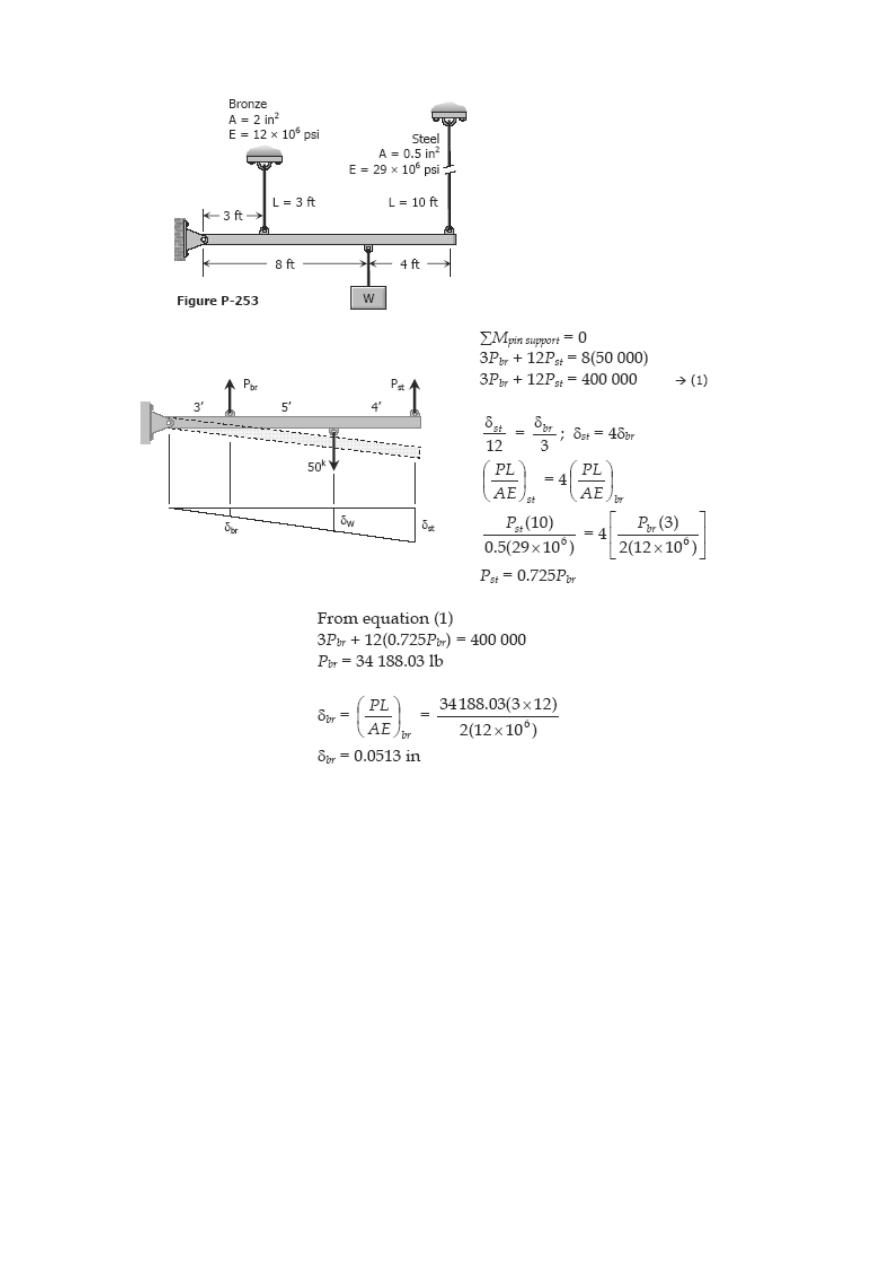

Problem 253

As shown in Fig. P-253, a rigid beam with negligible weight is pinned at one end and

attached to two vertical rods. The beam was initially horizontal before the load W = 50

kips was applied. Find the vertical movement of W.

Solution 253

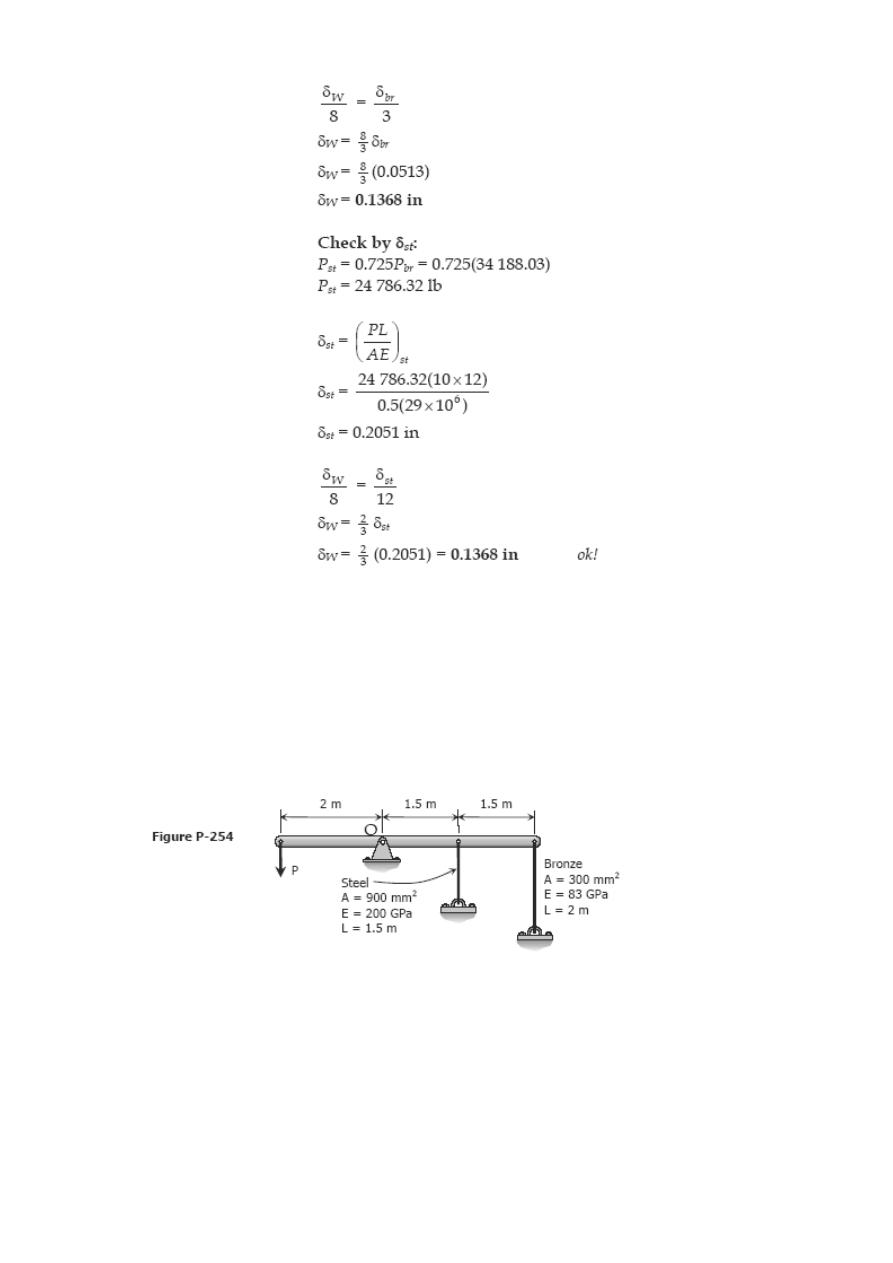

Problem 254

As shown in Fig. P-254, a rigid bar with negligible mass is pinned at O and attached to

two vertical rods. Assuming that the rods were initially tress-free, what maximum load P

can be applied without exceeding stresses of 150 MPa in the steel rod and 70 MPa in the

bronze rod.

Solution 254

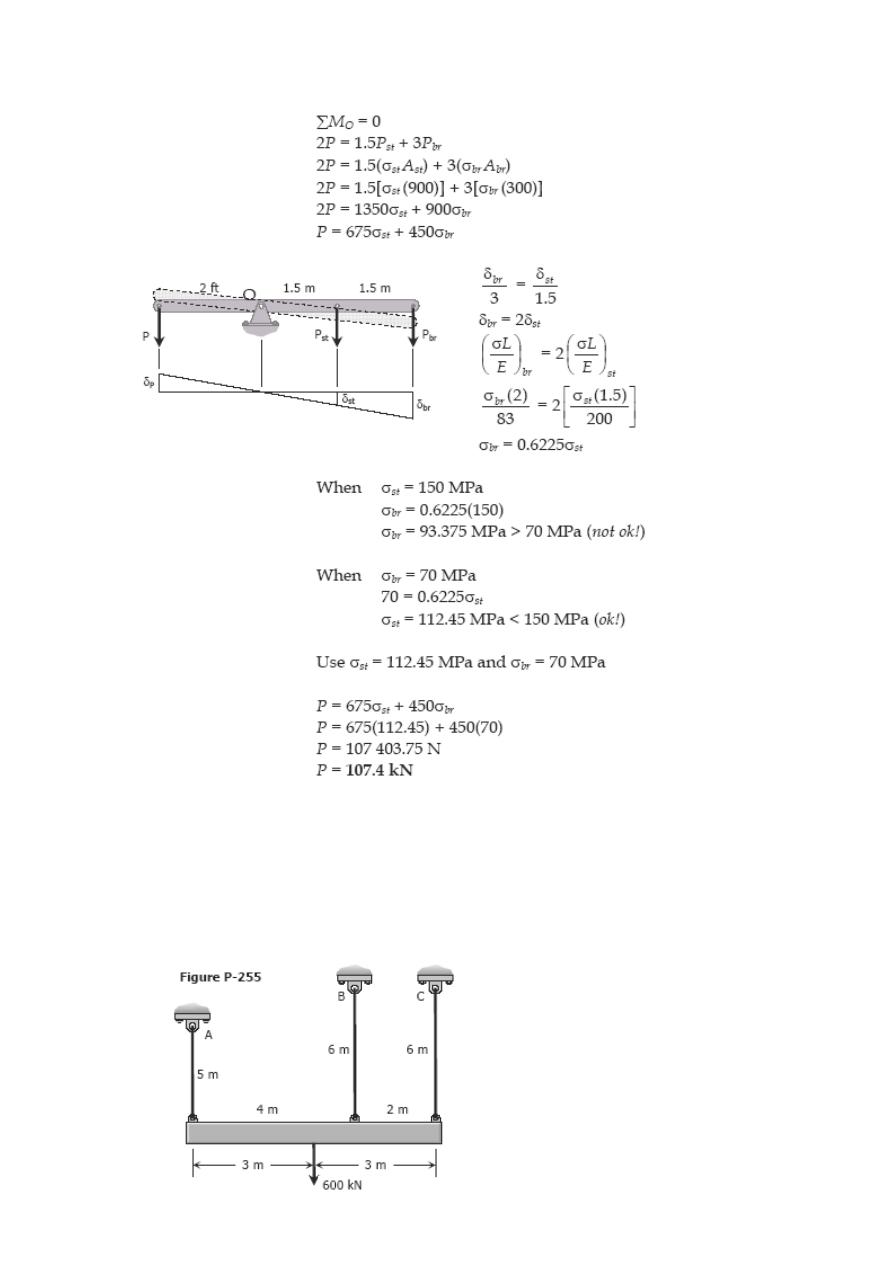

Problem 255

Shown in Fig. P-255 is a section through a balcony. The total uniform load of 600 kN is

supported by three rods of the same area and material. Compute the load in each rod.

Assume the floor to be rigid, but note that it does not necessarily remain horizontal.

Solution 255

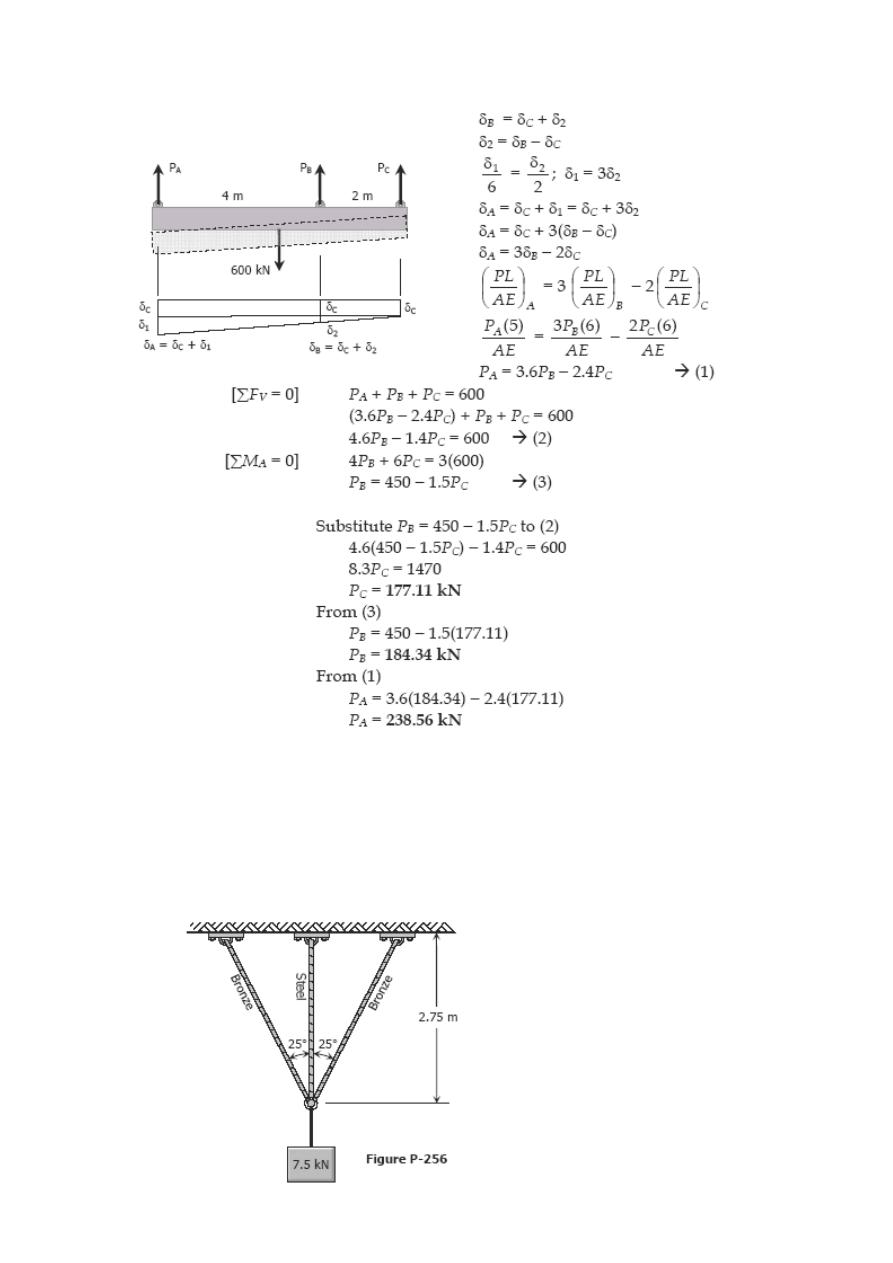

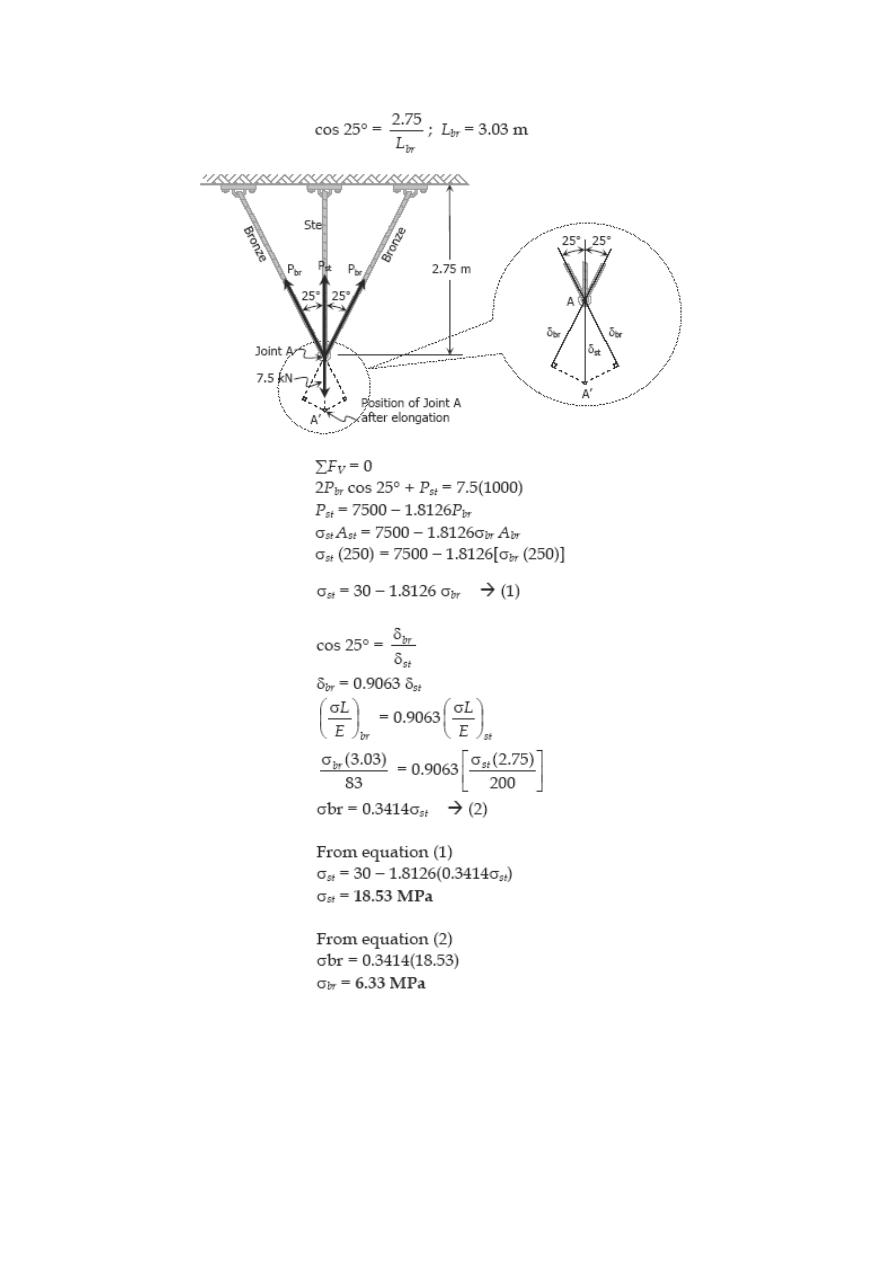

Problem 256

Three rods, each of area 250 mm2, jointly support a 7.5 kN load, as shown in Fig. P-

256. Assuming that there was no slack or stress in the rods before the load was applied,

find the stress in each rod. Use E

st

= 200 GPa and E

br

= 83 GPa.

Solution 256

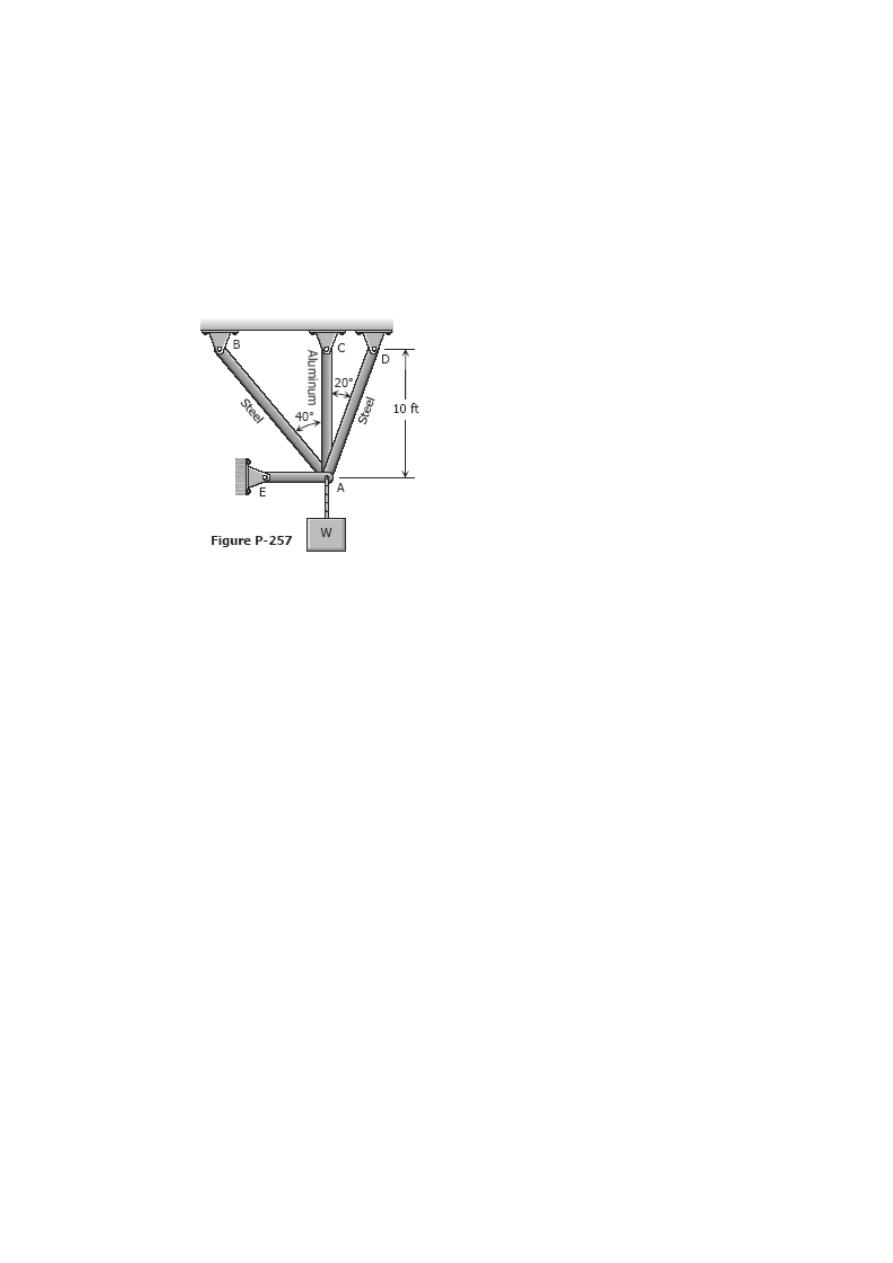

Problem 257

Three bars AB, AC, and AD are pinned together as shown in Fig. P-257. Initially, the

assembly is stressfree. Horizontal movement of the joint at A is prevented by a short

horizontal strut AE. Calculate the stress in each bar and the force in the strut AE when

the assembly is used to support the load W = 10 kips. For each steel bar, A = 0.3 in.

2

and E = 29 × 10

6

psi. For the aluminum bar, A = 0.6 in.

2

and E = 10 × 10

6

psi.

Solution 257

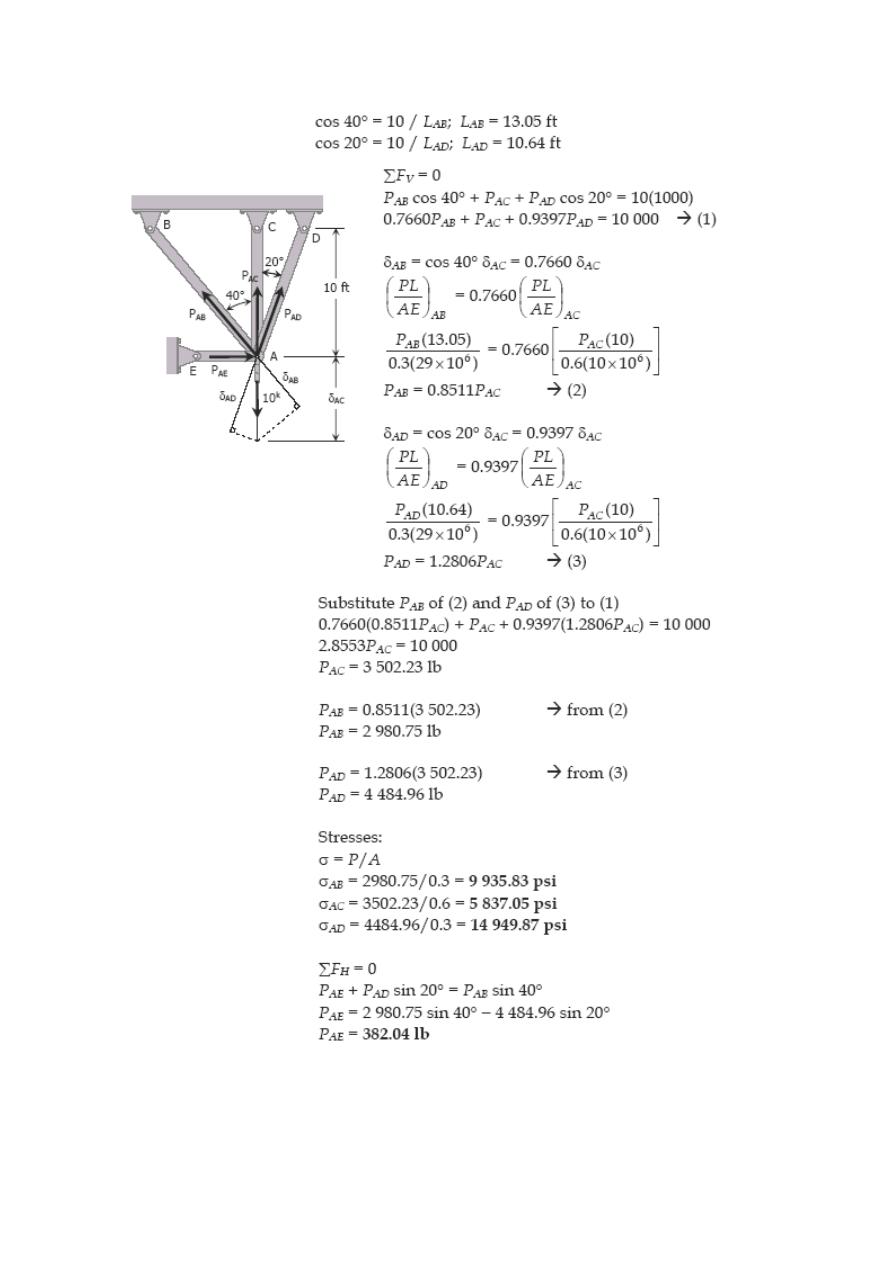

Thermal Stress

Temperature changes cause the body to expand or contract. The amount δ

T

, is given by

where α is the coefficient of thermal expansion in m/m°C, L is the length in meter, and

T

i

and T

f

are the initial and final temperatures, respectively in °C.

For steel, α = 11.25 × 10

–6

/ °C.

If temperature deformation is permitted to occur freely, no load or stress will be

induced in the structure. In some cases where temperature deformation is not

permitted, an internal stress is created. The internal stress created is termed as thermal

stress.

For a homogeneous rod mounted between unyielding supports as shown, the thermal

stress is computed as:

deformation due to temperature changes;

deformation due to equivalent axial stress;

where σ is the thermal stress in MPa and E is the modulus of elasticity of the rod in MPa.

If the wall yields a distance of x as shown, the following calculations will be made:

where σ represents the thermal stress.

Take note that as the temperature rises above the normal, the rod will be in

compression, and if the temperature drops below the normal, the rod is in tension.

Solved Problems in Thermal Stress

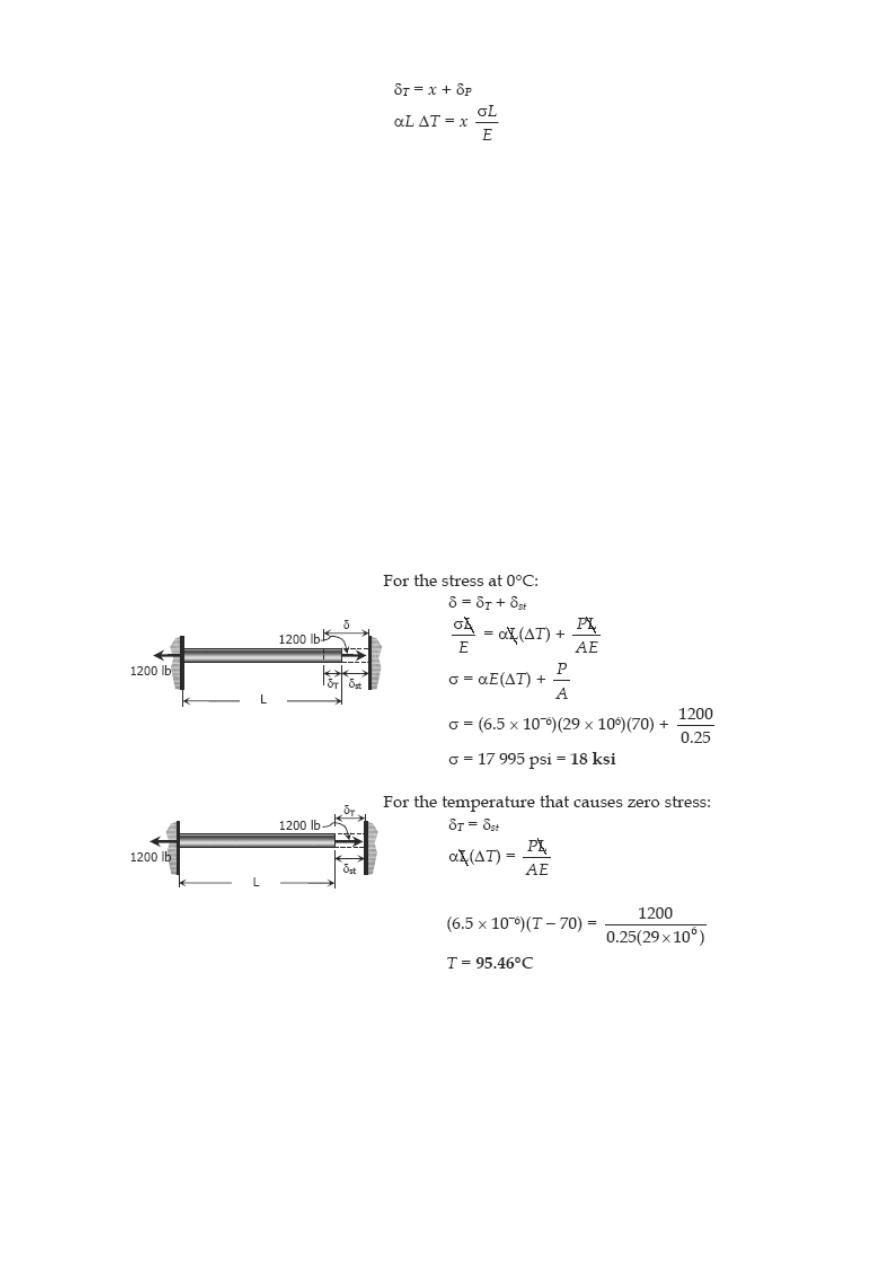

Problem 261

A steel rod with a cross-sectional area of 0.25 in

2

is stretched between two fixed points.

The tensile load at 70°F is 1200 lb. What will be the stress at 0°F? At what temperature

will the stress be zero? Assume α = 6.5 × 10

-6

in / (in·°F) and E = 29 × 10

6

psi.

Solution 261

Problem 262

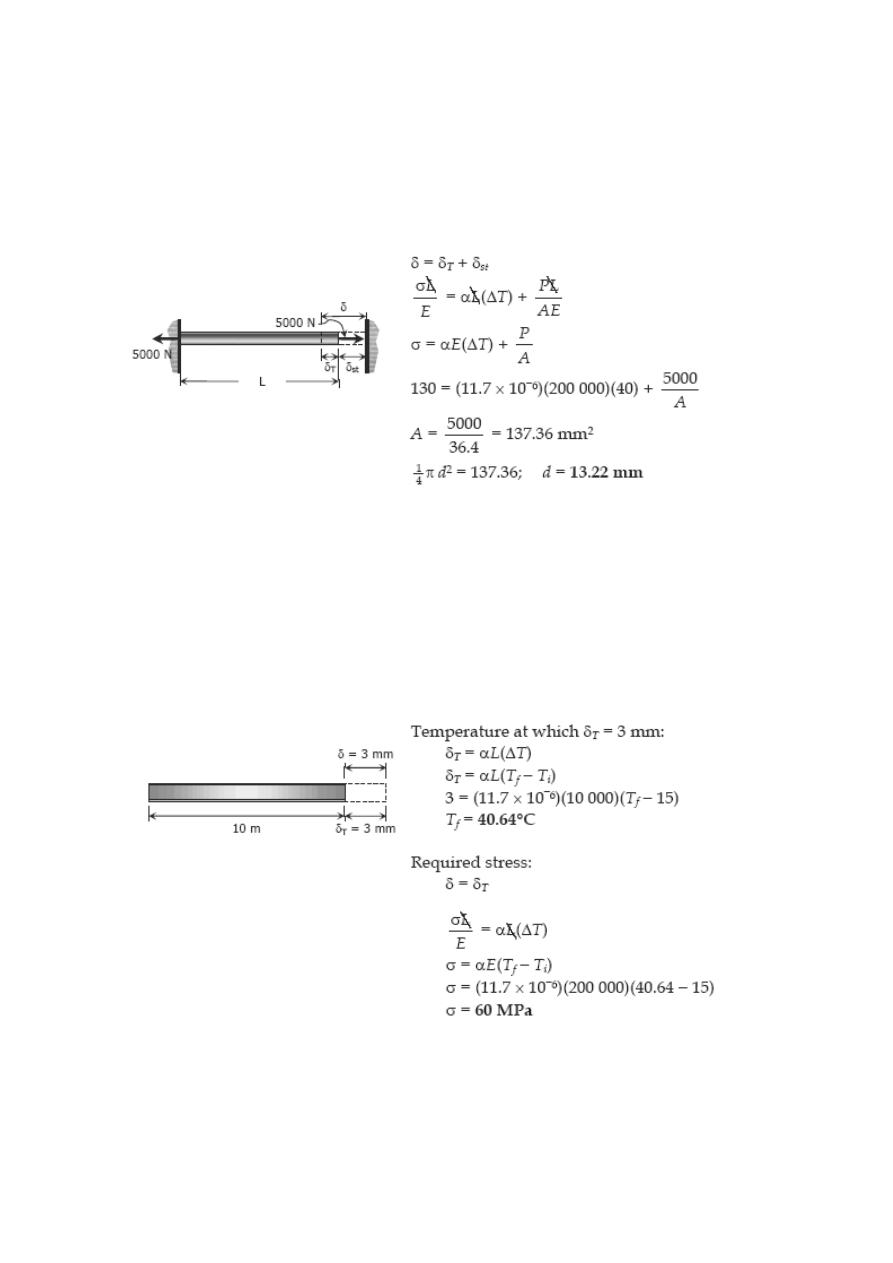

A steel rod is stretched between two rigid walls and carries a tensile load of 5000 N at

20°C. If the allowable stress is not to exceed 130 MPa at -20°C, what is the minimum

diameter of the rod? Assume α = 11.7 µm/(m·°C) and E = 200 GPa.

Solution 262

Problem 263

Steel railroad reels 10 m long are laid with a clearance of 3 mm at a temperature of

15°C. At what temperature will the rails just touch? What stress would be induced in the

rails at that temperature if there were no initial clearance? Assume α = 11.7 µm/(m·°C)

and E = 200 GPa.

Solution 263

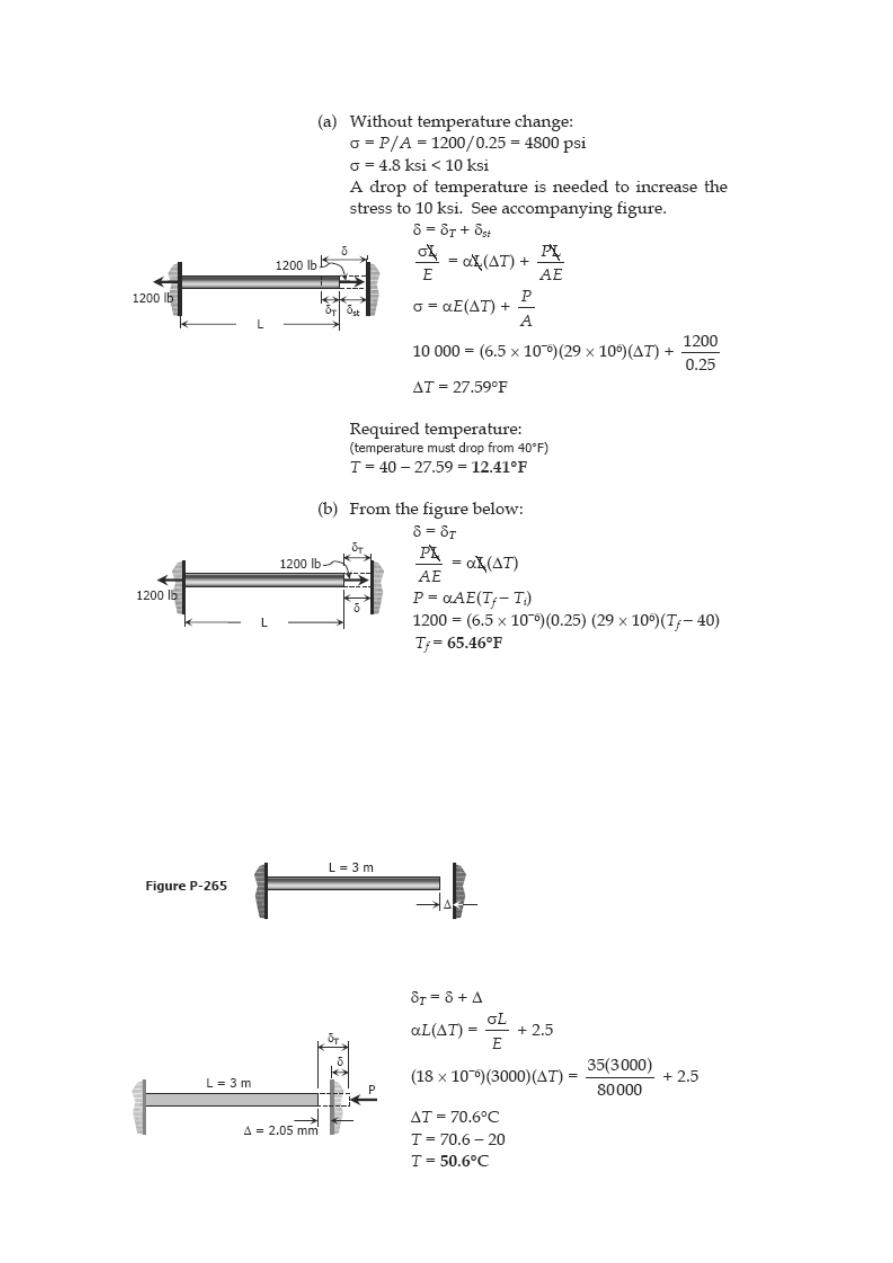

Problem 264

A steel rod 3 feet long with a cross-sectional area of 0.25 in.

2

is stretched between two

fixed points. The tensile force is 1200 lb at 40°F. Using E = 29 × 10

6

psi and α = 6.5 ×

10

-6

in./(in.·°F), calculate (a) the temperature at which the stress in the bar will be 10

ksi; and (b) the temperature at which the stress will be

zero.

Solution 264

Problem 265

A bronze bar 3 m long with a cross sectional area of 320 mm

2

is placed between two

rigid walls as shown in Fig. P-265. At a temperature of -20°C, the gap Δ = 25 mm. Find

the temperature at which the compressive stress in the bar will be 35 MPa. Use α =

18.0 × 10

-6

m/(m·°C) and E = 80 GPa.

Solution 265

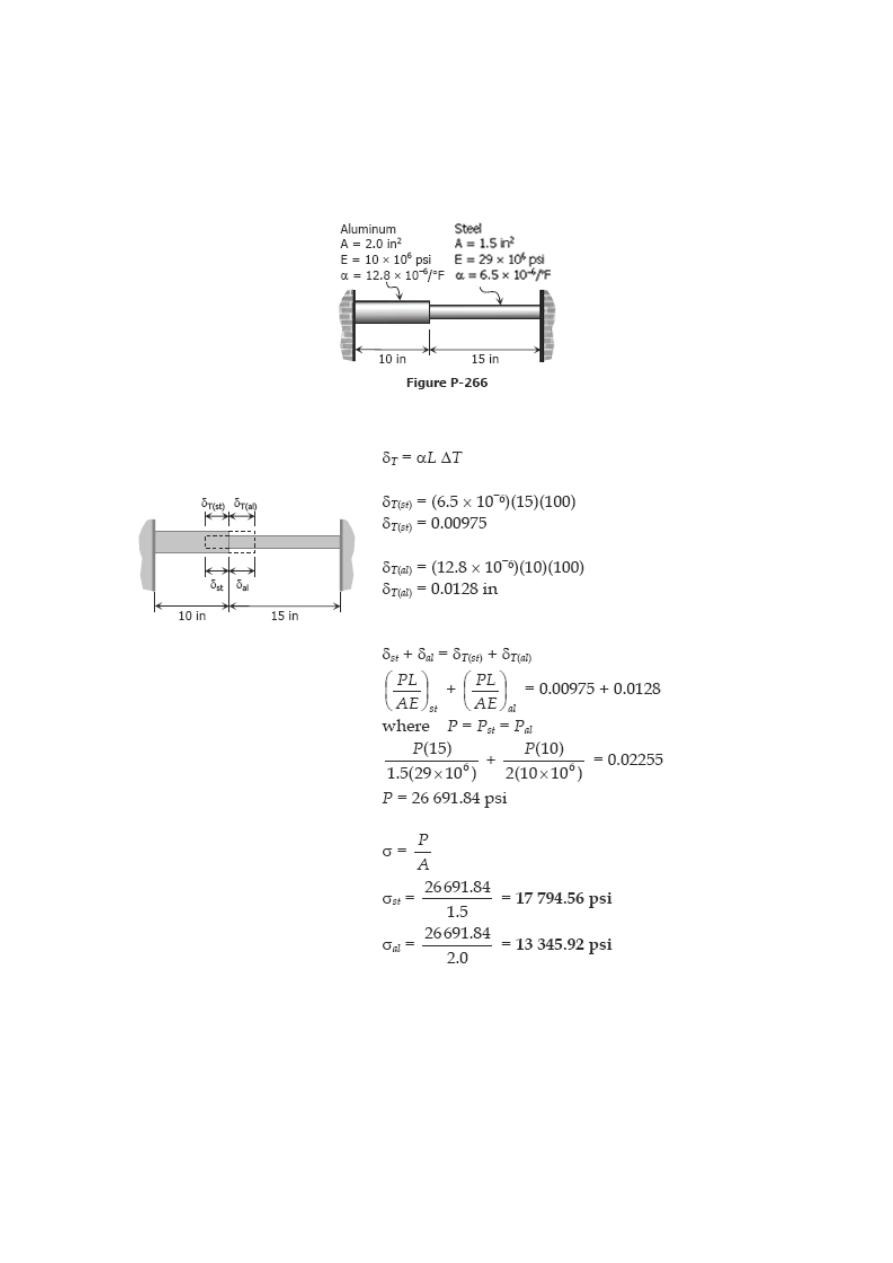

Problem 266

Calculate the increase in stress for each segment of the compound bar shown in Fig. P-

266 if the temperature increases by 100°F. Assume that the supports are unyielding

and that the bar is suitably braced against buckling.

Solution 266

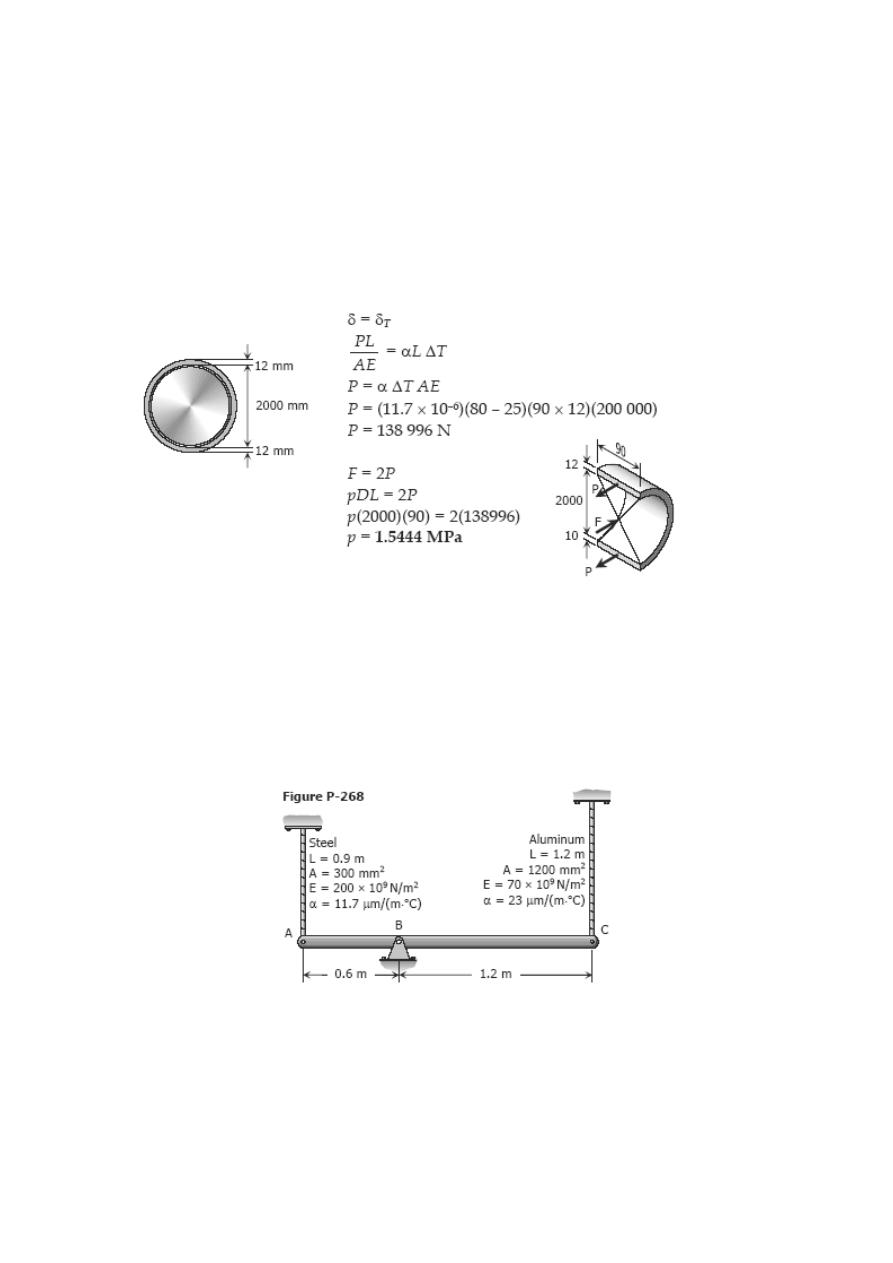

Problem 267

At a temperature of 80°C, a steel tire 12 mm thick and 90 mm wide that is to be shrunk

onto a locomotive driving wheel 2 m in diameter just fits over the wheel, which is at a

temperature of 25°C. Determine the contact pressure between the tire and wheel after

the assembly cools to 25°C. Neglect the deformation of the wheel caused by the

pressure of the tire. Assume α = 11.7 µm/(m·°C) and E = 200 GPa.

Solution 267

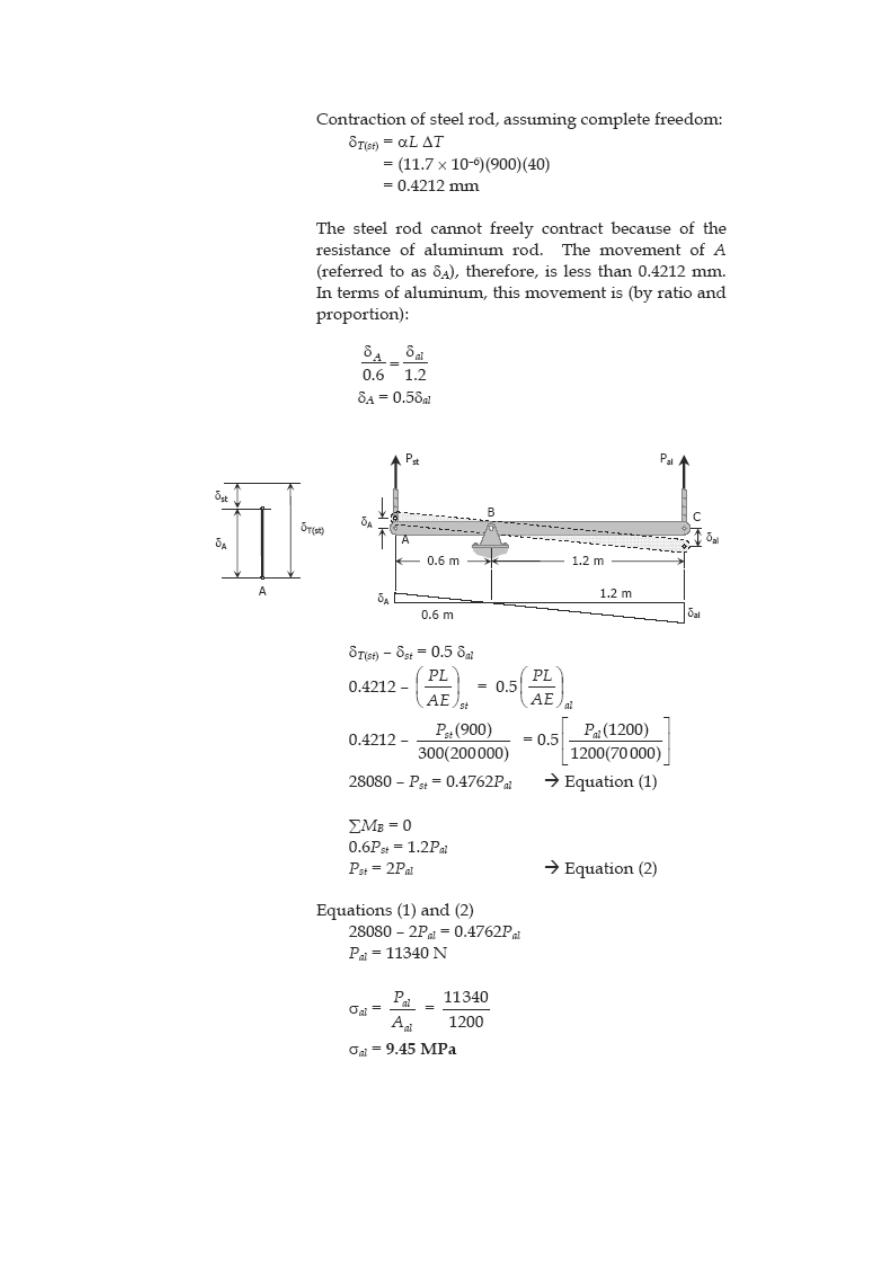

Problem 268

The rigid bar ABC in Fig. P-268 is pinned at B and attached to the two vertical rods.

Initially, the bar is horizontal and the vertical rods are stress-free. Determine the stress

in the aluminum rod if the temperature of the steel rod is decreased by 40°C. Neglect

the weight of bar ABC.

Solution 268

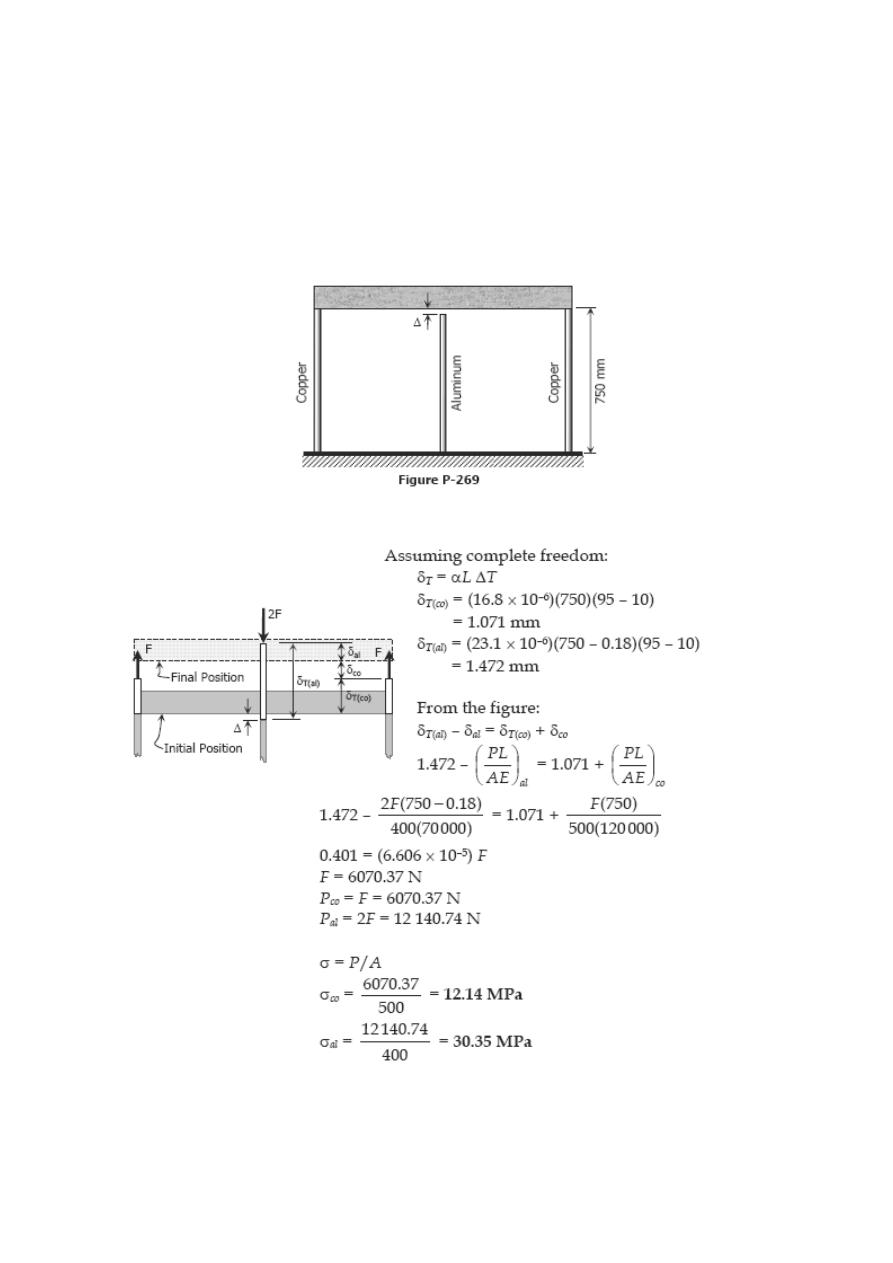

Problem 269

As shown in Fig. P-269, there is a gap between the aluminum bar and the rigid slab that

is supported by two copper bars. At 10°C, Δ = 0.18 mm. Neglecting the mass of the

slab, calculate the stress in each rod when the temperature in the assembly is increased

to 95°C. For each copper bar, A= 500 mm

2

, E = 120 GPa, and α = 16.8 µm/(m·°C). For

the aluminum bar, A = 400 mm

2

, E = 70 GPa, and α = 23.1 µm/(m·°C).

Solution 269

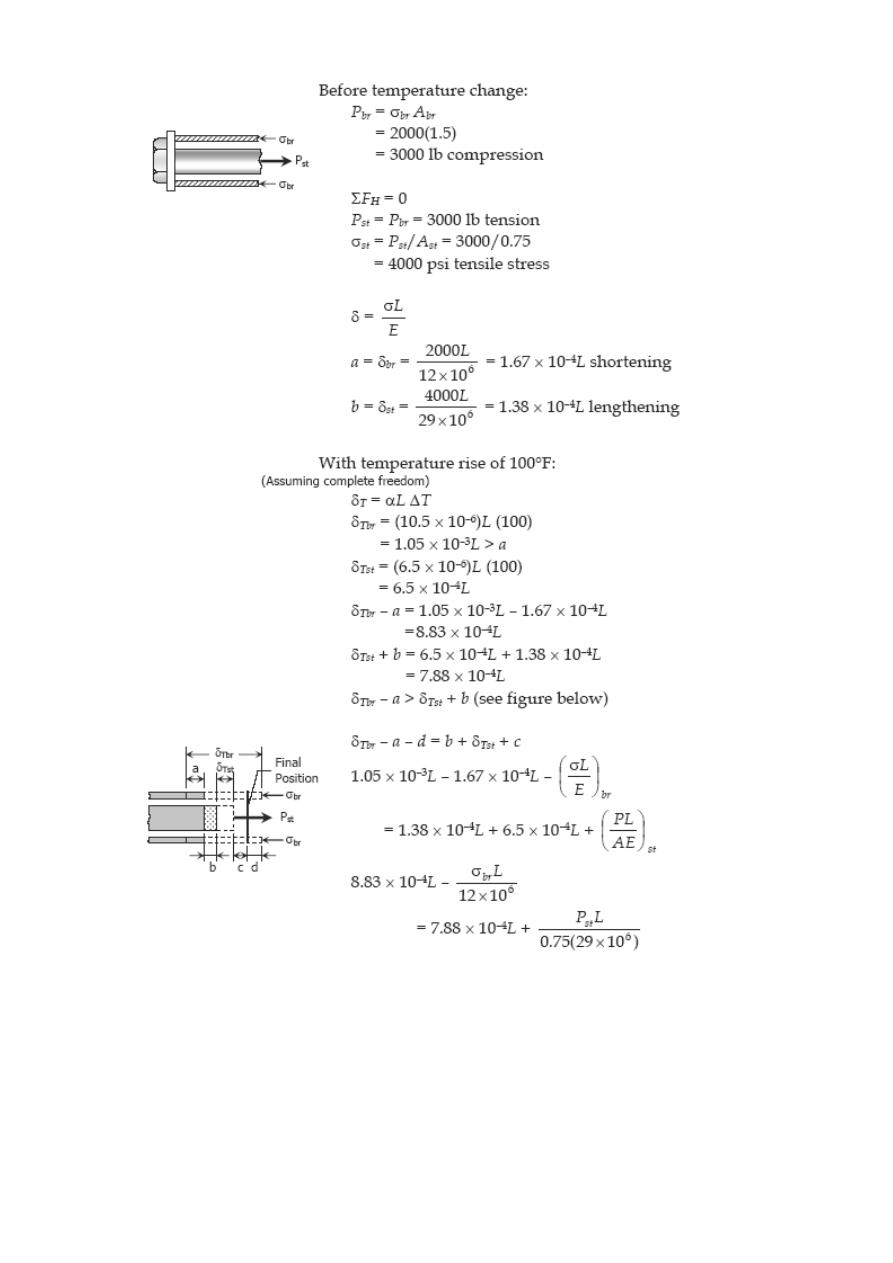

Problem 270

A bronze sleeve is slipped over a steel bolt and held in place by a nut that is turned to

produce an initial stress of 2000 psi in the bronze. For the steel bolt, A = 0.75 in

2

, E =

29 × 10

6

psi, and α = 6.5 × 10

–6

in/(in·°F). For the bronze sleeve, A = 1.5 in

2

, E = 12 ×

10

6

psi and α = 10.5 × 10

–6

in/(in·°F). After a temperature rise of 100°F, find the final

stress in each material.

Solution 270

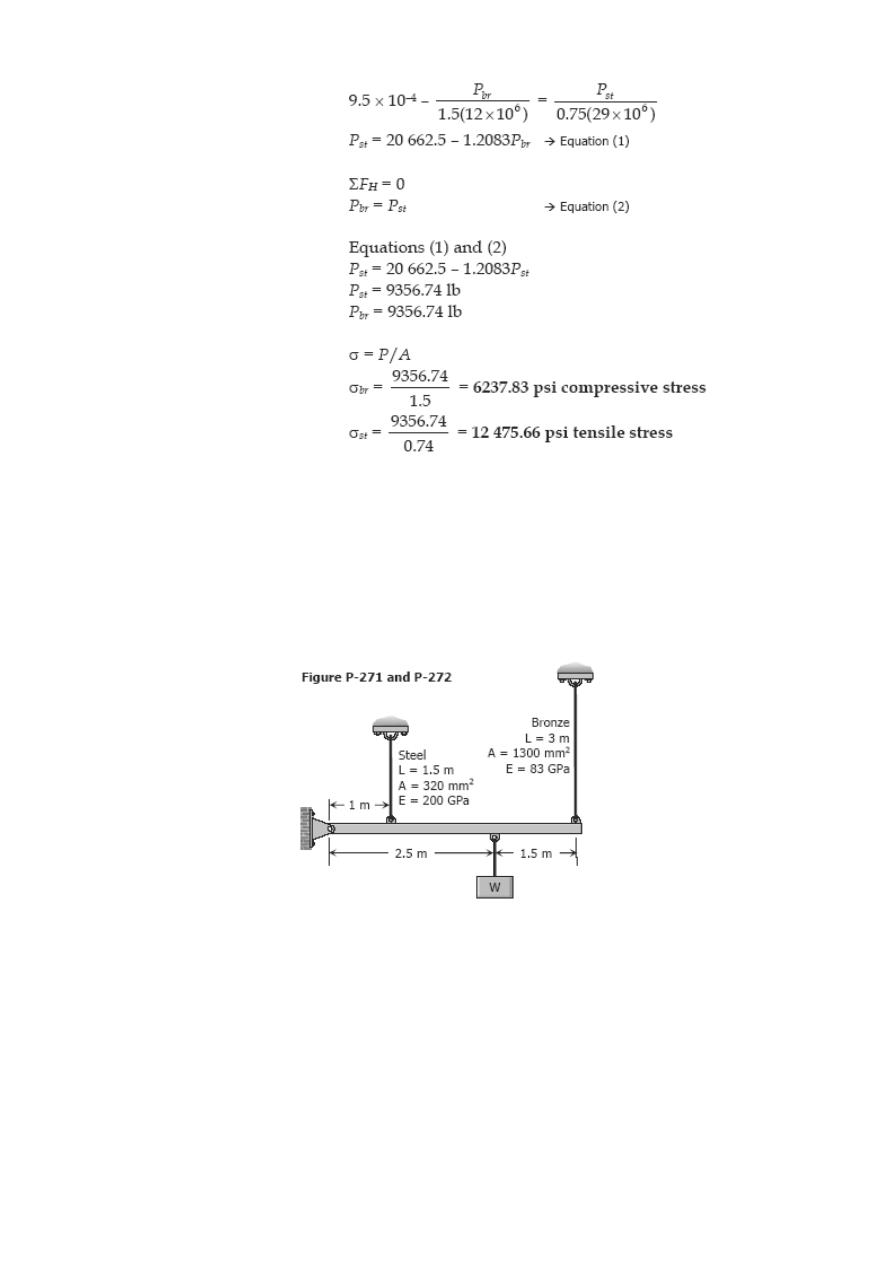

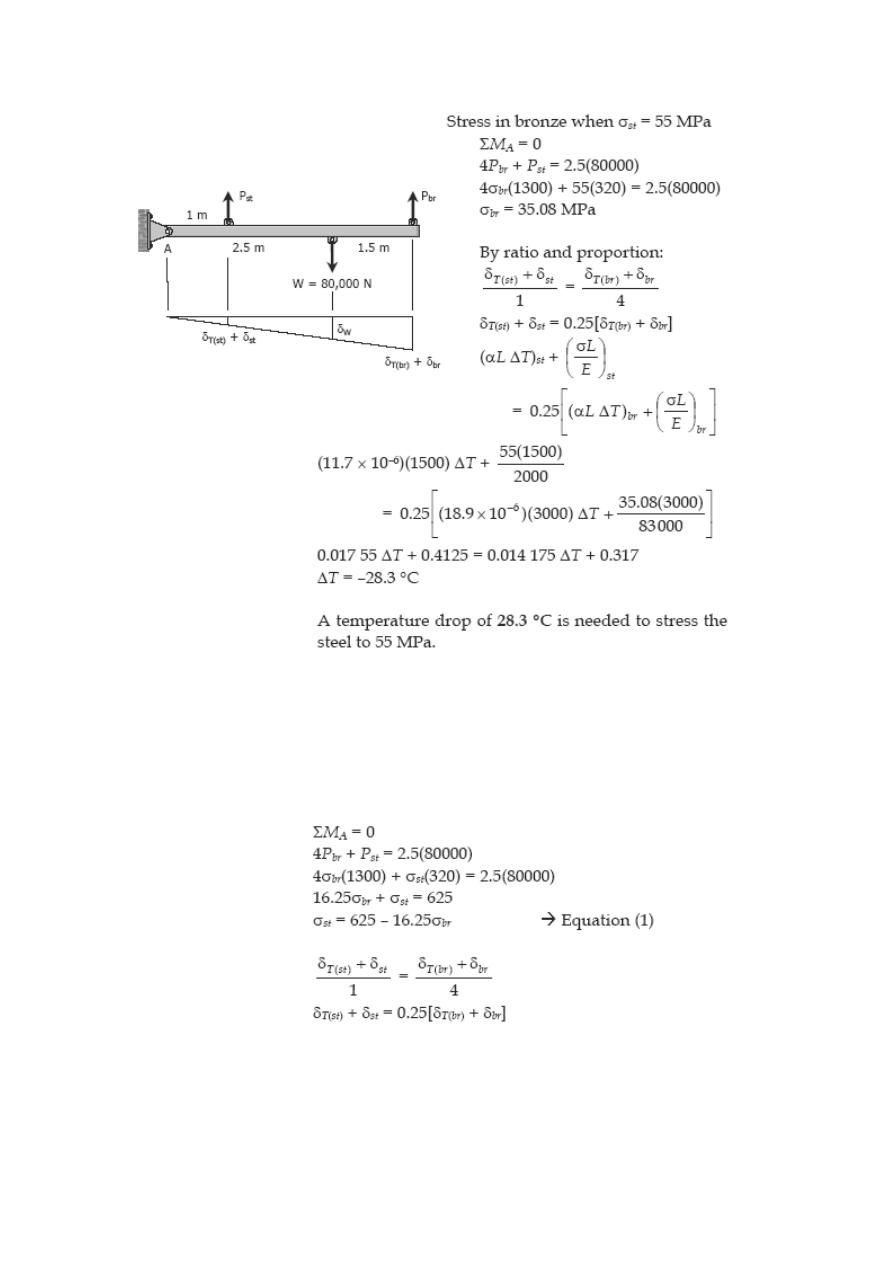

Problem 271

A rigid bar of negligible weight is supported as shown in Fig. P-271. If W = 80 kN,

compute the temperature change that will cause the stress in the steel rod to be 55

MPa. Assume the coefficients of linear expansion are 11.7 µm/(m·°C) for steel and 18.9

µm / (m·°C) for bronze.

Solution 271

Problem 272

For the assembly in Fig. 271, find the stress in each rod if the temperature rises 30°C

after a load W = 120 kN is applied.

Solution 272

Problem 273

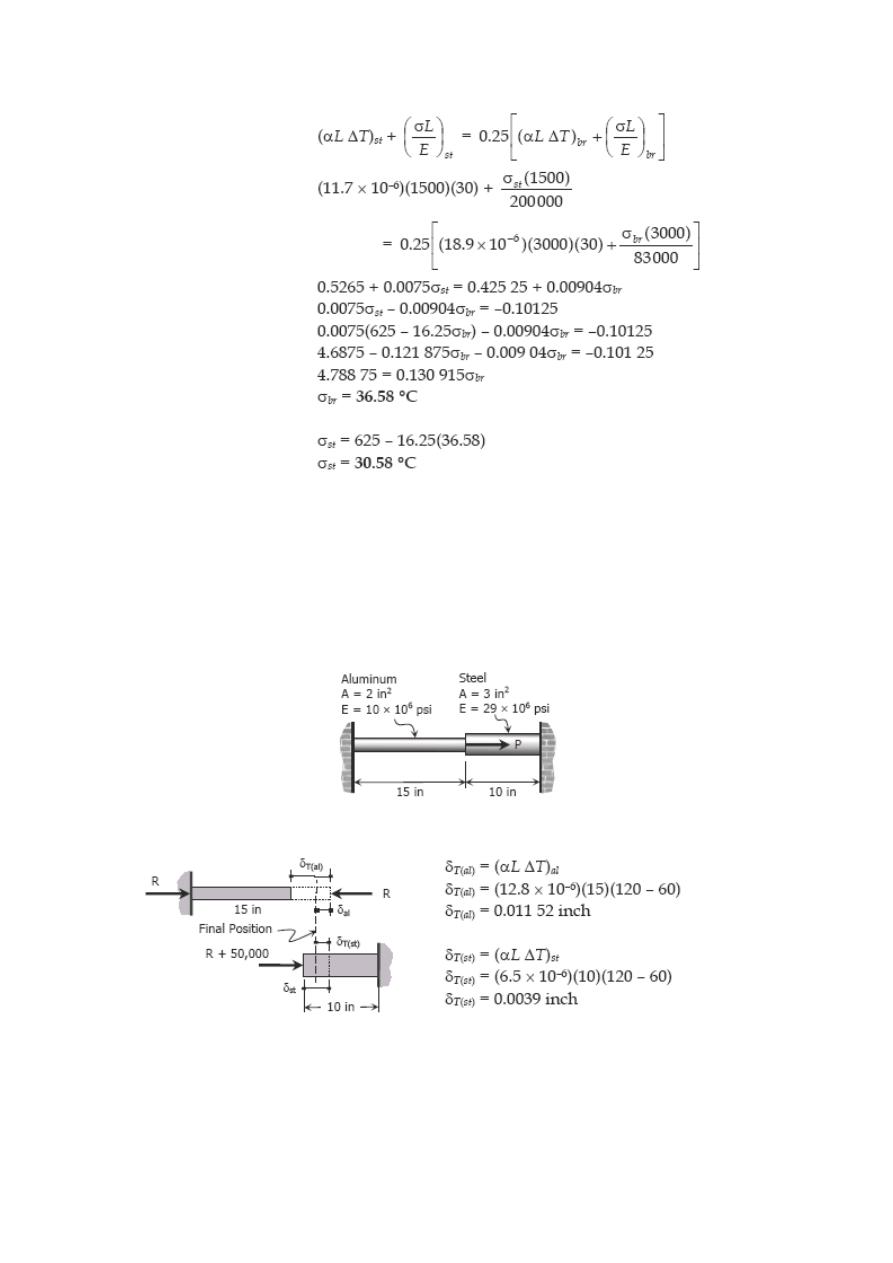

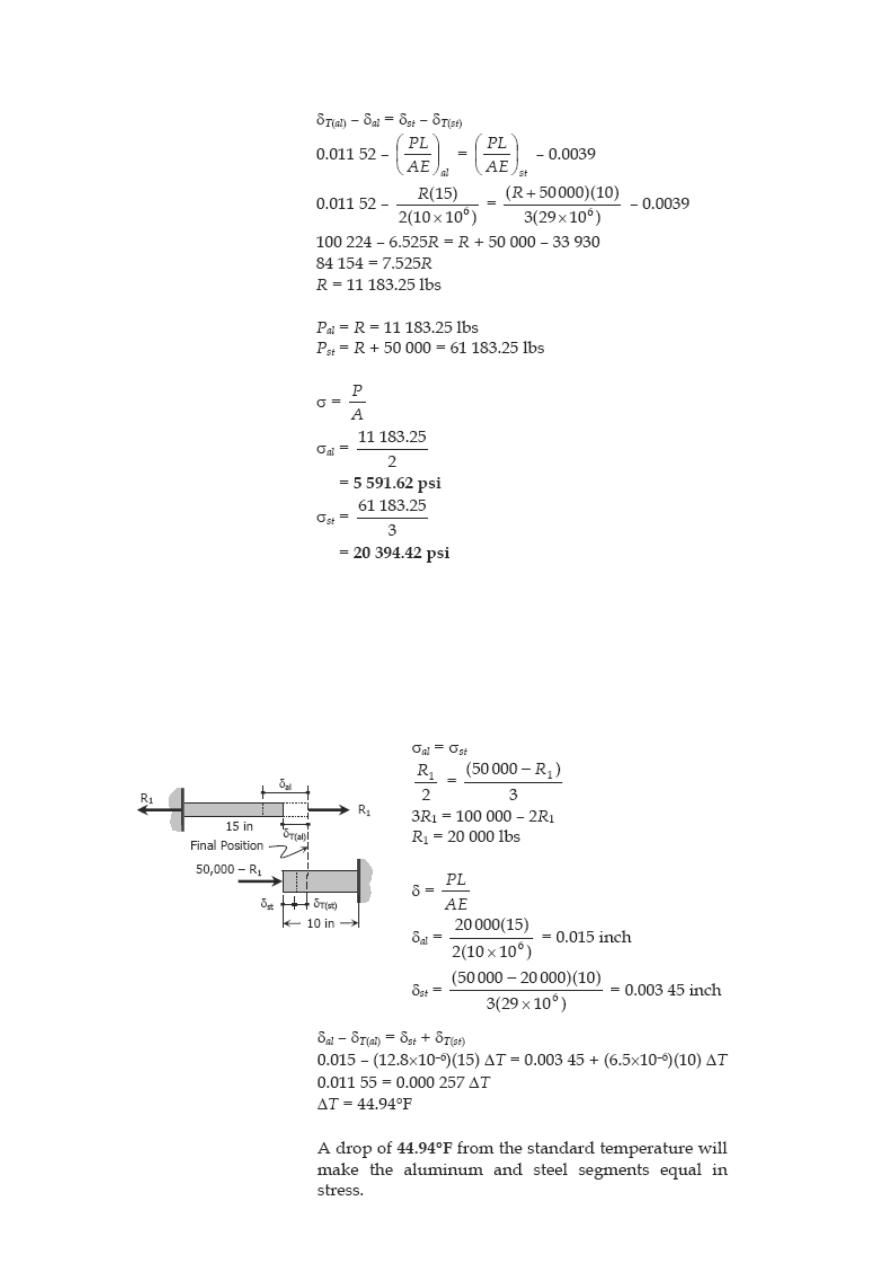

The composite bar shown in Fig. P-273 is firmly attached to unyielding supports. An

axial force P = 50 kips is applied at 60°F. Compute the stress in each material at 120°F.

Assume α = 6.5 × 10

–6

in/(in·°F) for steel and 12.8 × 10

–6

in/(in·°F) for aluminum.

Figure P-273 and P-274

Solution 273

Problem 274

At what temperature will the aluminum and steel segments in Prob. 273 have

numerically equal stress?

Solution 274

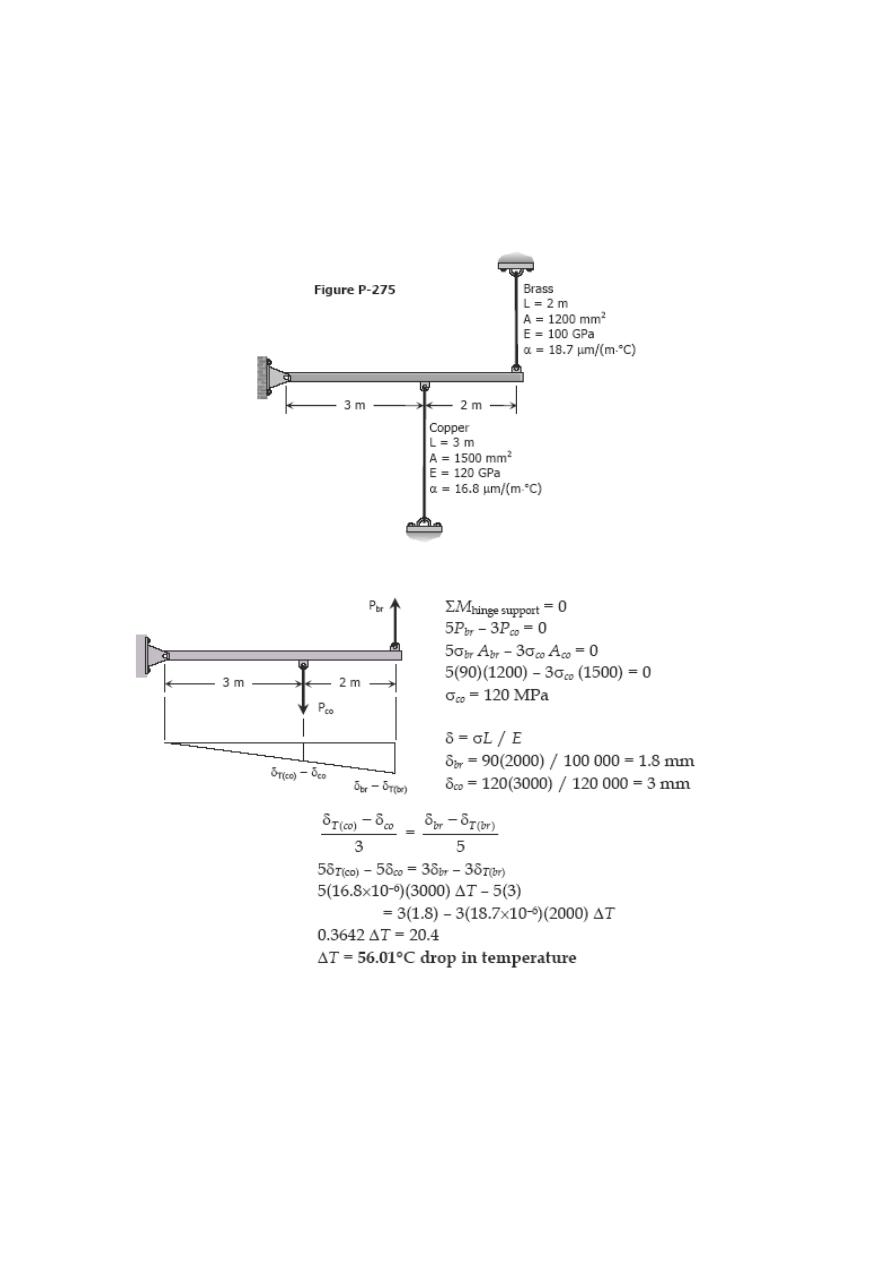

Problem 275

A rigid horizontal bar of negligible mass is connected to two rods as shown in Fig. P-

275. If the system is initially stress-free. Calculate the temperature change that will

cause a tensile stress of 90 MPa in the brass rod. Assume that both rods are subjected

to the change in temperature.

Solution 275

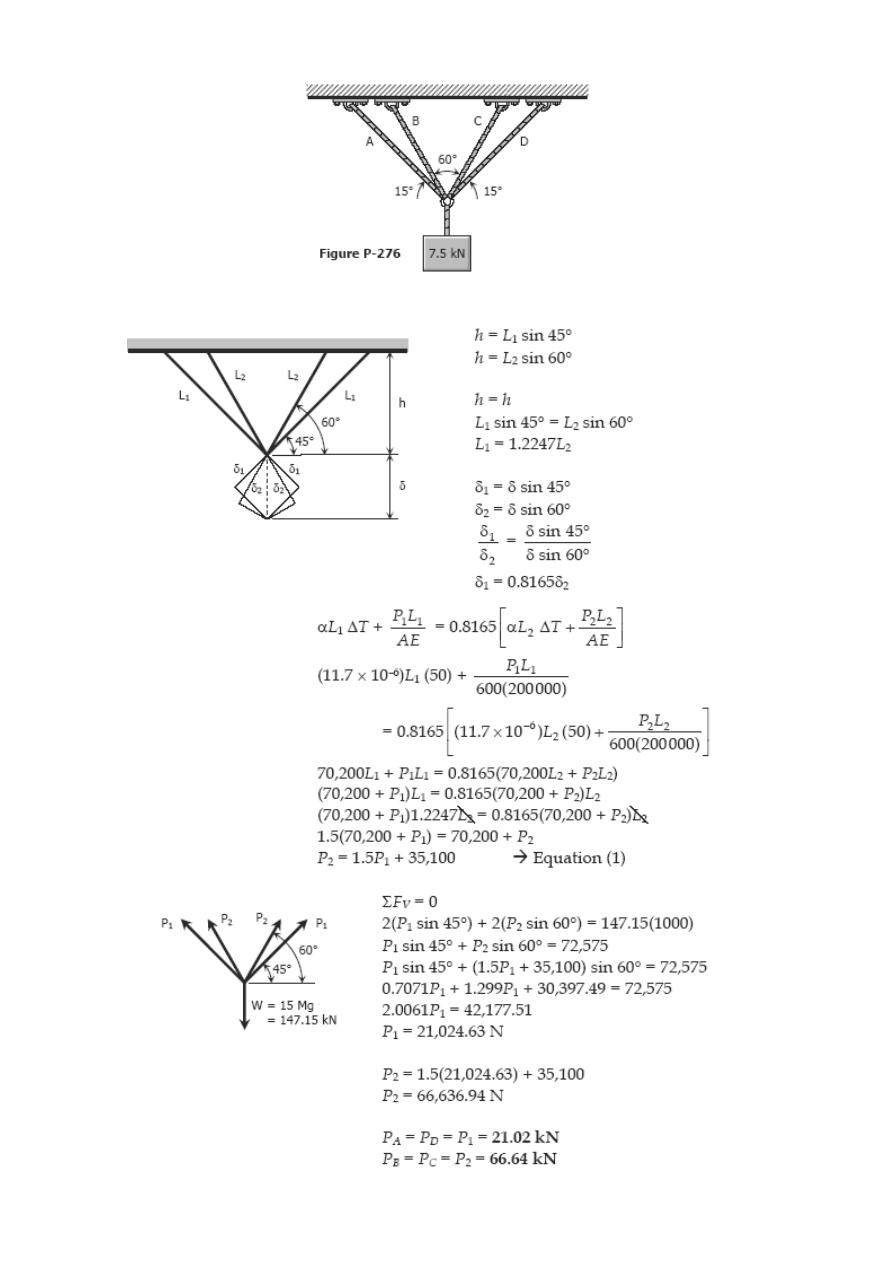

Problem 276

Four steel bars jointly support a mass of 15 Mg as shown in Fig. P-276. Each bar has a

cross-sectional area of 600 mm2. Find the load carried by each bar after a temperature

rise of 50°C. Assume α = 11.7 µm/(m·°C) and E = 200 GPa.

Solution 276

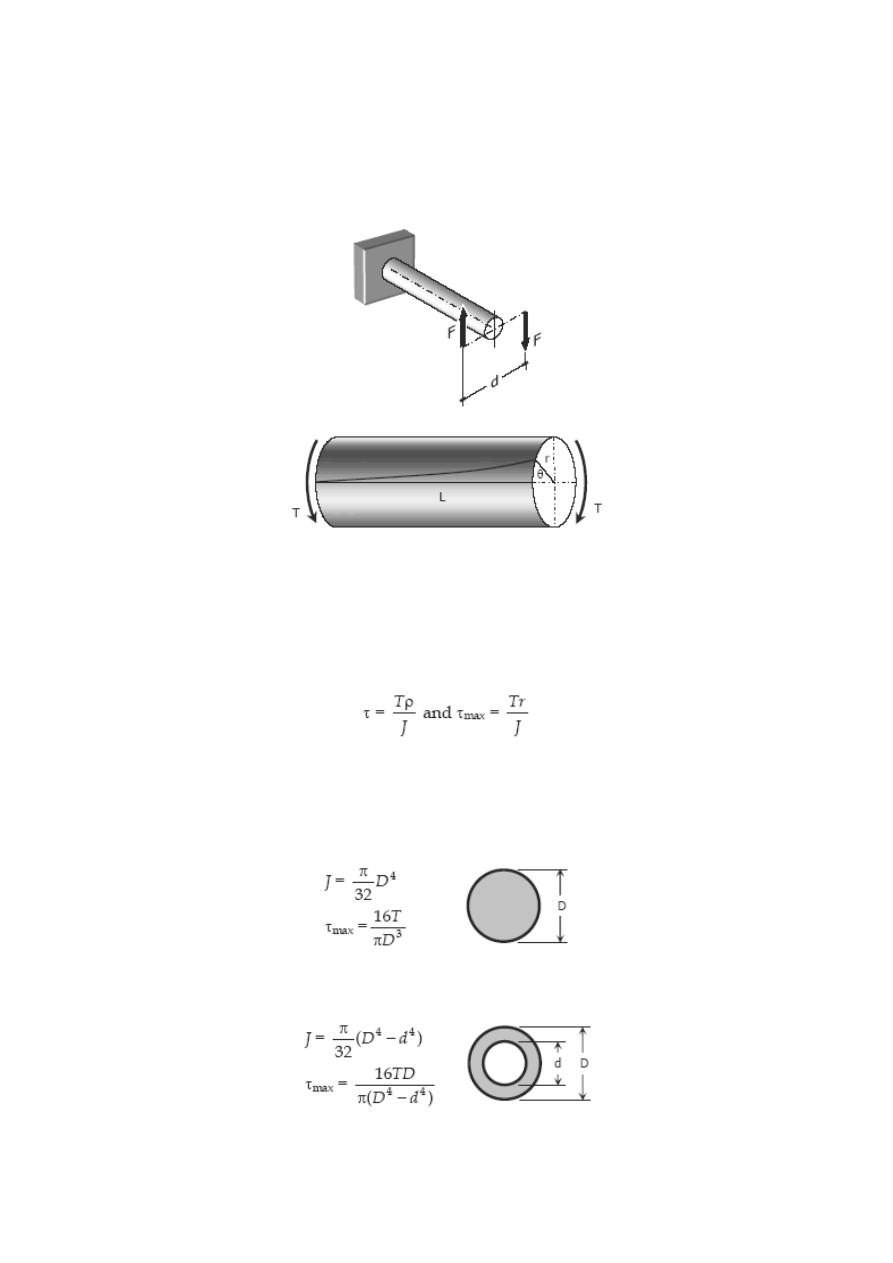

Torsion

Consider a bar to be rigidly attached at one end and twisted at the other end by a

torque or twisting moment T equivalent to F × d, which is applied perpendicular to the

axis of the bar, as shown in the figure. Such a bar is said to be in torsion.

TORSIONAL SHEARING STRESS, τ

For a solid or hollow circular shaft subject to a twisting moment T, the torsional

shearing stress τ at a distance ρ from the center of the shaft is

where J is the polar moment of inertia of the section and r is the outer radius.

For solid cylindrical shaft:

For hollow cylindrical shaft:

ANGLE OF TWIST

The angle θ through which the bar length L will twist is

where T is the torque in N·mm, L is the length of shaft in mm, G is shear modulus in

MPa, J is the polar moment of inertia in mm

4

, D and d are diameter in mm, and r is the

radius in mm.

POWER TRANSMITTED BY THE SHAFT

A shaft rotating with a constant angular velocity ω (in radians per second) is being acted

by a twisting moment T. The power transmitted by the shaft is

where T is the torque in N·m, f is the number of revolutions per second, and P is the

power in watts.

Solved Problems in Torsion

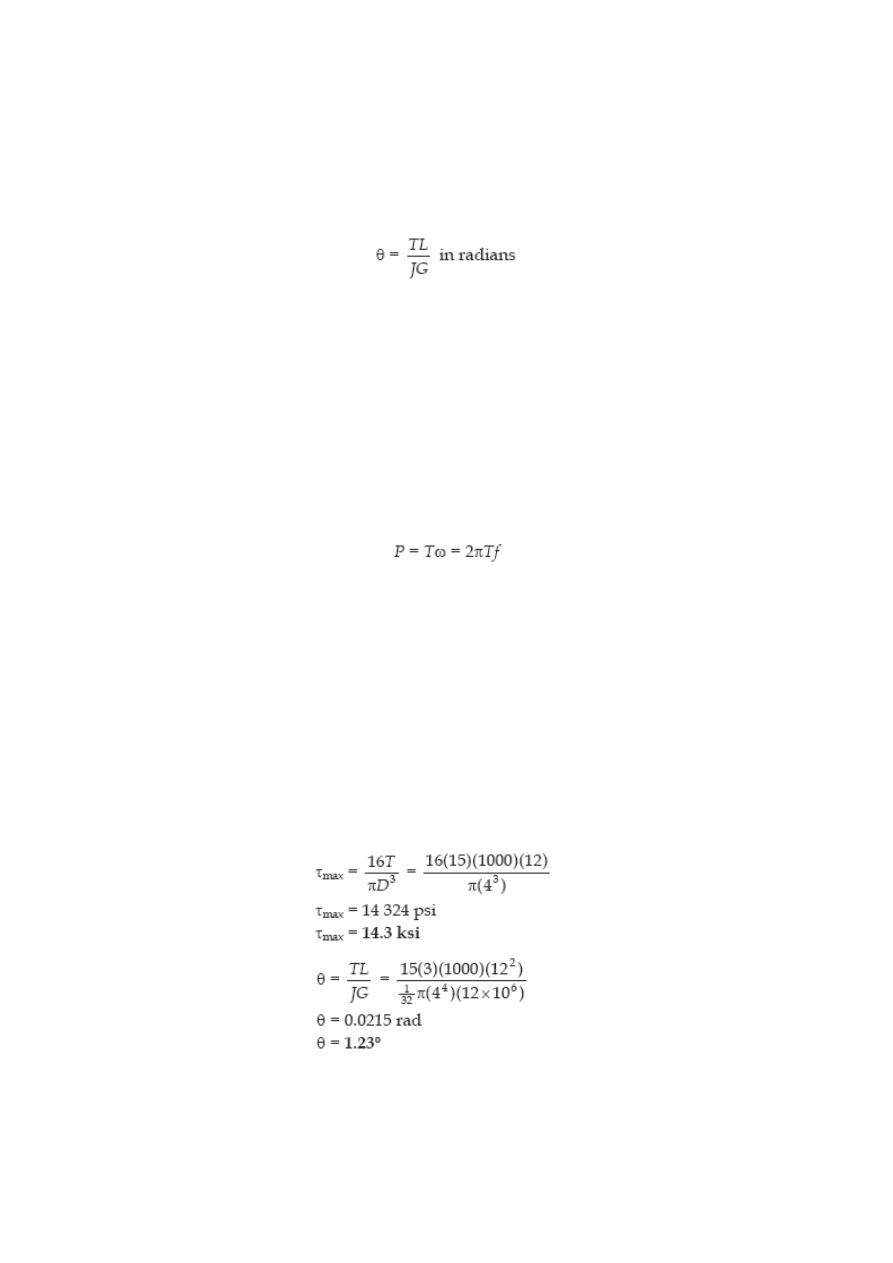

Problem 304

A steel shaft 3 ft long that has a diameter of 4 in. is subjected to a torque of 15 kip·ft.

Determine the maximum shearing stress and the angle of twist. Use G = 12 × 10

6

psi.

Solution 304

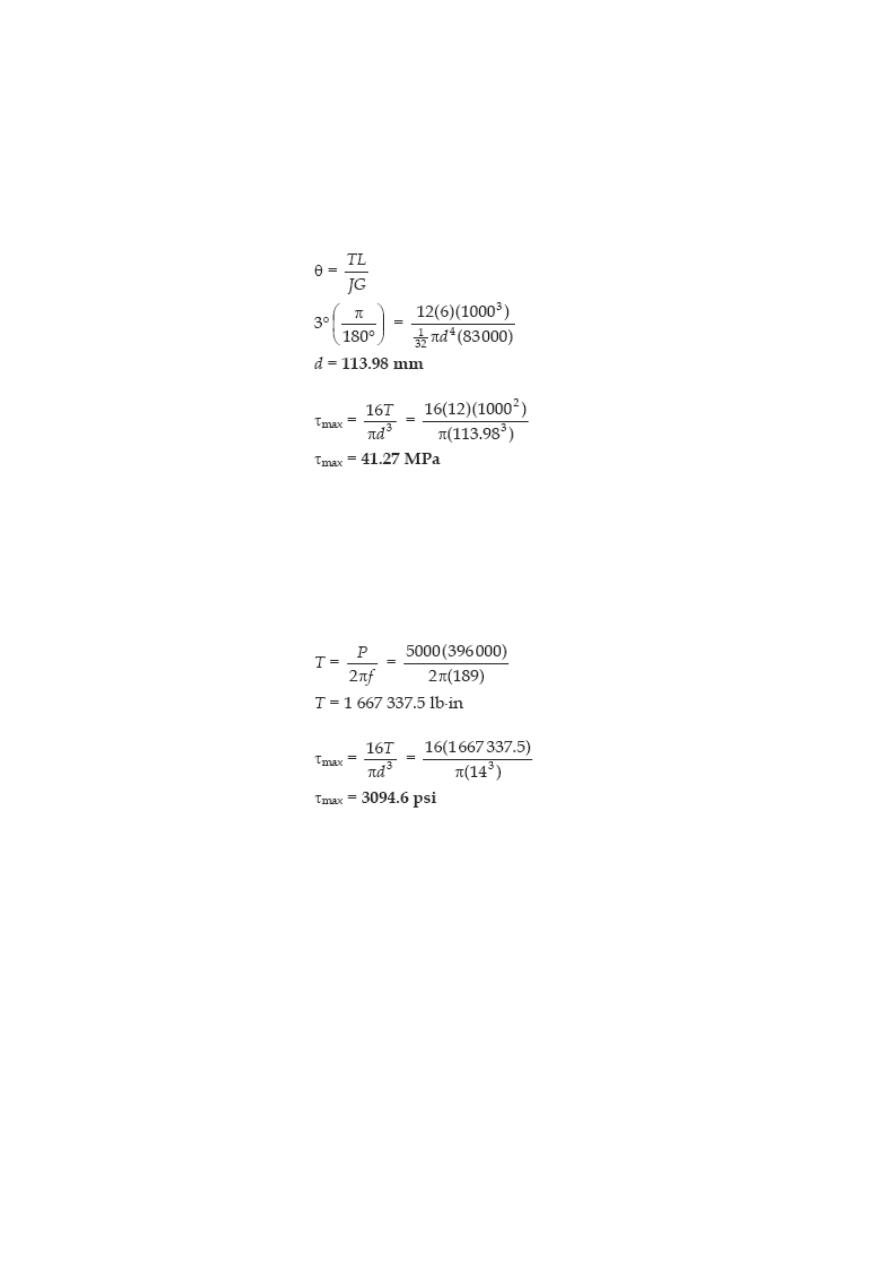

Problem 305

What is the minimum diameter of a solid steel shaft that will not twist through more

than 3° in a 6-m length when subjected to a torque of 12 kN·m? What maximum

shearing stress is developed? Use G = 83 GPa.

Solution 305

Problem 306

A steel marine propeller shaft 14 in. in diameter and 18 ft long is used to transmit 5000

hp at 189 rpm. If G = 12 × 10

6

psi, determine the maximum shearing stress.

Solution 306

Problem 307

A solid steel shaft 5 m long is stressed at 80 MPa when twisted through 4°. Using G =

83 GPa, compute the shaft diameter. What power can be transmitted by the shaft at 20

Hz?

Solution 307

Problem 308

A 2-in-diameter steel shaft rotates at 240 rpm. If the shearing stress is limited to 12

ksi, determine the maximum horsepower that can be transmitted.

Solution 308

Problem 309

A steel propeller shaft is to transmit 4.5 MW at 3 Hz without exceeding a shearing stress

of 50 MPa or twisting through more than 1° in a length of 26 diameters. Compute the

proper diameter if G = 83 GPa.

Solution 309

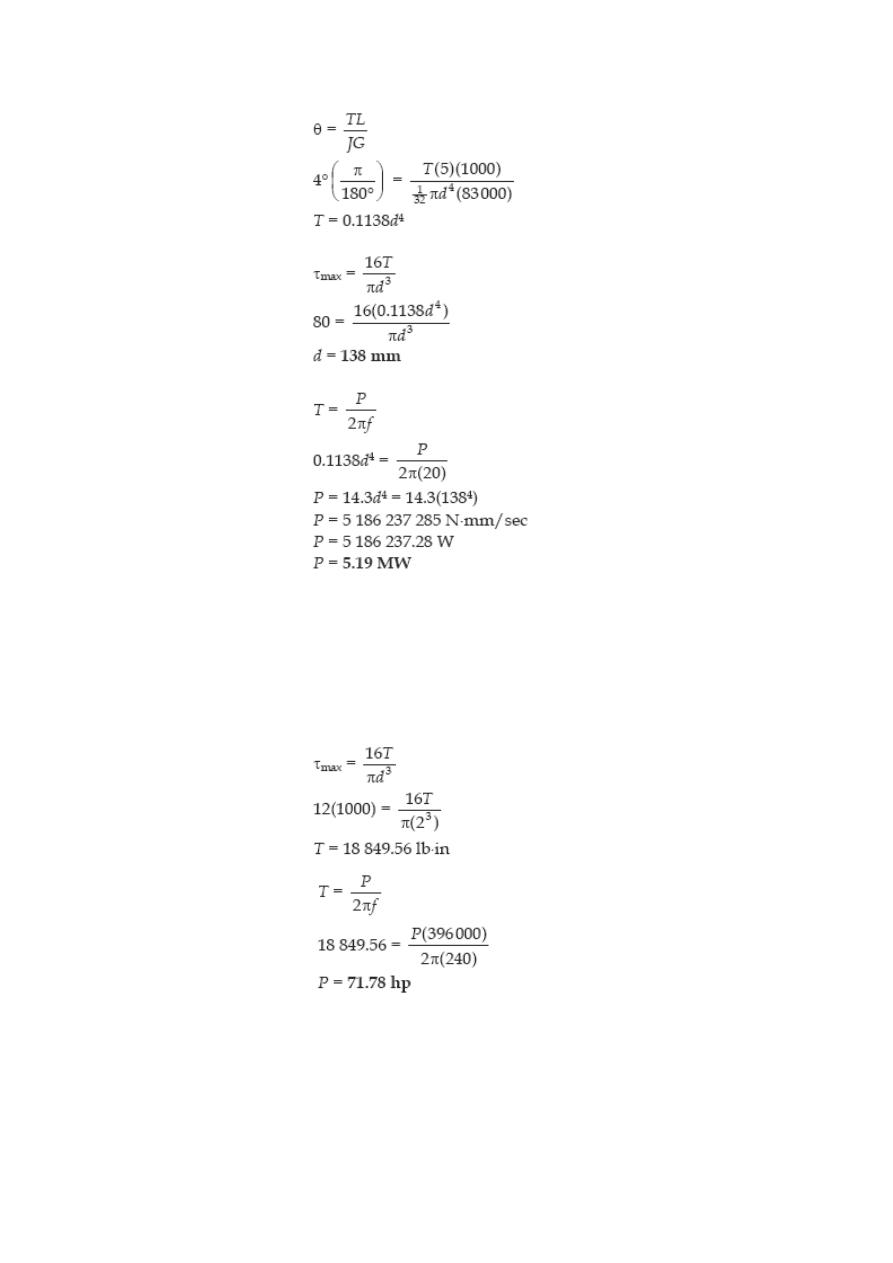

Problem 310

Show that the hollow circular shaft whose inner diameter is half the outer diameter has

a torsional strength equal to 15/16 of that of a solid shaft of the same outside diameter.

Solution 310

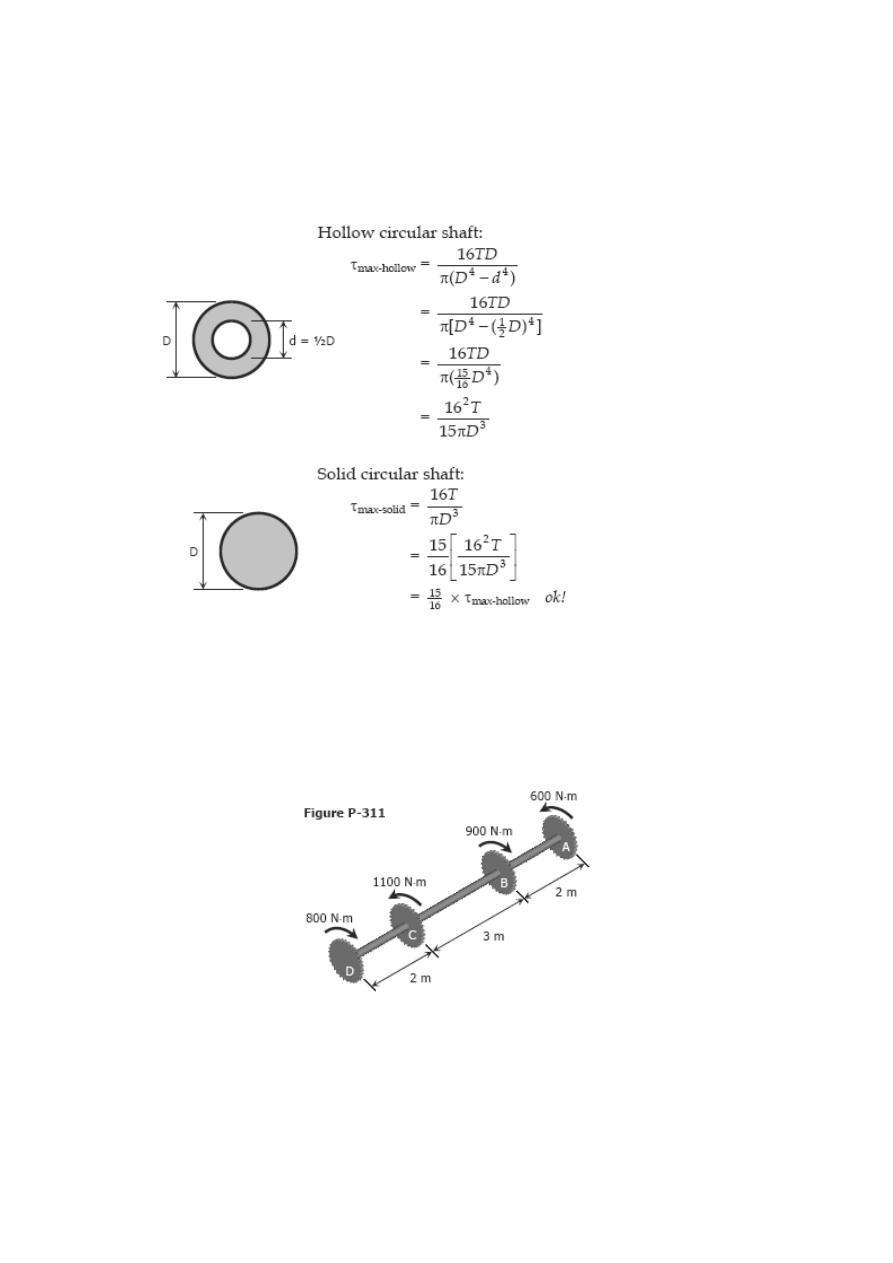

Problem 311

An aluminum shaft with a constant diameter of 50 mm is loaded by torques applied to

gears attached to it as shown in Fig. P-311. Using G = 28 GPa, determine the relative

angle of twist of gear D relative to gear A.

Solution 311

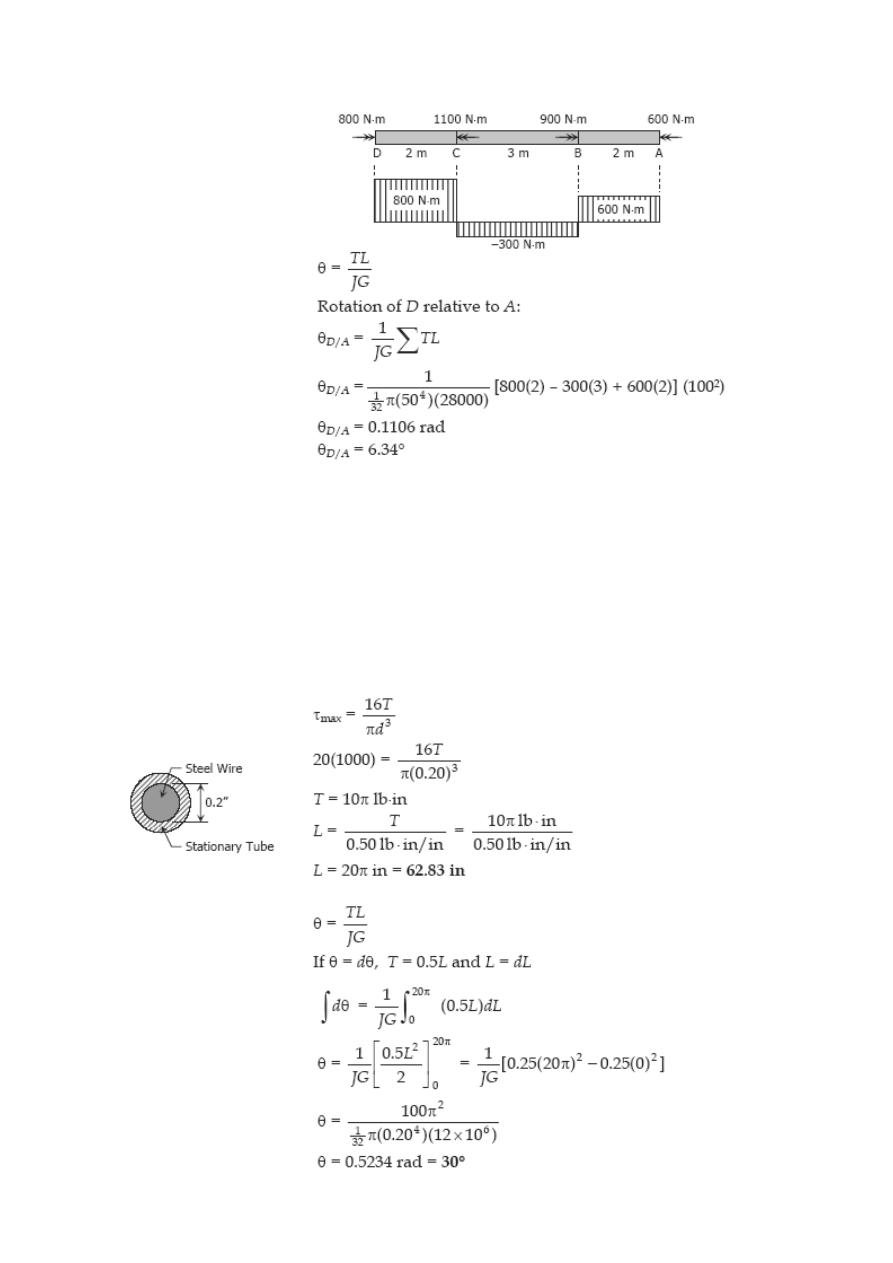

Problem 312

A flexible shaft consists of a 0.20-in-diameter steel wire encased in a stationary tube

that fits closely enough to impose a frictional torque of 0.50 lb·in/in. Determine the

maximum length of the shaft if the shearing stress is not to exceed 20 ksi. What will be

the angular deformation of one end relative to the other end? G = 12 × 10

6

psi.

Solution 312

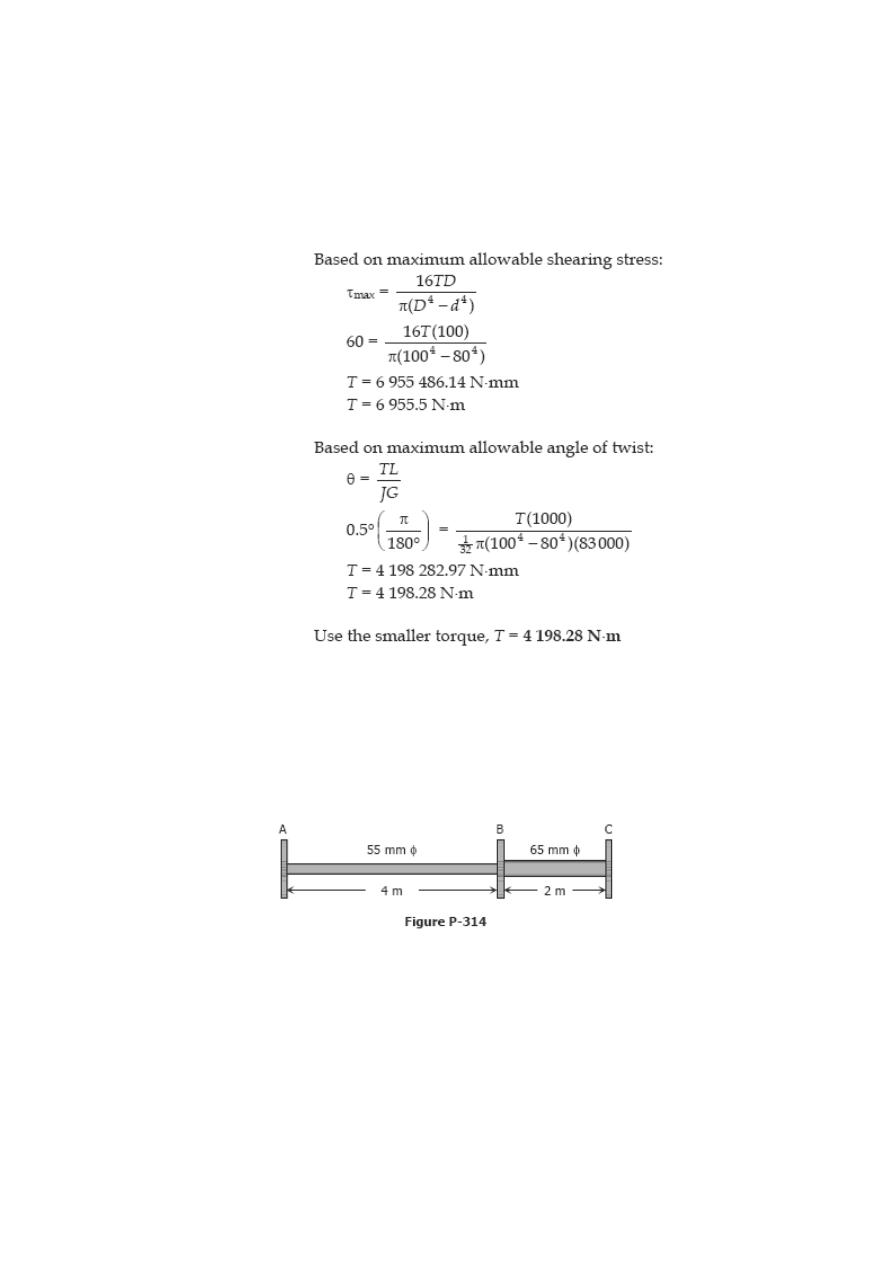

Problem 313

Determine the maximum torque that can be applied to a hollow circular steel shaft of

100-mm outside diameter and an 80-mm inside diameter without exceeding a shearing

stress of 60 MPa or a twist of 0.5 deg/m. Use G = 83 GPa.

Solution 313

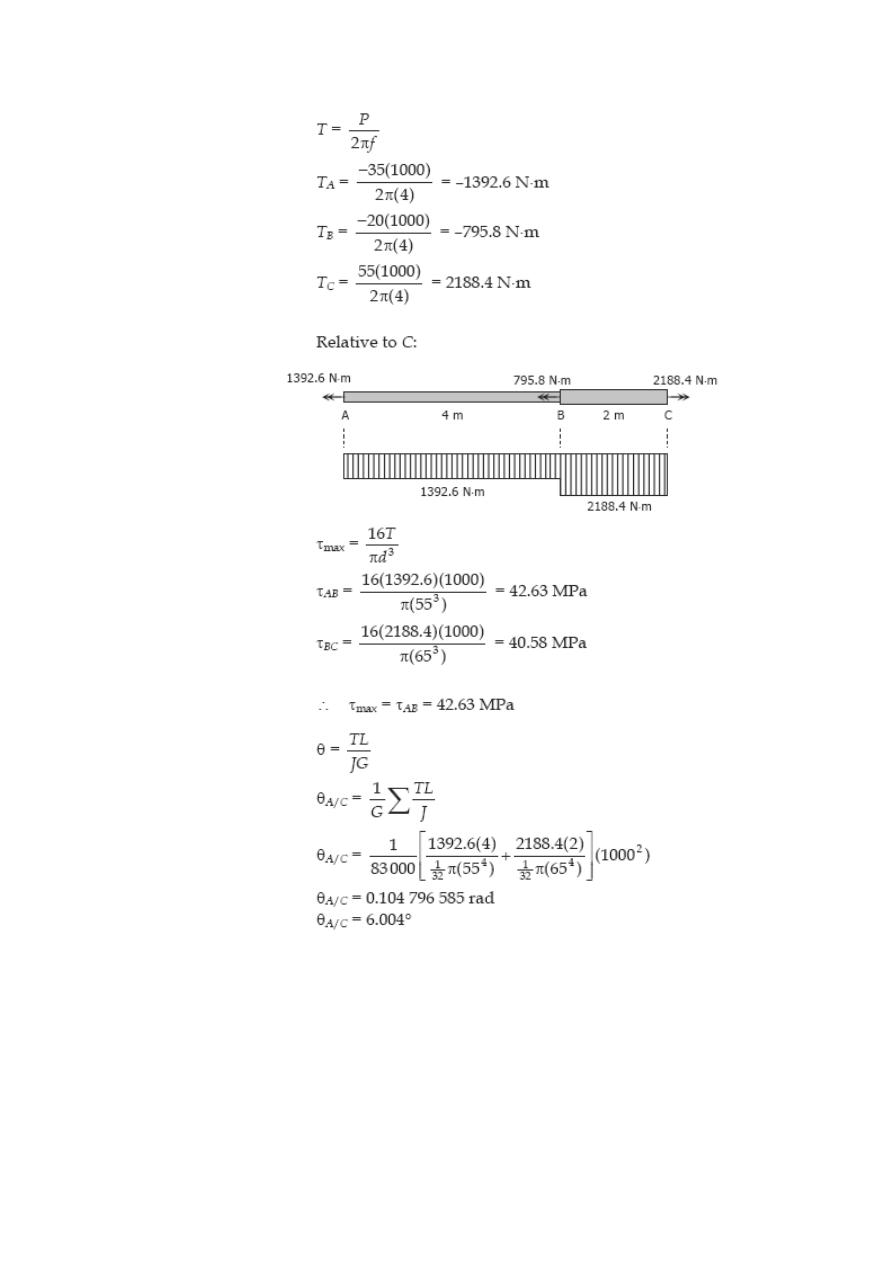

Problem 314

The steel shaft shown in Fig. P-314 rotates at 4 Hz with 35 kW taken off at A, 20 kW

removed at B, and 55 kW applied at C. Using G = 83 GPa, find the maximum shearing

stress and the angle of rotation of gear A relative to gear C.

Solution 314

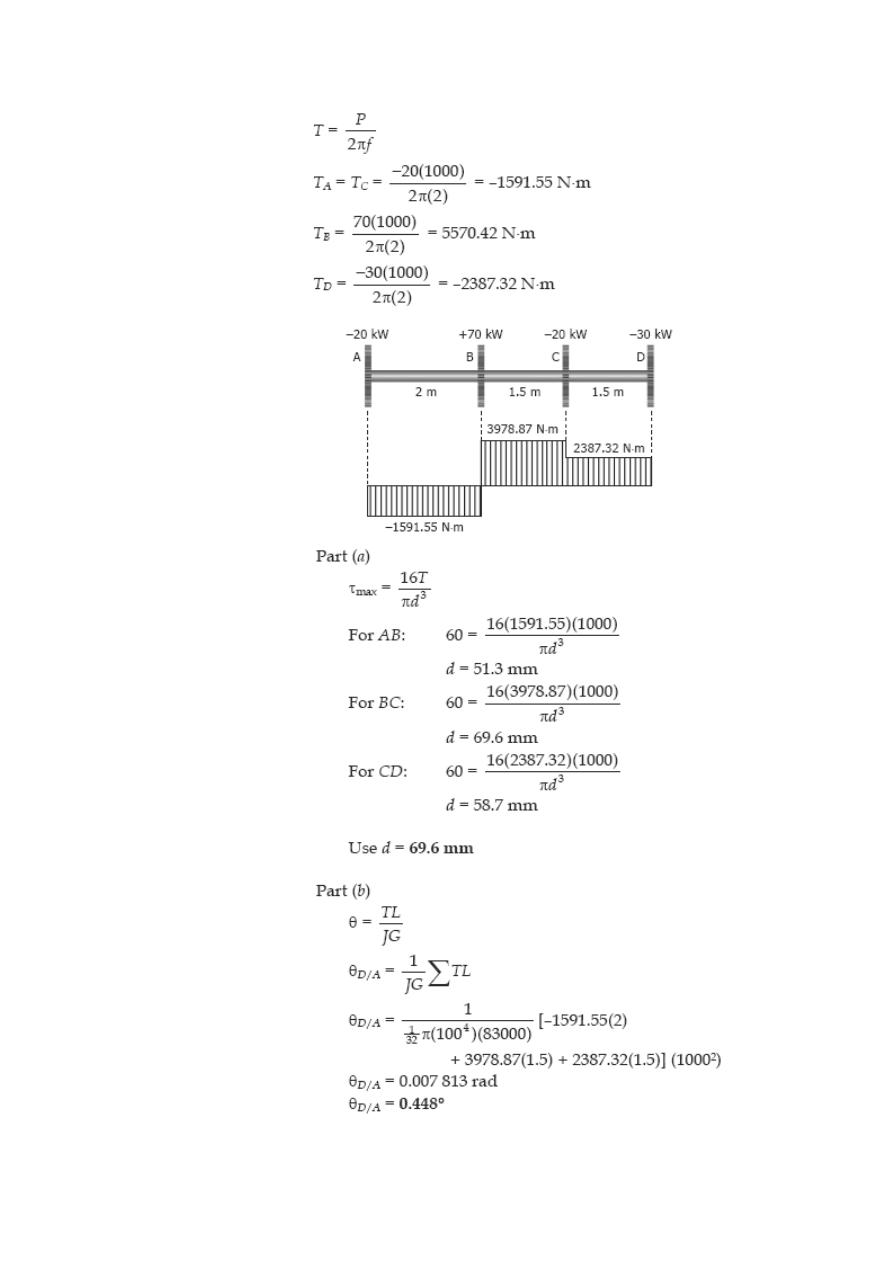

Problem 315

A 5-m steel shaft rotating at 2 Hz has 70 kW applied at a gear that is 2 m from the left

end where 20 kW are removed. At the right end, 30 kW are removed and another 20

kW leaves the shaft at 1.5 m from the right end. (a) Find the uniform shaft diameter so

that the shearing stress will not exceed 60 MPa. (b) If a uniform shaft diameter of 100

mm is specified, determine the angle by which one end of the shaft lags behind the

other end. Use G = 83 GPa.

Solution 315

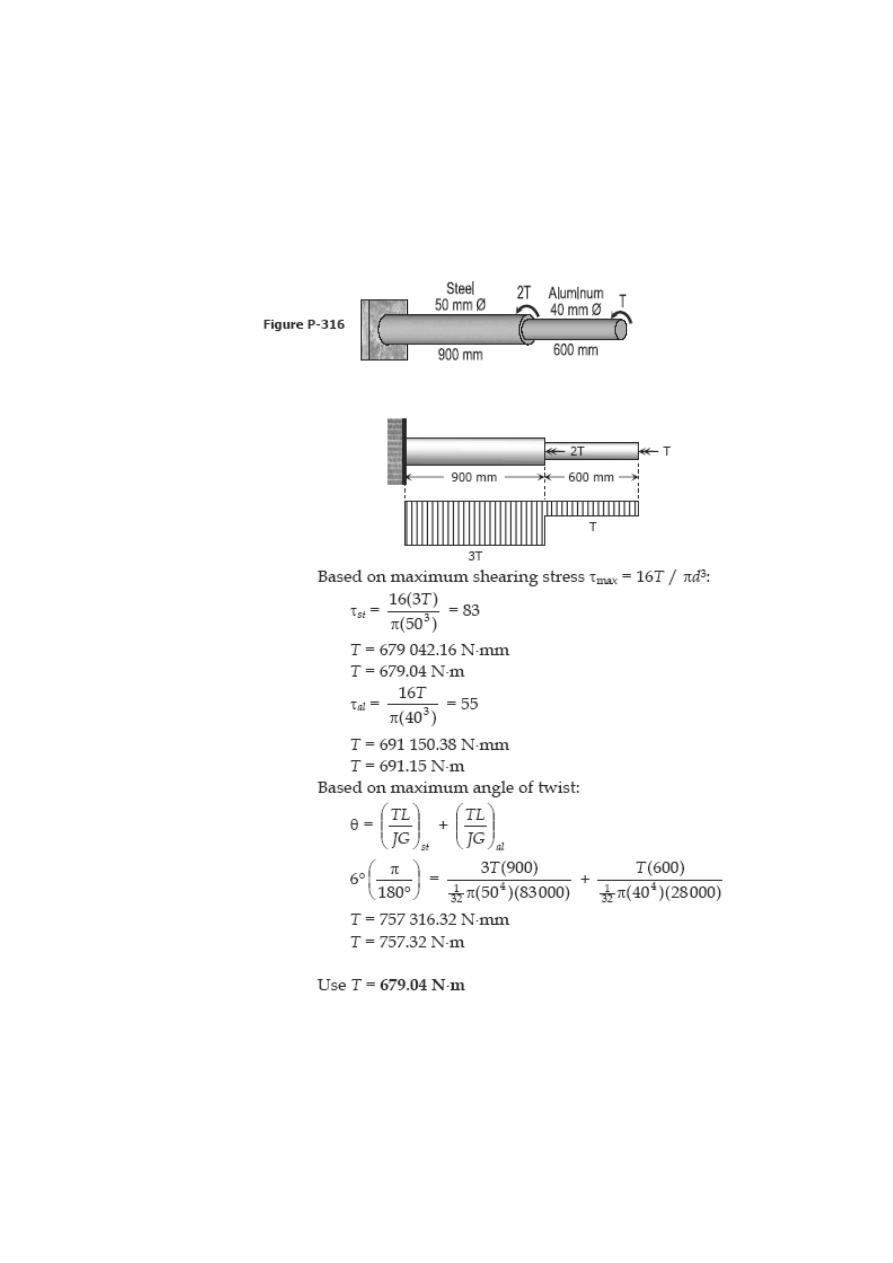

Problem 316

A compound shaft consisting of a steel segment and an aluminum segment is acted

upon by two torques as shown in Fig. P-316. Determine the maximum permissible value

of T subject to the following conditions: τ

st

= 83 MPa, τ

al

= 55 MPa, and the angle of

rotation of the free end is limited to 6°. For steel, G = 83 GPa and for aluminum, G =

28 GPa.

Solution 316

Problem 317

A hollow bronze shaft of 3 in. outer diameter and 2 in. inner diameter is slipped over a

solid steel shaft 2 in. in diameter and of the same length as the hollow shaft. The two

shafts are then fastened rigidly together at their ends. For bronze, G = 6 × 10

6

psi, and

for steel, G = 12 × 10

6

psi. What torque can be applied to the composite shaft without

exceeding a shearing stress of 8000 psi in the bronze or 12 ksi in the steel?

Solution 317

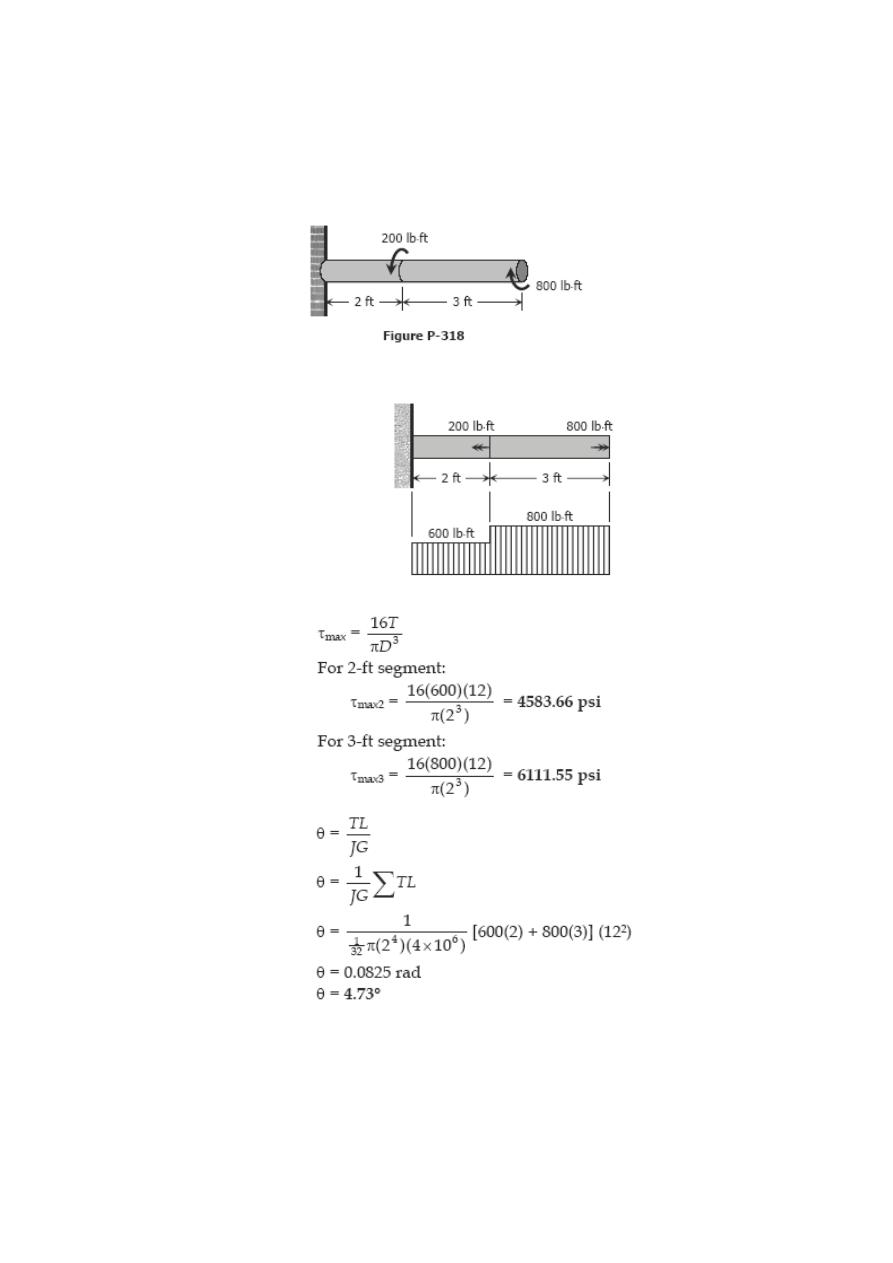

Problem 318

A solid aluminum shaft 2 in. in diameter is subjected to two torques as shown in Fig. P-

318. Determine the maximum shearing stress in each segment and the angle of rotation

of the free end. Use G = 4 × 10

6

psi.

Solution 318

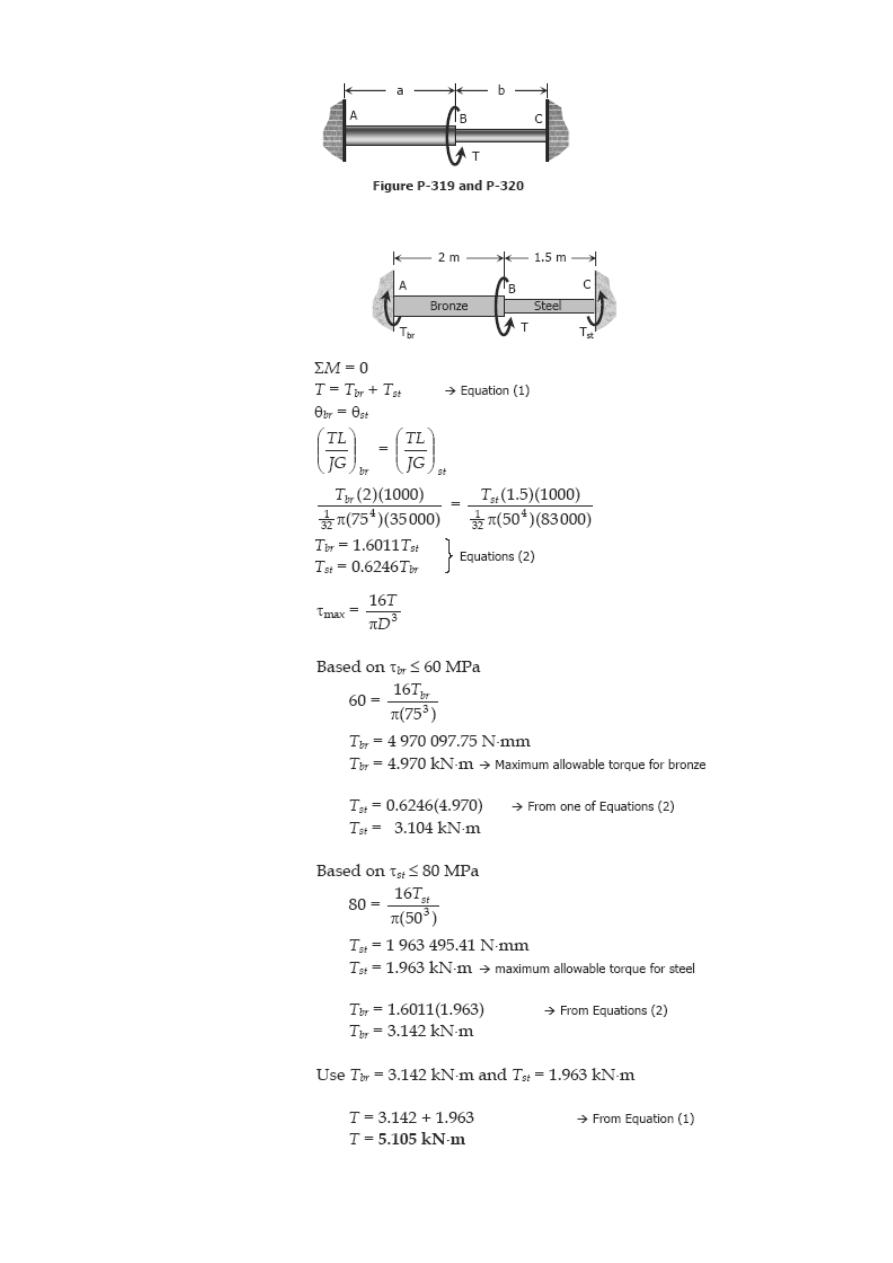

Problem 319

The compound shaft shown in Fig. P-319 is attached to rigid supports. For the bronze

segment AB, the diameter is 75 mm, τ ≤ 60 MPa, and G = 35 GPa. For the steel

segment BC, the diameter is 50 mm, τ ≤ 80 MPa, and G = 83 GPa. If a = 2 m and b =

1.5 m, compute the maximum torque T that can be applied.

Solution 319

Problem 320

In Prob. 319, determine the ratio of lengths b/a so that each material will be stressed to

its permissible limit. What torque T is required?

Solution 320

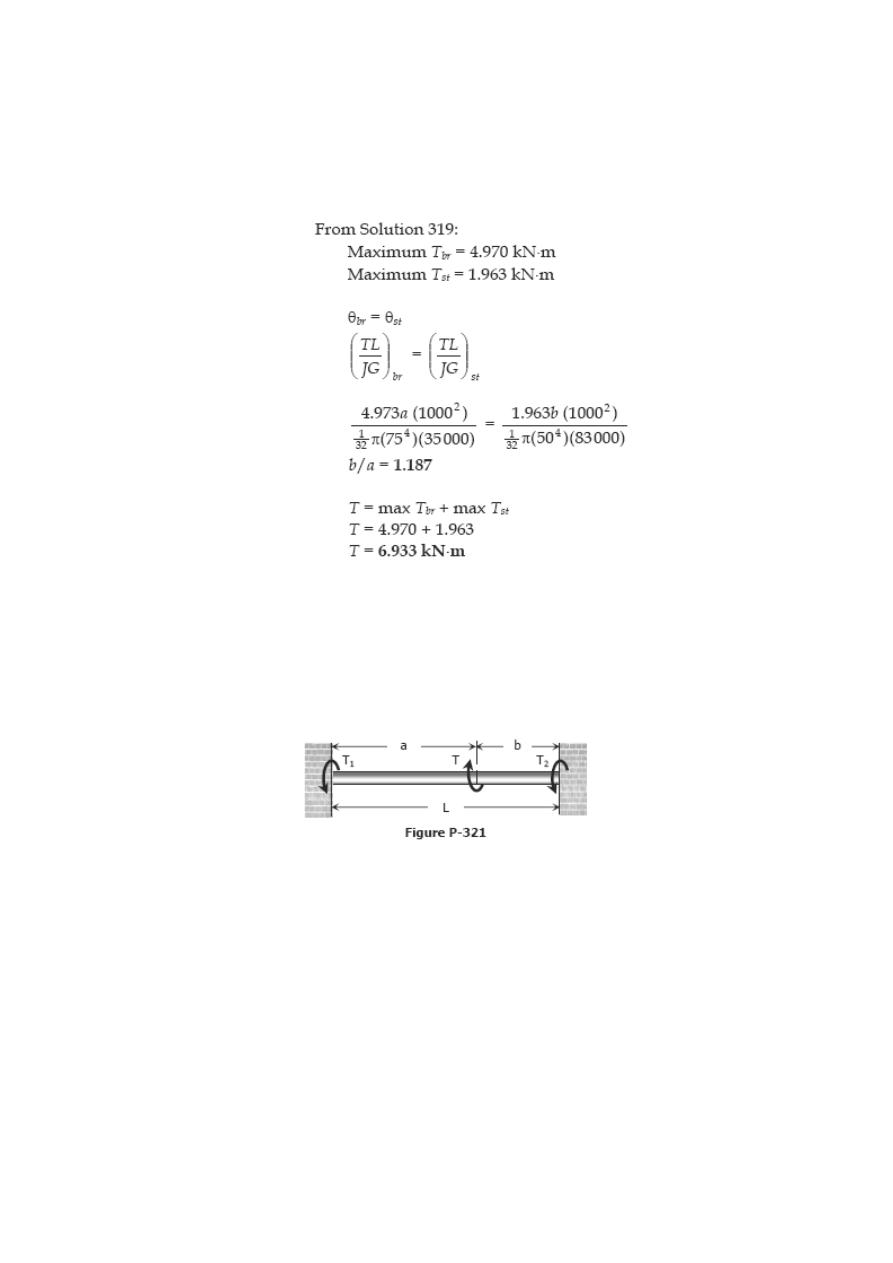

Problem 321

A torque T is applied, as shown in Fig. P-321, to a solid shaft with built-in ends. Prove

that the resisting torques at the walls are T

1

= Tb/L and T

2

= Ta/L. How would these

values be changed if the shaft were hollow?

Solution 321

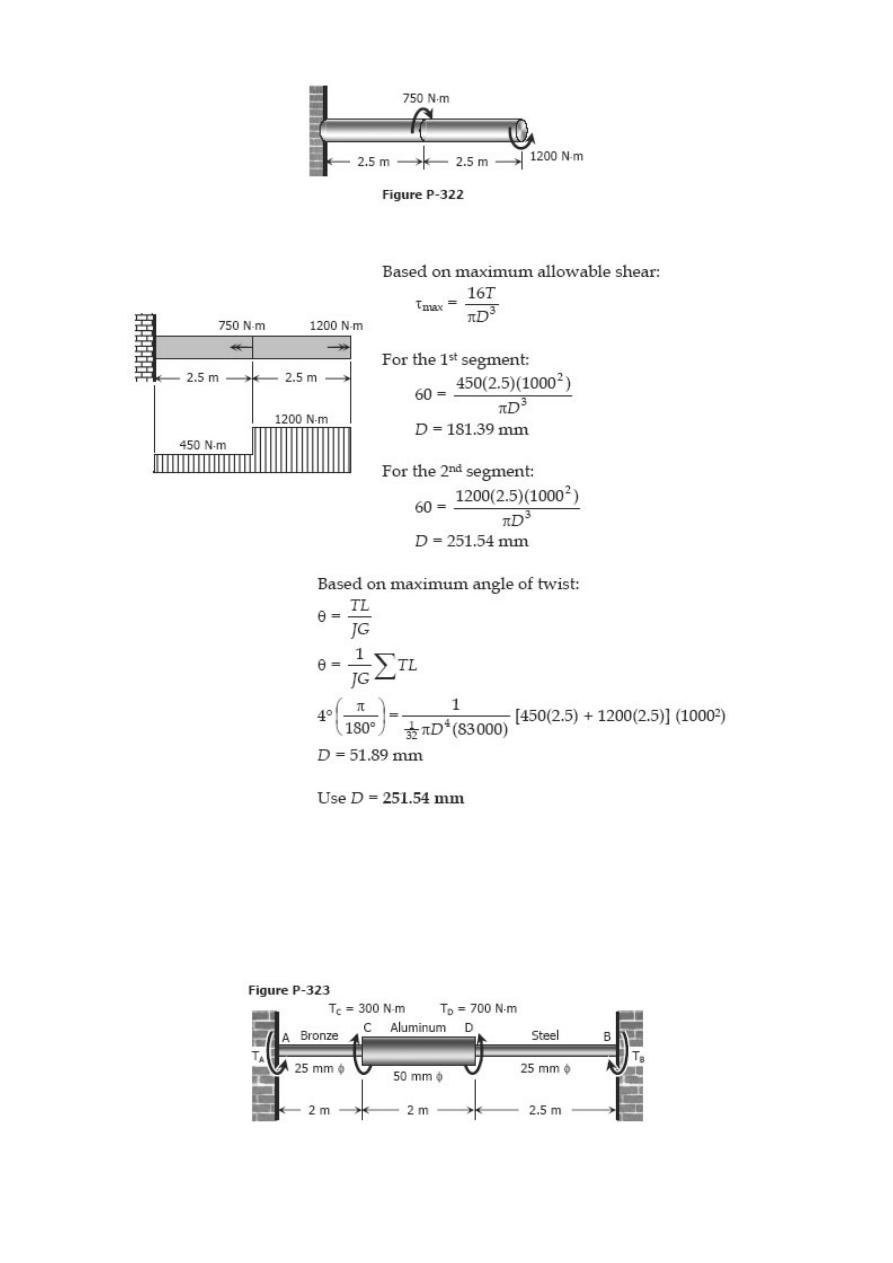

Problem 322

A solid steel shaft is loaded as shown in Fig. P-322. Using G = 83 GPa, determine the

required diameter of the shaft if the shearing stress is limited to 60 MPa and the angle

of rotation at the free end is not to exceed 4 deg.

Solution 322

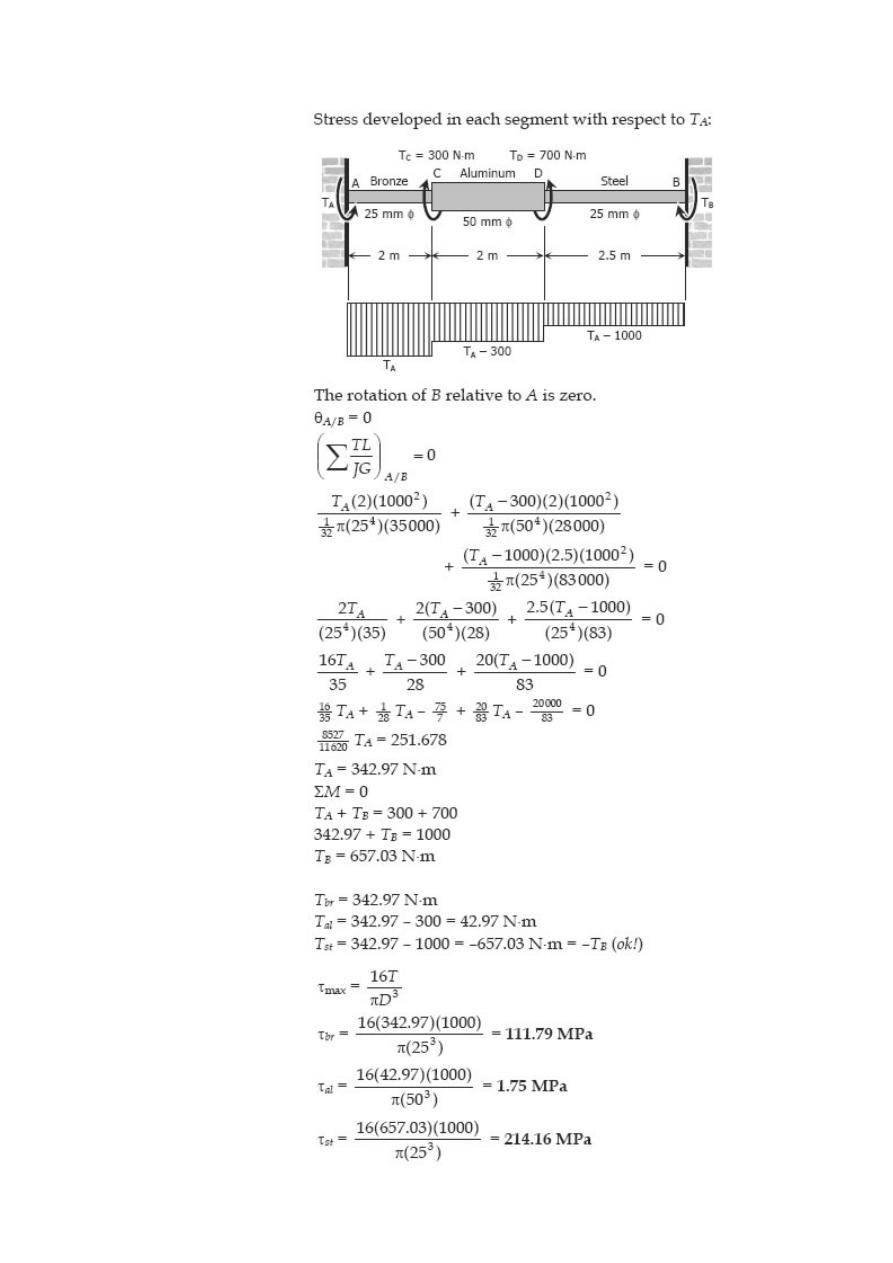

Problem 323

A shaft composed of segments AC, CD, and DB is fastened to rigid supports and loaded

as shown in Fig. P-323. For bronze, G = 35 GPa; aluminum, G = 28 GPa, and for steel,

G = 83 GPa. Determine the maximum shearing stress developed in each segment.

Solution 323

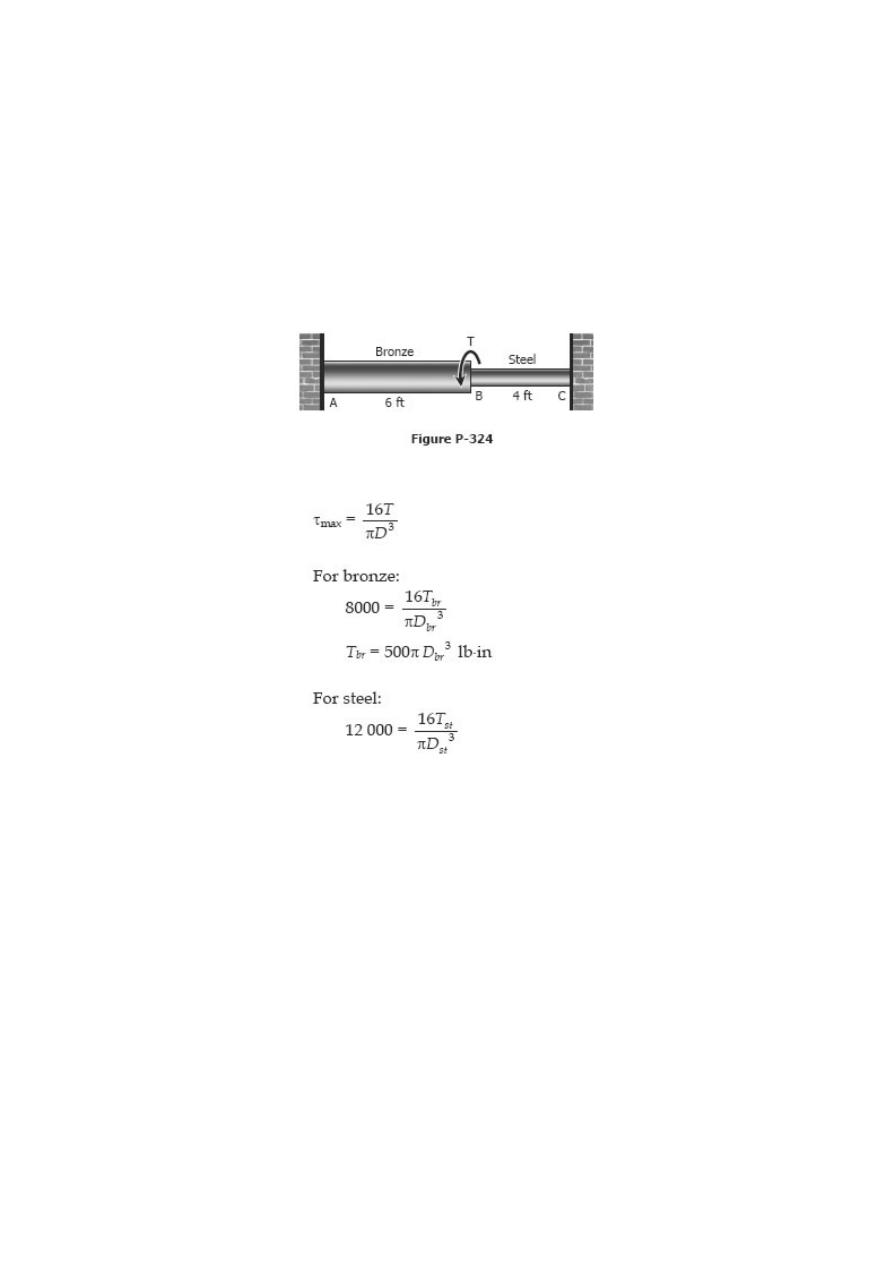

Problem 324

The compound shaft shown in Fig. P-324 is attached to rigid supports. For the bronze

segment AB, the maximum shearing stress is limited to 8000 psi and for the steel

segment BC, it is limited to 12 ksi. Determine the diameters of each segment so that

each material will be simultaneously stressed to its permissible limit when a torque T =

12 kip·ft is applied. For bronze, G = 6 × 10

6

psi and for steel, G = 12 × 10

6

psi.

Solution 324

Problem 325

The two steel shaft shown in Fig. P-325, each with one end built into a rigid support

have flanges rigidly attached to their free ends. The shafts are to be bolted together at

their flanges. However, initially there is a 6° mismatch in the location of the bolt holes

as shown in the figure. Determine the maximum shearing stress in each shaft after the

shafts are bolted together. Use G = 12 × 10

6

psi and neglect deformations of the bolts

and

flanges.

Solution 325

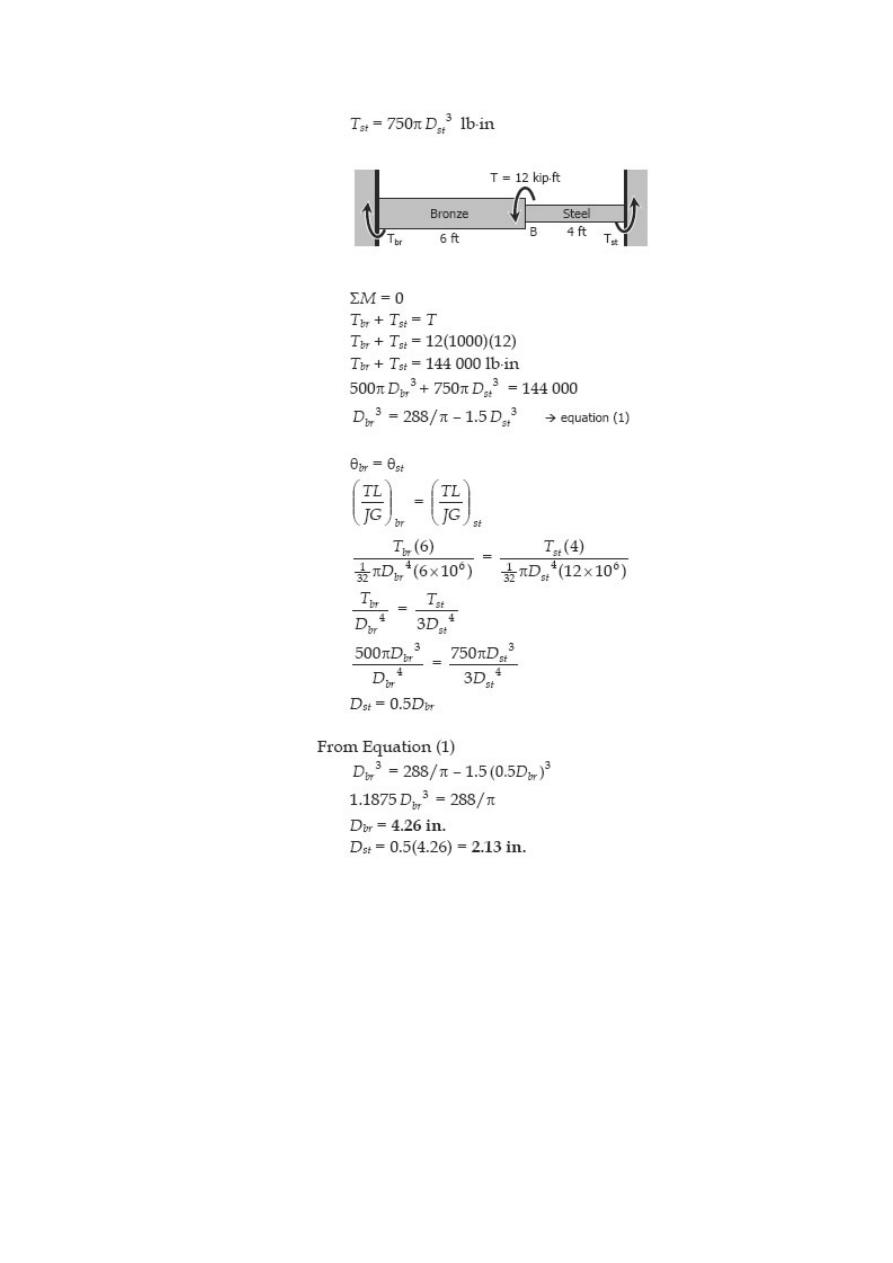

Flanged Bolt Couplings

In shaft connection called flanged bolt couplings (see figure above), the torque is

transmitted by the shearing force P created in he bolts that is assumed to be uniformly

distributed. For any number of bolts n, the torque capacity of the coupling is

If a coupling has two concentric rows of bolts, the torque capacity

is

where the subscript 1 refer to bolts on the outer circle an

subscript 2 refer to bolts on the inner circle. See figure.

For rigid flanges, the shear deformations in the bolts are proportional to their radial

distances from the shaft axis. The shearing strains are related by

Using Hooke’s law for shear, G = τ / γ, we have

If the bolts on the two circles have the same area, A

1

= A

2

, and if the bolts are made of

the same material, G

1

= G

2

, the relation between P

1

and P

2

reduces to

Solved Problems in Flanged Bolt Couplings

Problem 326

A flanged bolt coupling consists of ten 20-mmdiameter bolts spaced evenly around a

bolt circle 400 mm in diameter. Determine the torque capacity of the coupling if the

allowable shearing stress in the bolts is 40 MPa.

Solution 326

Problem 327

A flanged bolt coupling consists of ten steel ½ -in.-diameter bolts spaced evenly around

a bolt circle 14 in. in diameter. Determine the torque capacity of the coupling if the

allowable shearing stress in the bolts is 6000 psi.

Solution 327

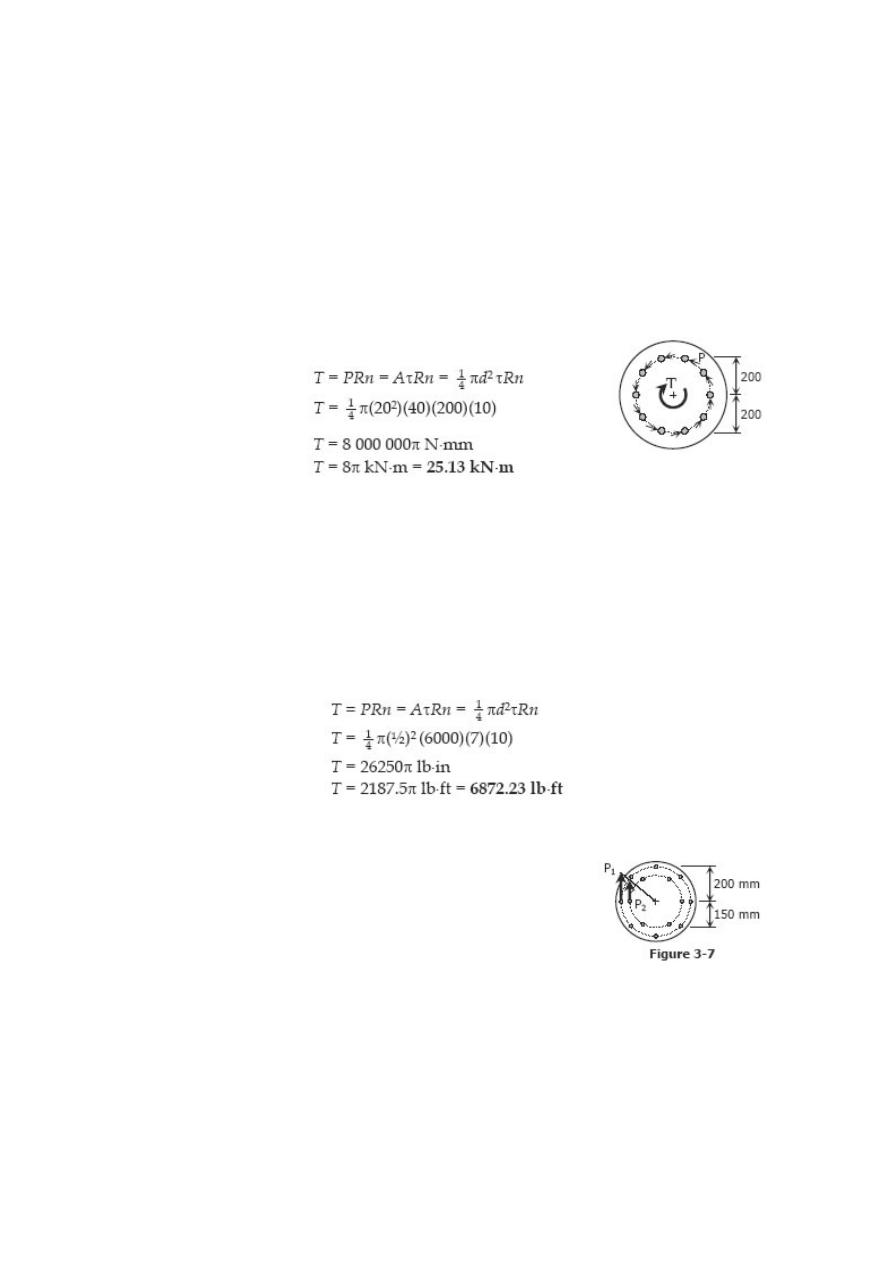

Problem 328

A flanged bolt coupling consists of eight 10-mmdiameter steel

bolts on a bolt circle 400 mm in diameter, and six 10-mm-

diameter steel bolts on a concentric bolt circle 300 mm in

diameter, as shown in Fig. 3-7. What torque can be applied

without exceeding a shearing stress of 60 MPa in the bolts?

Solution 328

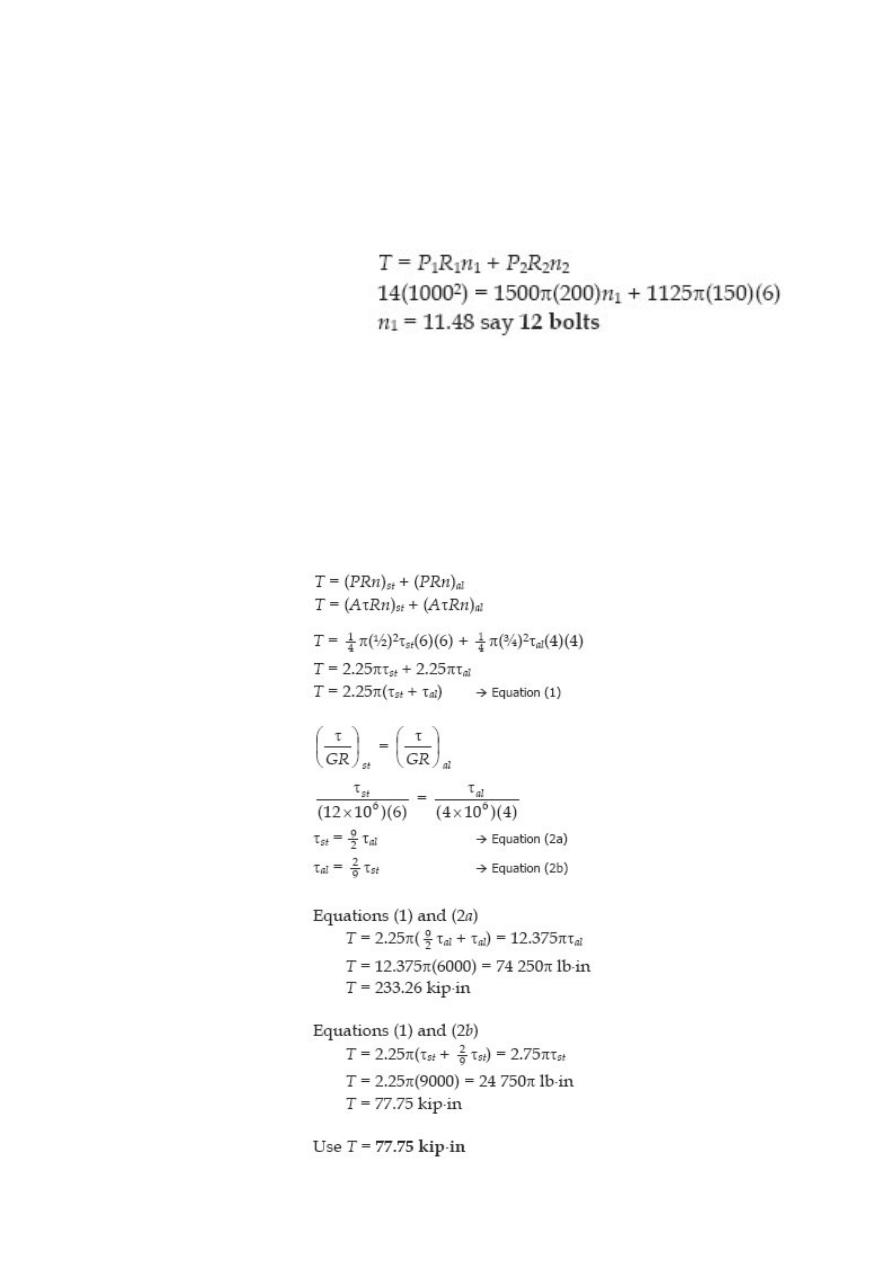

Problem 329

A torque of 700 lb-ft is to be carried by a flanged bolt coupling that consists of eight ½ -

in.-diameter steel bolts on a circle of diameter 12 in. and six ½ -in.-diameter steel bolts

on a circle of diameter 9 in. Determine the shearing stress in the bolts.

Solution 329

Problem 330

Determine the number of 10-mm-diameter steel bolts that must be used on the 400-

mm bolt circle of the coupling described in Prob. 328 to increase the torque capacity to

14 kN·m

Solution 330

Problem 331

A flanged bolt coupling consists of six ½ -in. steel bolts evenly spaced around a bolt

circle 12 in. in diameter, and four ¾ -in. aluminum bolts on a concentric bolt circle 8 in.

in diameter. What torque can be applied without exceeding 9000 psi in the steel or

6000 psi in the aluminum? Assume G

st

= 12 × 10

6

psi and G

al

= 4 × 10

6

psi.

Solution 331

Problem 332

In a rivet group subjected to a twisting couple T, show that the torsion formula τ = Tρ/J

can be used to find the shearing stress t at the center of any rivet. Let J = ΣAρ

2

, where

A is the area of a rivet at the radial distance ρ from the centroid of the rivet group.

Solution 332

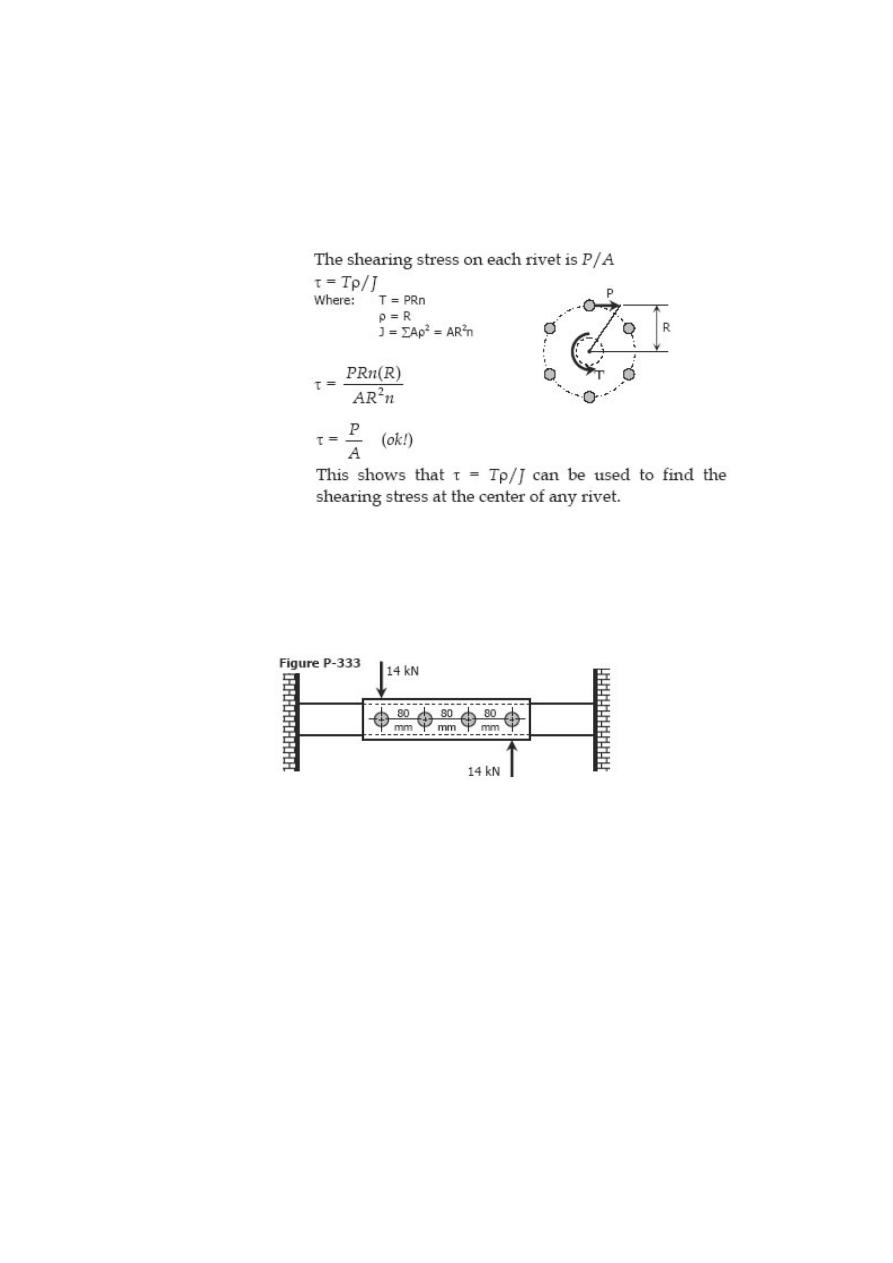

Problem 333

A plate is fastened to a fixed member by four 20-mm diameter rivets arranged as

shown in Fig. P-333. Compute the maximum and minimum shearing stress developed.

Solution 333

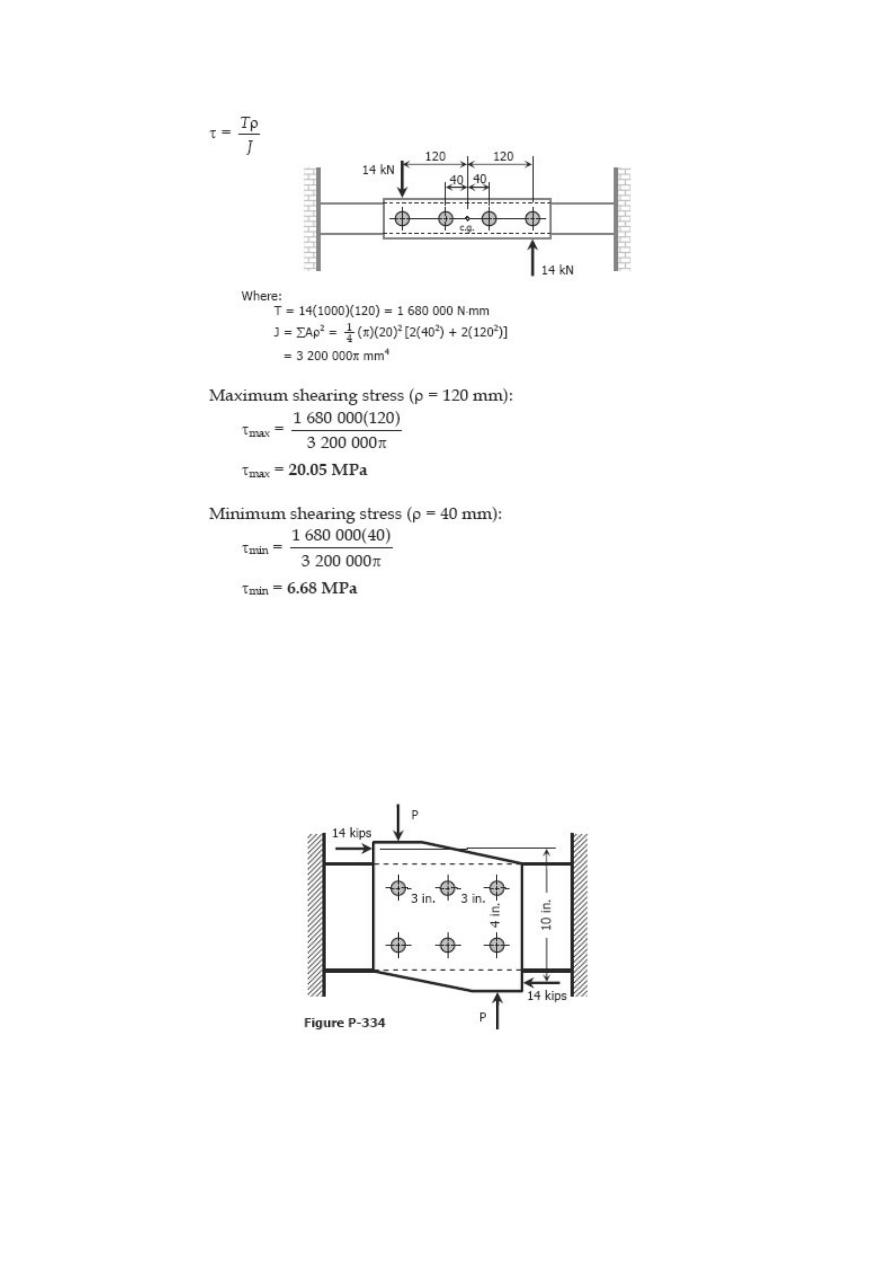

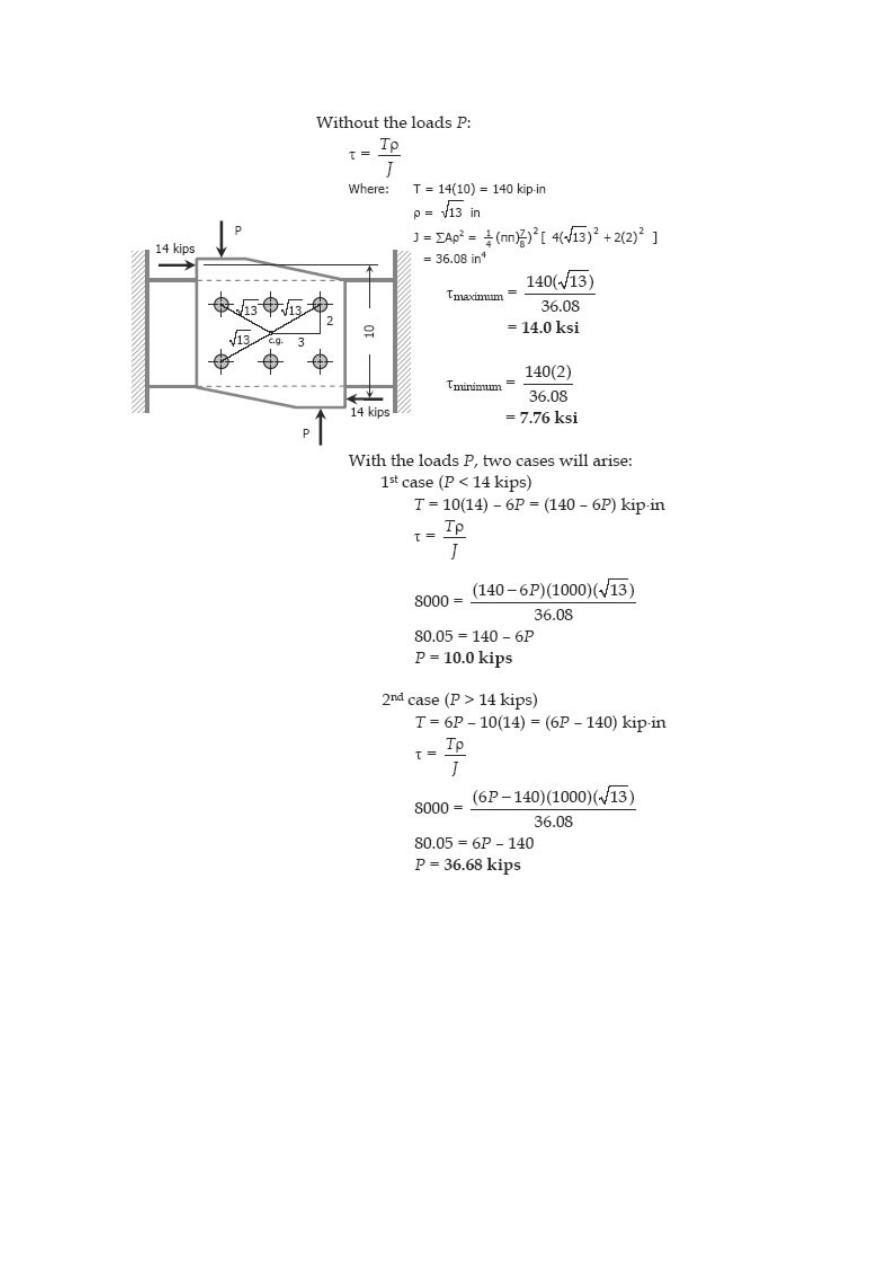

Problem 334

Six 7/8-in-diameter rivets fasten the plate in Fig. P-334 to the fixed member. Using the

results of Prob. 332, determine the average shearing stress caused in each rivet by the

14 kip loads. What additional loads P can be applied before the shearing stress in any

rivet exceeds 8000 psi?

Solution 334

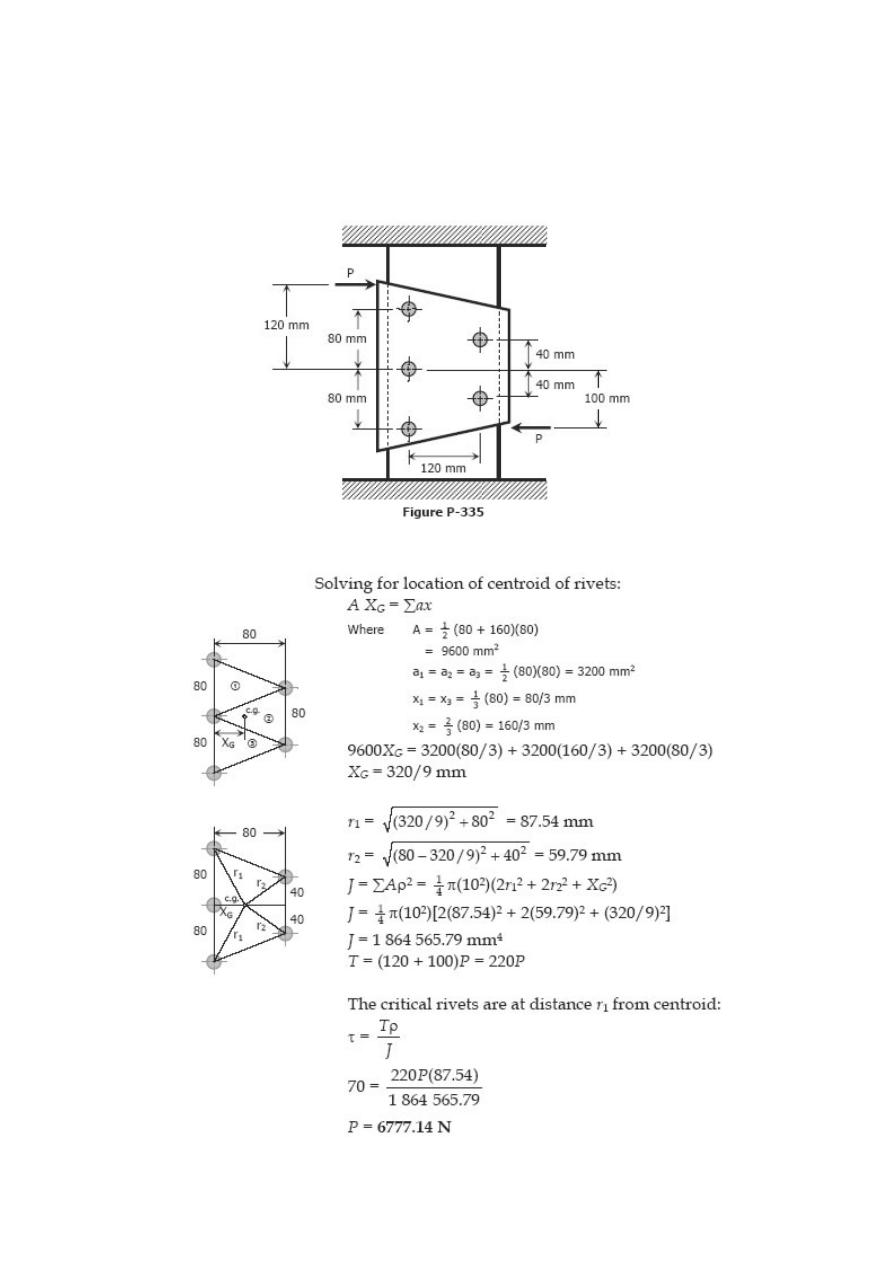

Problem 335

The plate shown in Fig. P-335 is fastened to the fixed member by five 10-mm-diameter

rivets. Compute the value of the loads P so that the average shearing stress in any rivet

does not exceed 70 MPa. (Hint: Use the results of Prob. 332.)

Solution 335

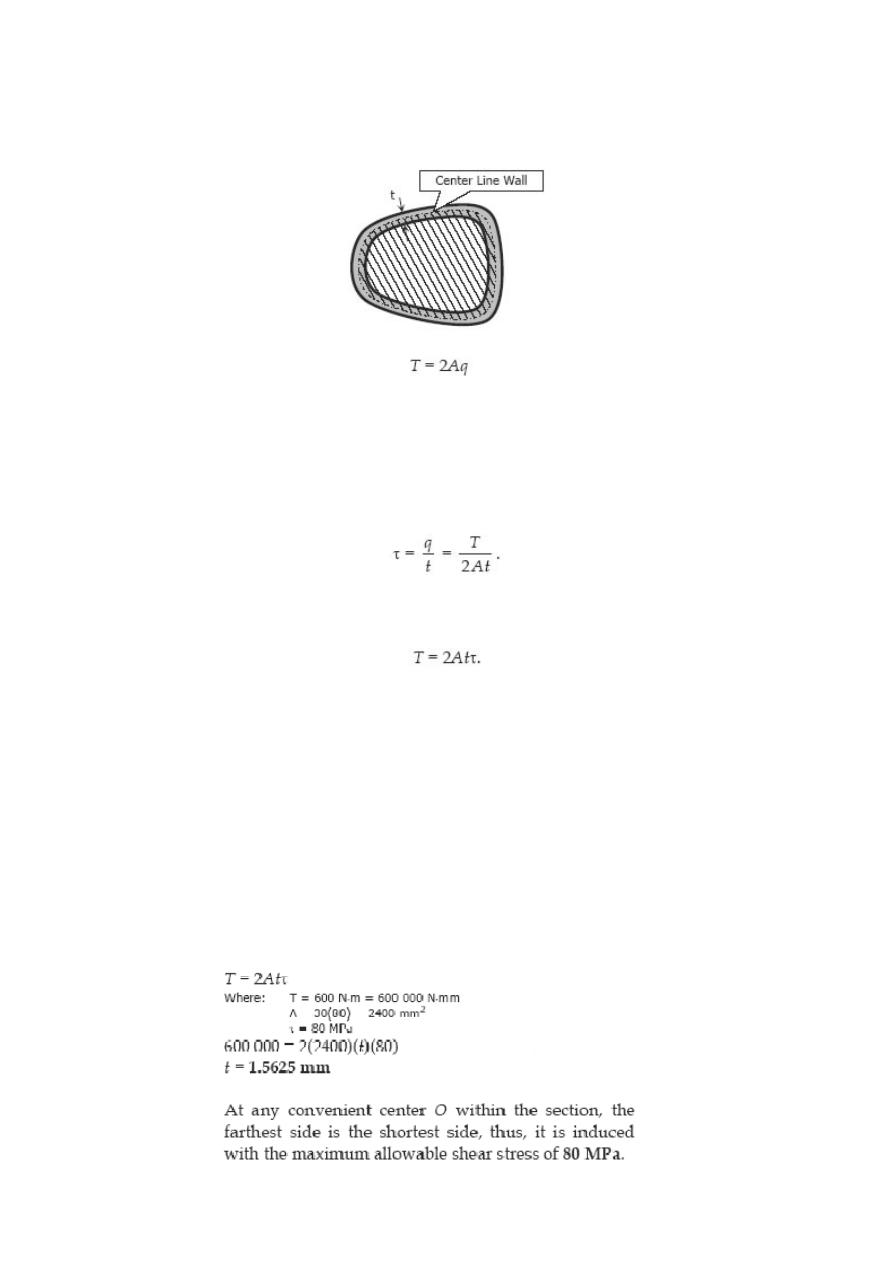

Torsion of Thin-Walled Tubes

The torque applied to thin-walled tubes is expressed as

where T is the torque in N·mm, A is the area enclosed by the centerline of the tube (as

shown in the stripefilled portion) in mm

2

, and q is the shear flow in N/mm.

The average shearing stress across any thickness t is

Thus, torque T ca also be expressed as

Solved Problems in Torsion of Thin-Walled Tubes

Problem 337

A torque of 600 N·m is applied to the rectangular section shown in Fig. P-337.

Determine the wall thickness t so as not to exceed a shear stress of 80 MPa. What is the

shear stress in the short sides? Neglect stress concentration at the corners.

Solution 337

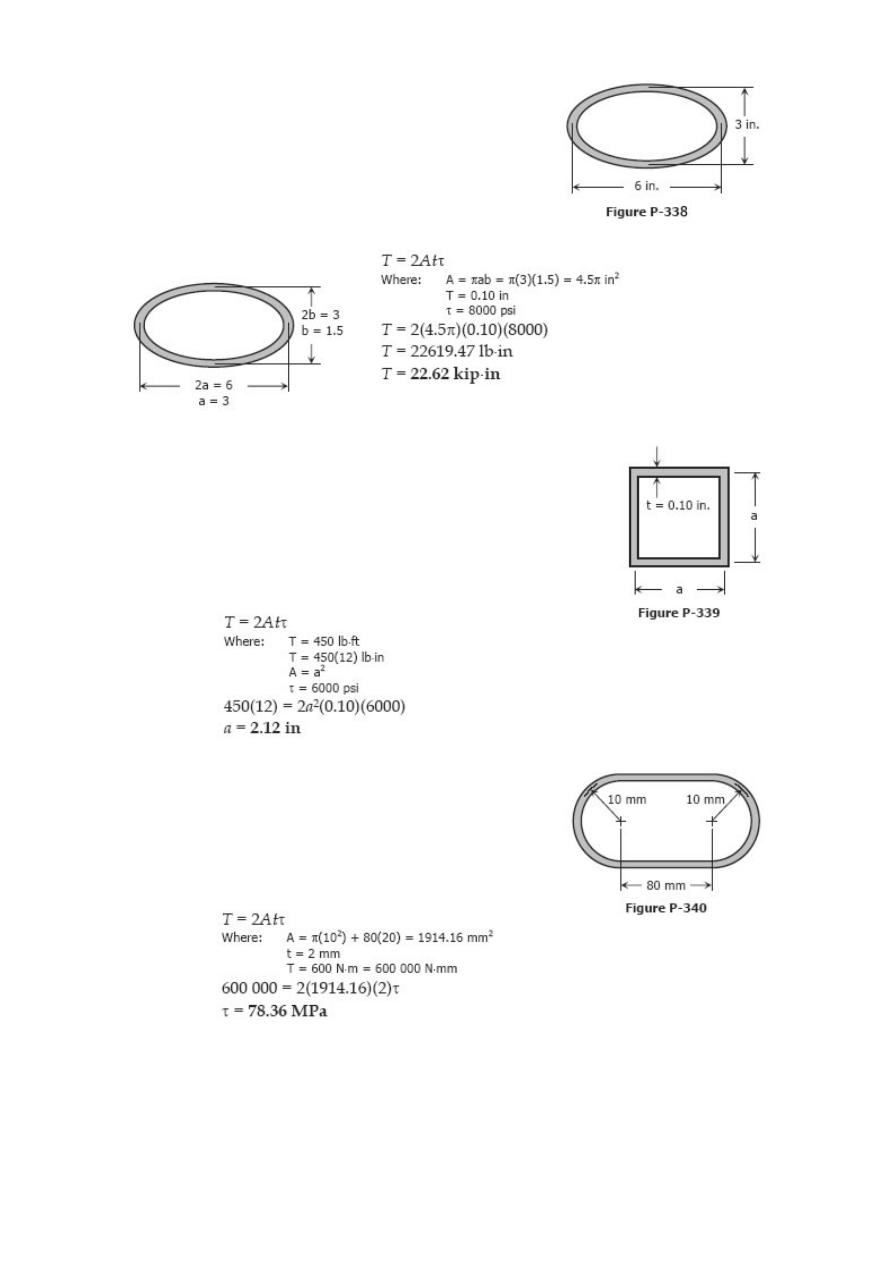

Problem 338

A tube 0.10 in. thick has an elliptical shape shown in Fig.

P-338. What torque will cause a shearing stress of 8000

psi?

Solution 338

Problem 339

A torque of 450 lb·ft is applied to the square section shown in Fi

P-339. Determine the smallest permissi

g.

ble dimension a if the

shearing stress is limited to 6000 psi.

Solution 339

Problem 340

A tube 2 mm thick has the shape shown in Fig. P-340. Find

the shearing stress caused by a torque of 600 N·m.

Solution 340

Problem 341

Derive the torsion formula τ = Tρ/J for a solid circular section by assuming the section is

composed of a series of concentric thin circular tubes. Assume that the shearing stress

at any point is proportional to its radial distance.

Solution 341

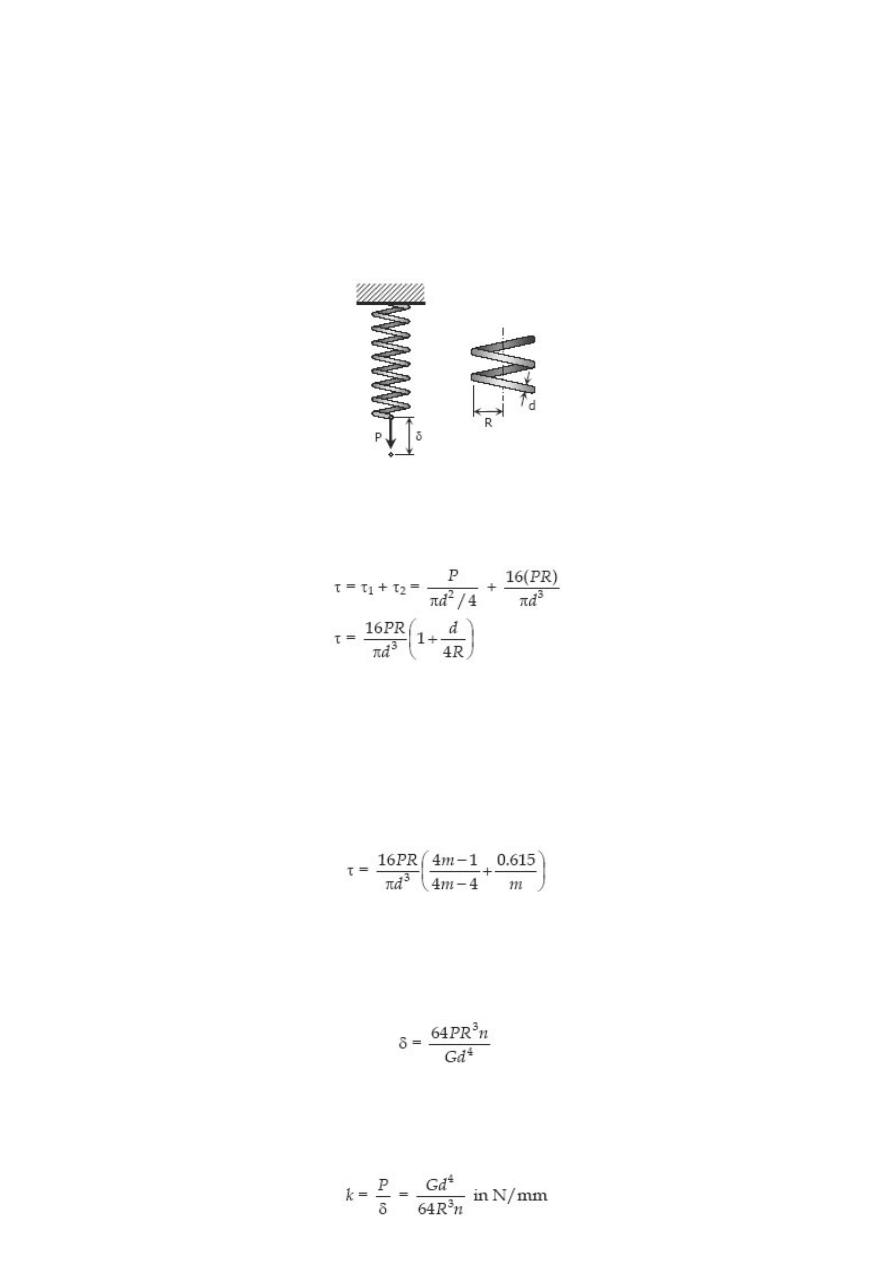

Helical Springs

When close-coiled helical spring, composed of a wire of round rod of diameter d wound

into a helix of mean radius R with n number of turns, is subjected to an axial load P

produces the following stresses and elongation:

The maximum shearing stress is the sum of the direct shearing stress τ

1

= P/A and the

torsional shearing stress τ

2

= Tr/J, with T = PR.

This formula neglects the curvature of the spring. This is used for light spring where the

ratio d/4R is small.

For heavy springs and considering the curvature of the spring, a more precise formula is

given by: (A.M.Wahl Formula)

where m is called the spring index and (4m – 1) / (4m – 4) is the Wahl Factor.

The elongation of the bar is

Notice that the deformation δ is directly proportional to the applied load P. The ratio of P

to δ is called the spring constant k and is equal to

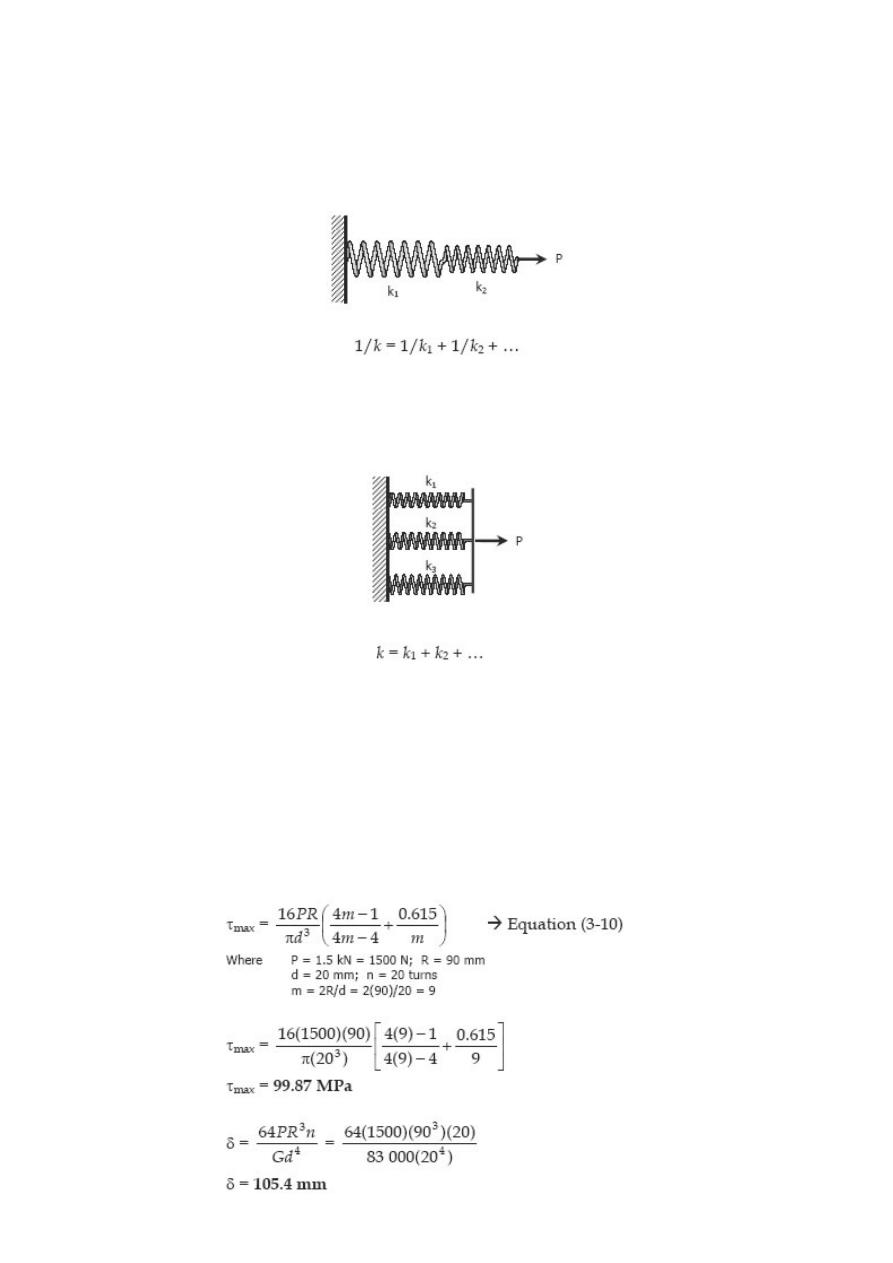

SPRINGS IN SERIES

For two or more springs with spring laid in series, the resulting spring constant k is

given by

where k

1

, k

2

,… are the spring constants for different springs.

SPRINGS IN PARALLEL

Solved Problems in Helical Springs

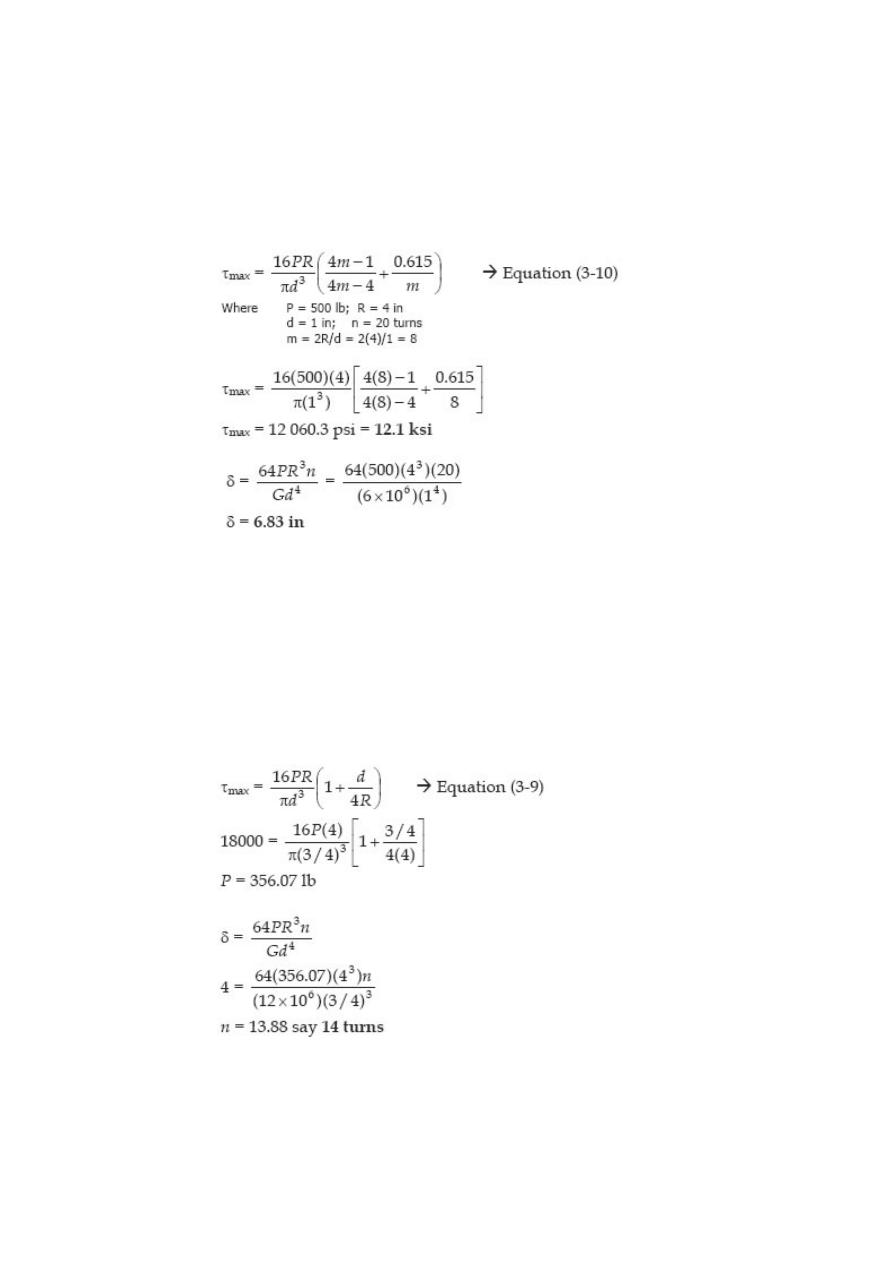

Problem 343

Determine the maximum shearing stress and elongation in a helical steel spring

composed of 20 turns of 20-mm-diameter wire on a mean radius of 90 mm when the

spring is supporting a load of 1.5 kN. Use Eq. (3-10) and G = 83 GPa.

Solution 343

Problem 344

Determine the maximum shearing stress and elongation in a bronze helical spring

composed of 20 turns of 1.0-in.-diameter wire on a mean radius of 4 in. when the

spring is supporting a load of 500 lb. Use Eq. (3-10) and G = 6 × 10

6

psi.

Solution 344

Problem 345

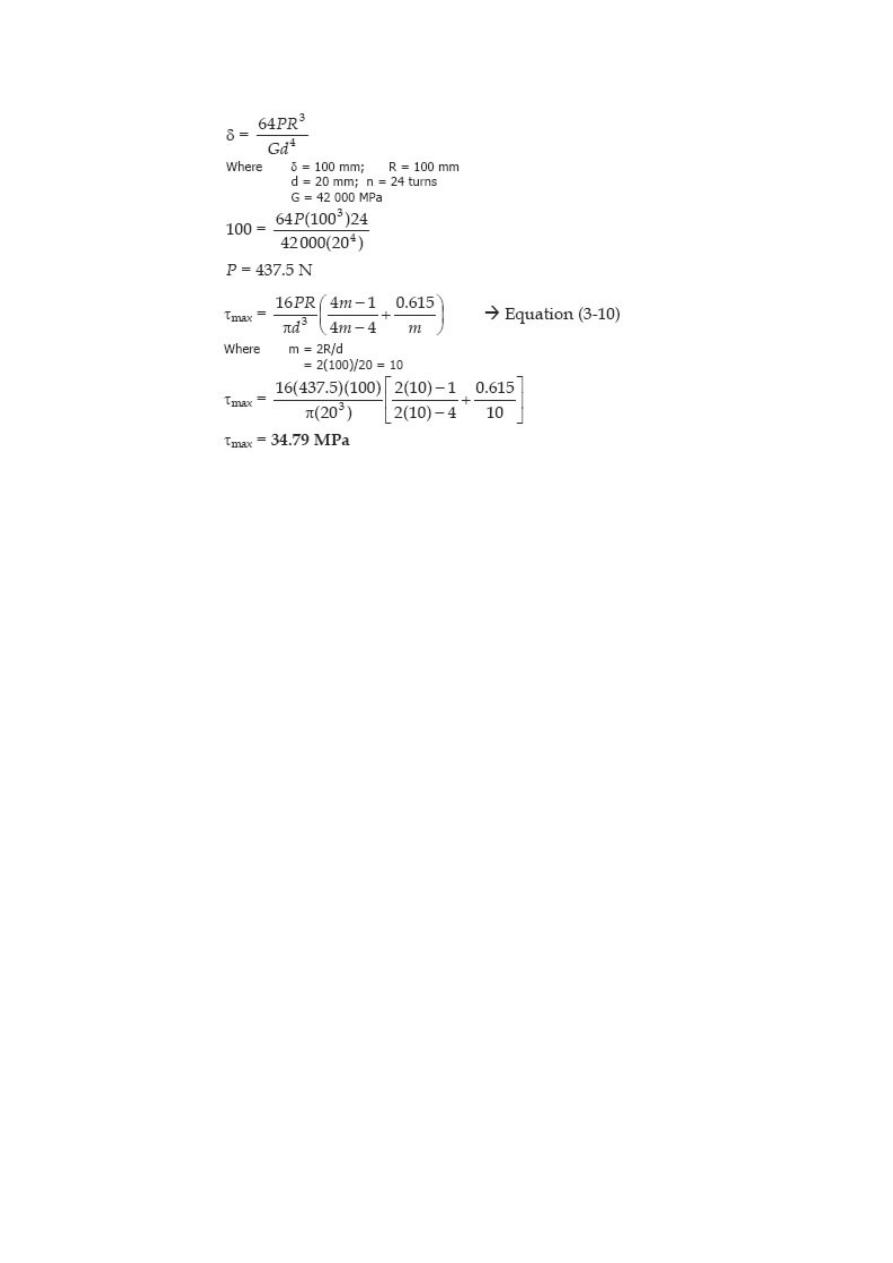

A helical spring is fabricated by wrapping wire ¾ in. in diameter around a forming

cylinder 8 in. in diameter. Compute the number of turns required to permit an

elongation of 4 in. without exceeding a shearing stress of 18 ksi. Use Eq. (3-9) and G =

12 × 106 psi.

Solution 345

Problem 346

Compute the maximum shearing stress developed in a phosphor bronze spring having

mean diameter of 200 mm and consisting of 24 turns of 200-mm-diameter wire when

the spring is stretched 100 mm. Use Eq. (3-10) and G = 42 GPa.

Solution 346

Problem 347

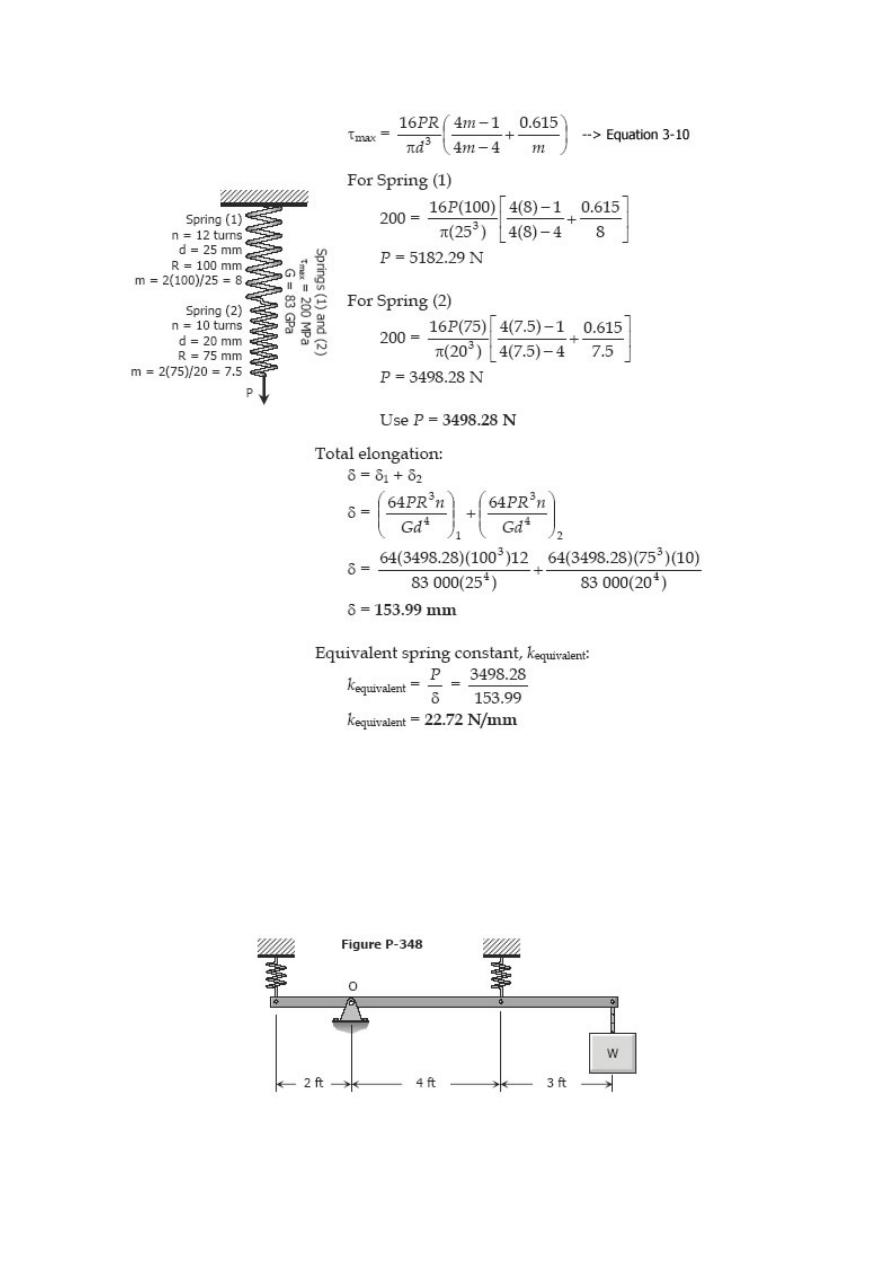

Two steel springs arranged in series as shown in Fig. P-347 supports a load P. The

upper spring has 12 turns of 25-mm-diameter wire on a mean radius of 100 mm. The

lower spring consists of 10 turns of 20-mmdiameter wire on a mean radius of 75 mm. If

the maximum shearing stress in either spring must not exceed 200 MPa, compute the

maximum value of P and the total elongation of the assembly. Use Eq. (3-10) and G =

83 GPa. Compute the equivalent spring constant by dividing the load by the total

elongation.

Solution 347

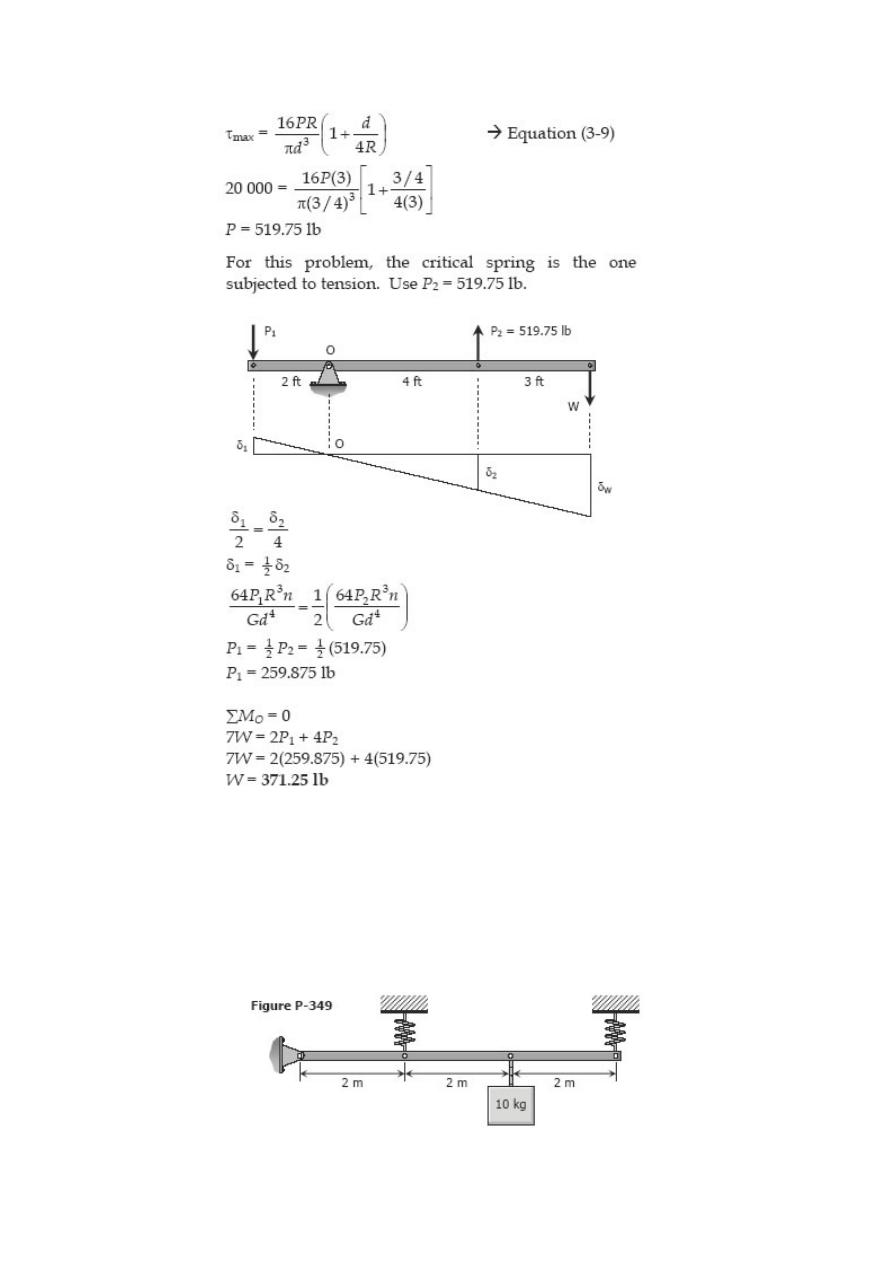

Problem 348

A rigid bar, pinned at O, is supported by two identical springs as shown in Fig. P-348.

Each spring consists of 20 turns of ¾-in-diameter wire having a mean diameter of 6 in.

Determine the maximum load W that may be supported if the shearing stress in the

springs is limited to 20 ksi. Use Eq. (3-9).

Solution 348

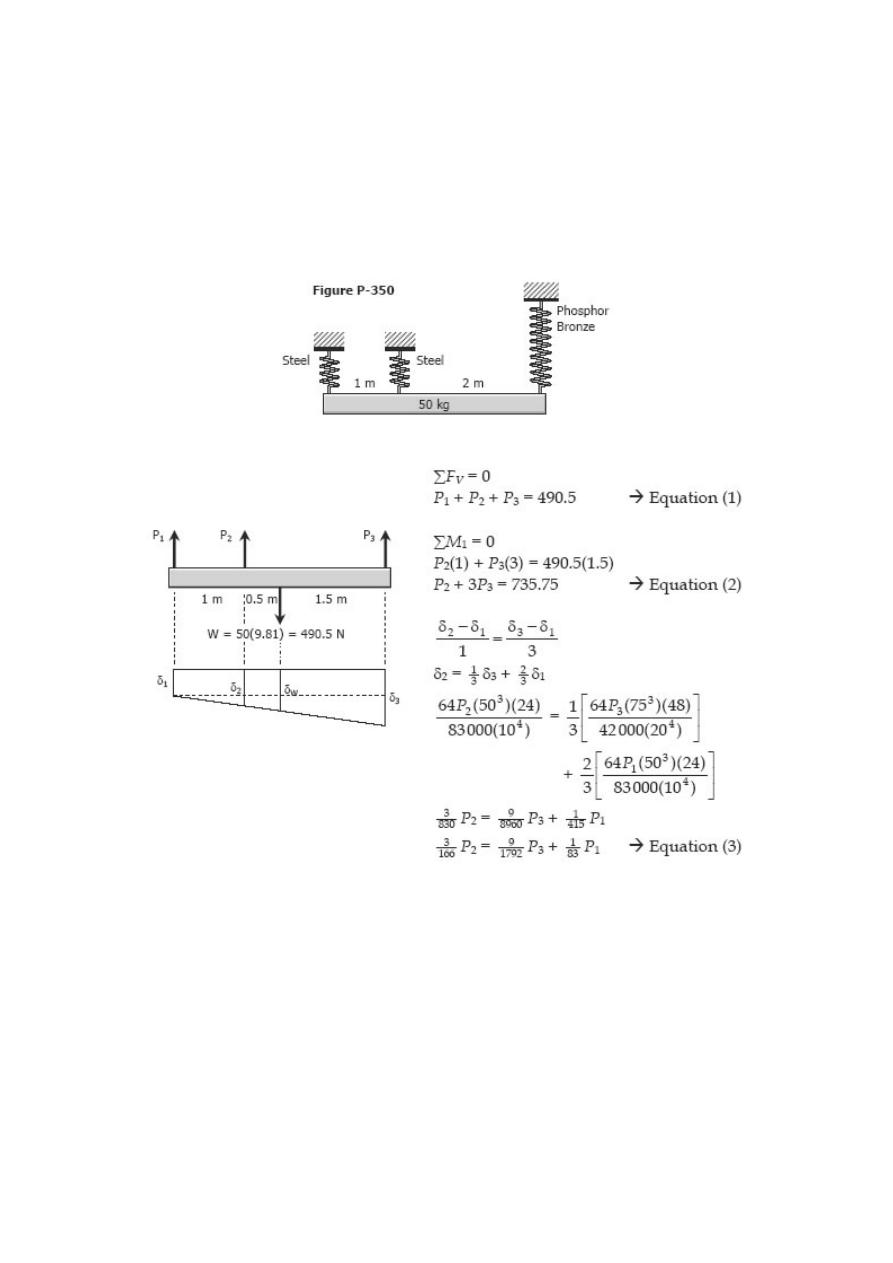

Problem 349

A rigid bar, hinged at one end, is supported by two identical springs as shown in Fig. P-

349. Each spring consists of 20 turns of 10-mm wire having a mean diameter of 150

mm. Compute the maximum shearing stress in the springs, using Eq. (3-9). Neglect the

mass of the rigid bar.

Solution 349

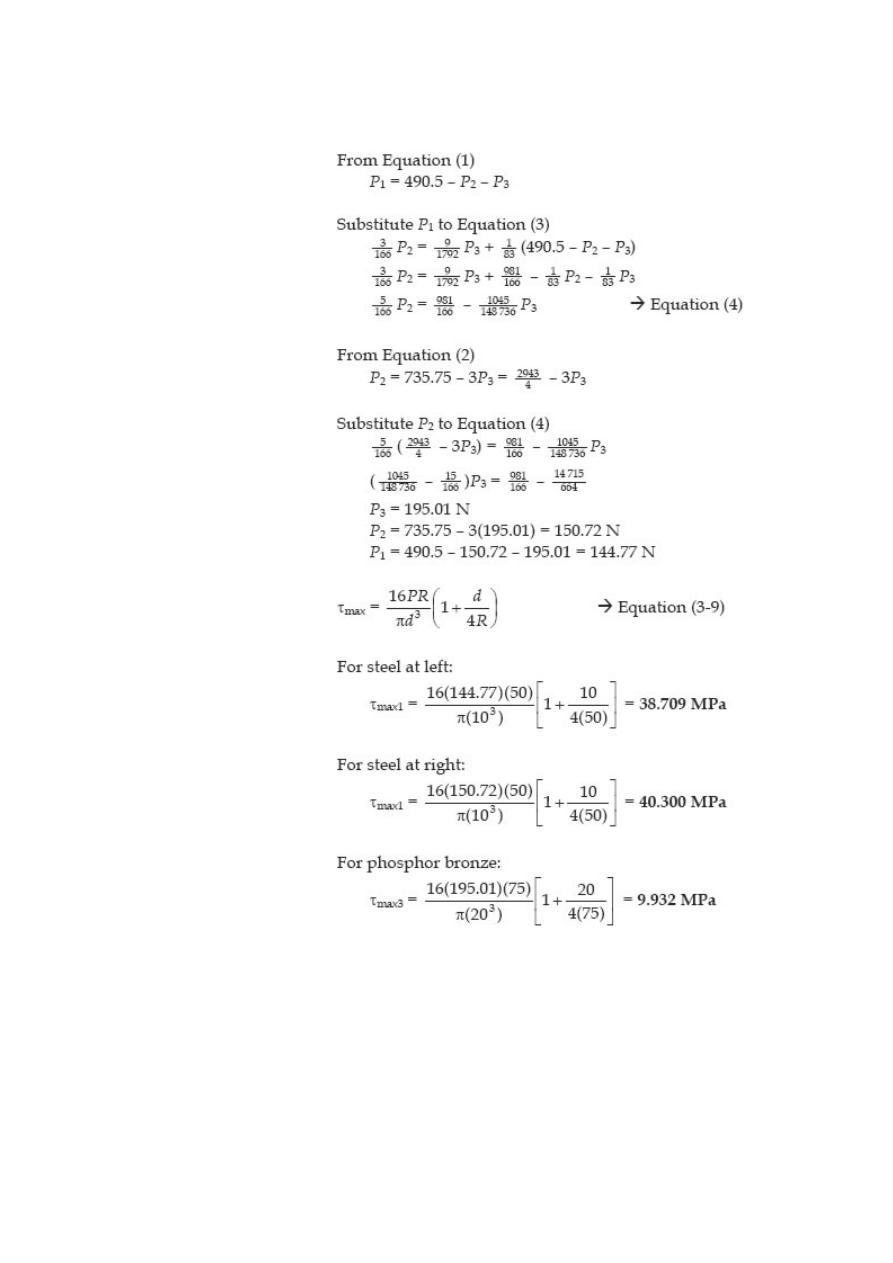

Problem 350

As shown in Fig. P-350, a homogeneous 50-kg rigid block is suspended by the three

springs whose lower ends were originally at the same level. Each steel spring has 24

turns of 10-mm-diameter on a mean diameter of 100 mm, and G = 83 GPa. The bronze

spring has 48 turns of 20-mm-diameter wire on a mean diameter of 150 mm, and G =

42 GPa. Compute the maximum shearing stress in each spring using Eq. (3-9).

Solution 350

Shear & Moment in Beams

DEFINITION OF A BEAM

A beam is a bar subject to forces or couples that lie in a plane containing the

longitudinal of the bar. According to determinacy, a beam may be determinate or

indeterminate.

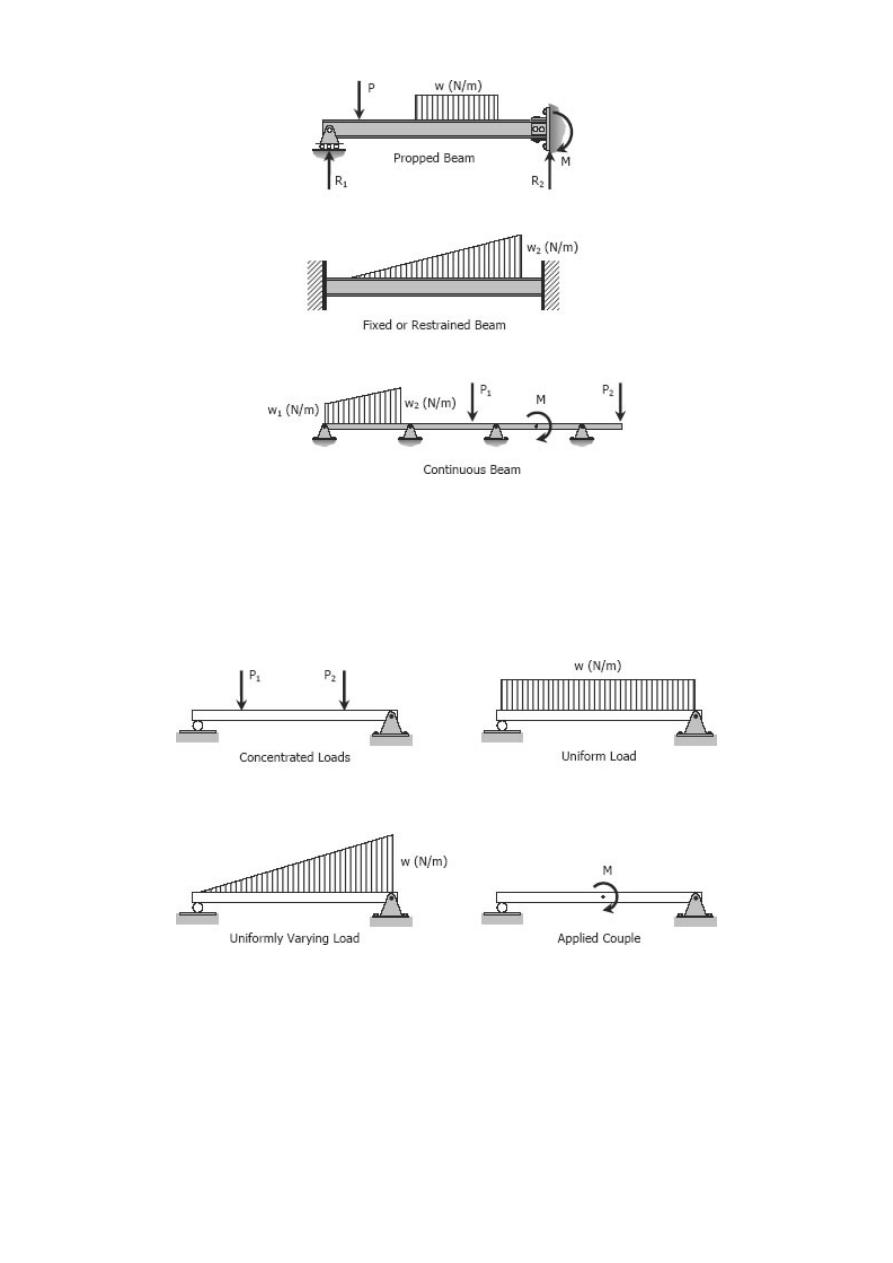

STATICALLY DETERMINATE BEAMS

Statically determinate beams are those beams in which the reactions of the supports

may be determined by the use of the equations of static equilibrium. The beams shown

below are examples of statically determinate beams.

STATICALLY INDETERMINATE BEAMS

If the number of reactions exerted upon a beam exceeds the number of equations in

static equilibrium, the beam is said to be statically indeterminate. In order to solve the

reactions of the beam, the static equations must be supplemented by equations based

upon the elastic deformations of the beam.

The degree of indeterminacy is taken as the difference between the umber of reactions

to the number of equations in static equilibrium that can be applied. In the case of the

propped beam shown, there are three reactions R

1

, R

2

, and M and only two equations

(∑M = 0 and sum;F

v

= 0) can be applied, thus the beam is indeterminate to the first

degree (3 – 2 = 1).

TYPES OF LOADING

Loads applied to the beam may consist of a concentrated load (load applied at a point),

uniform load, uniformly varying load, or an applied couple or moment. These loads are

shown in the following figures.

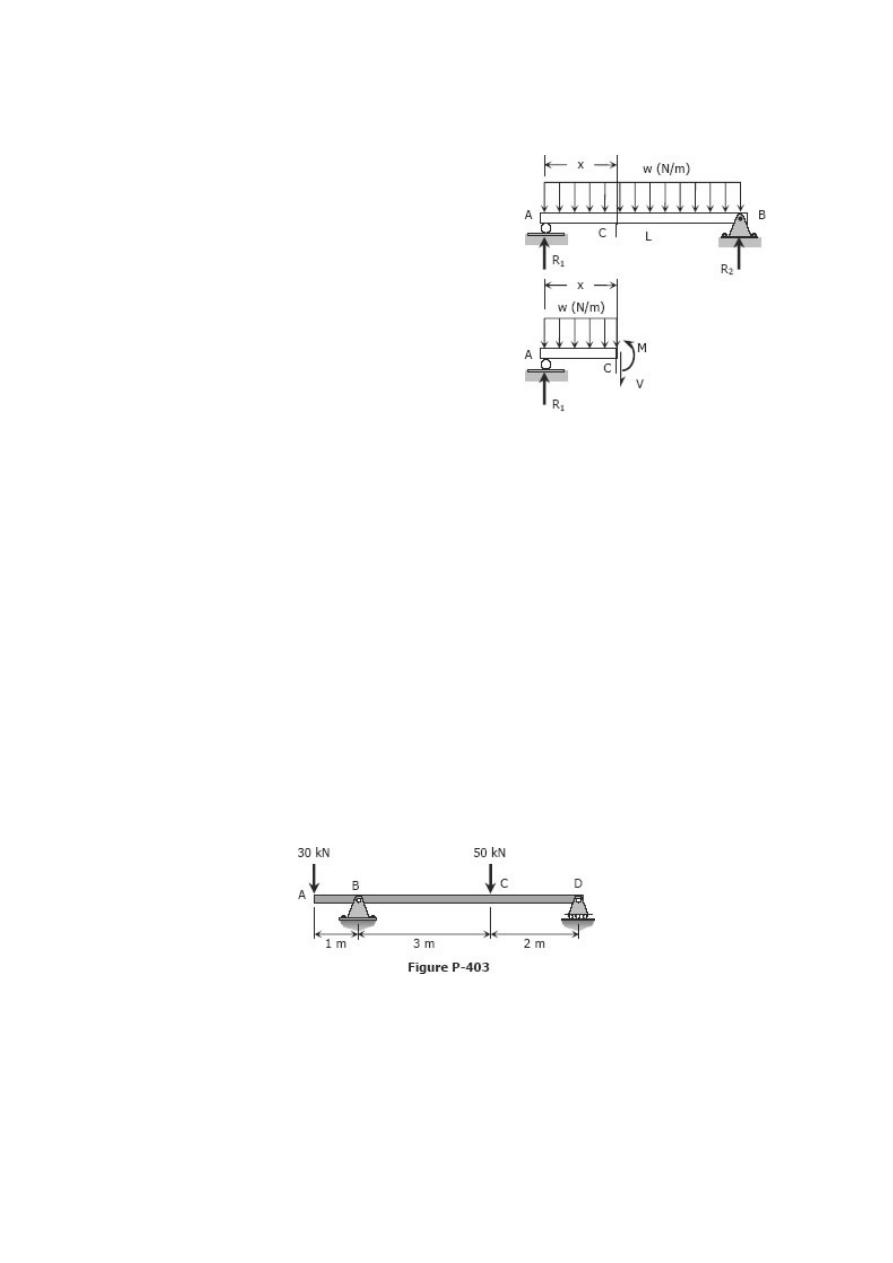

Shear and Moment Diagrams

Consider a simple beam shown of length L that

carries a uniform load of w (N/m) throughout its

length and is held in equilibrium by reactions R

1

and R

2

. Assume that the beam is cut at point

distance of x from he left support and the portion of

the beam to the right of C be removed. The portion

removed must then be replaced by vertical

shearing force V together with a couple M to hold

the left portion of the bar in equilibrium under the

action of R

1

and wx. The couple M is called the resisting moment or moment and the

force V is called the resisting shear or shear. The sign of V and M are taken to be

positive if they have the senses ind

C a

icated above.

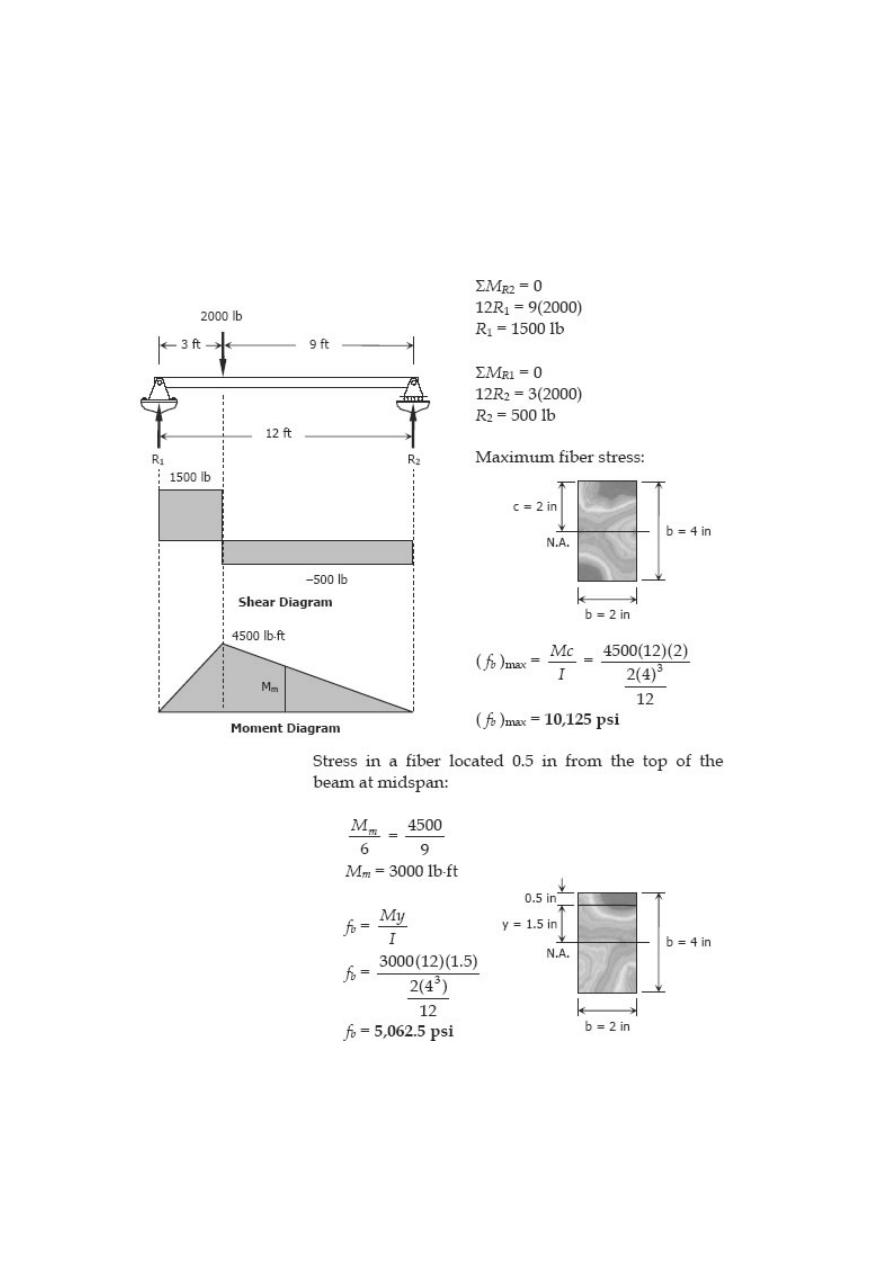

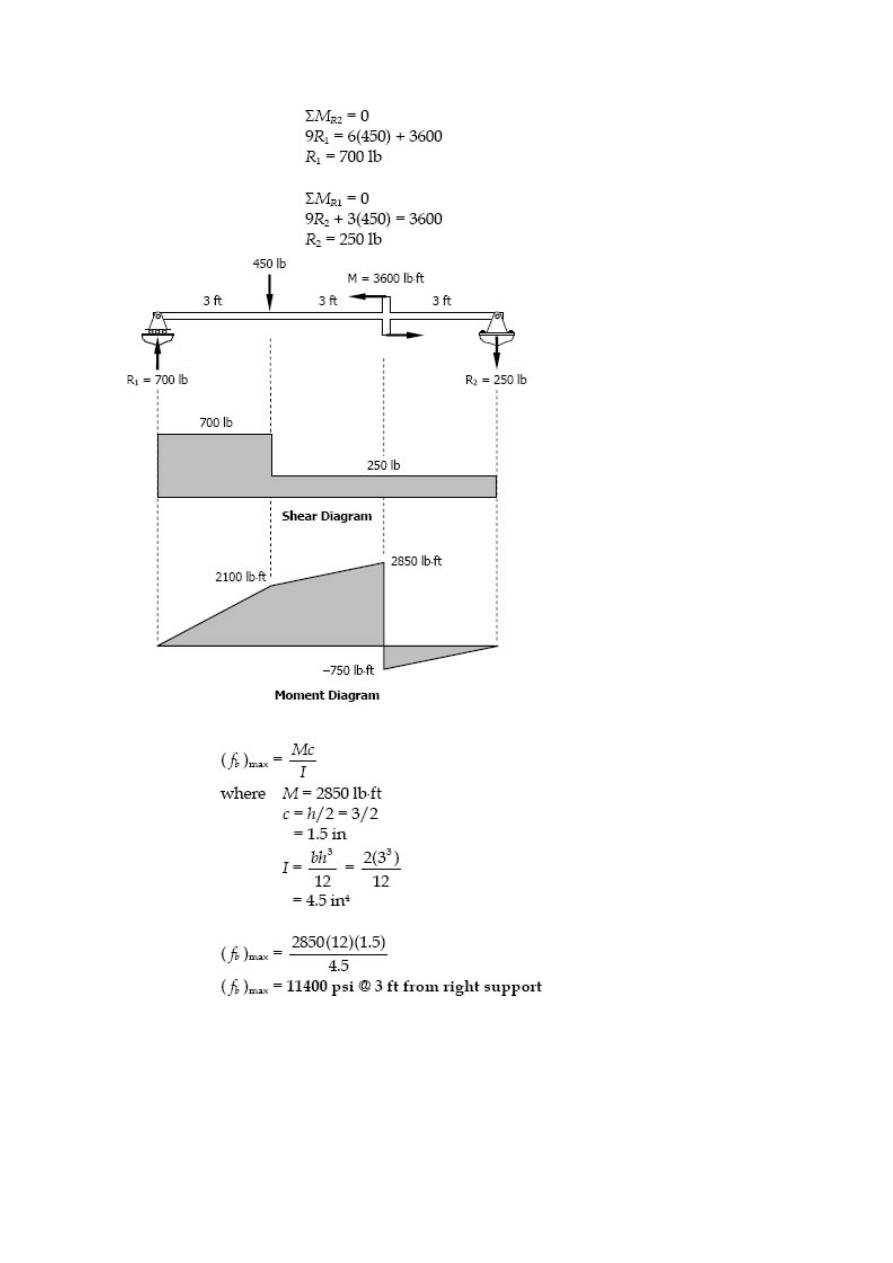

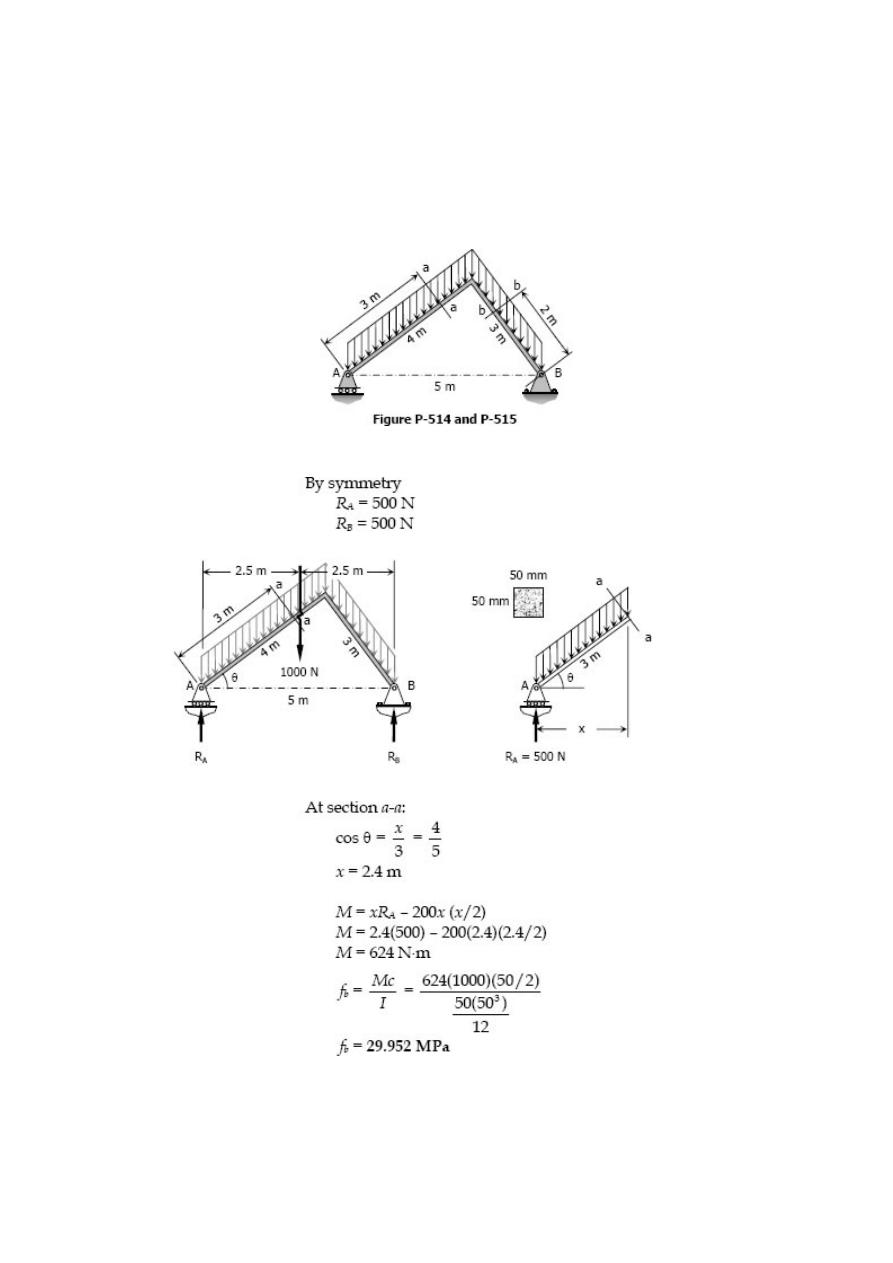

Solved Problems in Shear and Moment Diagrams

INSTRUCTION

Write shear and moment equations for the beams in the following problems. In each

problem, let x be the distance measured from left end of the beam. Also, draw shear

and moment diagrams, specifying values at all change of loading positions and at points

of zero shear. Neglect the mass of the beam in each problem.

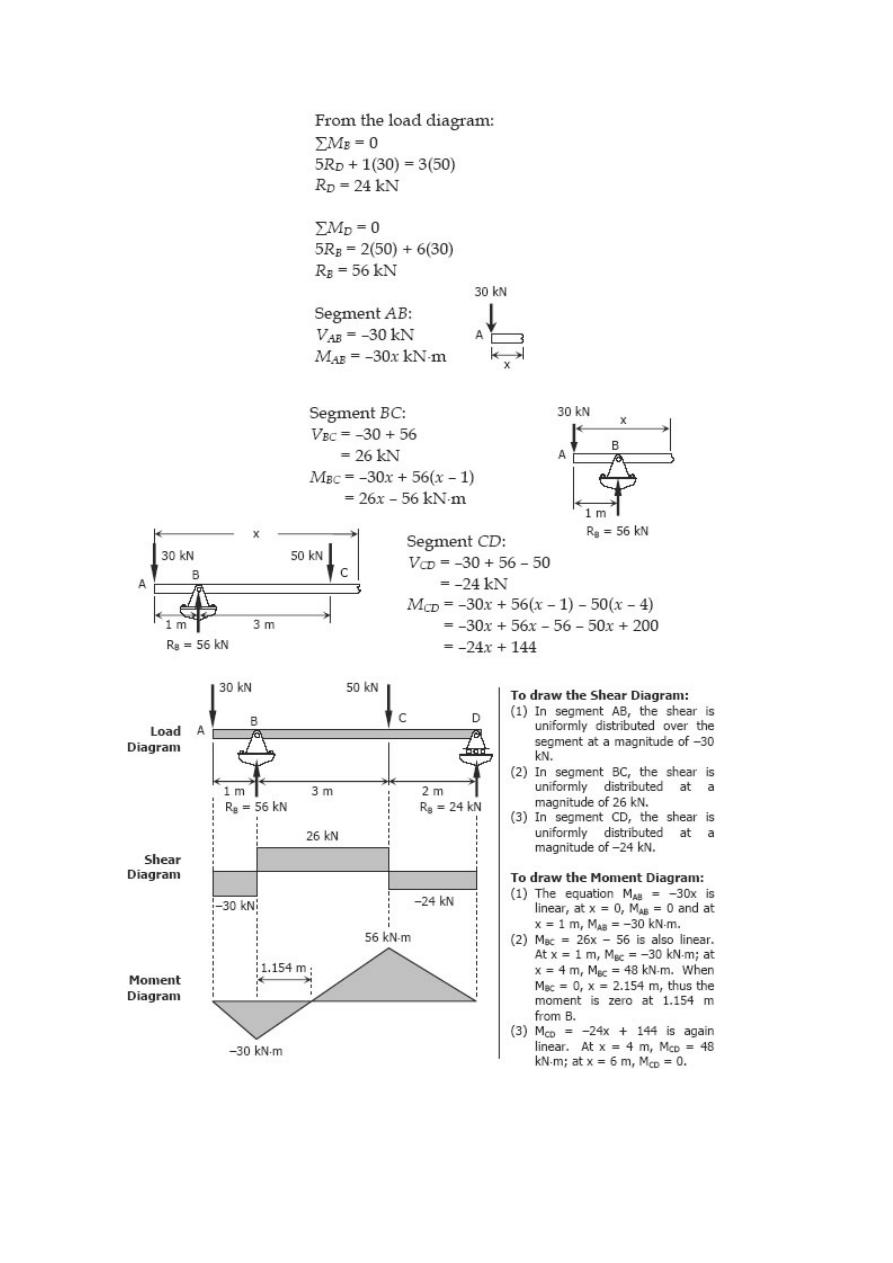

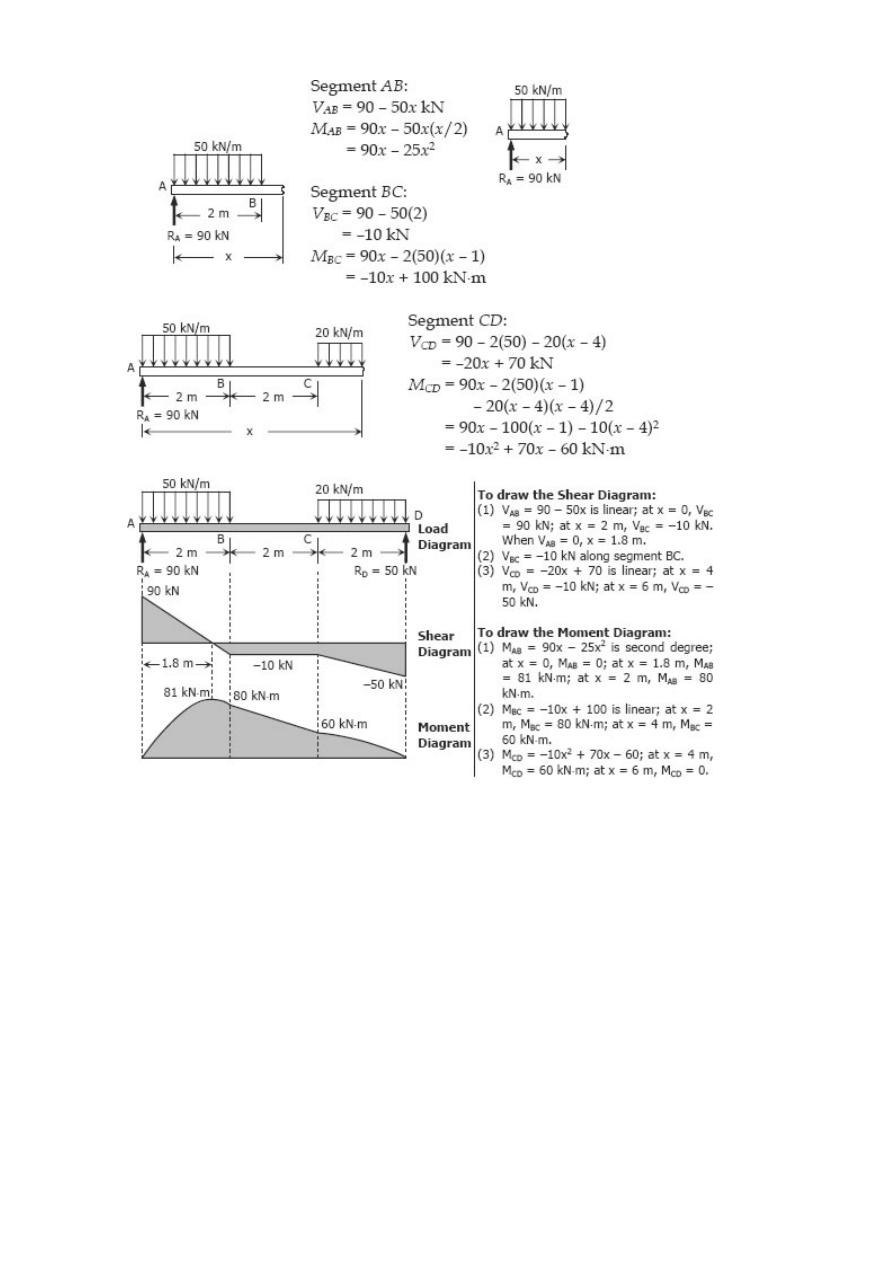

Problem 403

Beam loaded as shown in Fig. P-403.

Solution 403

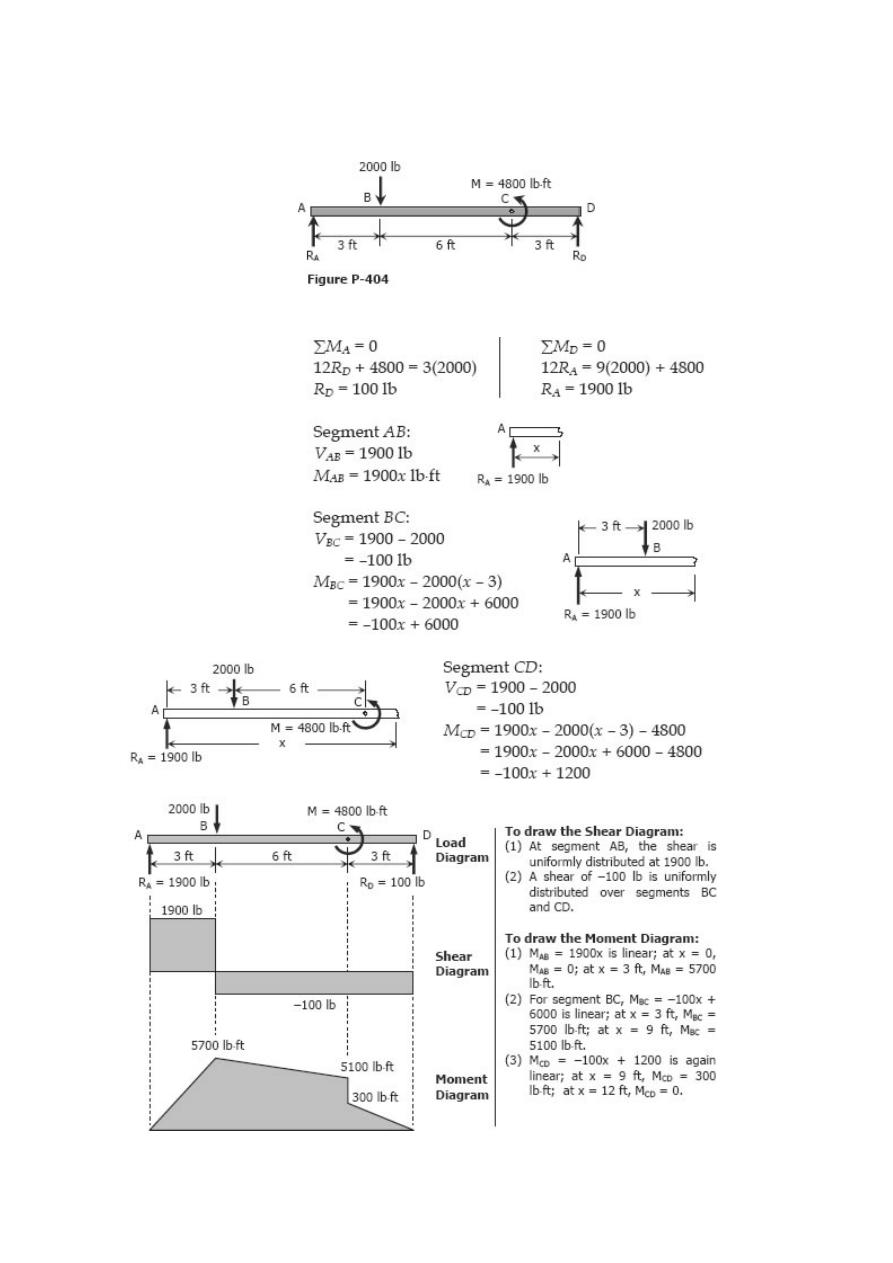

Problem 404

Beam loaded as shown in Fig. P-404.

Solution 404

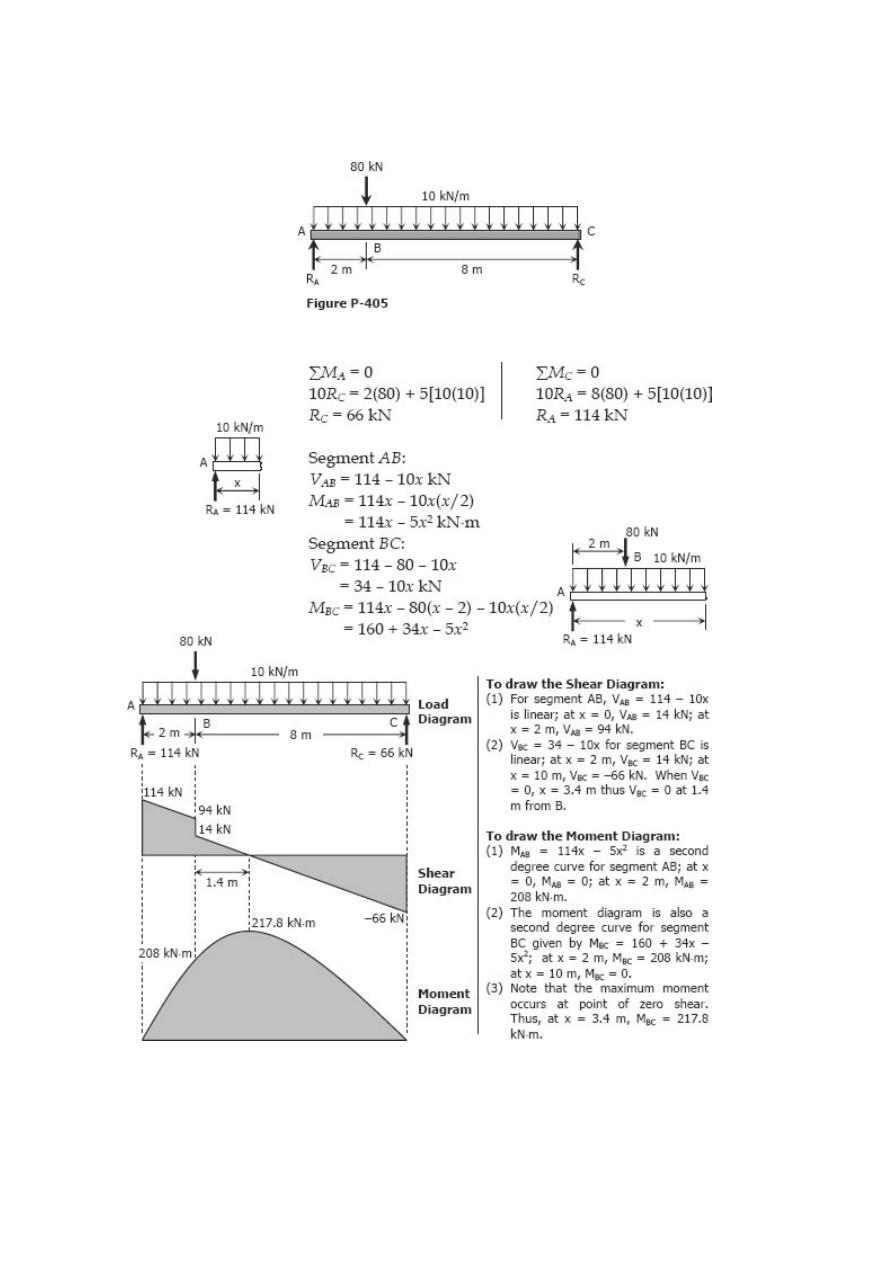

Problem 405

Beam loaded as shown in Fig. P-405.

Solution 405

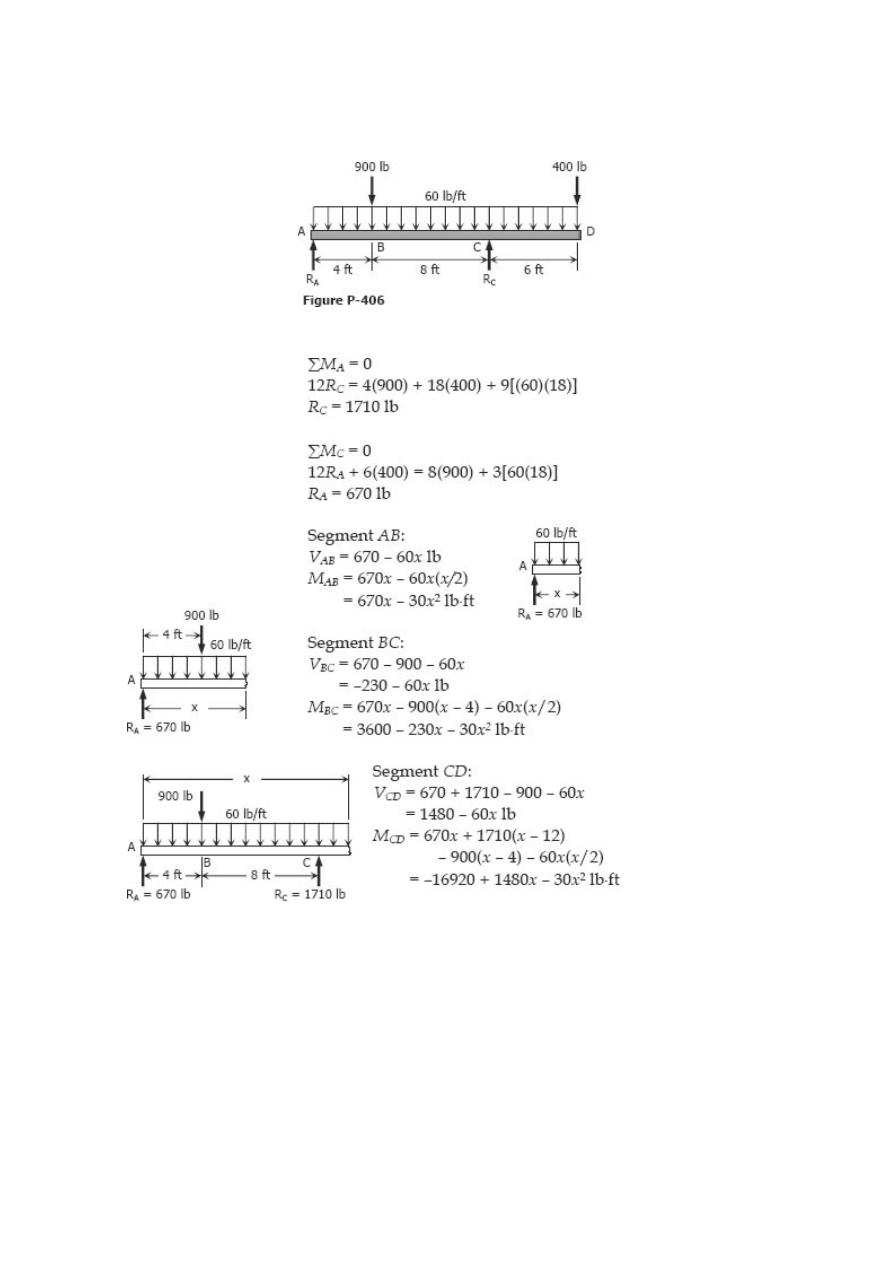

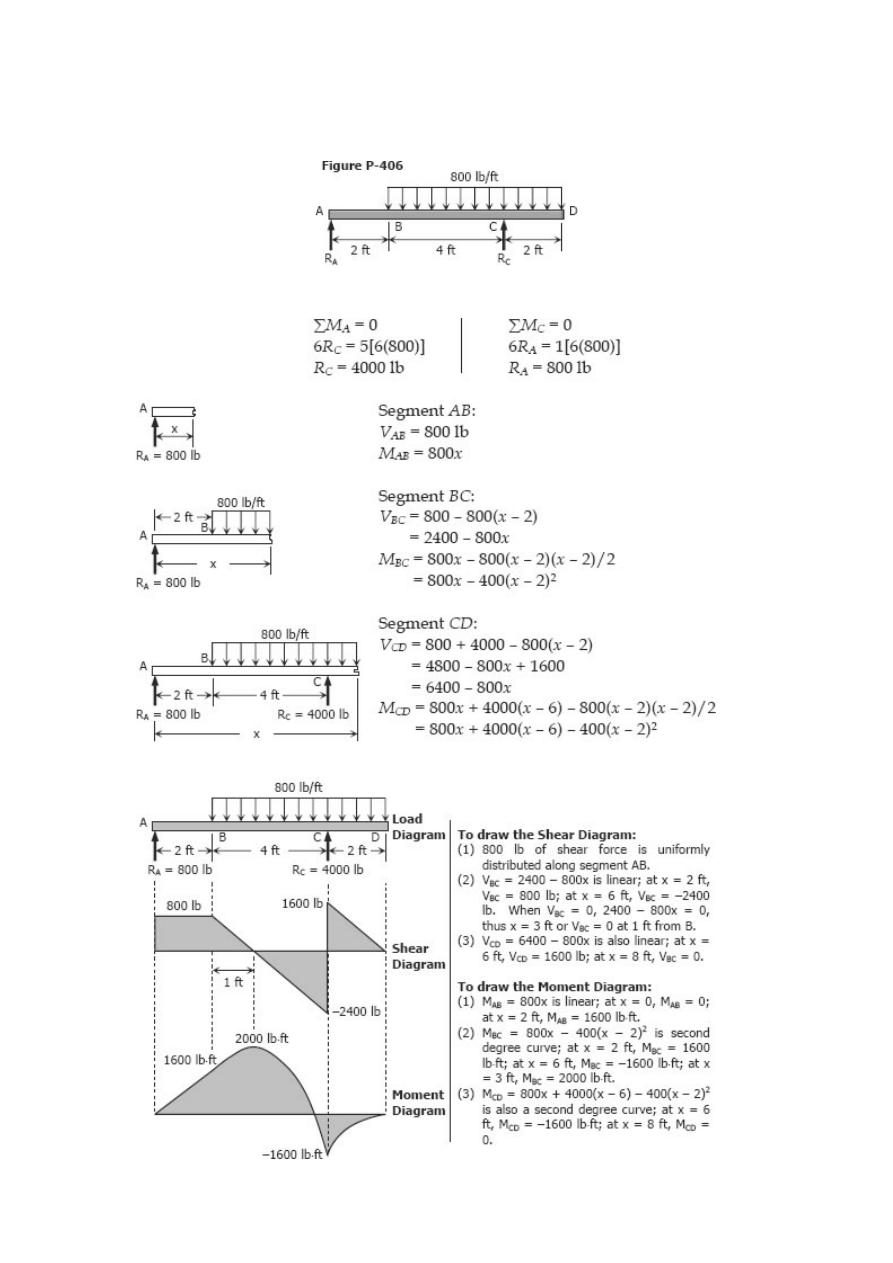

Problem 406

Beam loaded as shown in Fig. P-406.

Solution 406

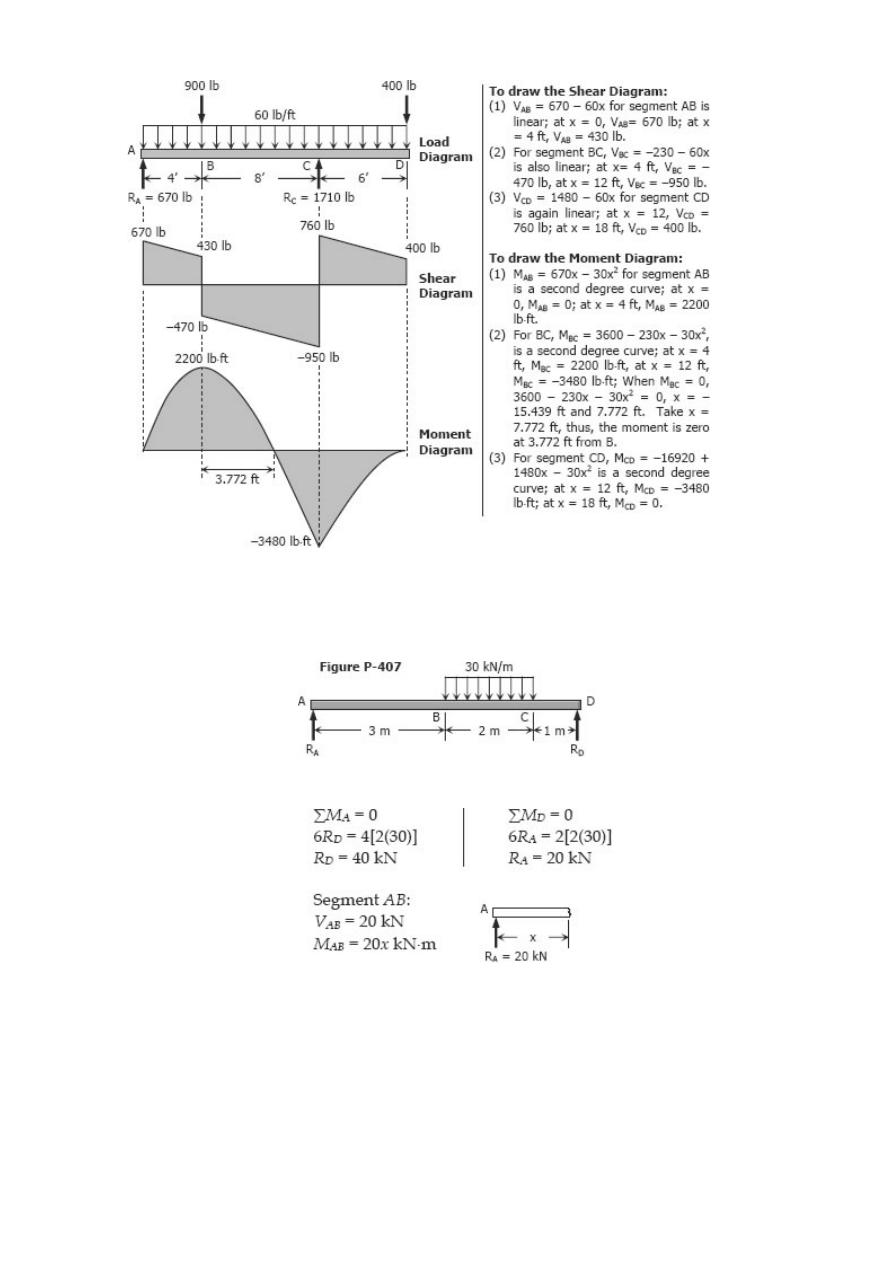

Problem 407

Beam loaded as shown in Fig. P-407.

Solution 407

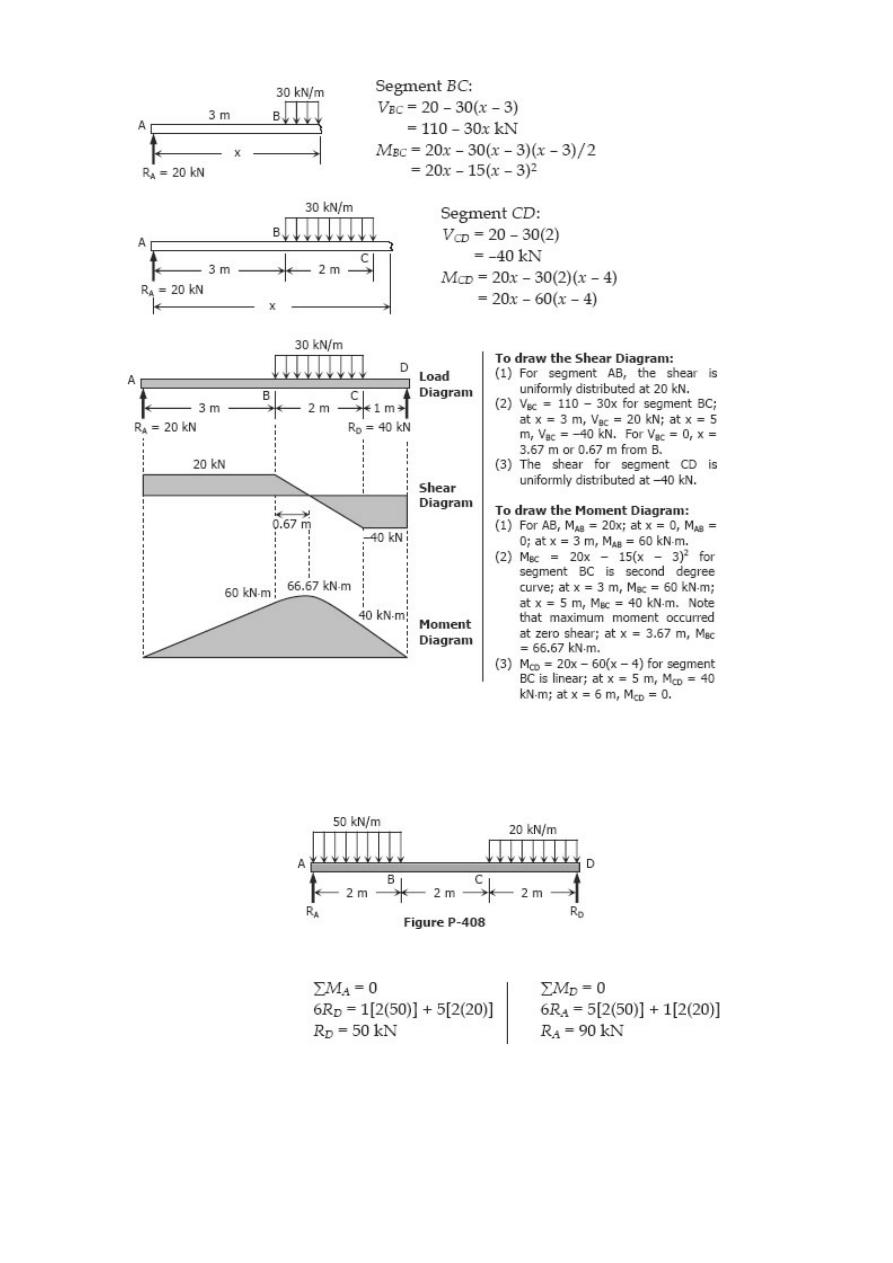

Problem 408

Beam loaded as shown in Fig. P-408.

Solution 408

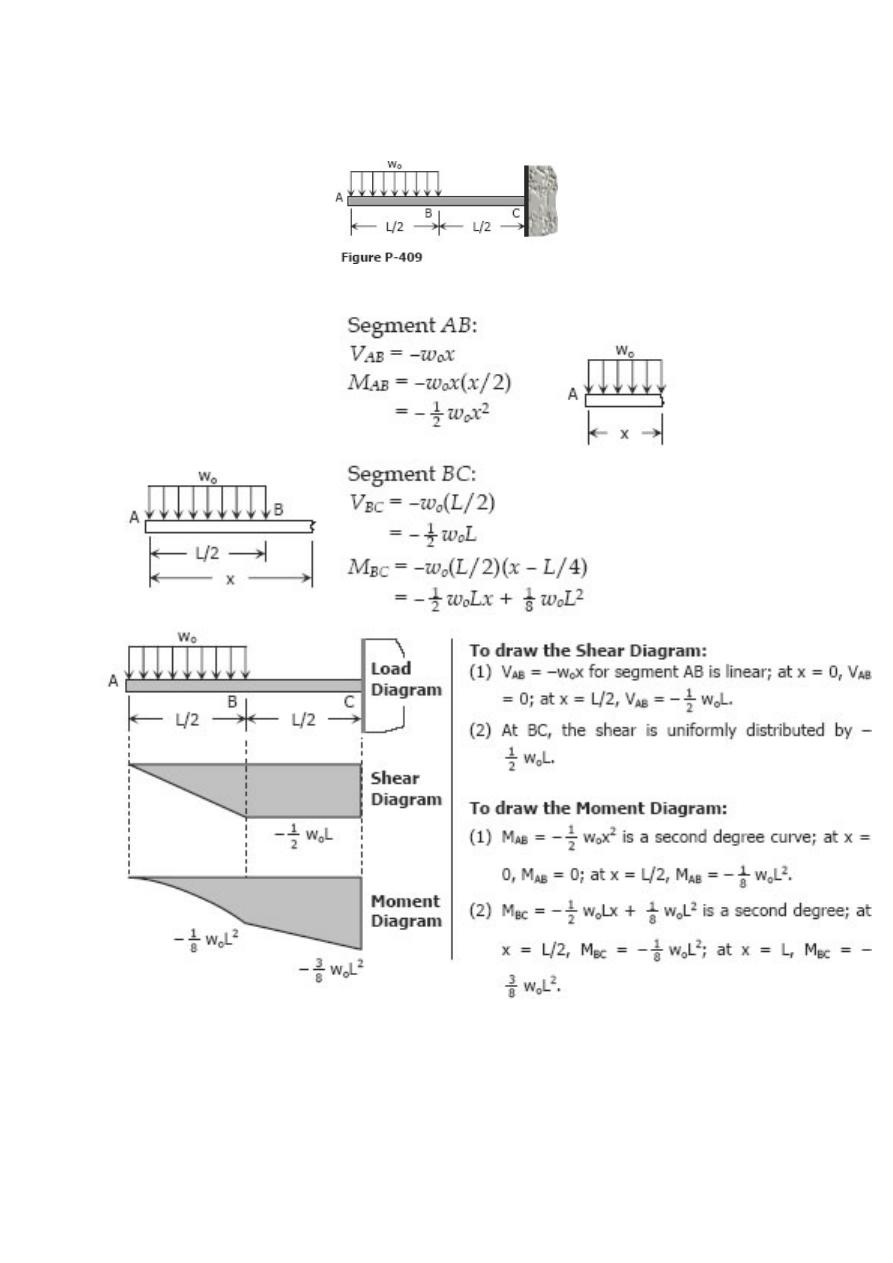

Problem 409

Cantilever beam loaded as shown in Fig. P-409.

Solution 409

Problem 410

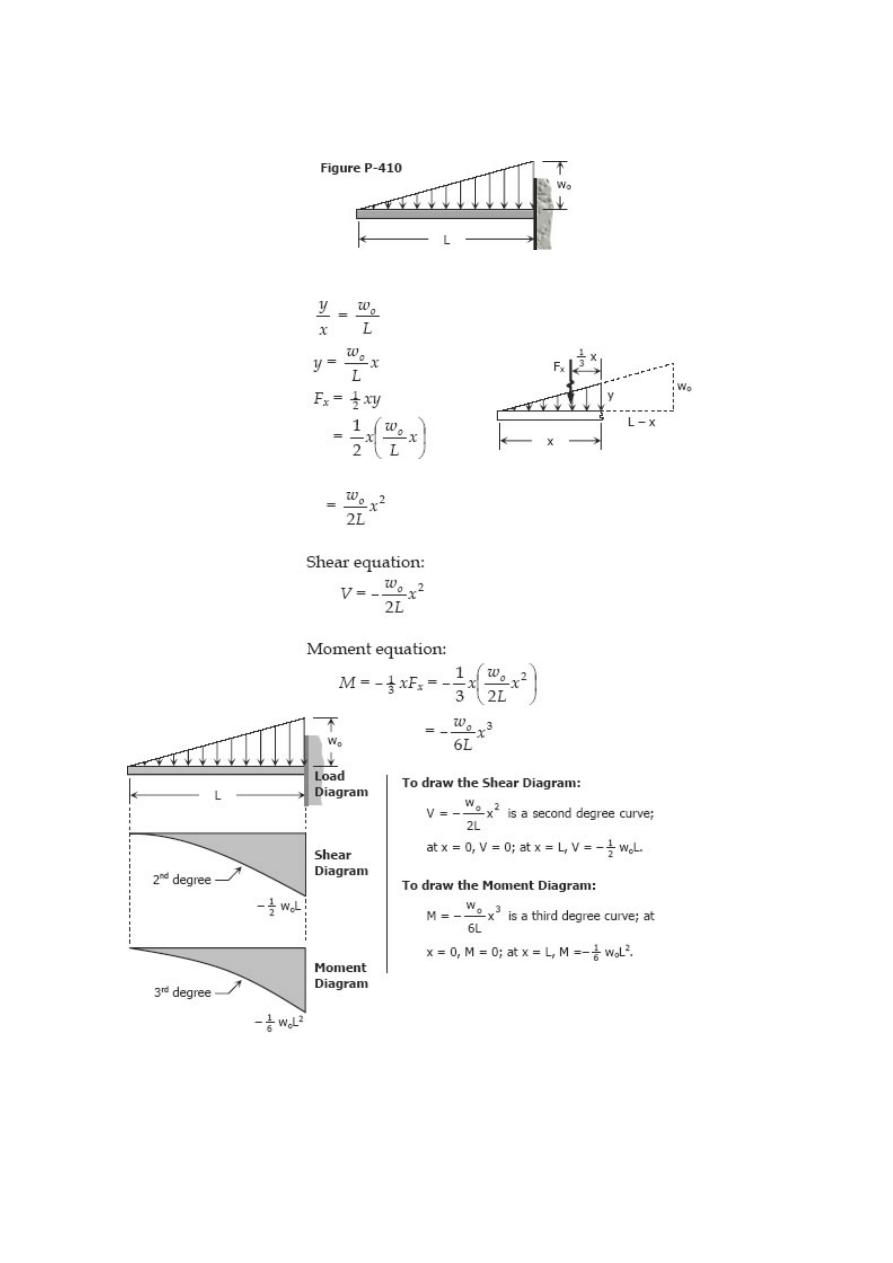

Cantilever beam carrying the uniformly varying load shown in Fig. P-410.

Solution 410

Problem 411

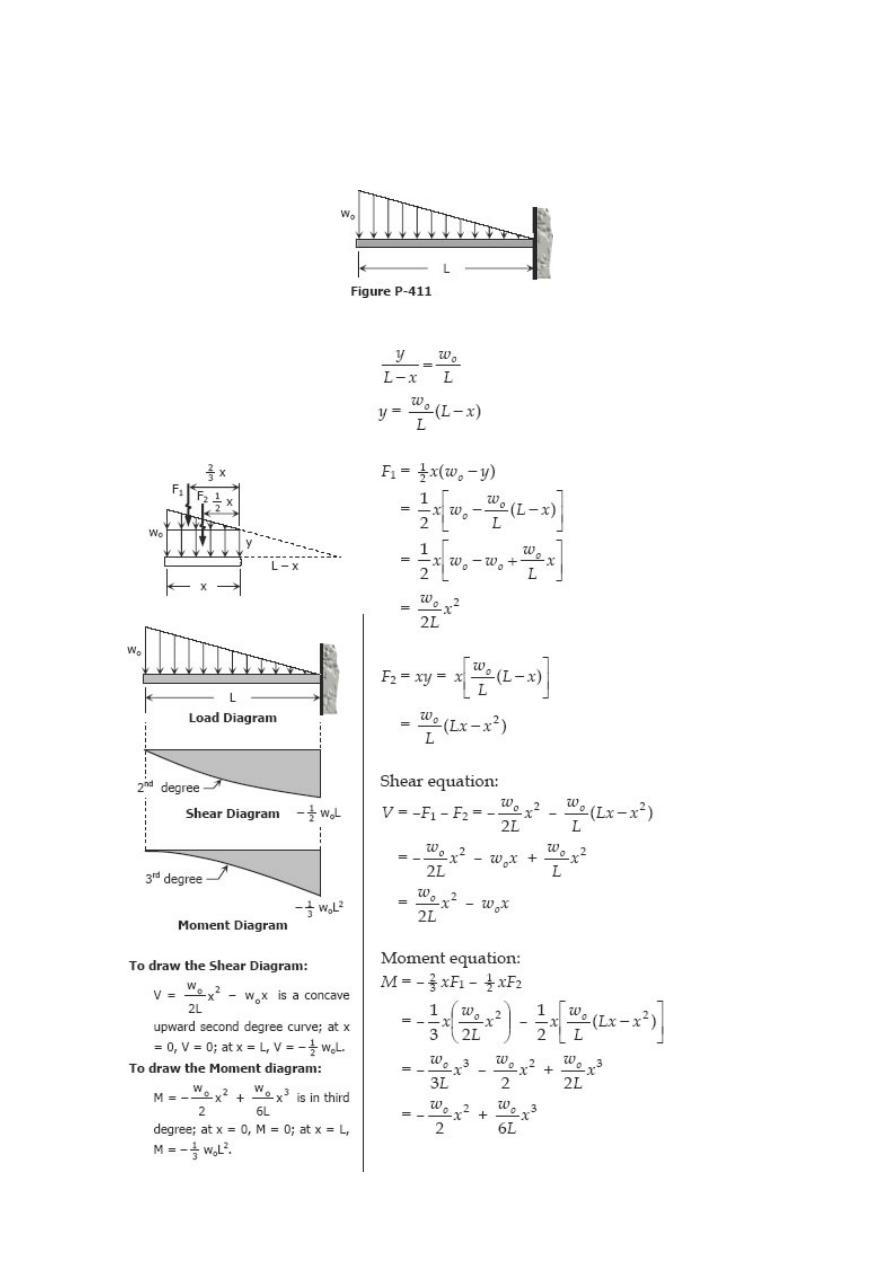

Cantilever beam carrying a distributed load with intensity varying from wo at the free

end to zero at the wall, as shown in Fig. P-411.

Solution 411

Problem 412

Beam loaded as shown in Fig. P-412.

Solution 412

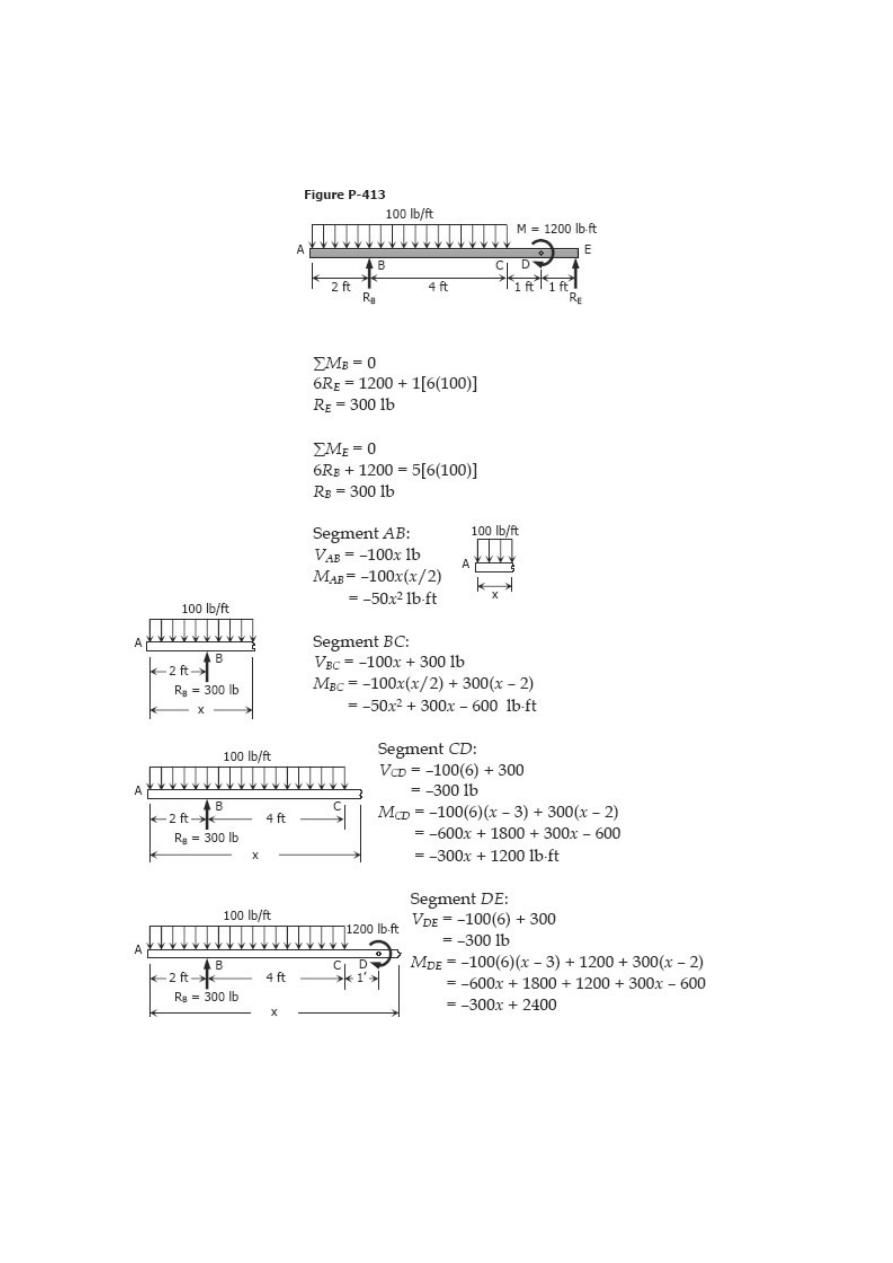

Problem 413

Beam loaded as shown in Fig. P-413.

Solution 413

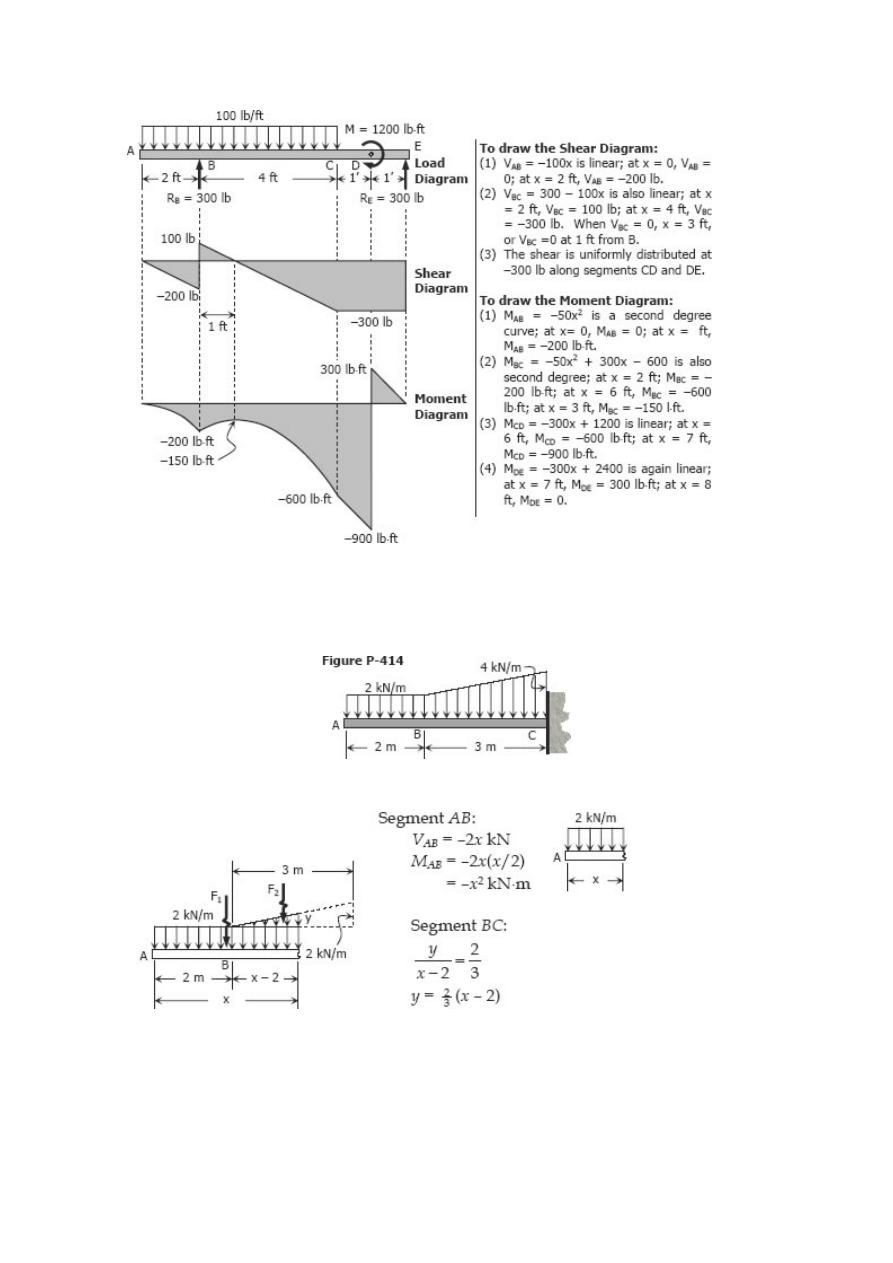

Problem 414

Cantilever beam carrying the load shown in Fig. P-414.

Solution 414

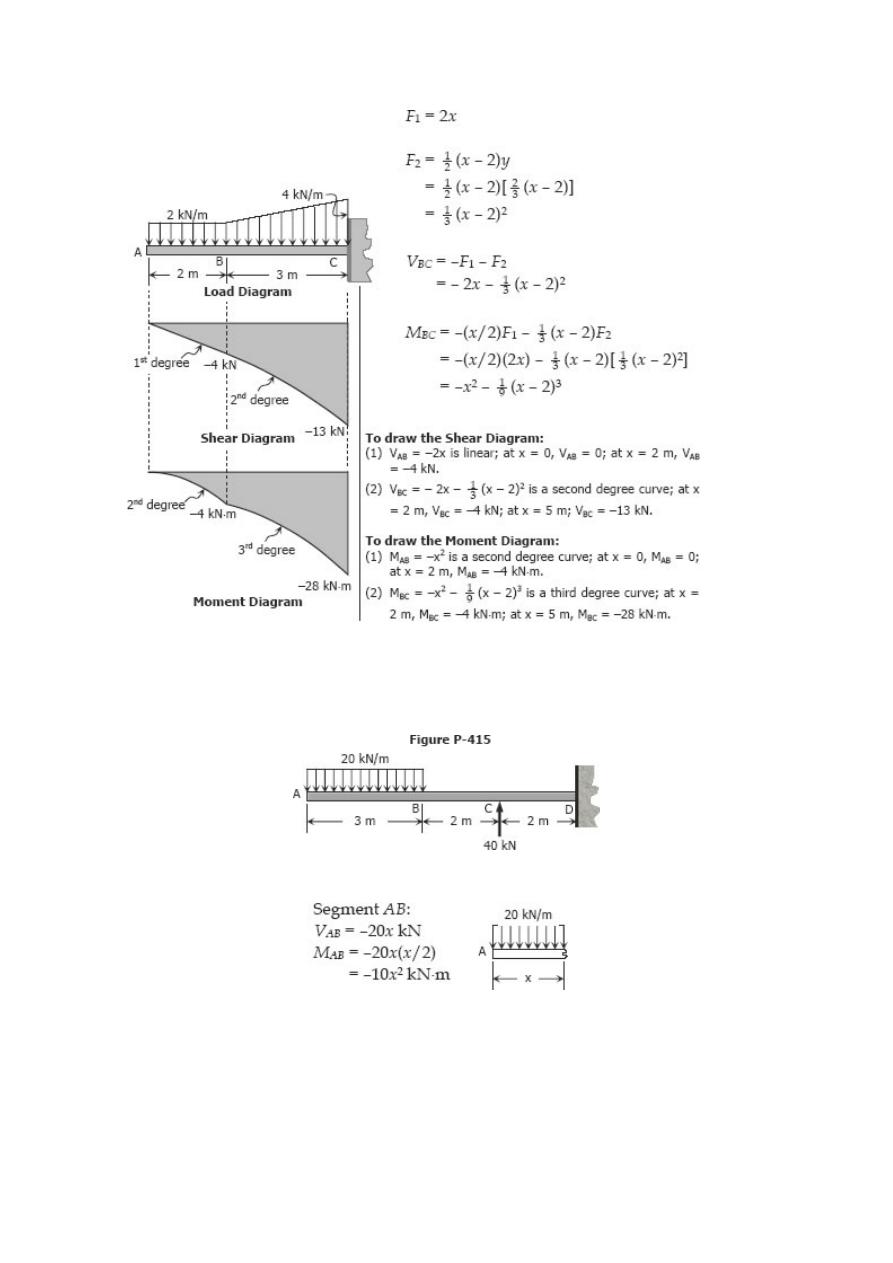

Problem 415

Cantilever beam loaded as shown in Fig. P-415.

Solution 415

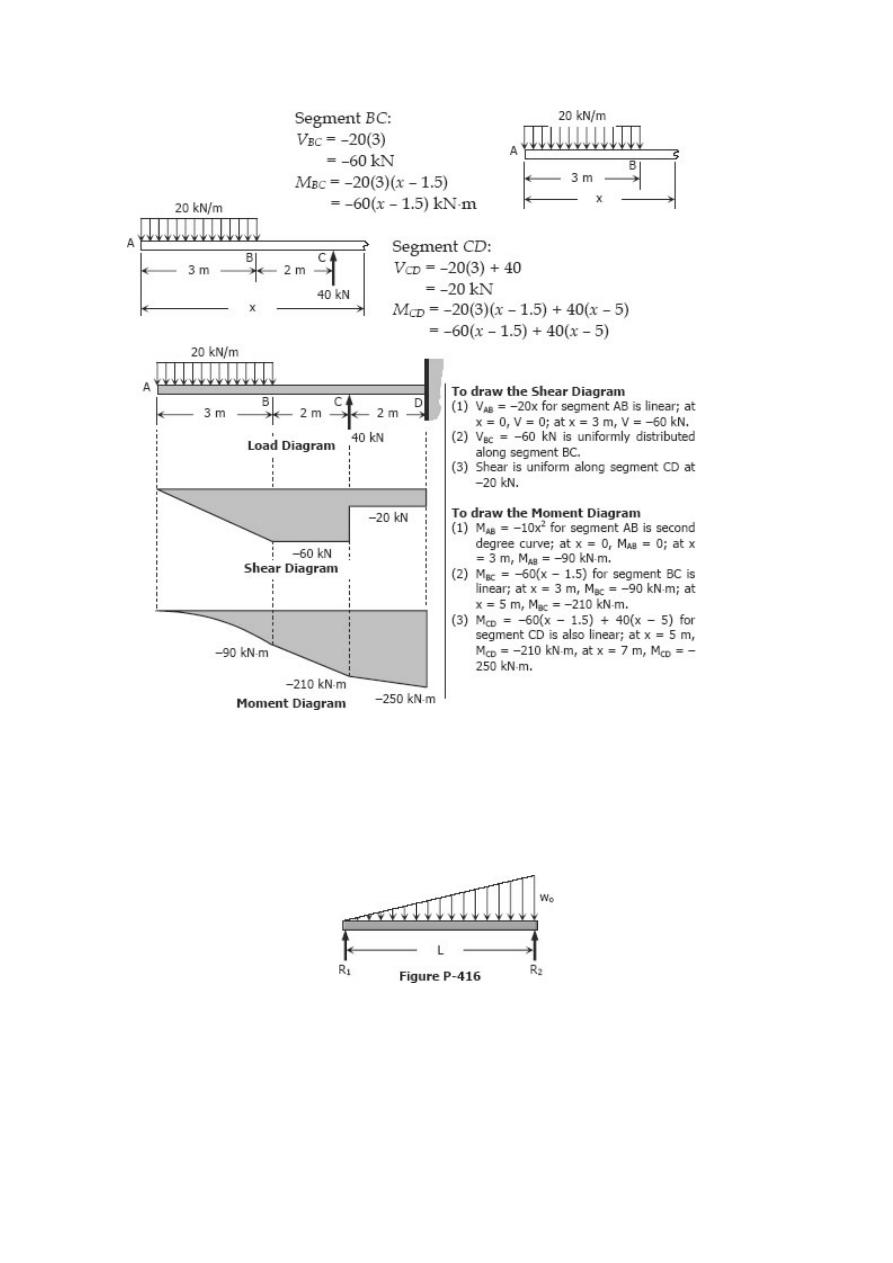

Problem 416

Beam carrying uniformly varying load shown in Fig. P-416.

Solution 416

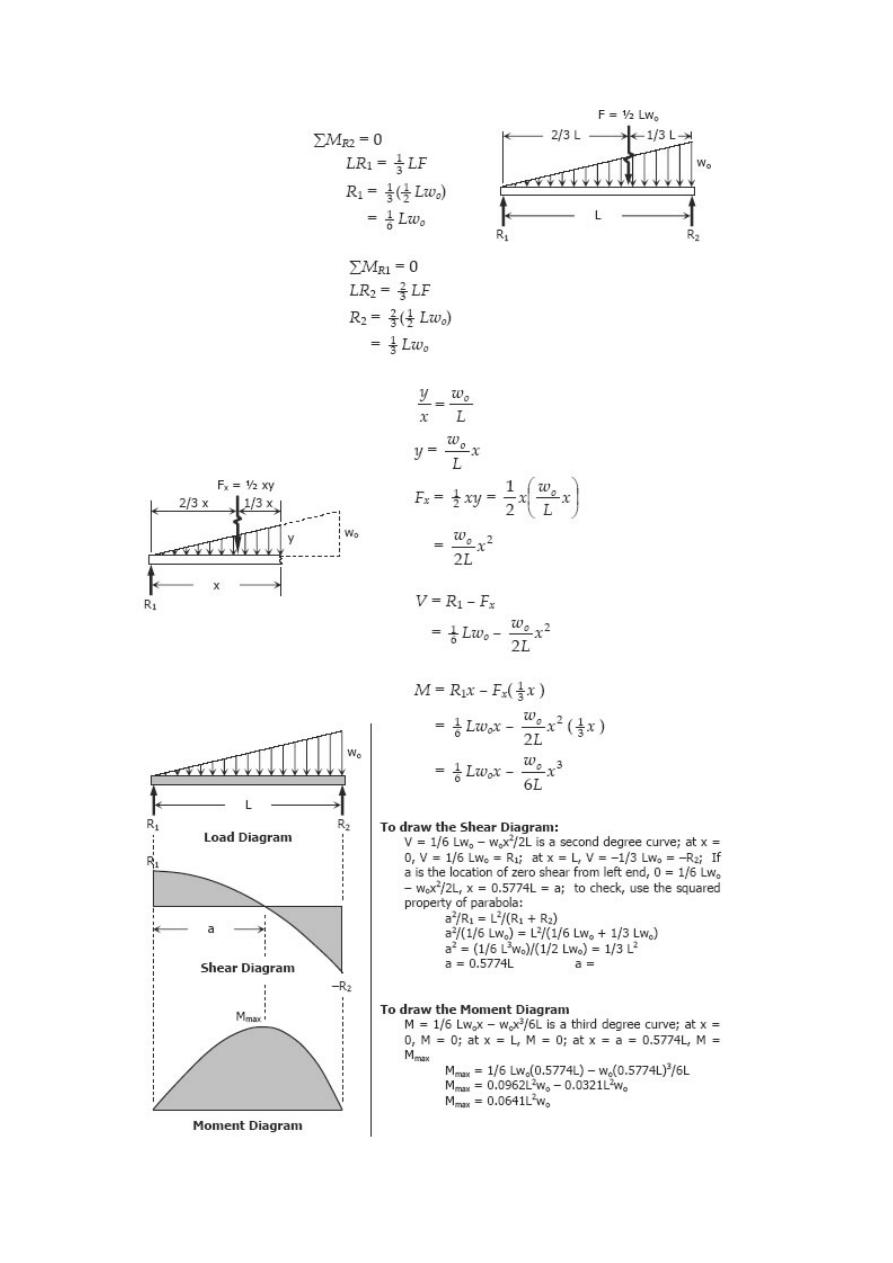

Problem 417

Beam carrying the triangular loading shown in Fig. P- 417.

Solution 417

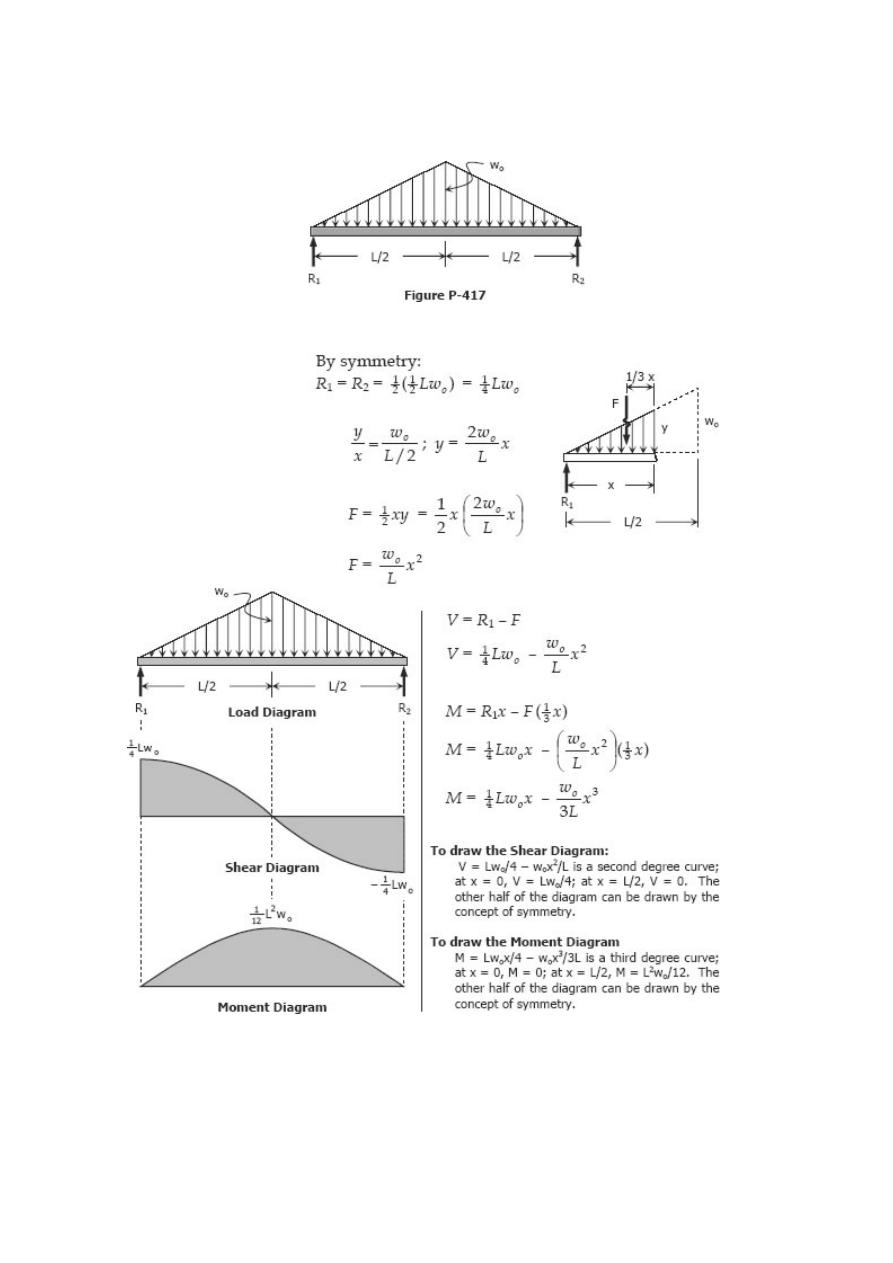

Problem 418

Cantilever beam loaded as shown in Fig. P-418.

Solution 418

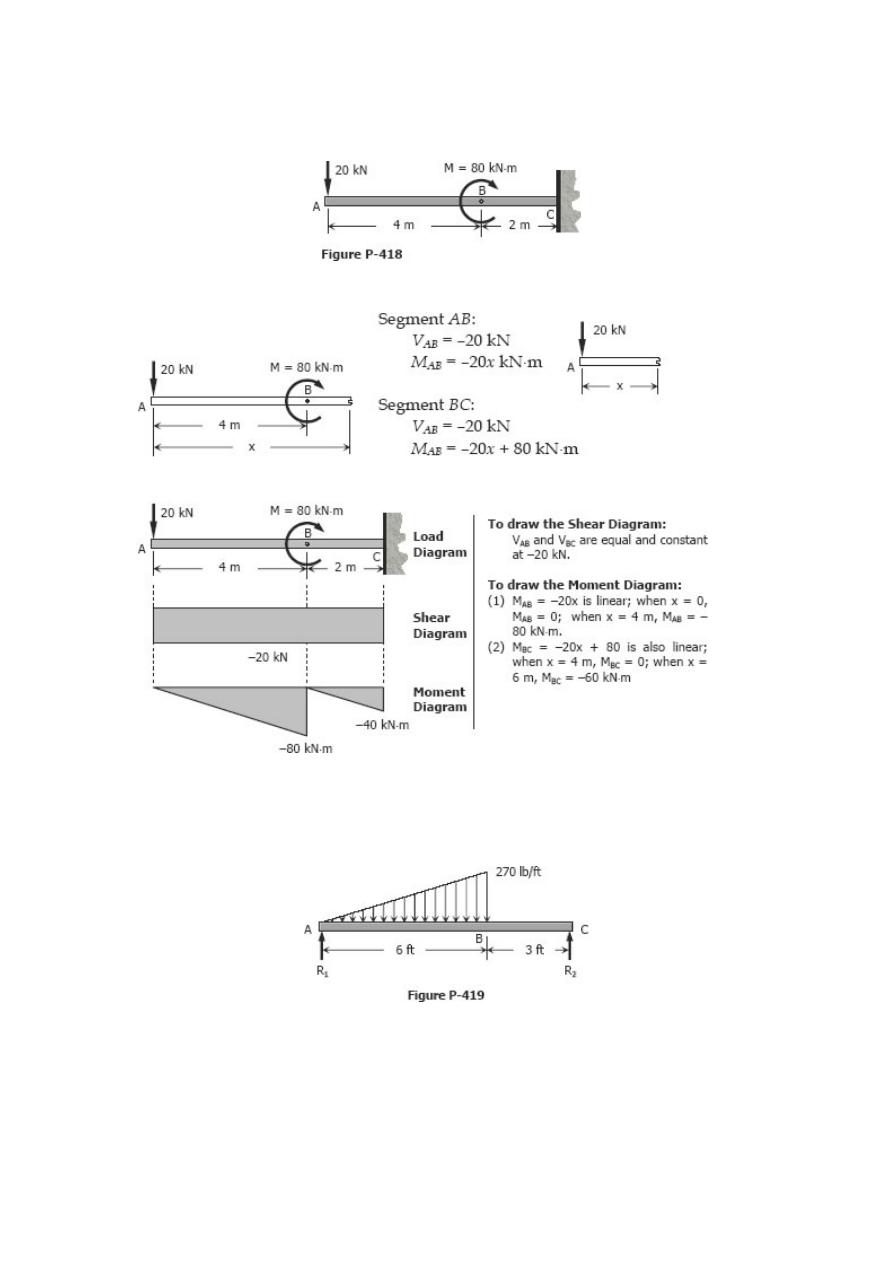

Problem 419

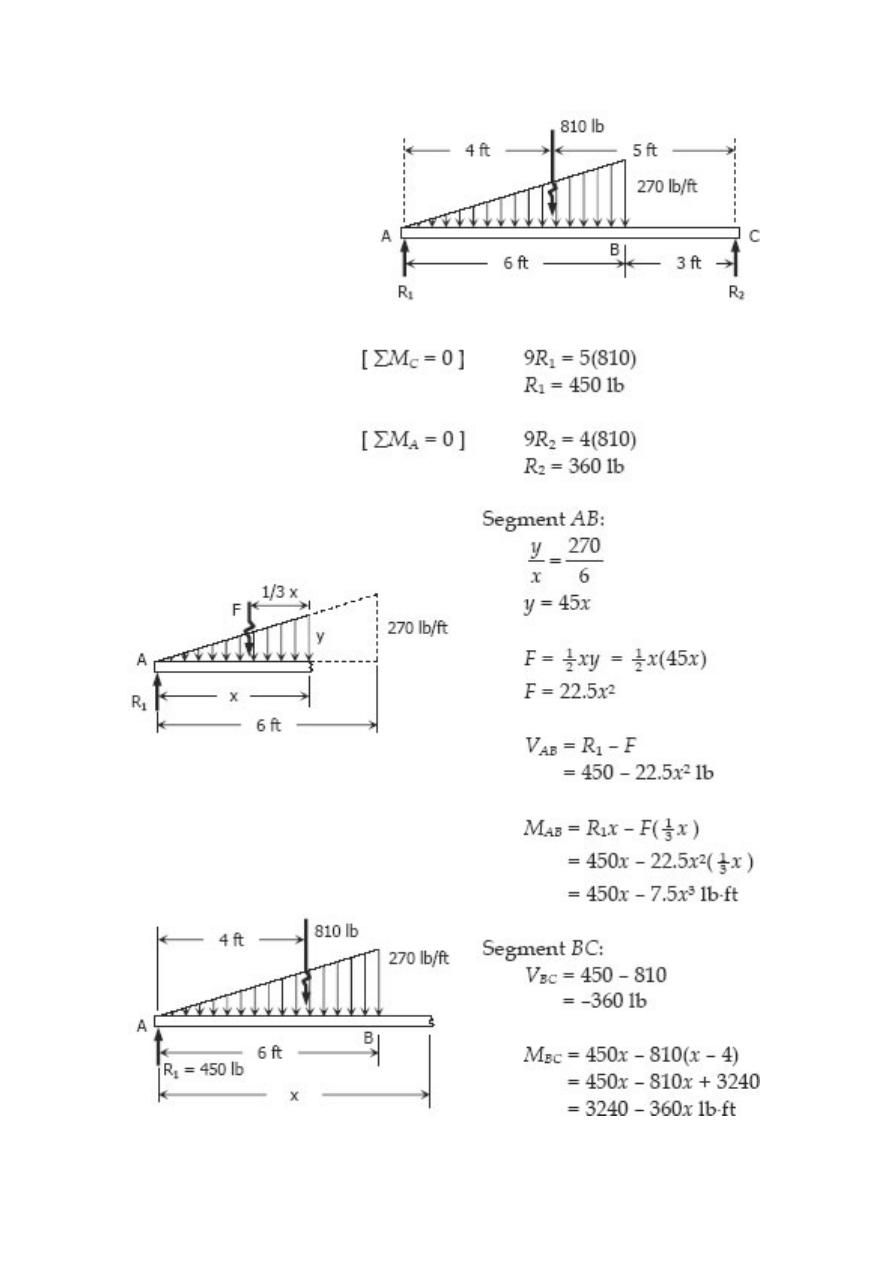

Beam loaded as shown in Fig. P-419.

Solution 419

Problem 420

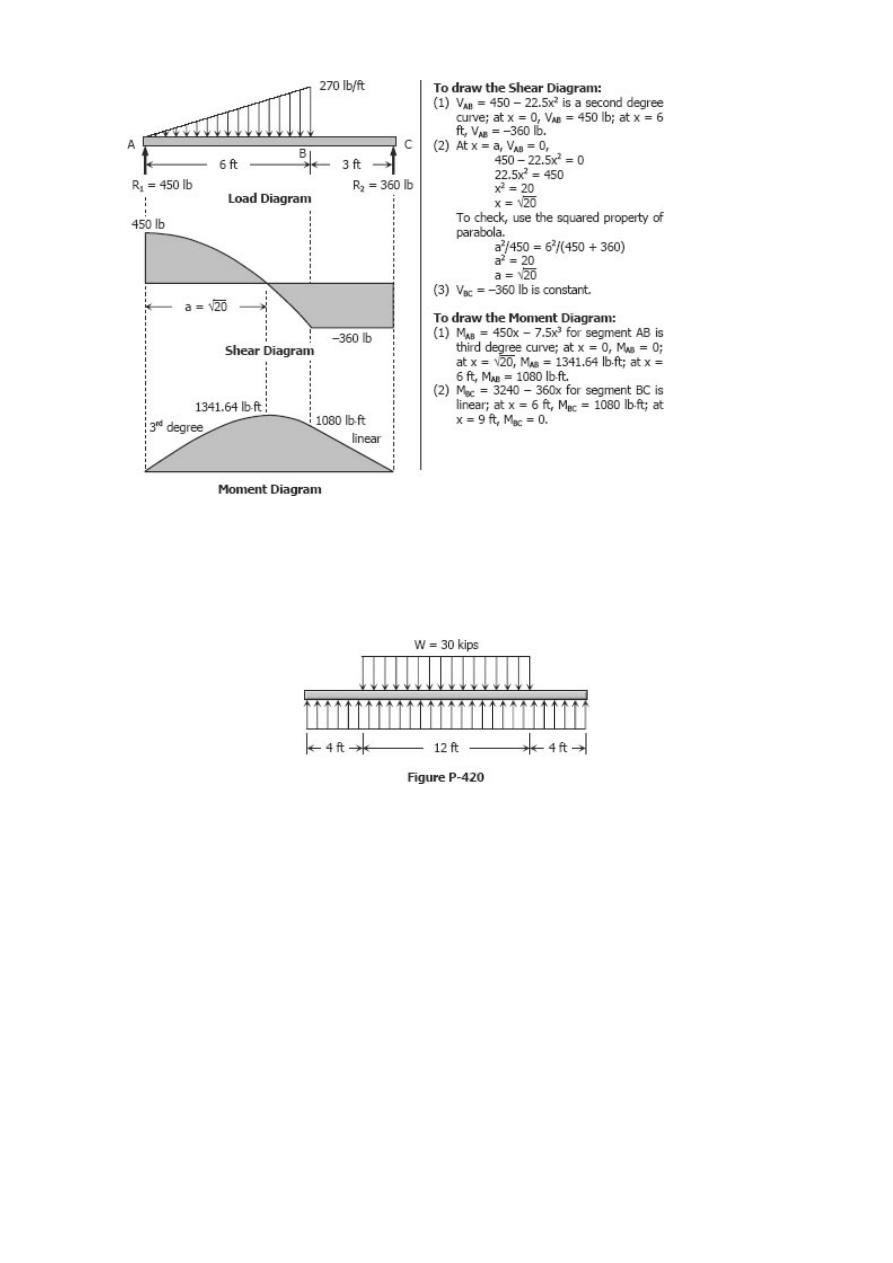

A total distributed load of 30 kips supported by a uniformly distributed reaction as

shown in Fig. P-420.

Solution 420

Problem 421

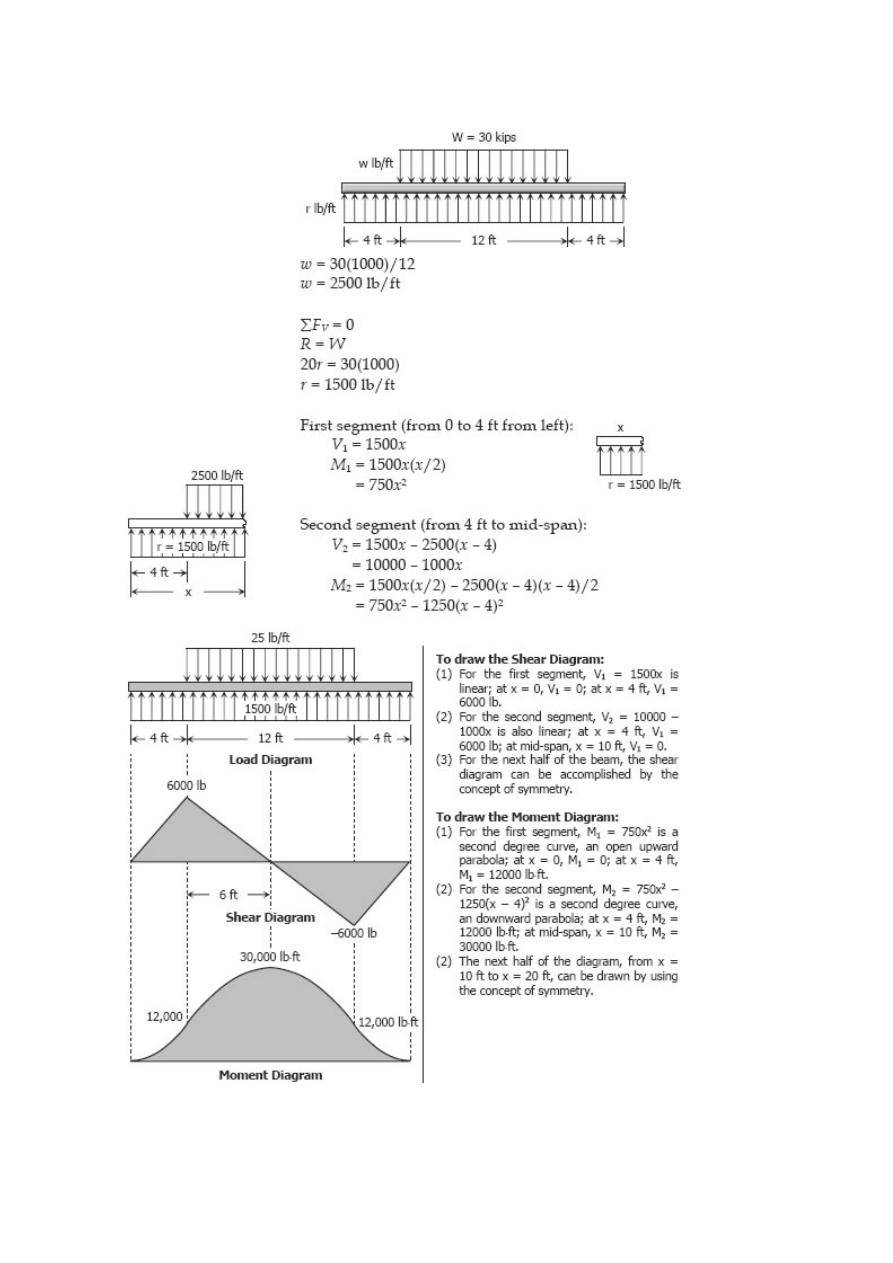

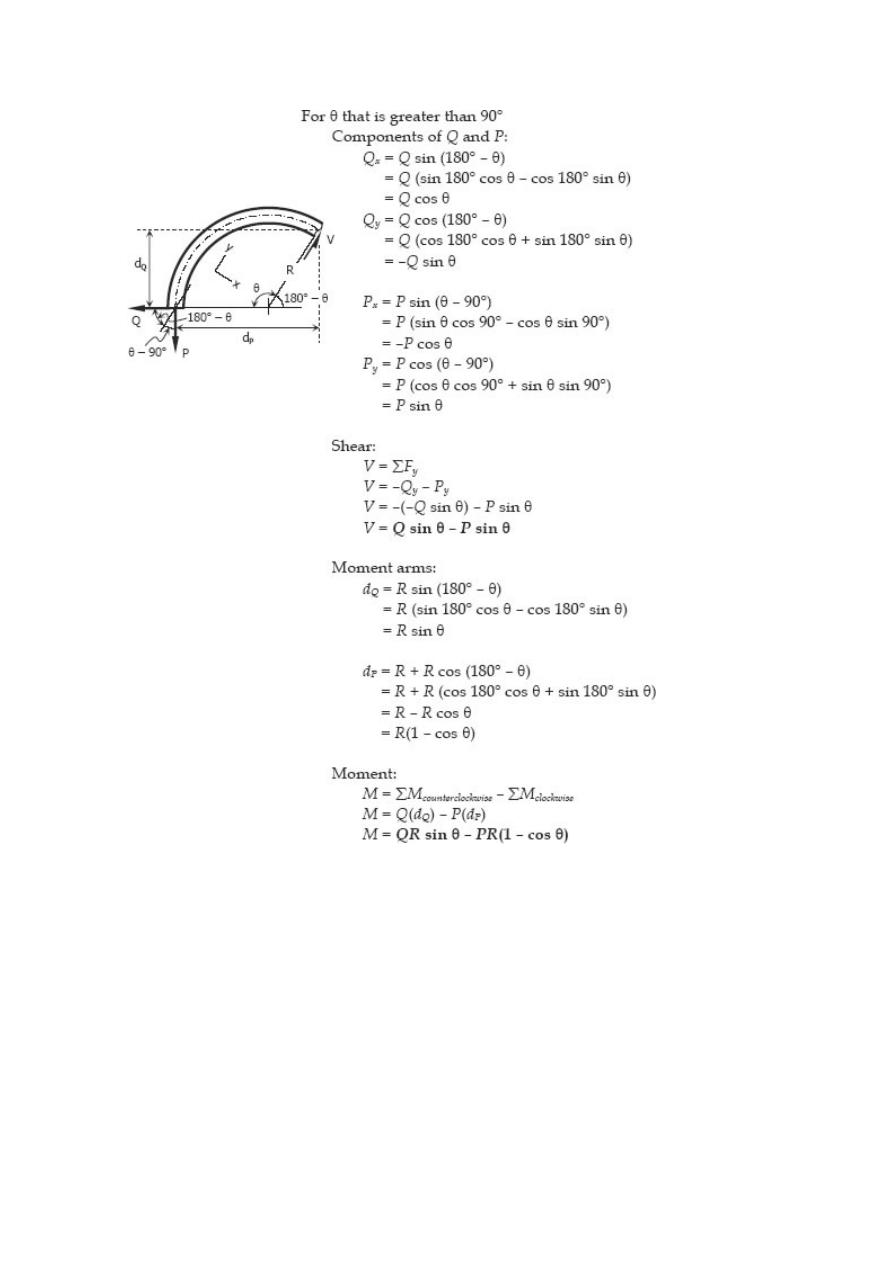

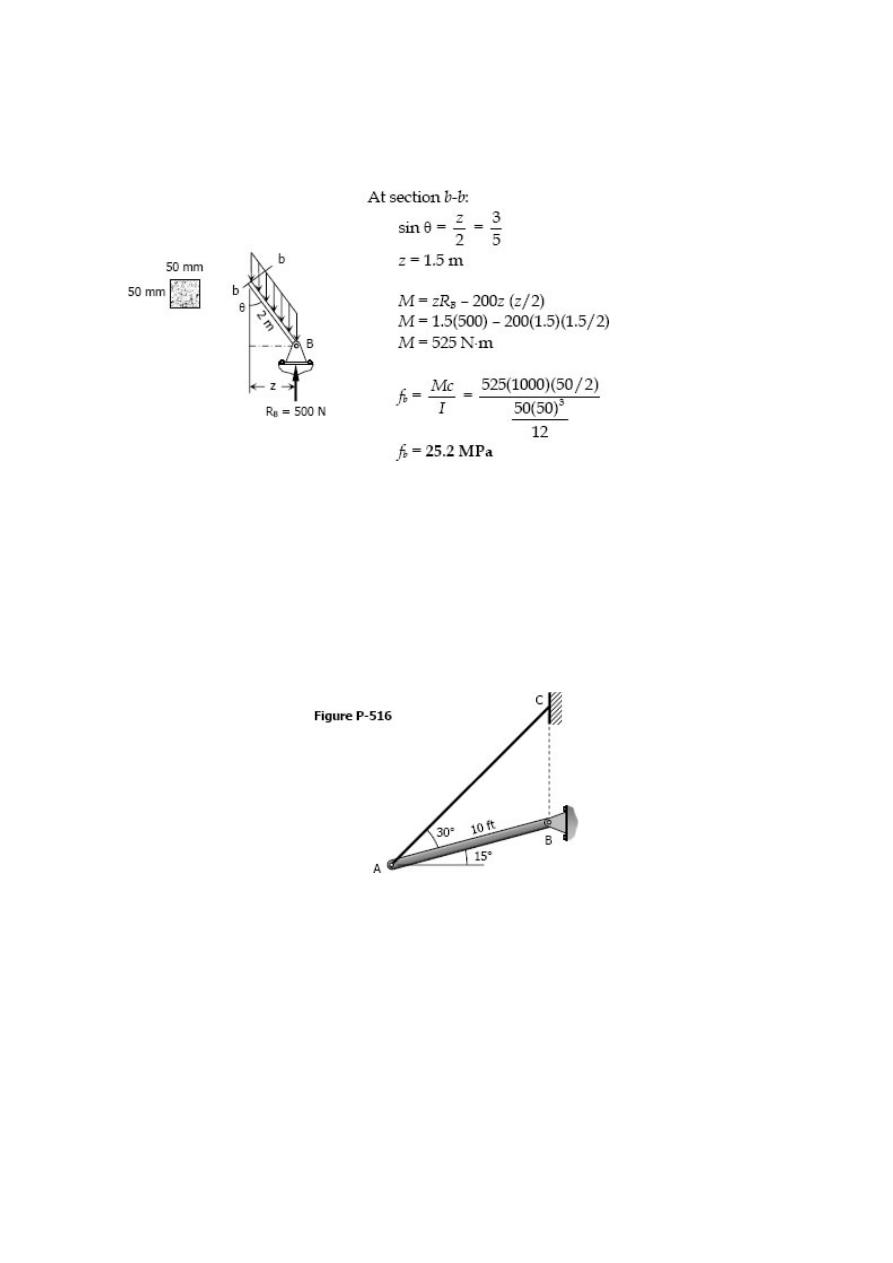

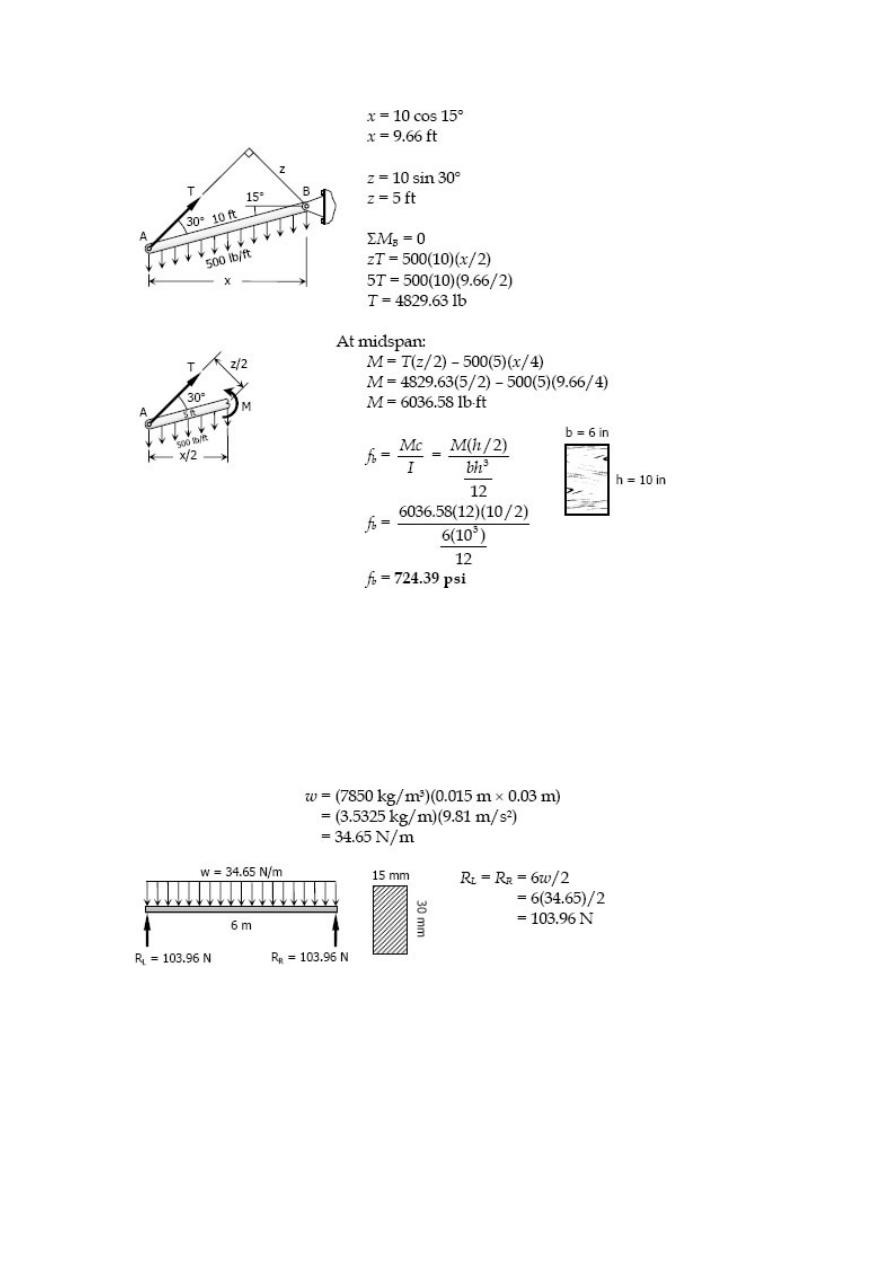

Write the shear and moment equations as functions of the angle θ for the built-in arch

shown in Fig. P-421.

Solution 421

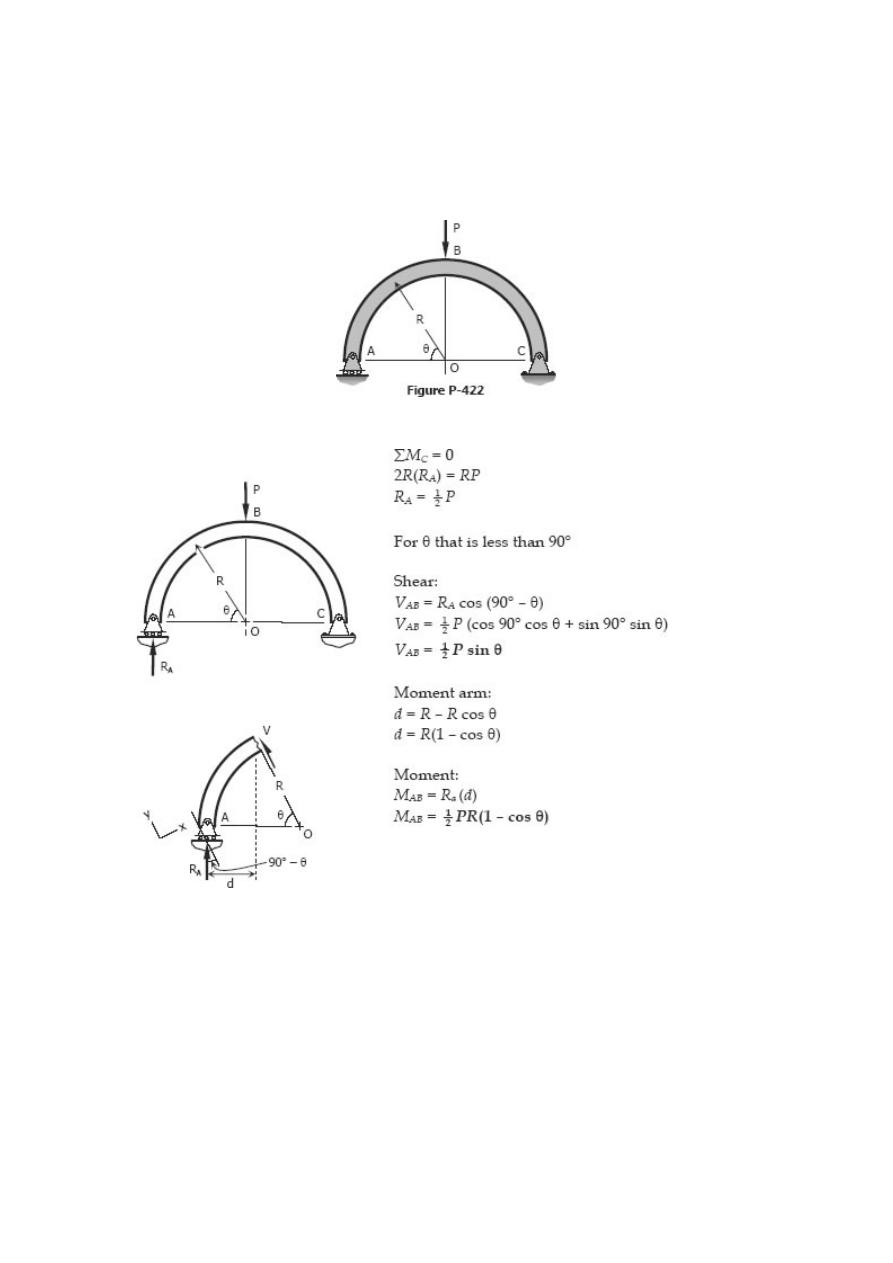

Problem 422

Write the shear and moment equations for the semicircular arch as shown in Fig. P-422

if (a) the load P is vertical as shown, and (b) the load is applied horizontally to the left

at the top of the arch.

Solution 422

Relationship between Load, Shear, and Moment

The vertical shear at C in the figure shown in previous section is taken as

where R

1

= R

2

= wL/2

If we differentiate M with respect to x:

thus,

Thus, the rate of change of the bending moment with respect to x is equal to the

shearing force, or the slope of the moment diagram at the given point is the

shear at that point.

Differentiate V with respect to x gives

Thus, the rate of change of the shearing force with respect to x is equal to the load or

the slope of the shear diagram at a given point equals the load at that point.

PROPERTIES OF SHEAR AND MOMENT DIAGRAMS

The following are some important properties of shear and moment diagrams:

1. The area of the shear diagram to the left or to the right of the section is equal to

the moment at that section.

2. The slope of the moment diagram at a given point is the shear at that point.

3. The slope of the shear diagram at a given point equals the load at that point.

4. The maximum moment occurs at the point of zero shears.

This is in reference to property number 2, that when the

shear (also the slope of the moment diagram) is zero, the

tangent drawn to the moment diagram is horizontal.

5. When the shear diagram is increasing, the moment diagram is concave upward.

6. When the shear diagram is decreasing, the moment diagram is concave

downward.

SIGN CONVENTIONS

The customary sign conventions for shearing force and bending moment are

represented by the figures below. A force that tends to bend the beam downward is said

to produce a positive bending moment. A force that tends to shear the left portion of

the beam upward with respect to the right portion is said to produce a positive shearing

force.

An easier way of determining the sign of the bending moment at any section is that

upward forces always cause positive bending moments regardless of whether they act

to the left or to the right of the exploratory section.

Solved Problems in Relationship between Load, Shear, and Moment

INSTRUCTION

Without writing shear and moment equations, draw the shear and moment diagrams for

the beams specified in the following problems. Give numerical values at all change of

loading positions and at all points of zero shear. (Note to instructor: Problems 403 to

420 may also be assigned for solution by semi graphical method describes in this

article.)

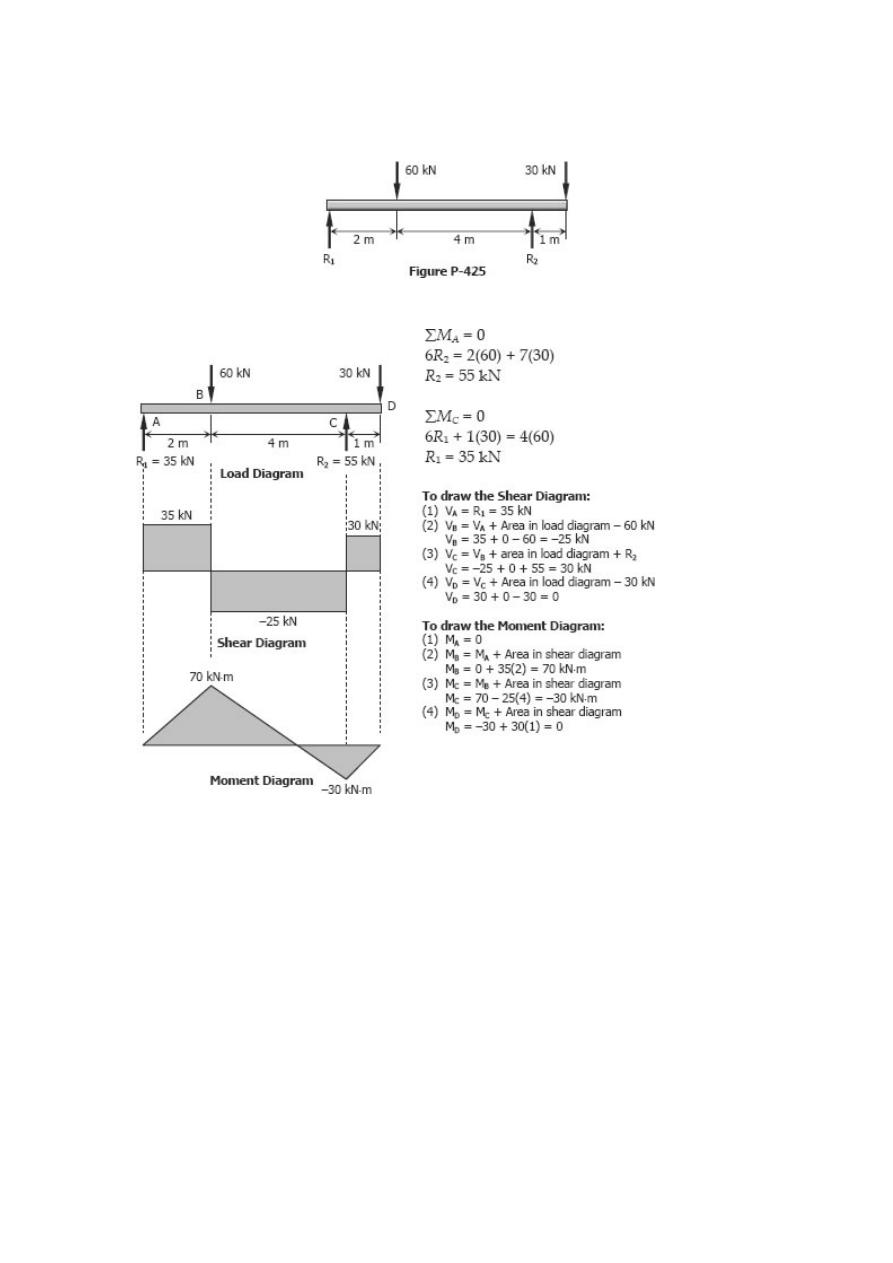

Problem 425

Beam loaded as shown in Fig. P-425.

Solution 425

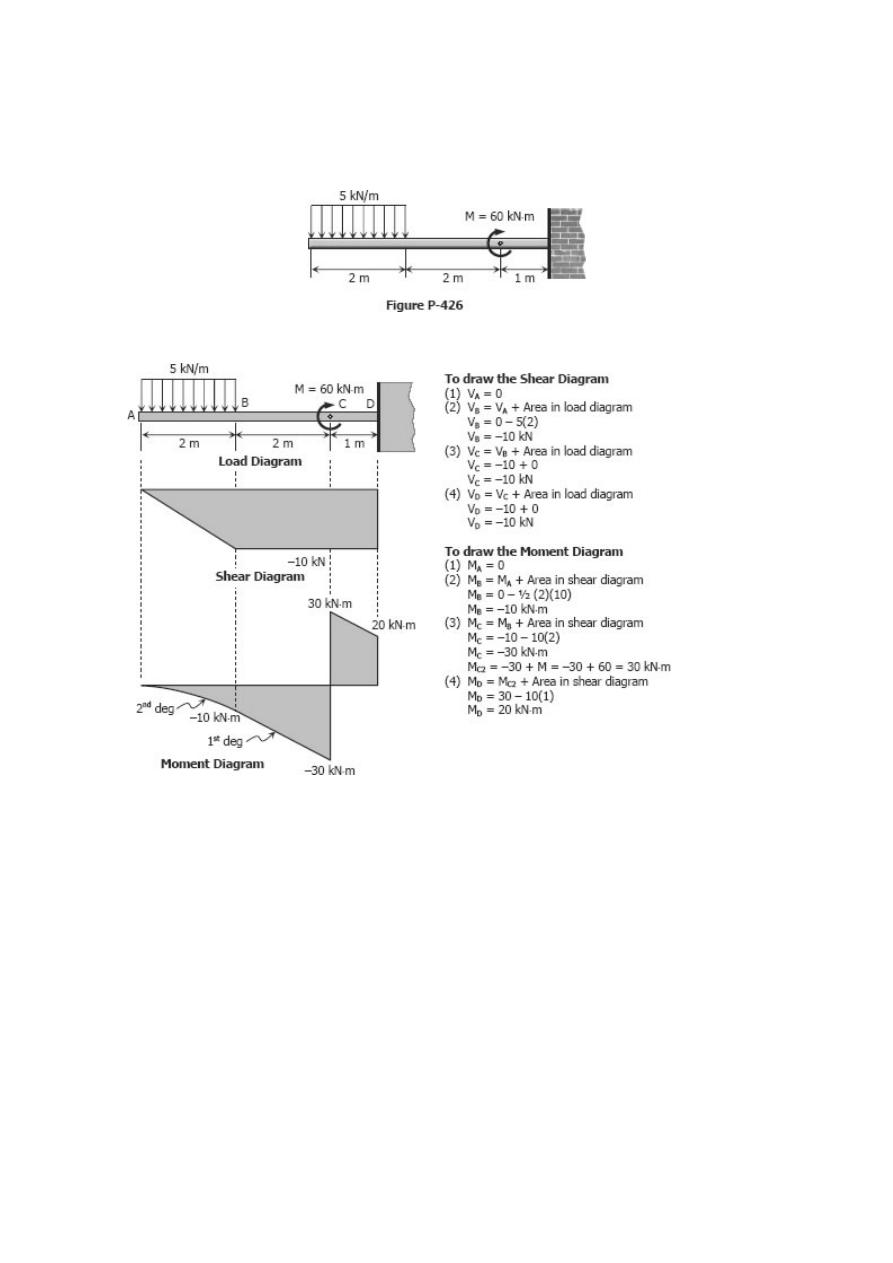

Problem 426

Cantilever beam acted upon by a uniformly distributed load and a couple as shown in

Fig. P-426.

Solution 426

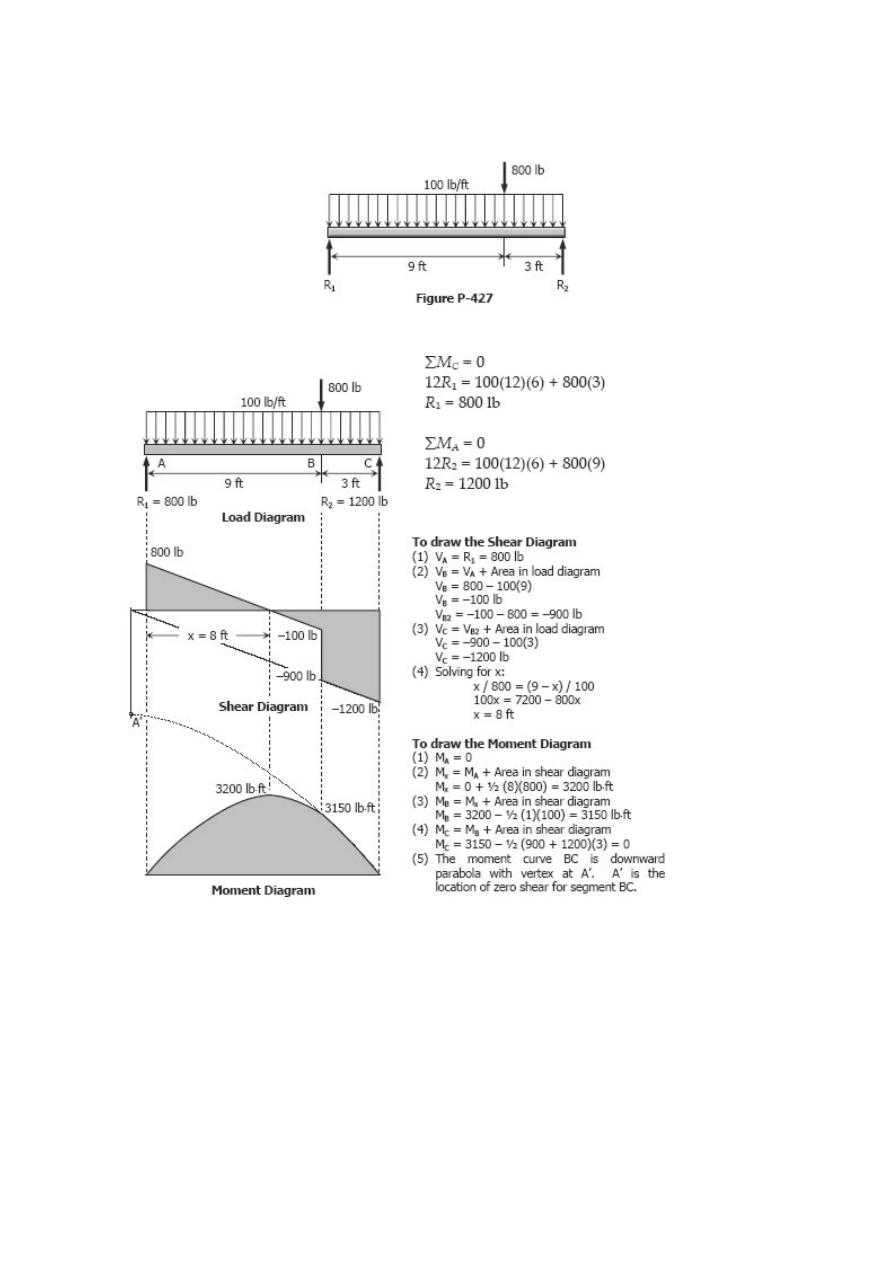

Problem 427

Beam loaded as shown in Fig. P-427.

Solution 427

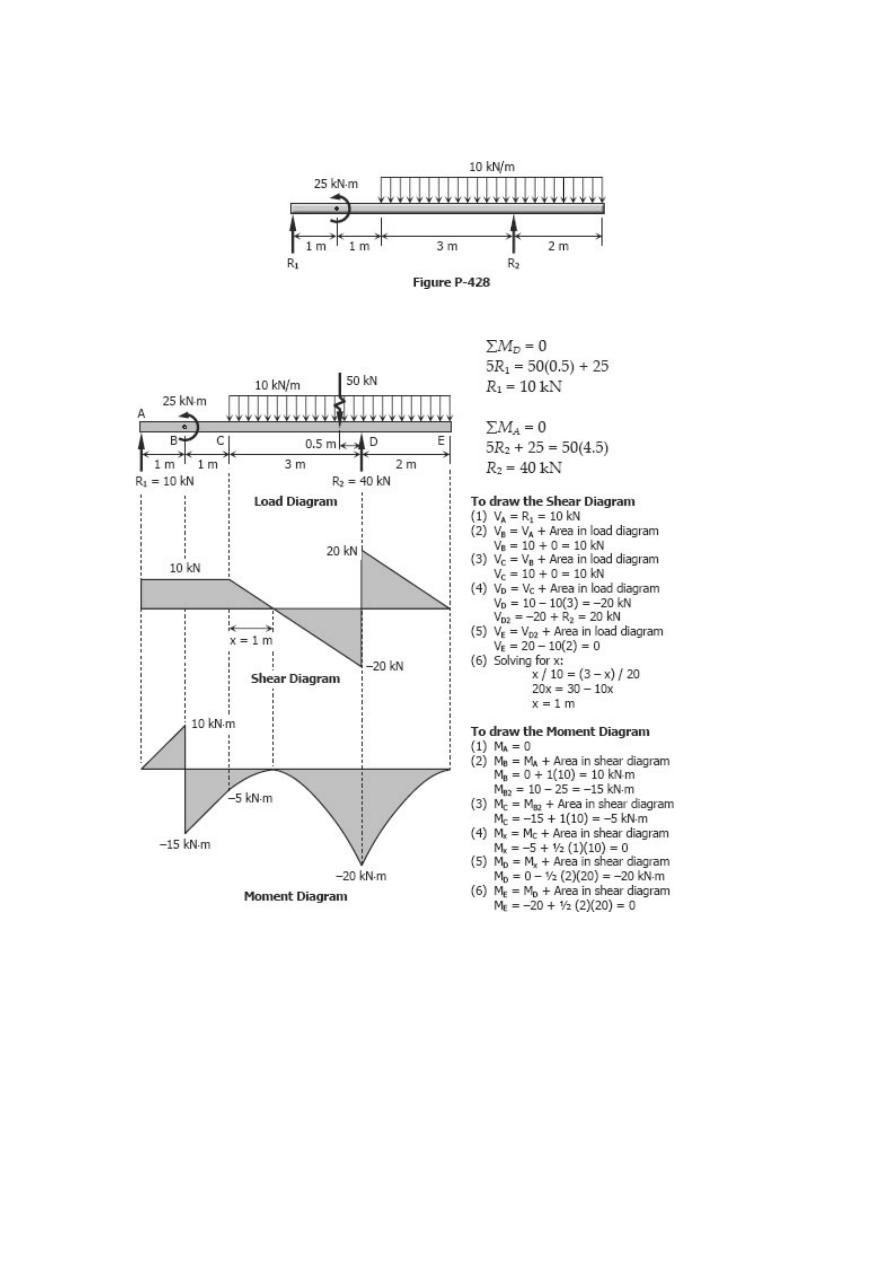

Problem 428

Beam loaded as shown in Fig. P-428.

Solution 428

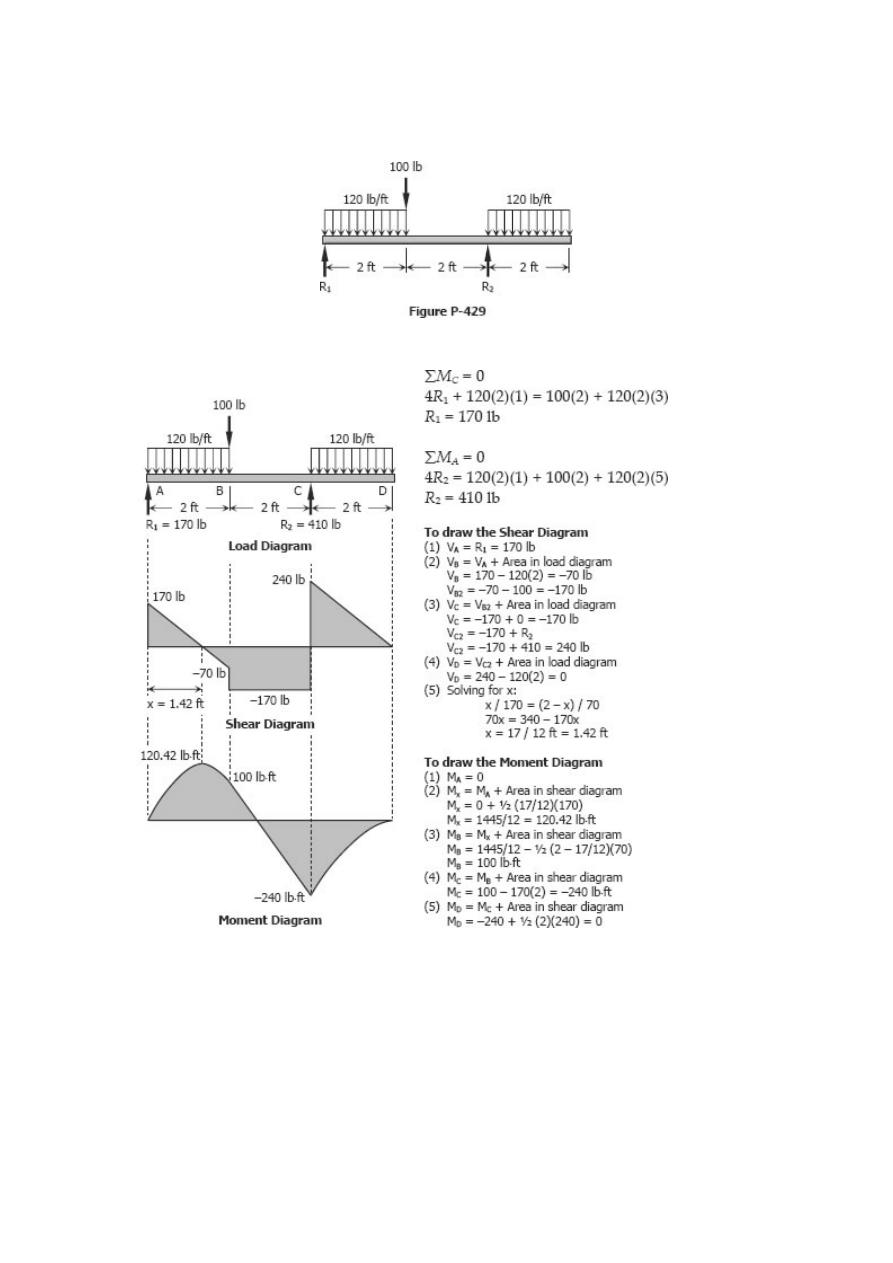

Problem 429

Beam loaded as shown in Fig. P-429.

Solution 429

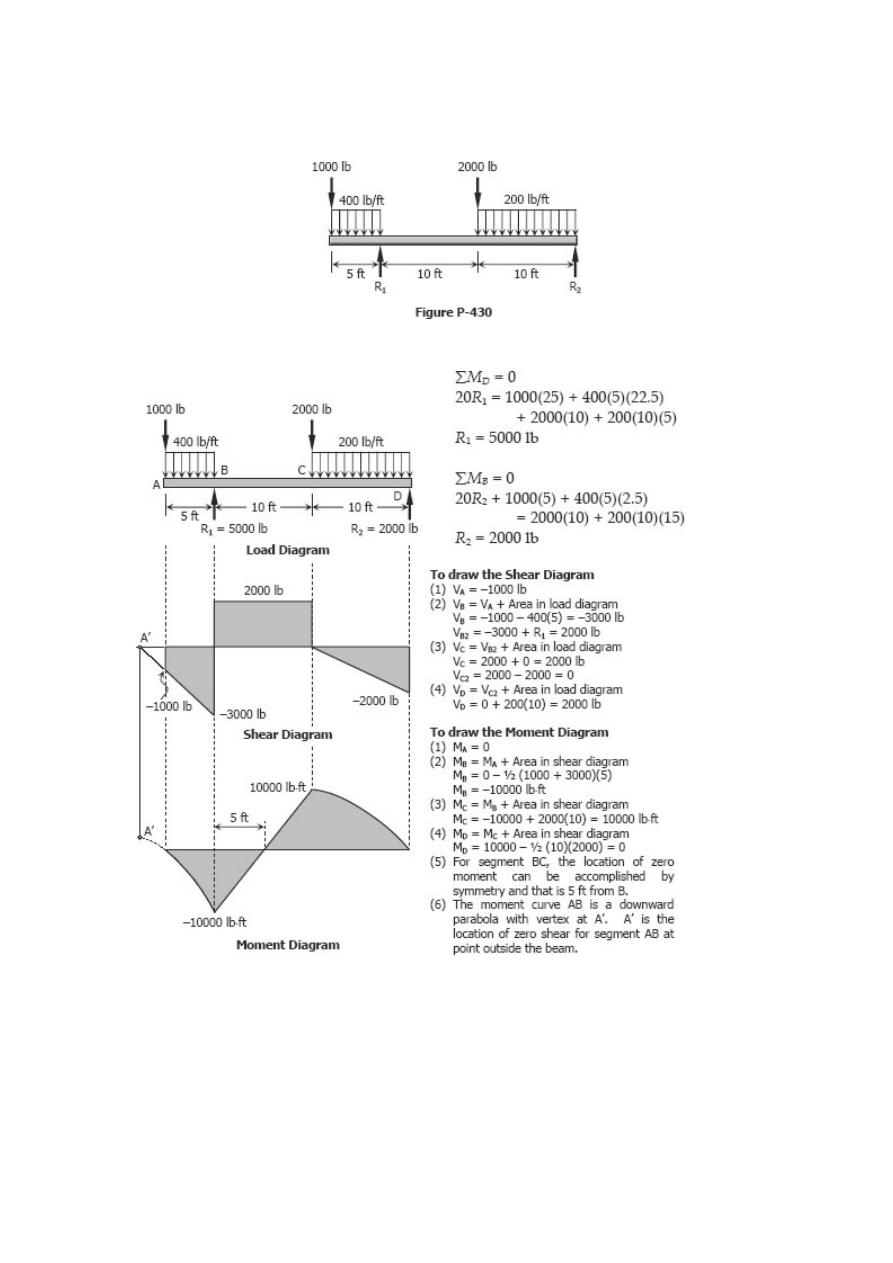

Problem 430

Beam loaded as shown in P-430.

Solution 430

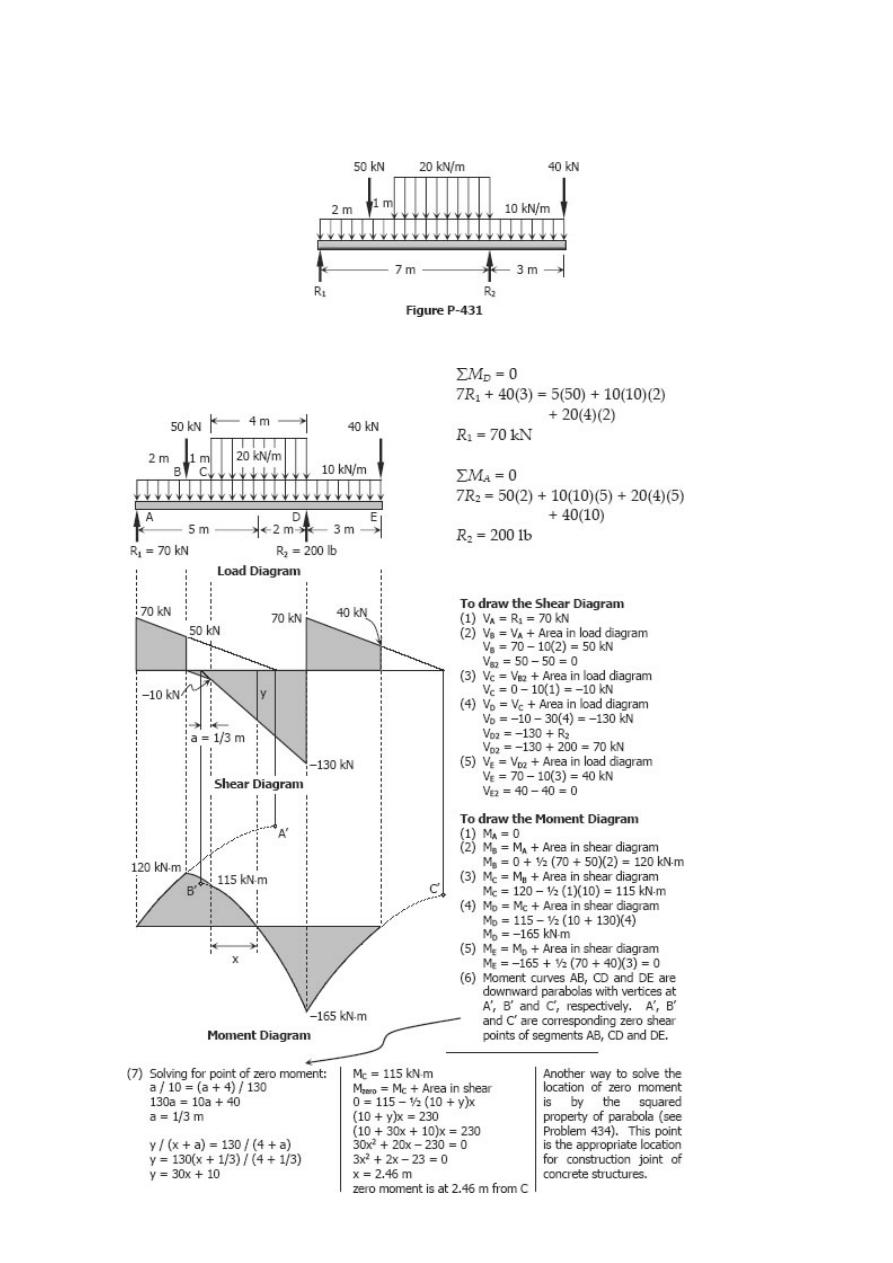

Problem 431

Beam loaded as shown in Fig. P-431.

Solution 431

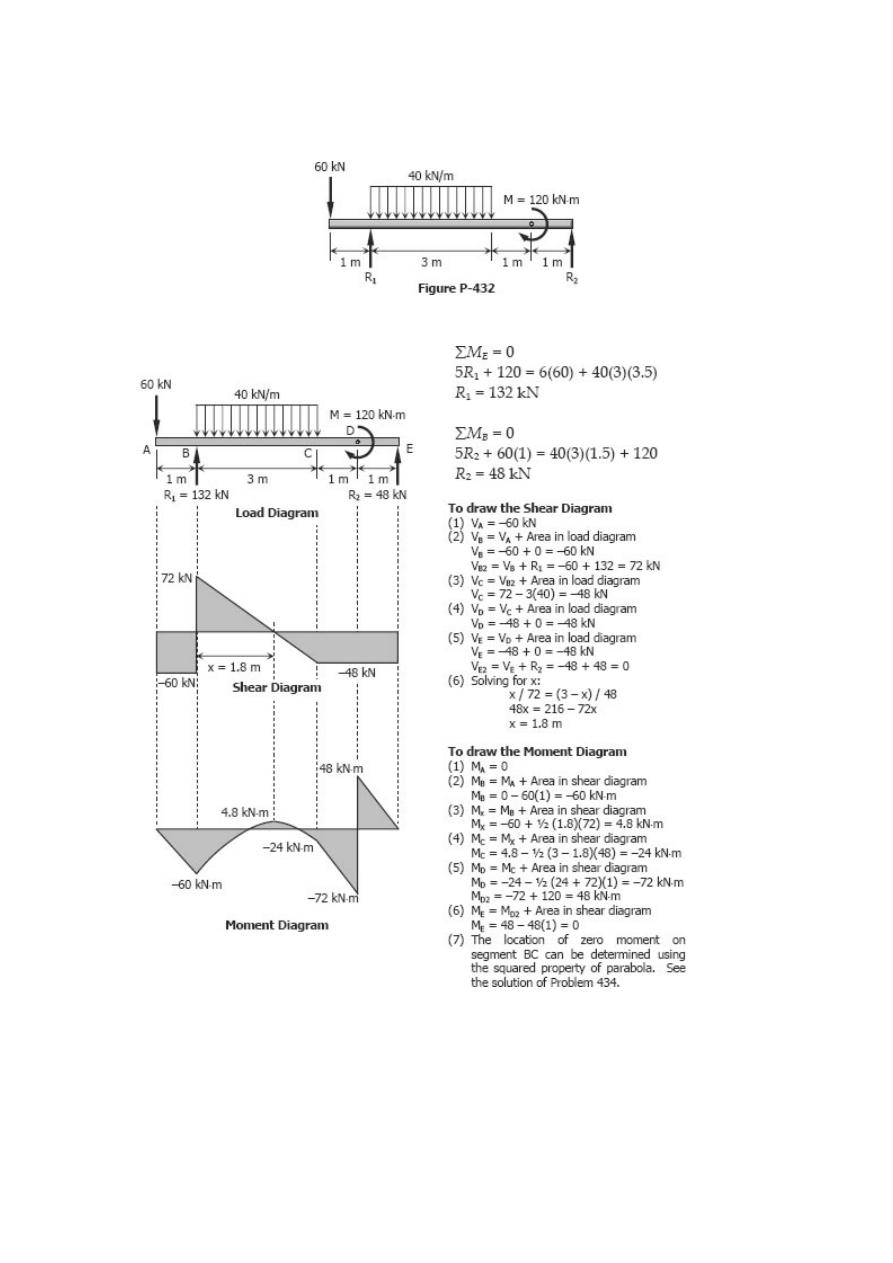

Problem 432

Beam loaded as shown in Fig. P-432.

Solution 432

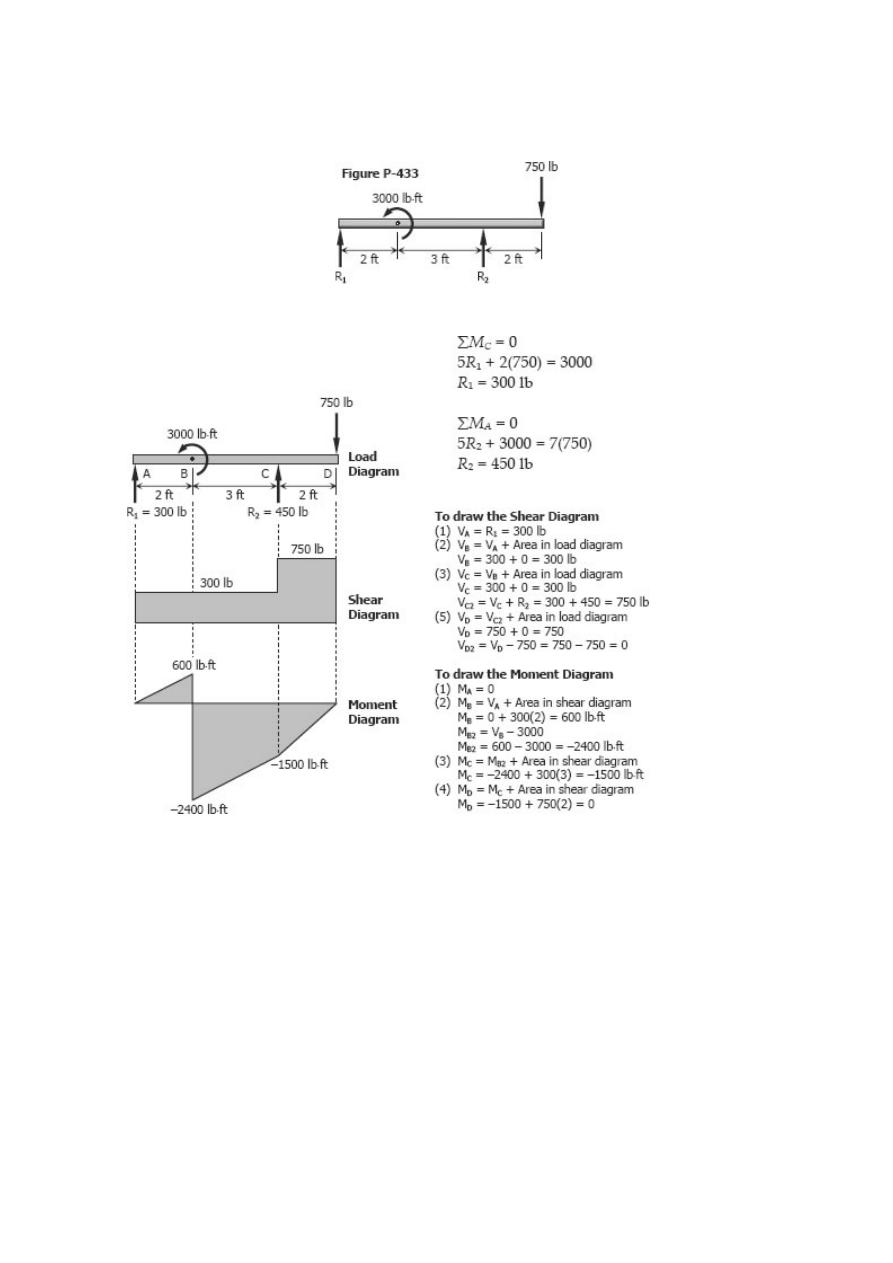

Problem 433

Overhang beam loaded by a force and a couple as shown in Fig. P-433.

Solution 433

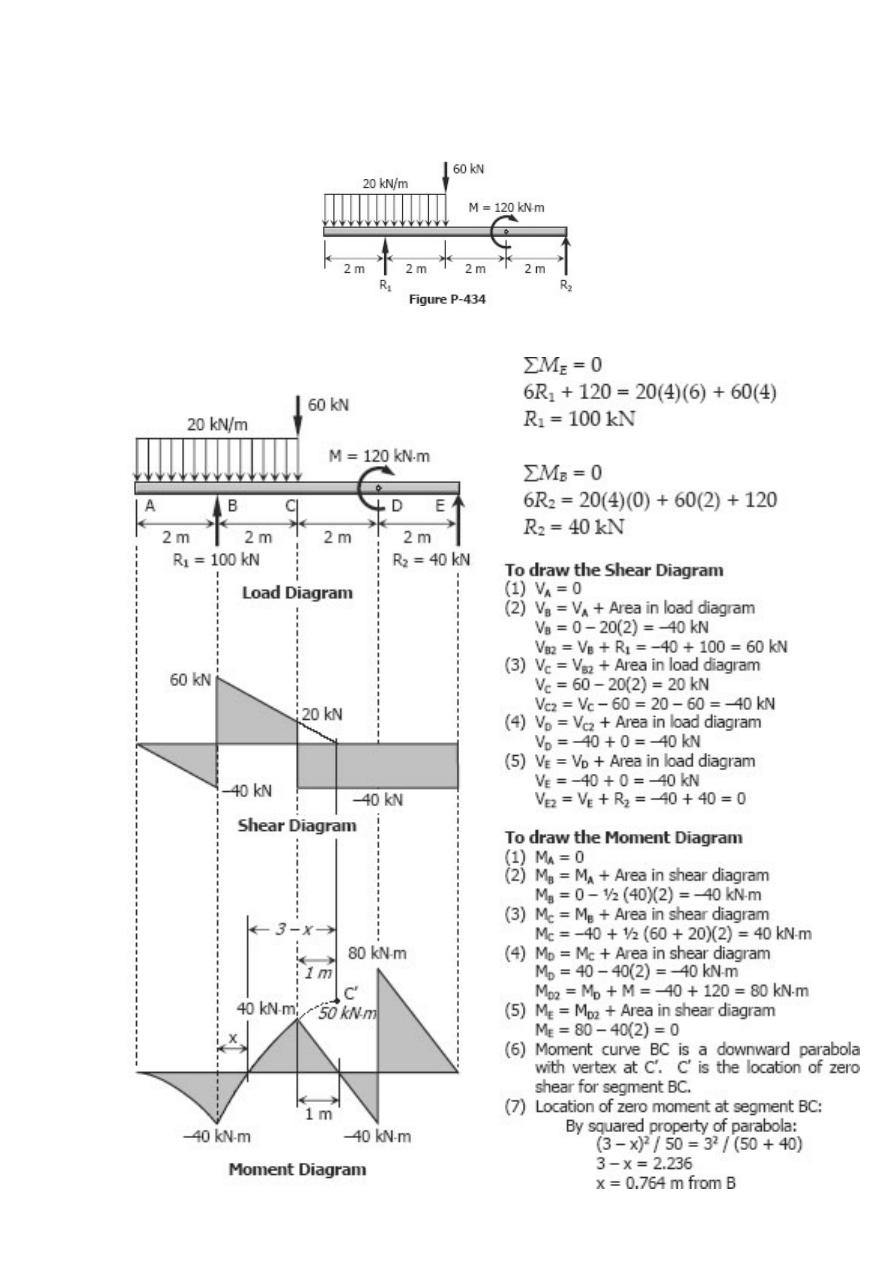

Problem 434

Beam loaded as shown in Fig. P-434.

Solution 434

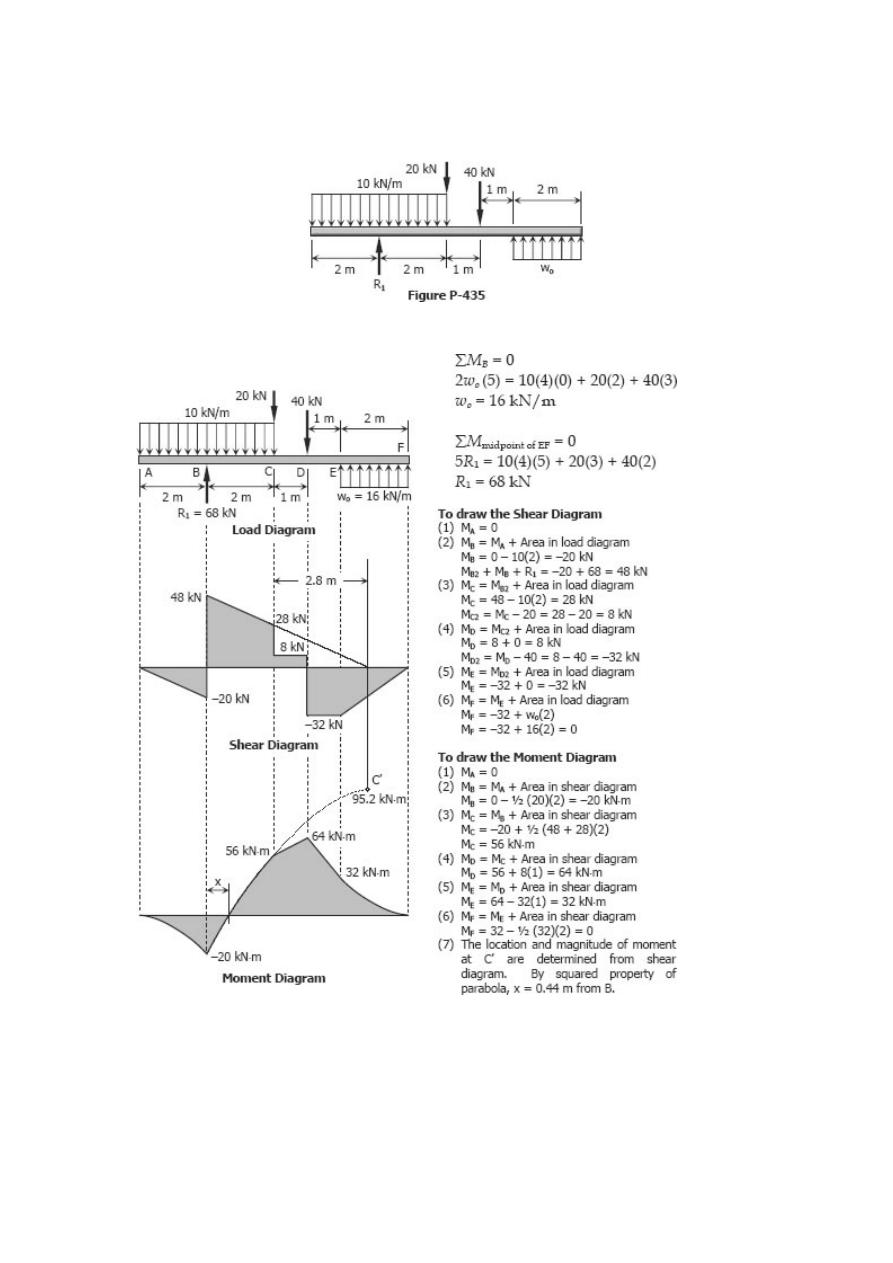

Problem 435

Beam loaded and supported as shown in Fig. P-435.

Solution 435

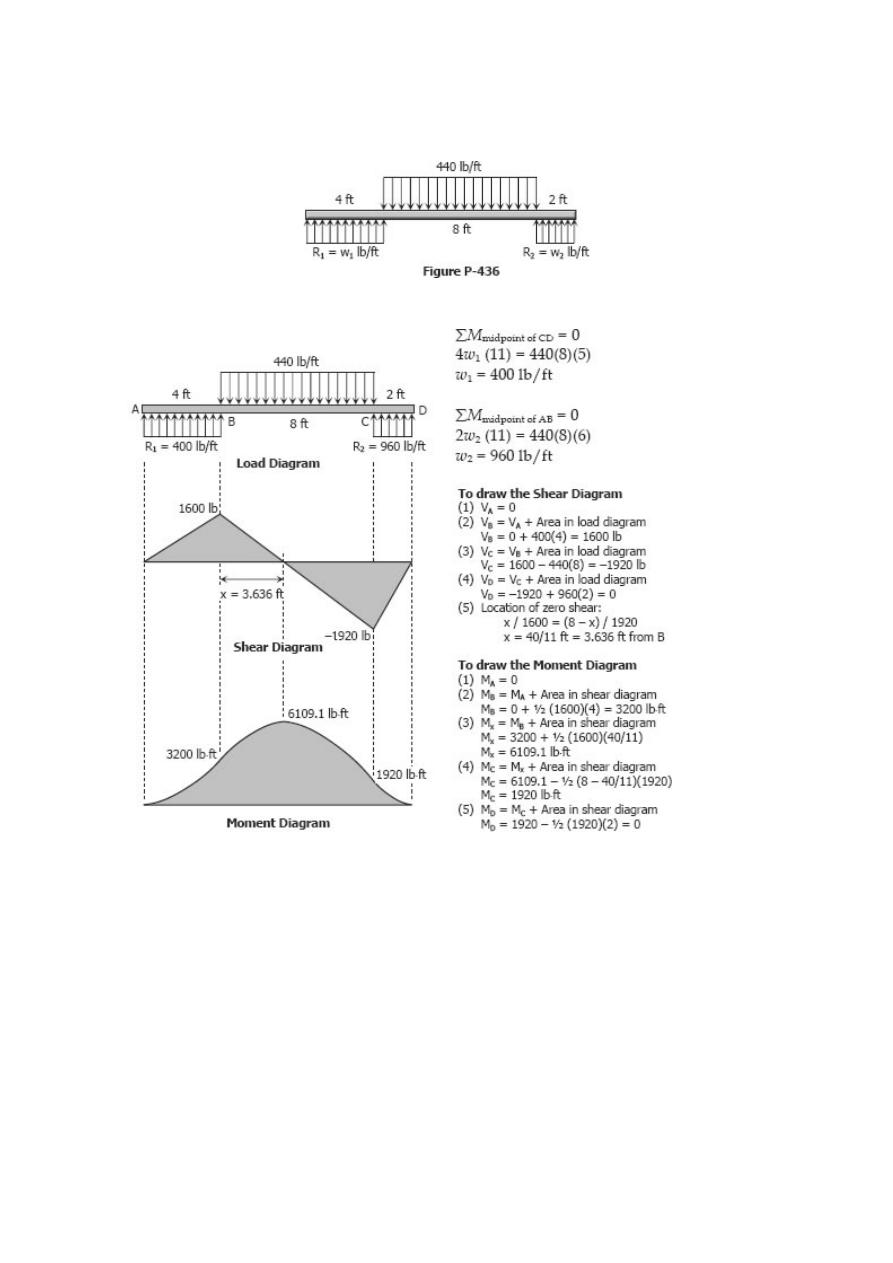

Problem 436

A distributed load is supported by two distributedreactions as shown in Fig. P-436.

Solution 436

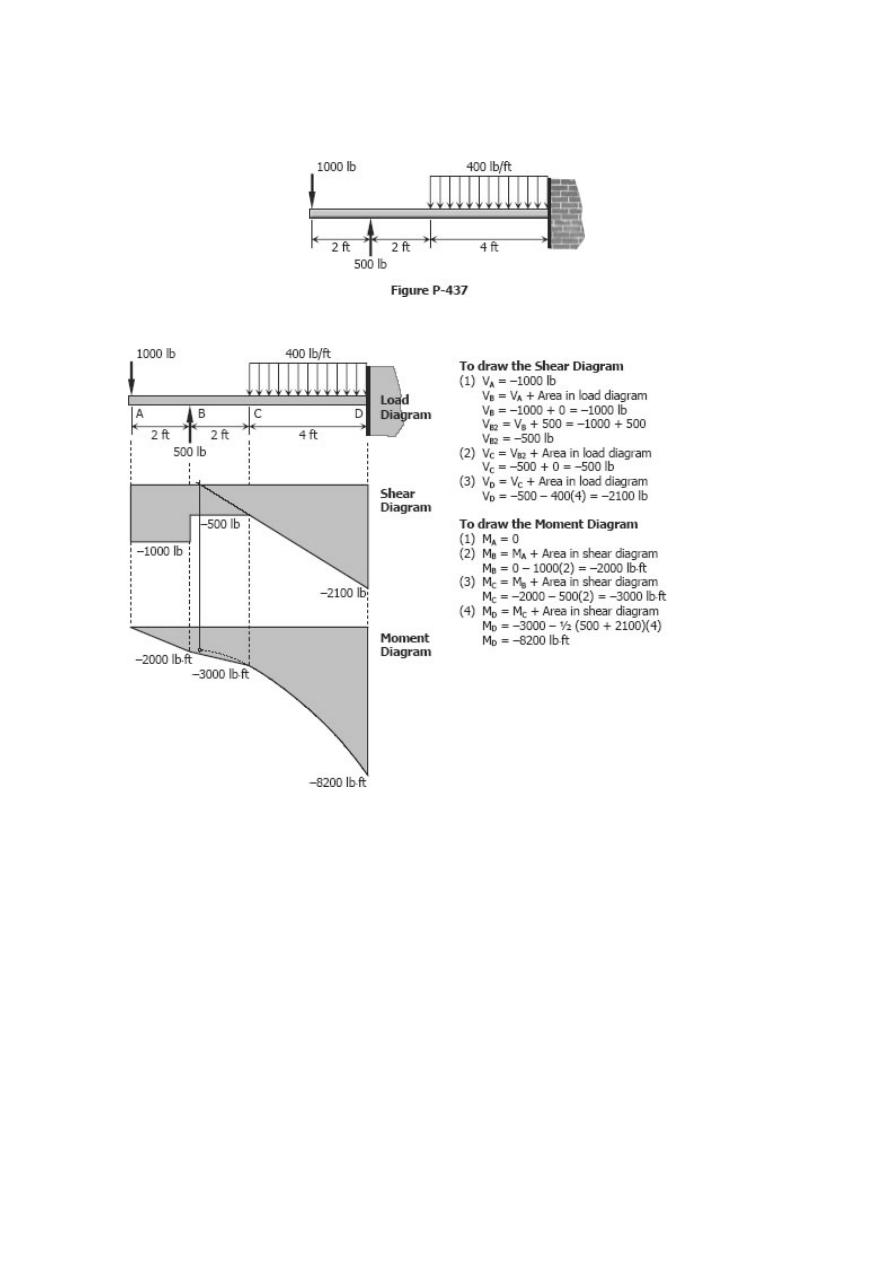

Problem 437

Cantilever beam loaded as shown in Fig. P-437

Solution 437

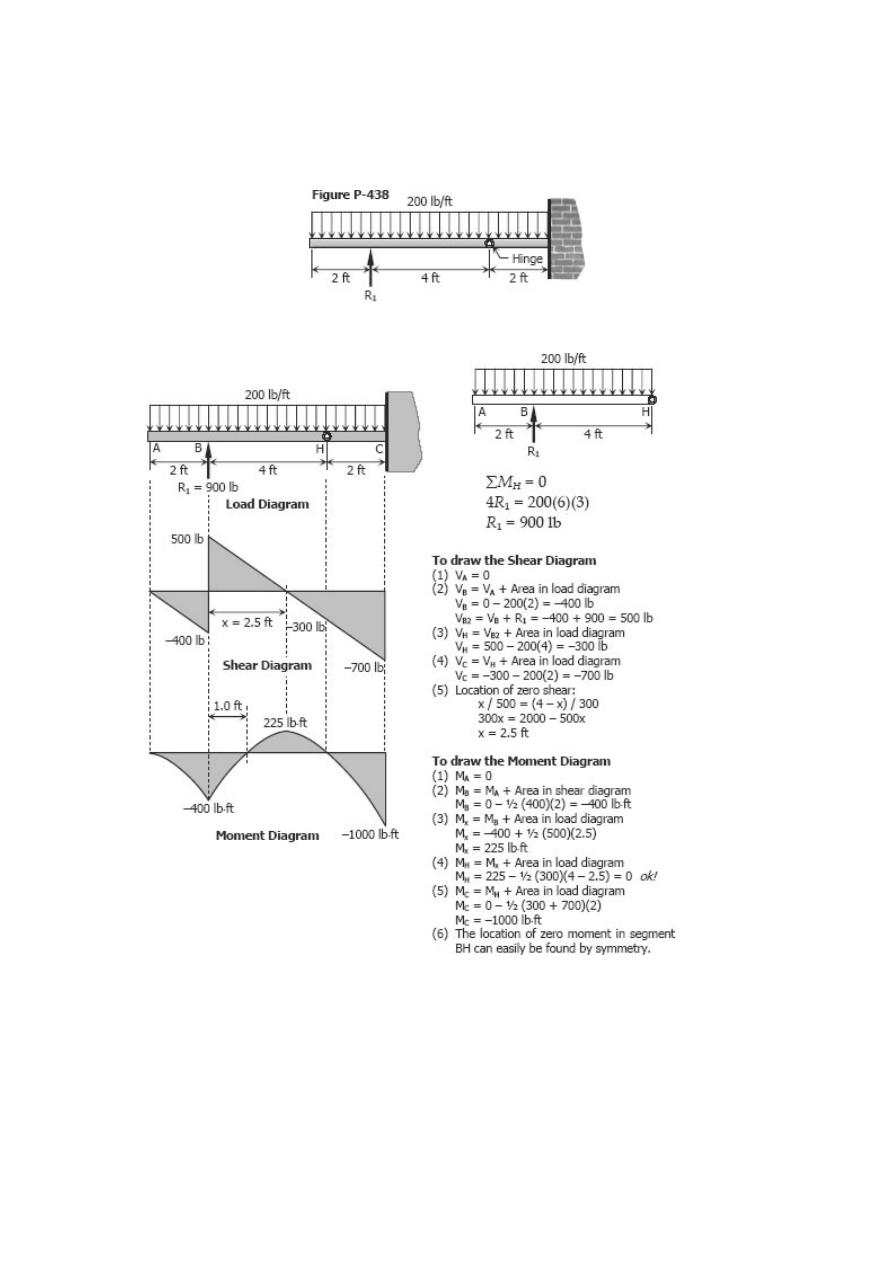

Problem 438

The beam loaded as shown in Fig. P-438 consists of two segments joined by a

frictionless hinge at which the bending moment is zero.

Solution 438

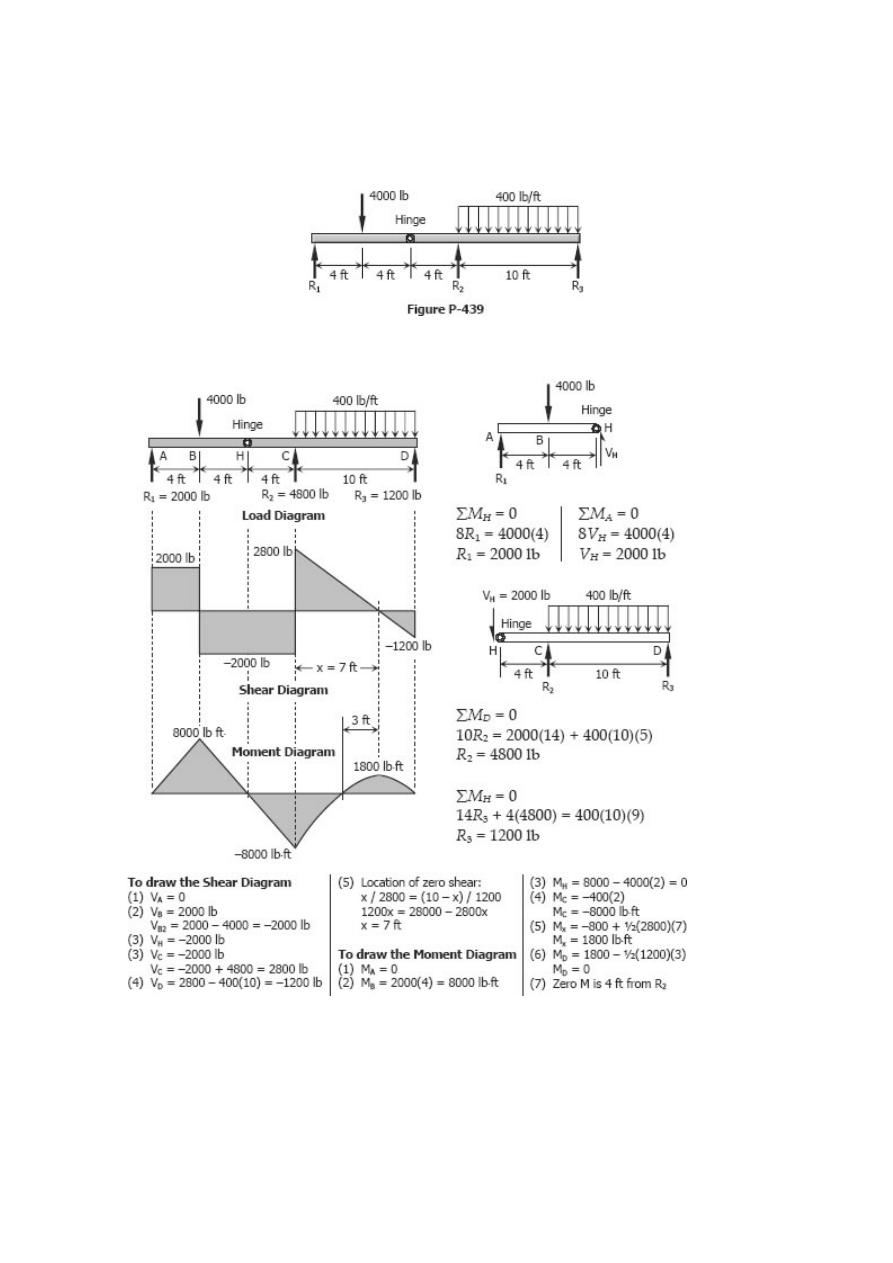

Problem 439

A beam supported on three reactions as shown in Fig. P-439 consists of two segments

joined by frictionless hinge at which the bending moment is zero.

Solution 439

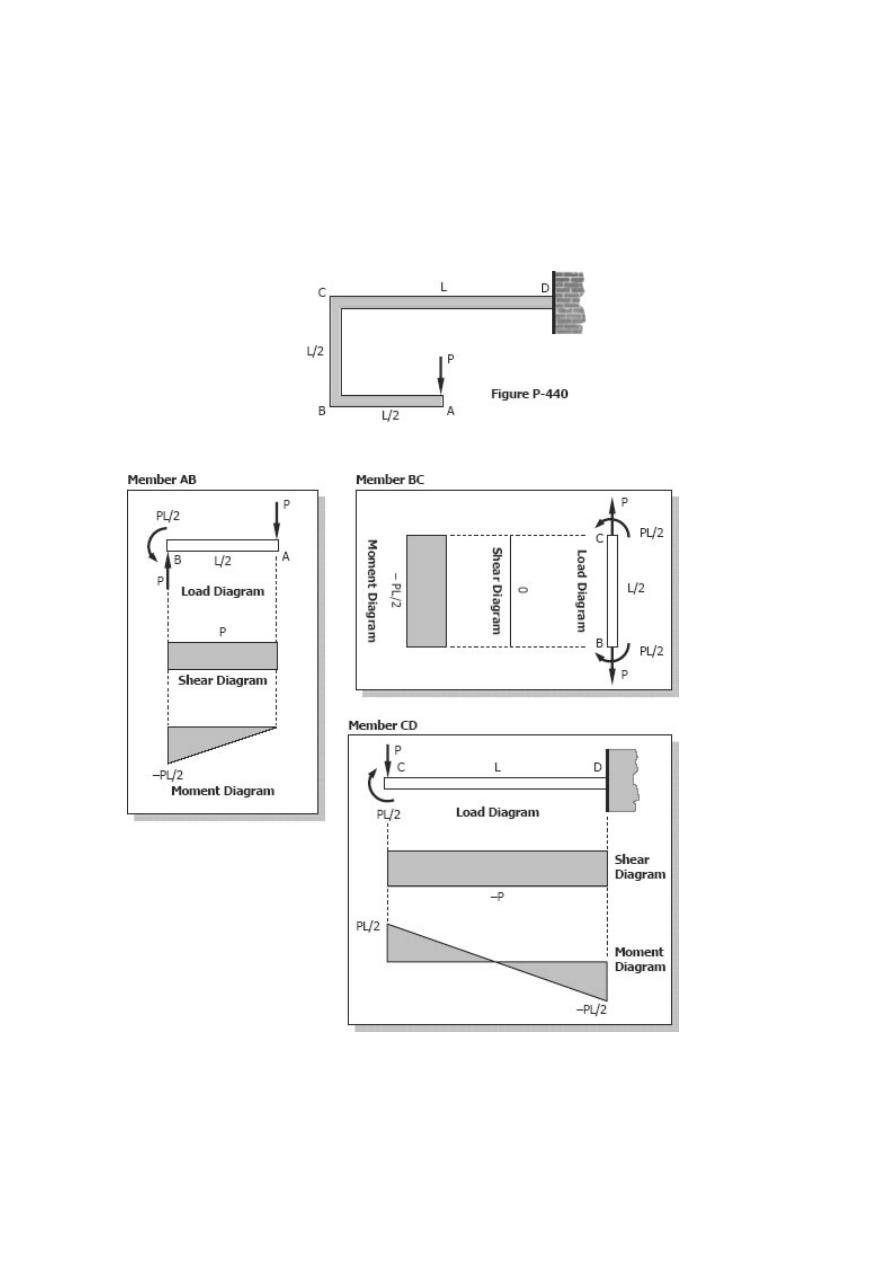

Problem 440

A frame ABCD, with rigid corners at B and C, supports the concentrated load as shown

in Fig. P-440. (Draw shear and moment diagrams for each of the three parts of the

frame.)

Solution 440

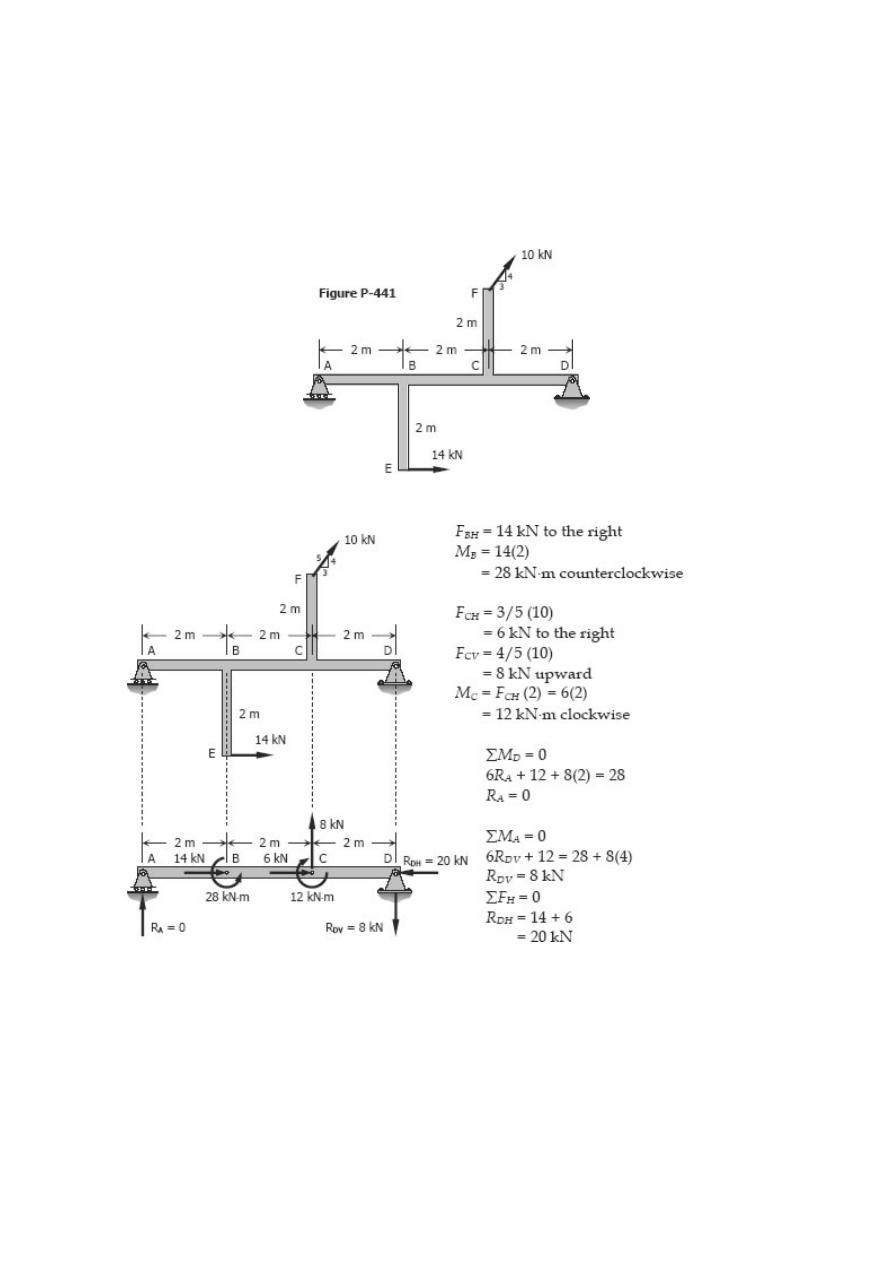

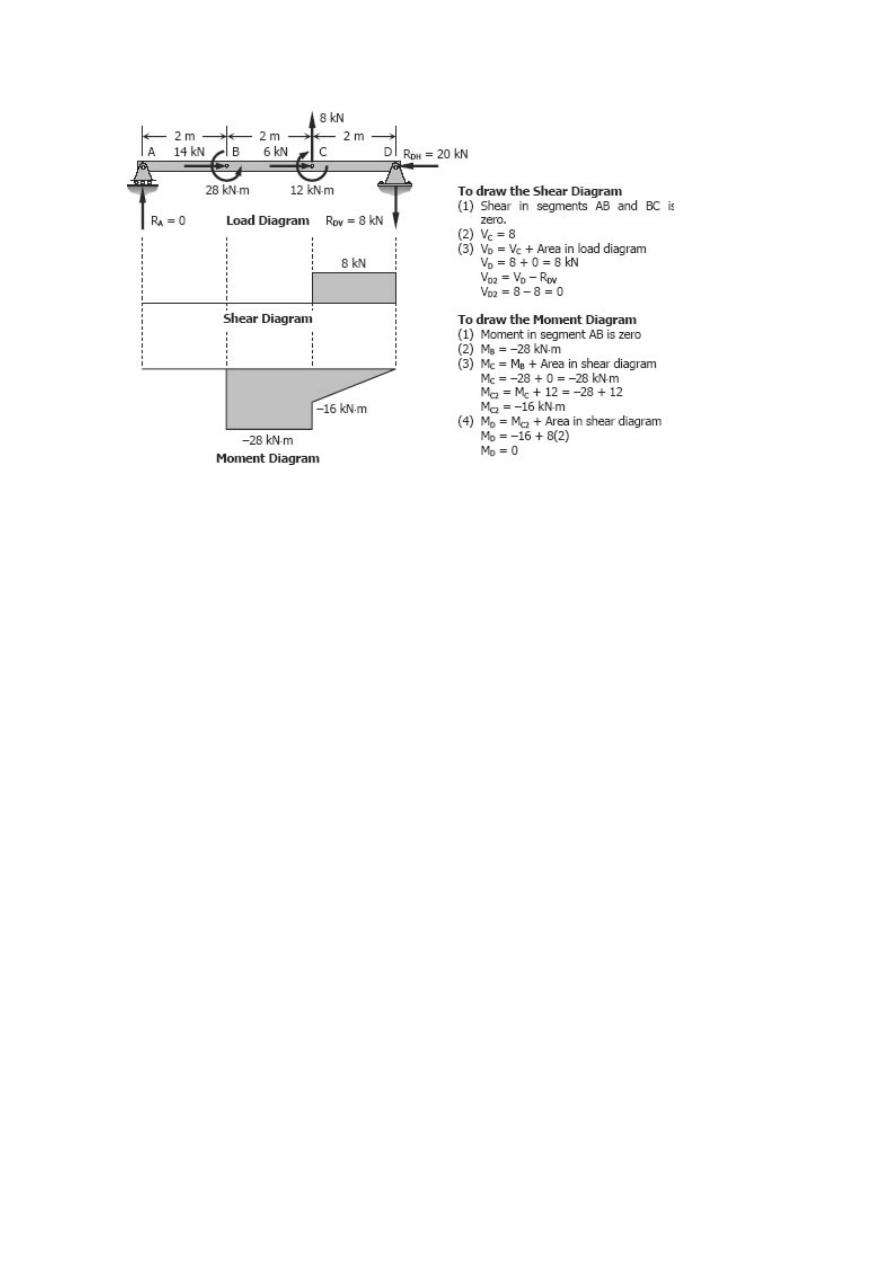

Problem 441

A beam ABCD is supported by a roller at A and a hinge at D. It is subjected to the loads

441, which act at the ends of the vertical members

shown in Fig. P-

BE and CF. These vertical members are rigidly attached to the beam at B and C. (Draw

shear and moment diagrams for the beam ABCD only.)

Solution 441

Problem 442

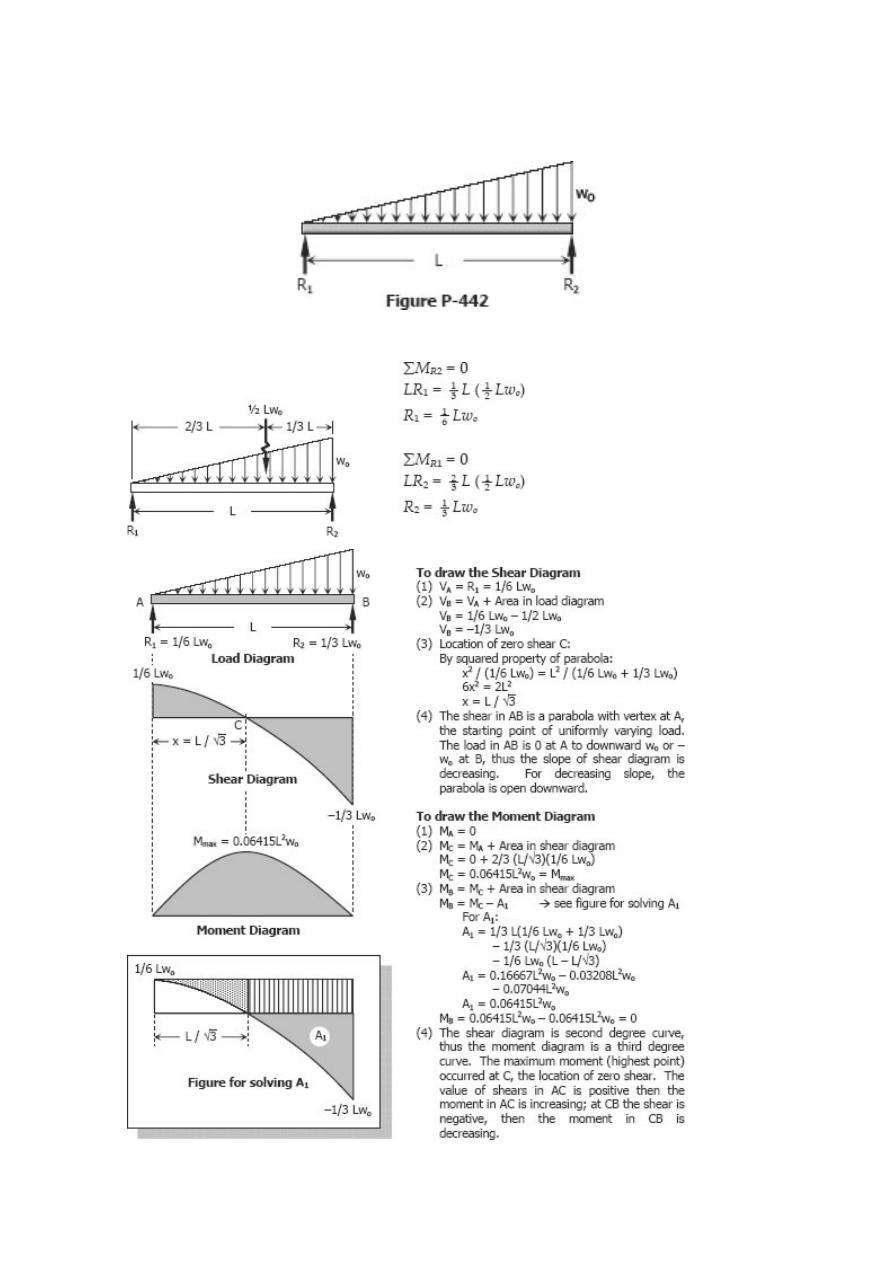

Beam carrying the uniformly varying load shown in Fig. P-442.

Solution 442

Problem 443

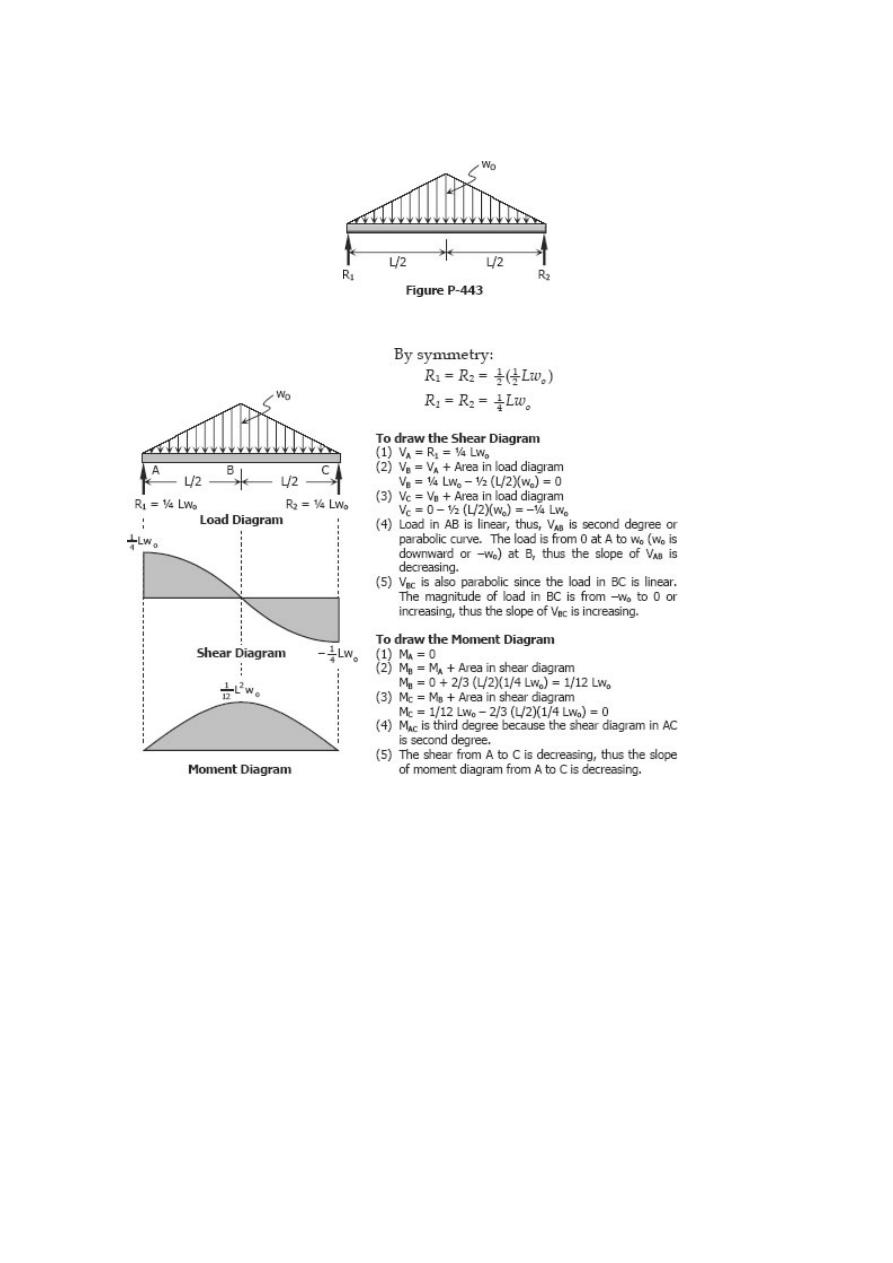

Beam carrying the triangular loads shown in Fig. P-443.

Solution 443

Problem 444

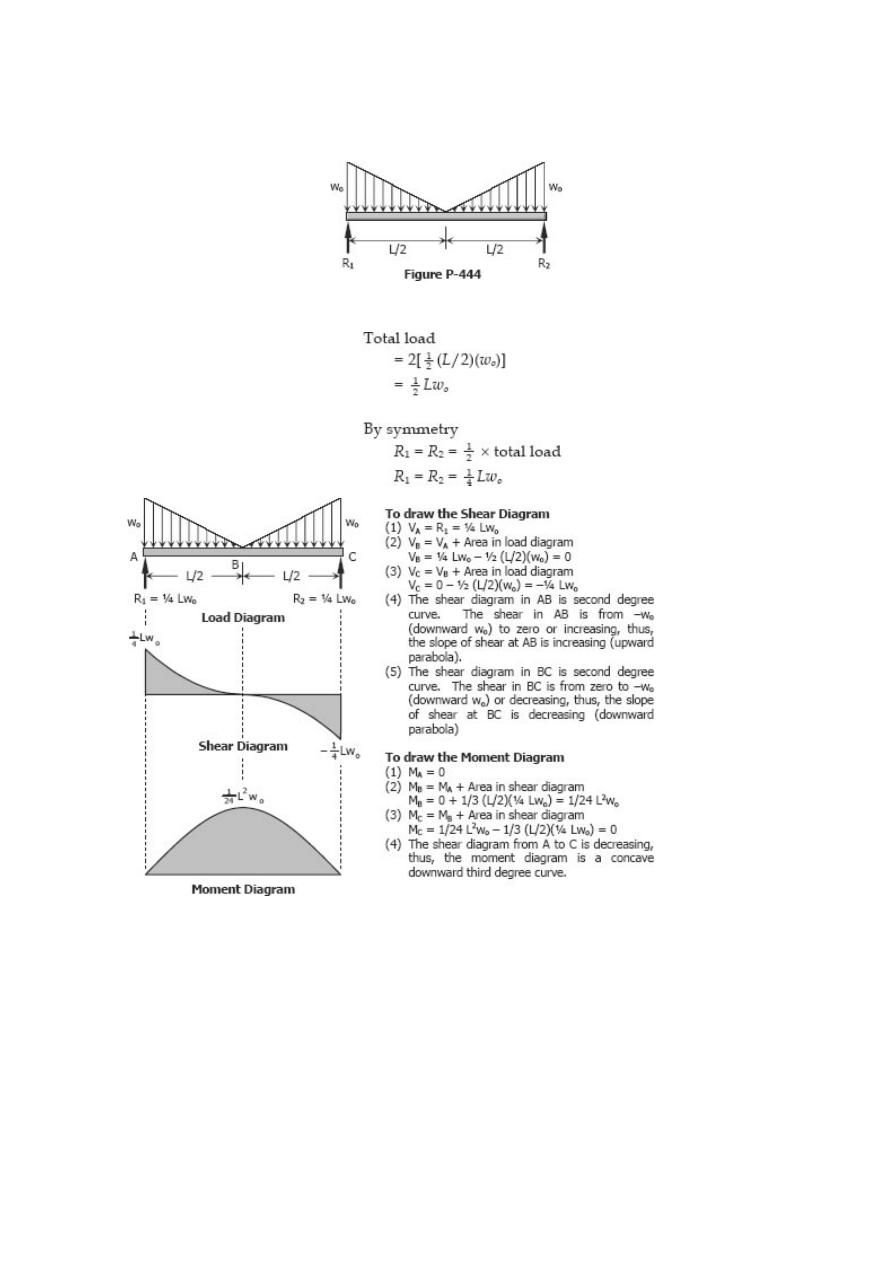

Beam loaded as shown in Fig. P-444.

Solution 444

Problem 445

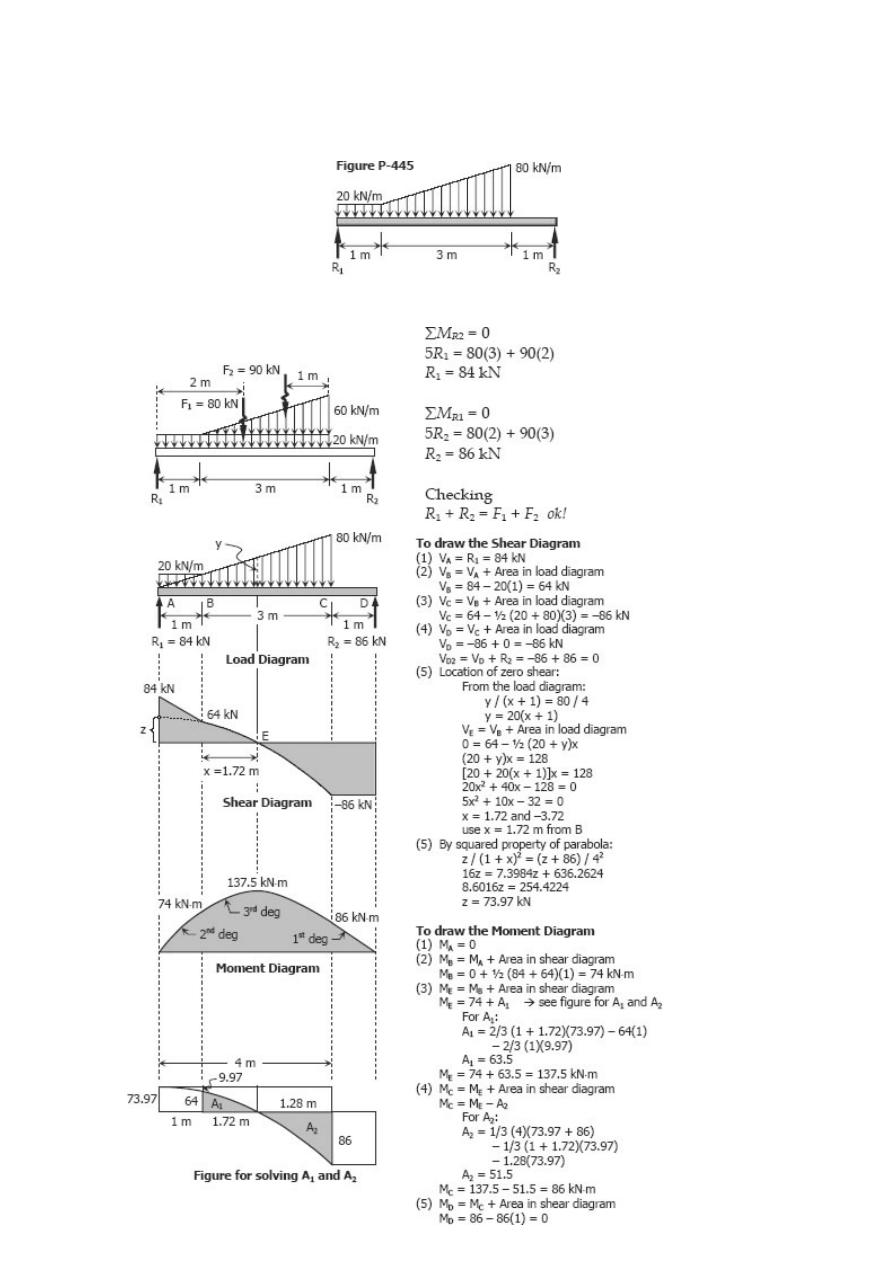

Beam carrying the loads shown in Fig. P-445.

Solution 445

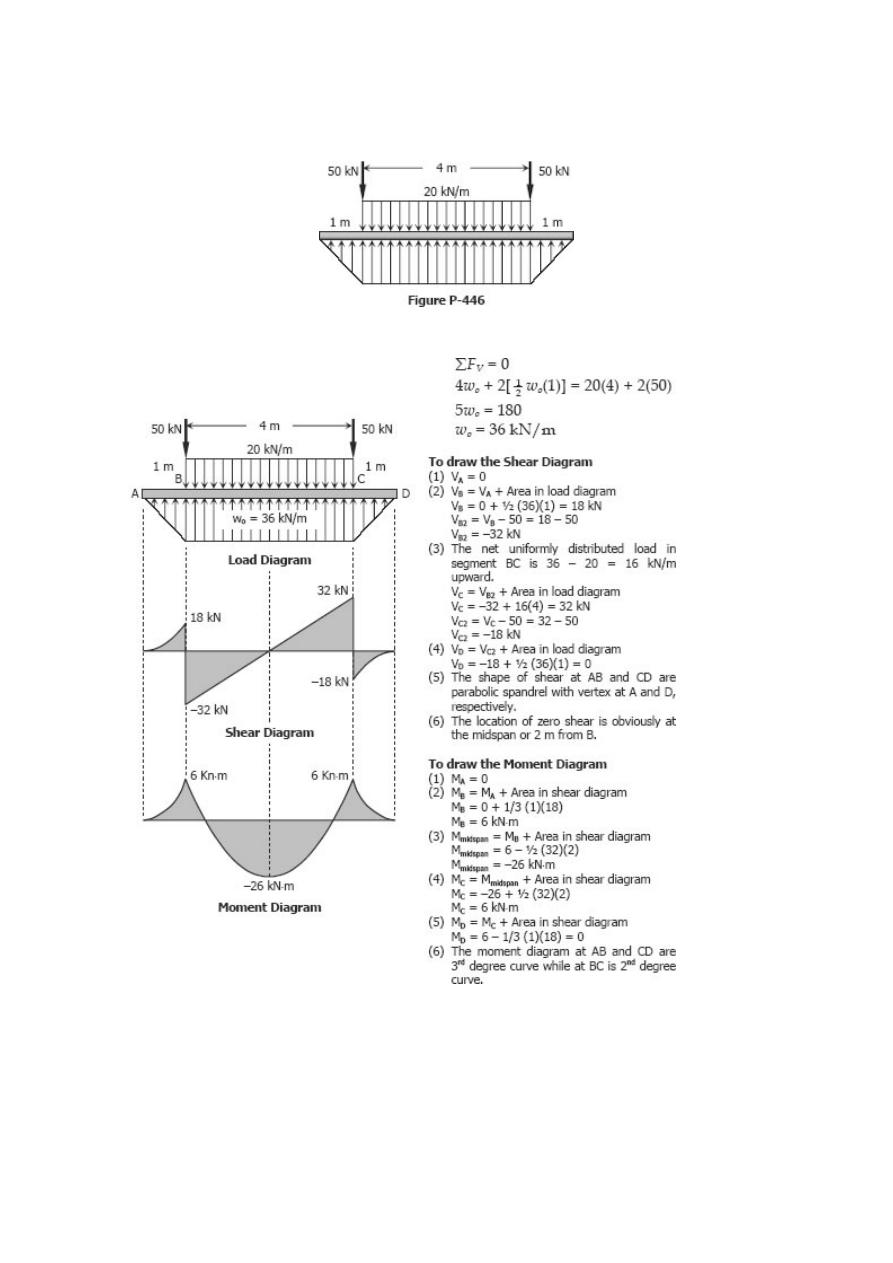

Problem 446

Beam loaded and supported as shown in Fig. P-446.

Solution 446

Finding the Load & Moment Diagrams with Given Shear

Diagram

INSTRUCTION

In the following problems, draw moment and load diagrams corresponding to the given

shear diagrams. Specify values at all change of load positions and at all points of zero

shear.

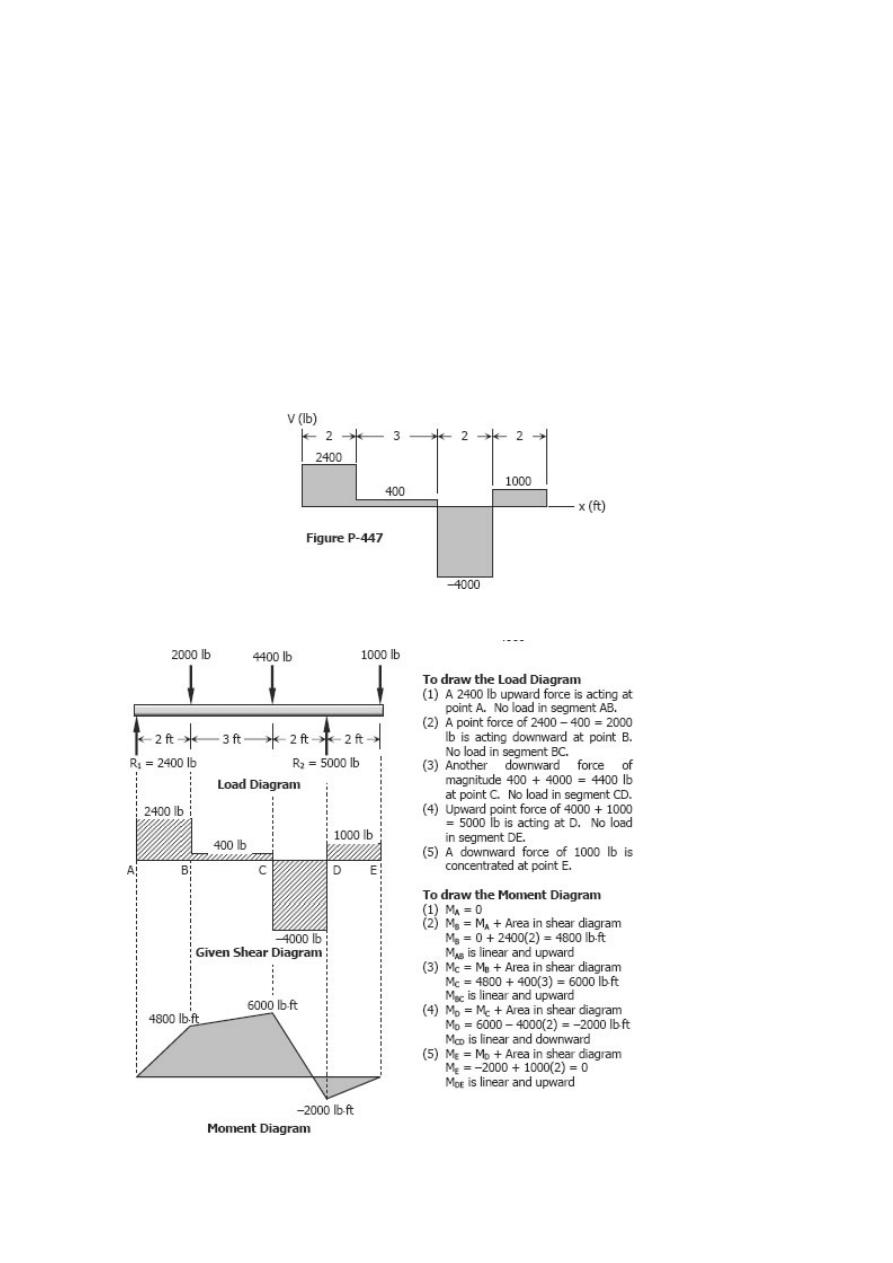

Problem 447

Shear diagram as shown in Fig. P-447.

Solution 447

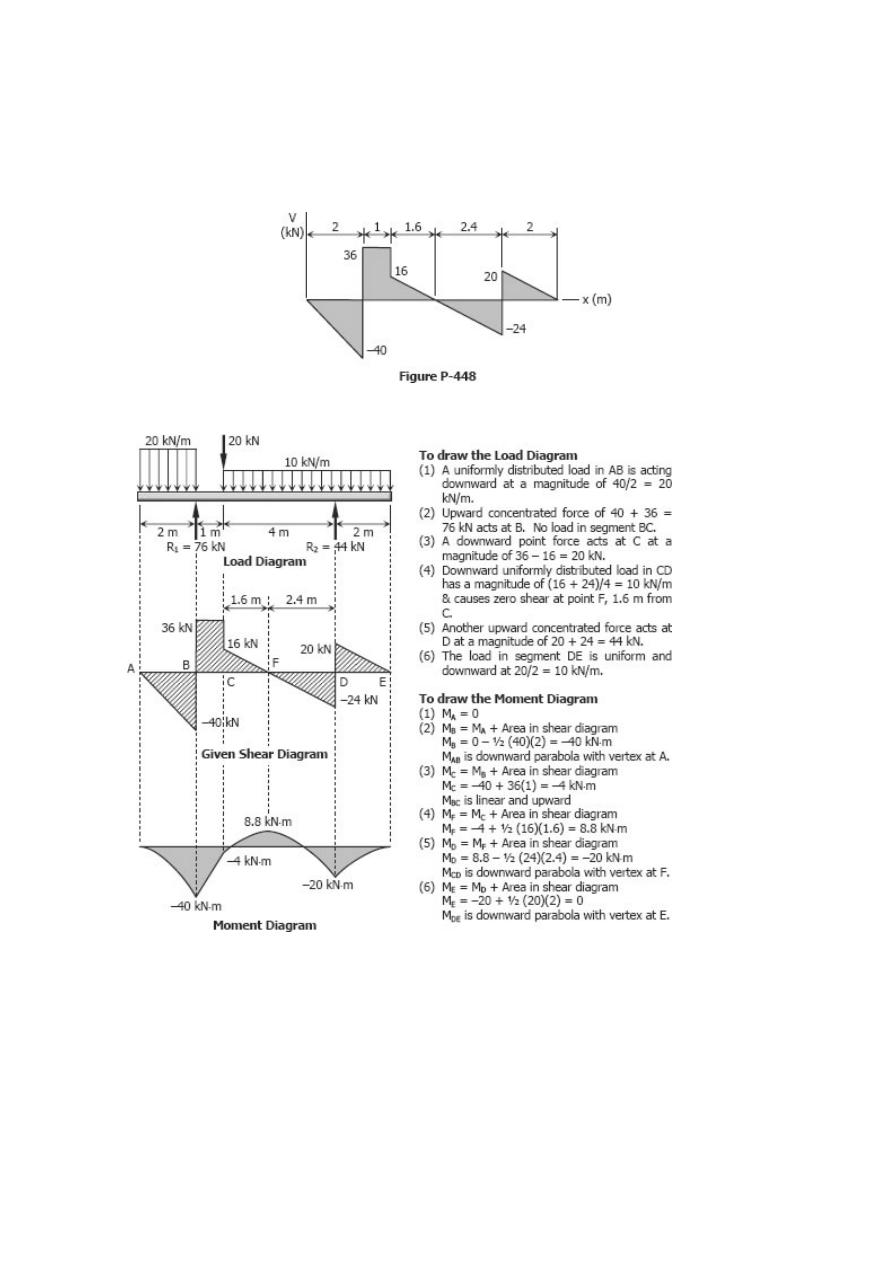

Problem 448

Shear diagram as shown in Fig. P-448.

Solution 448

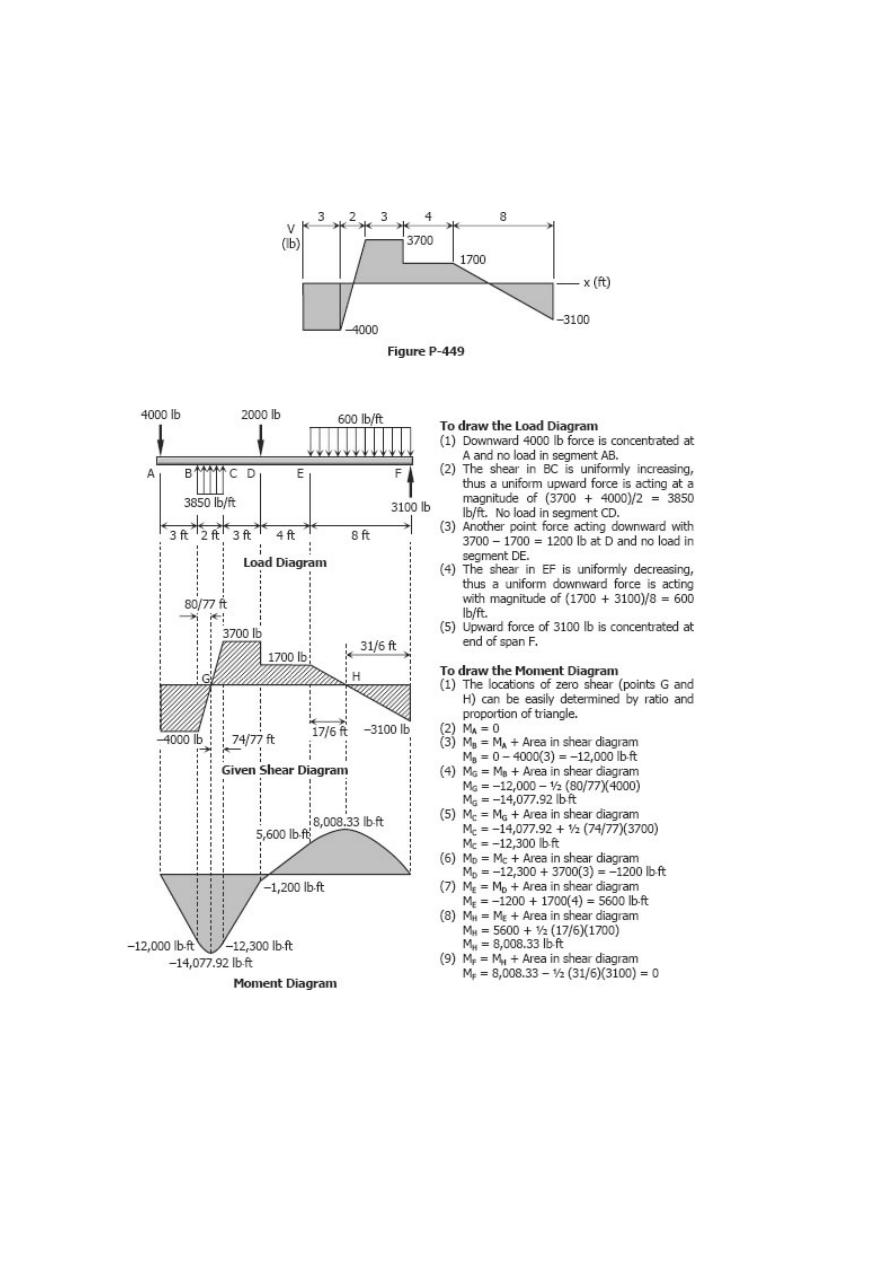

Problem 449

Shear diagram as shown in Fig. P-449.

Solution 449

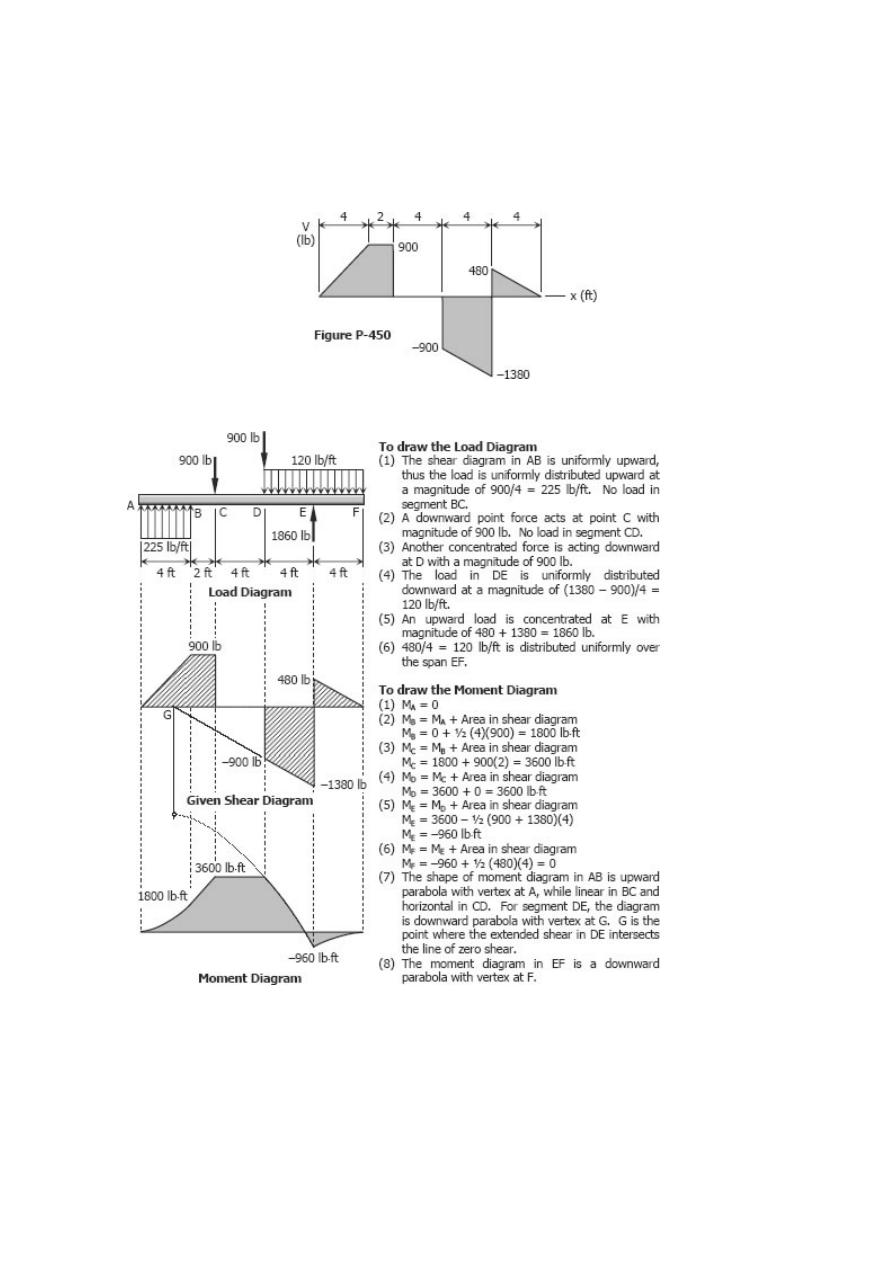

Problem 450

Shear diagram as shown in Fig. P-450.

Solution 450

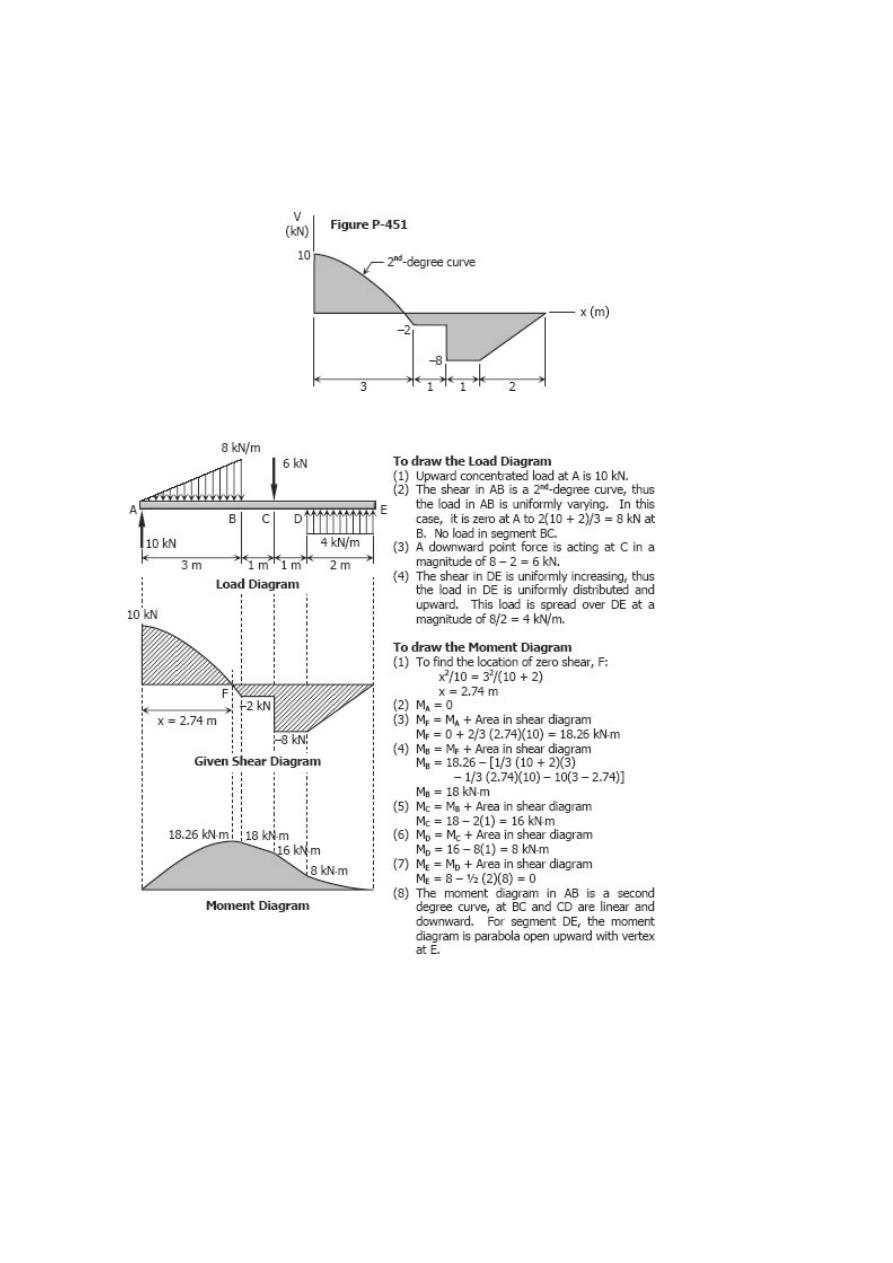

Problem 451

Shear diagram as shown in Fig. P-451.

Solution 451

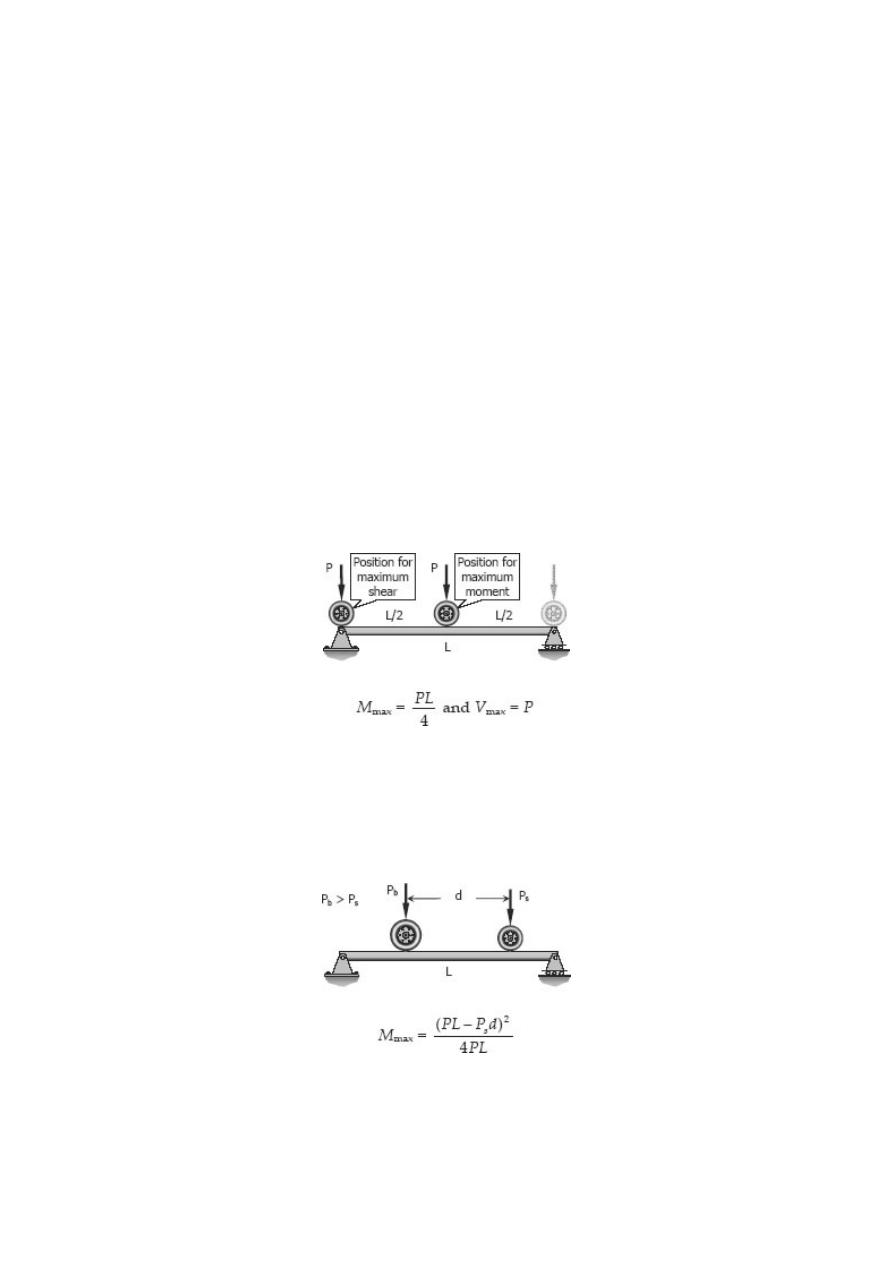

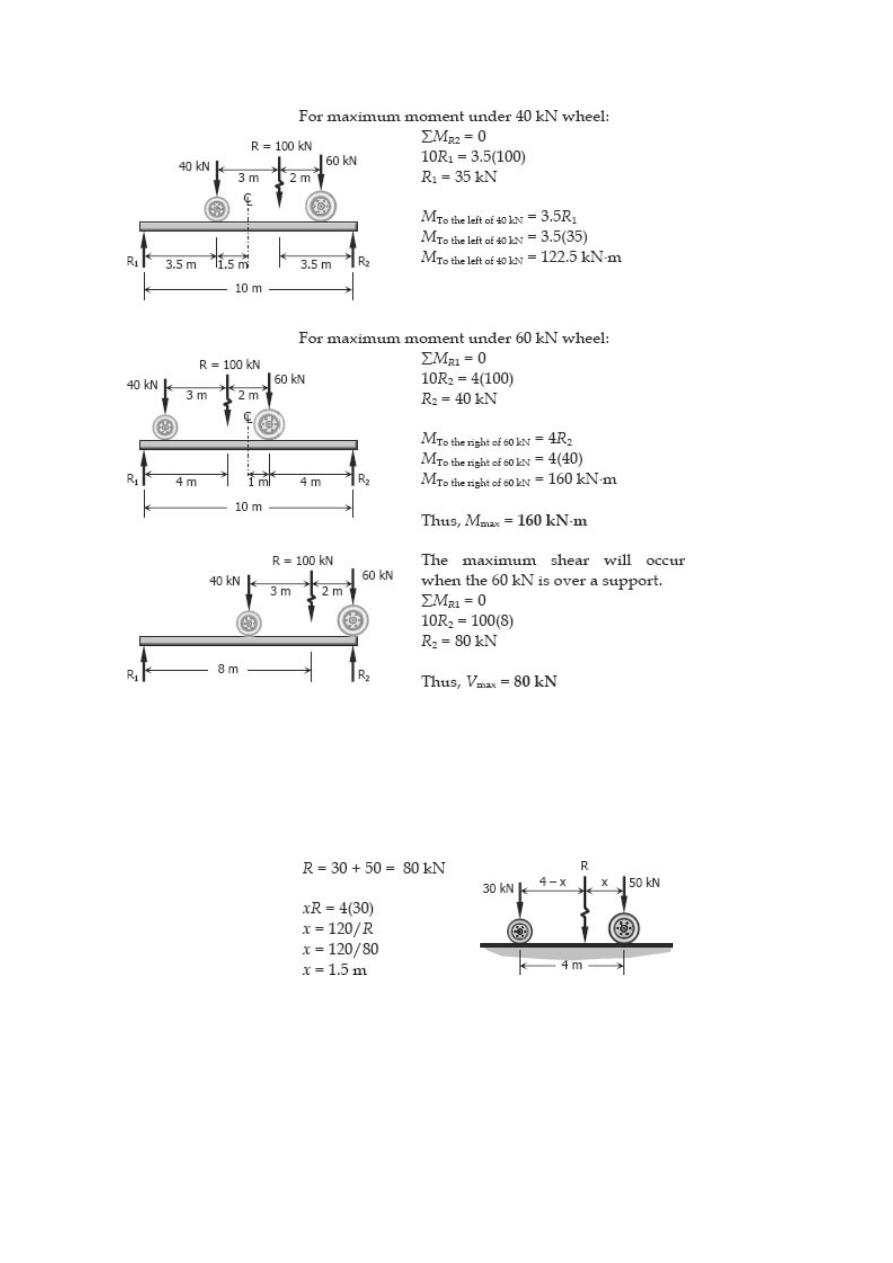

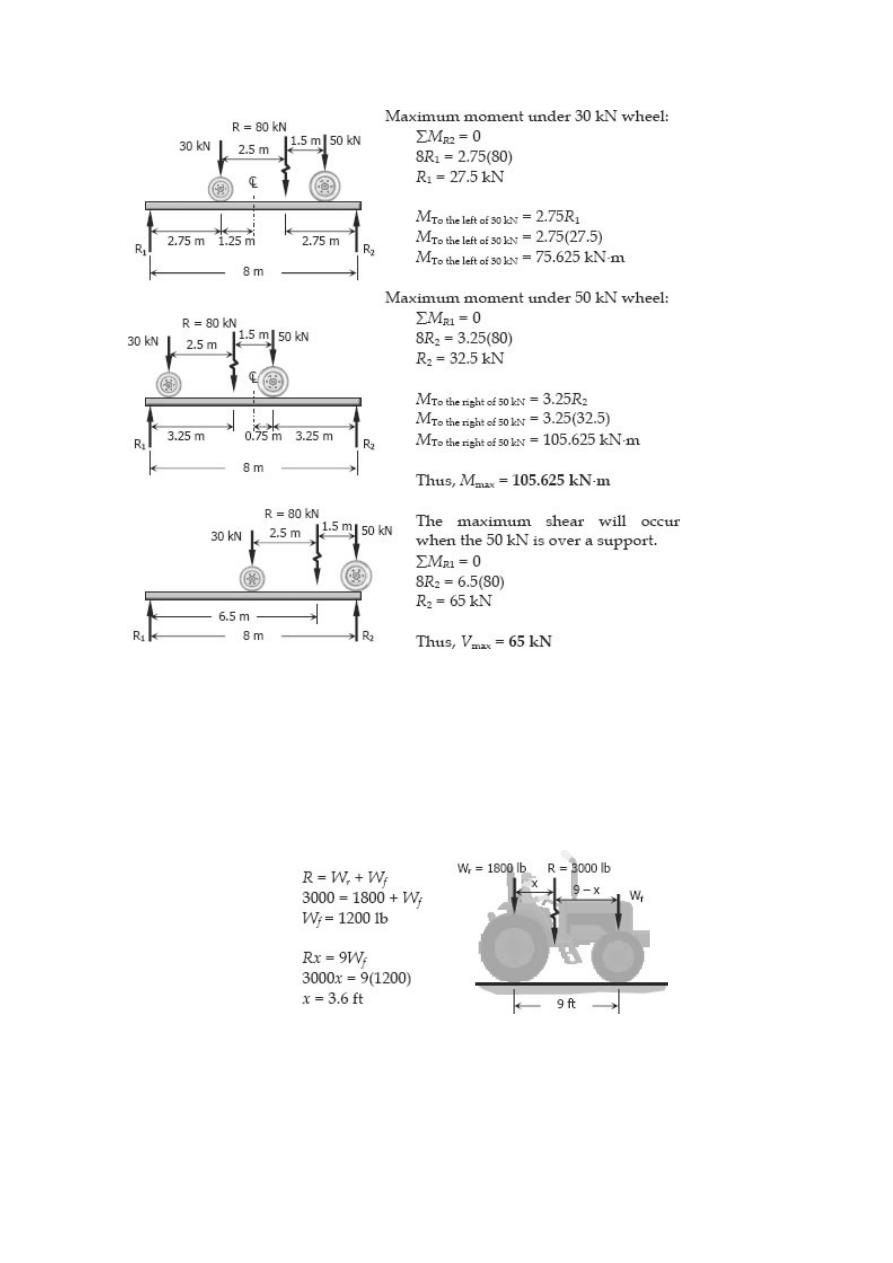

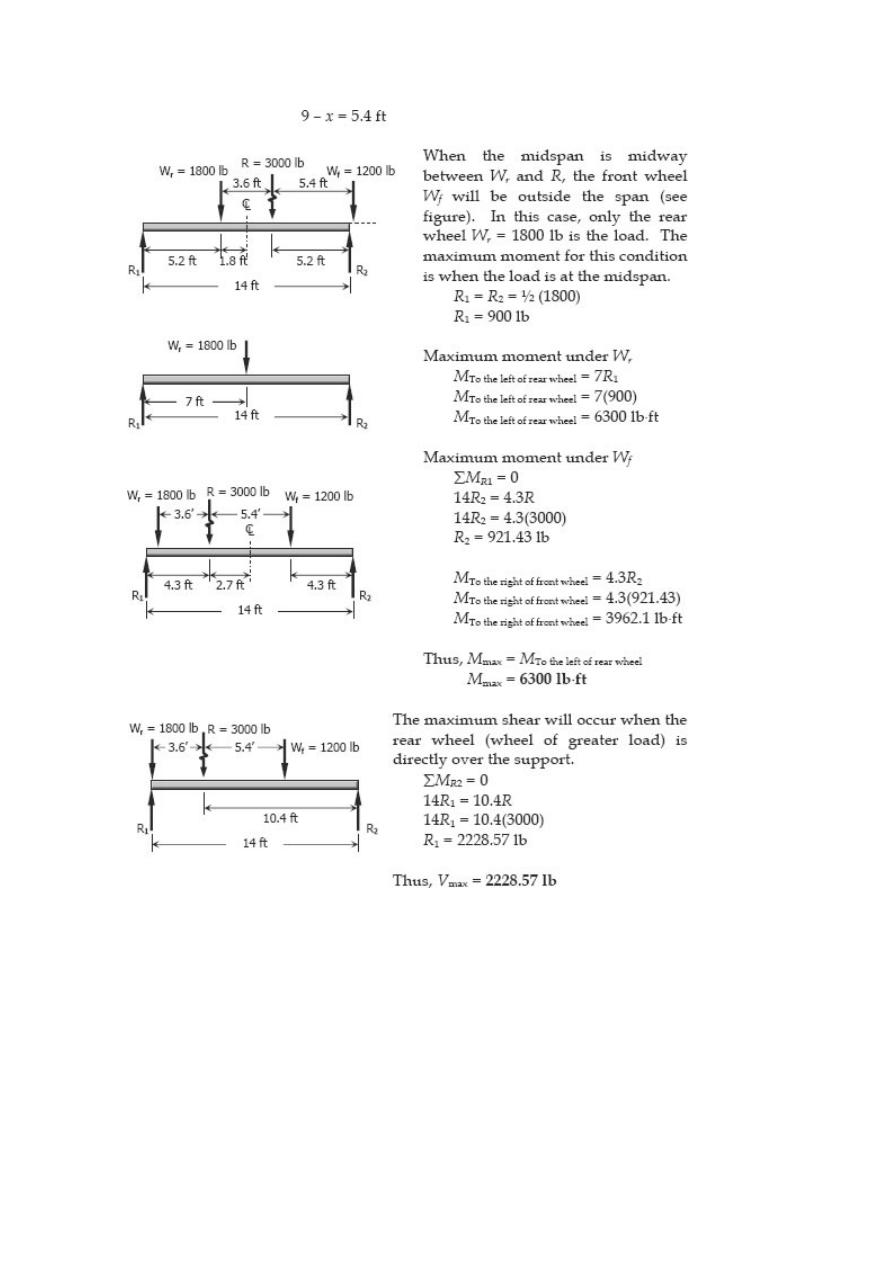

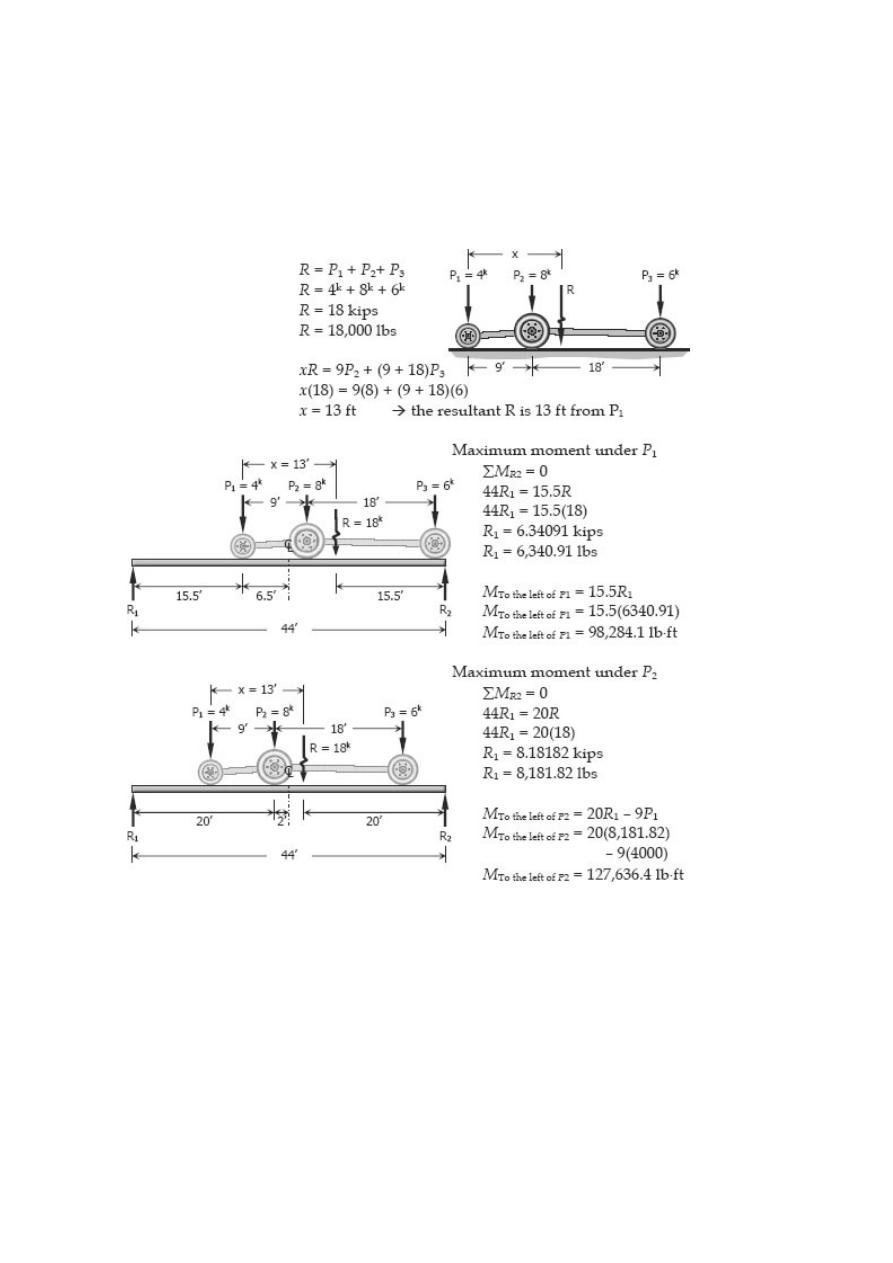

Moving Loads

From the previous section, we see that the maximum moment occurs at a point of zero

shears. For beams loaded with concentrated loads, the point of zero shears usually

occurs under a concentrated load and so the maximum moment.

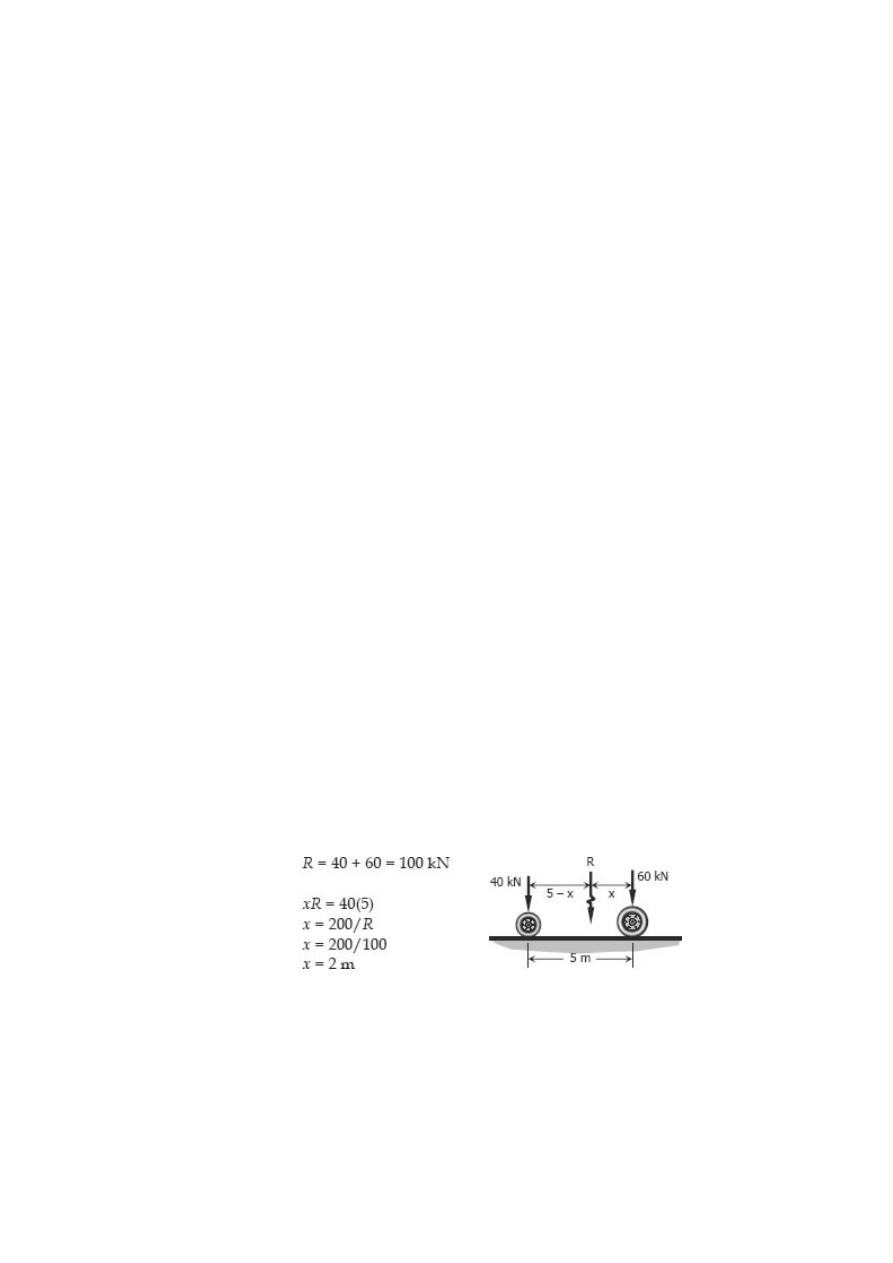

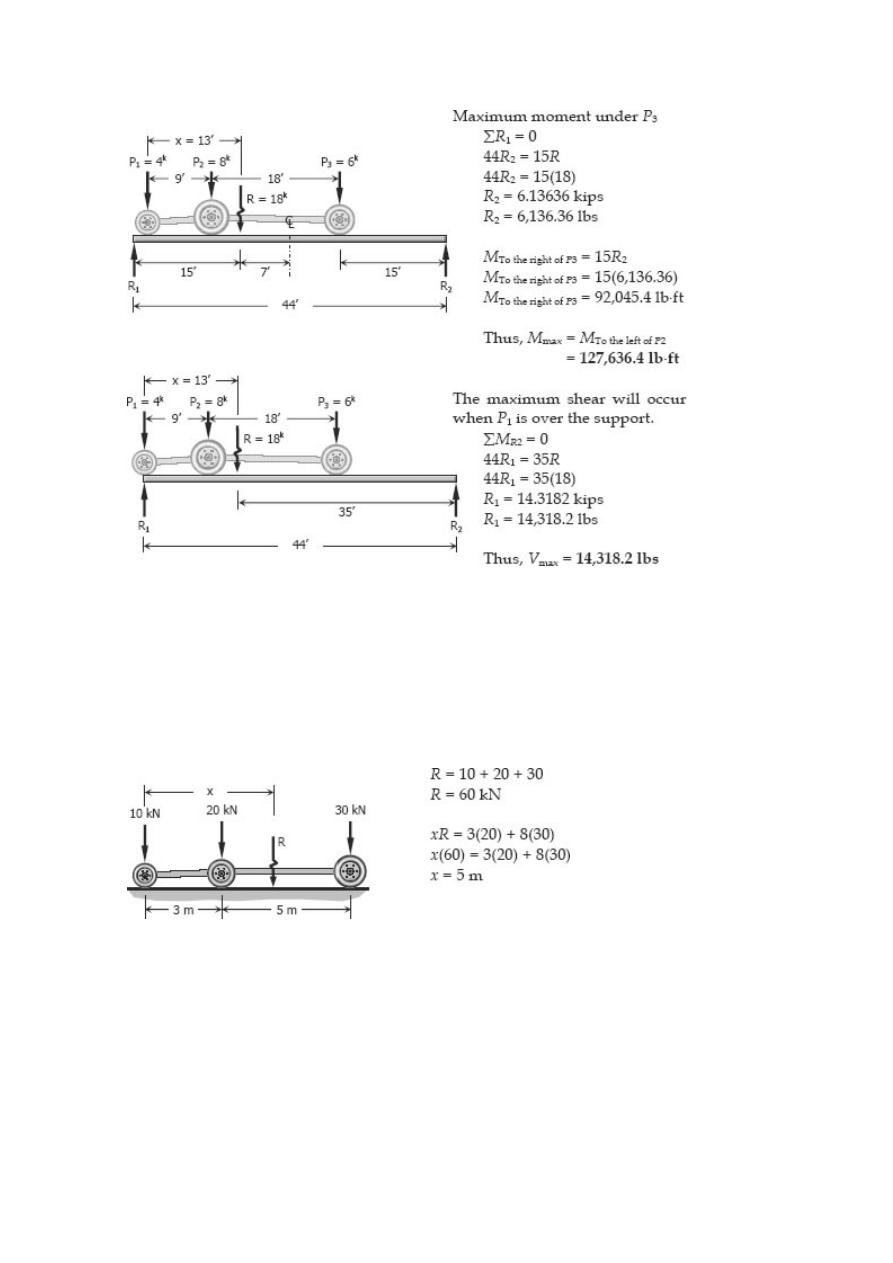

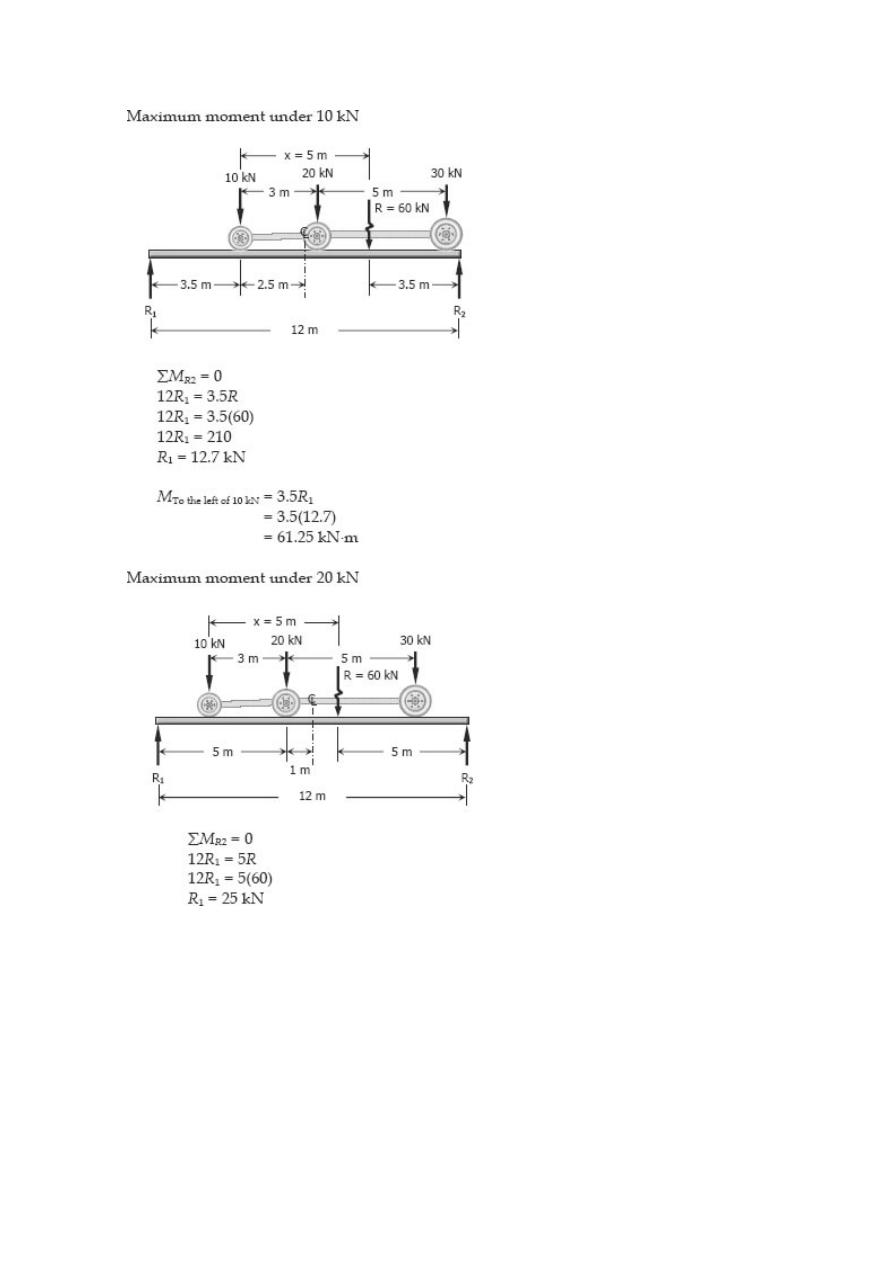

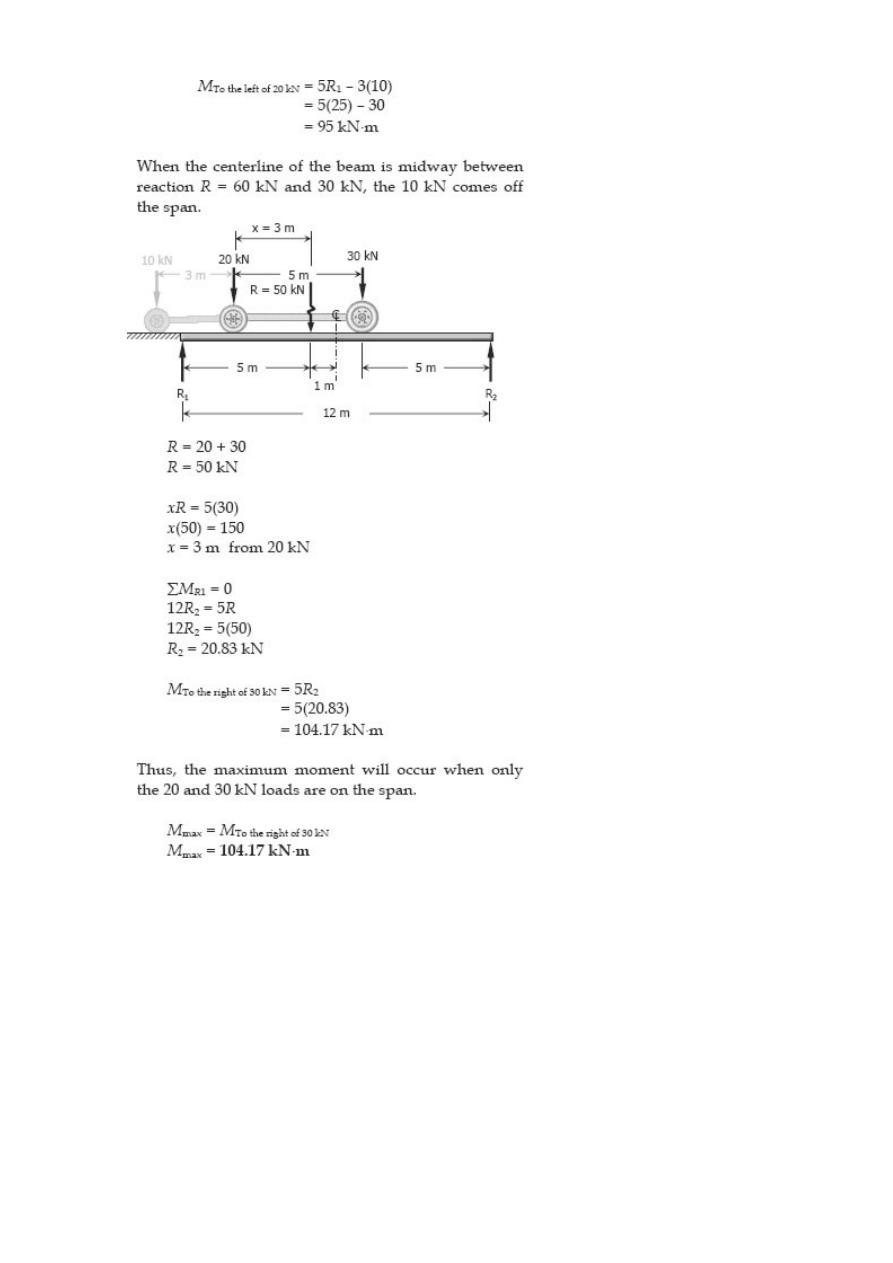

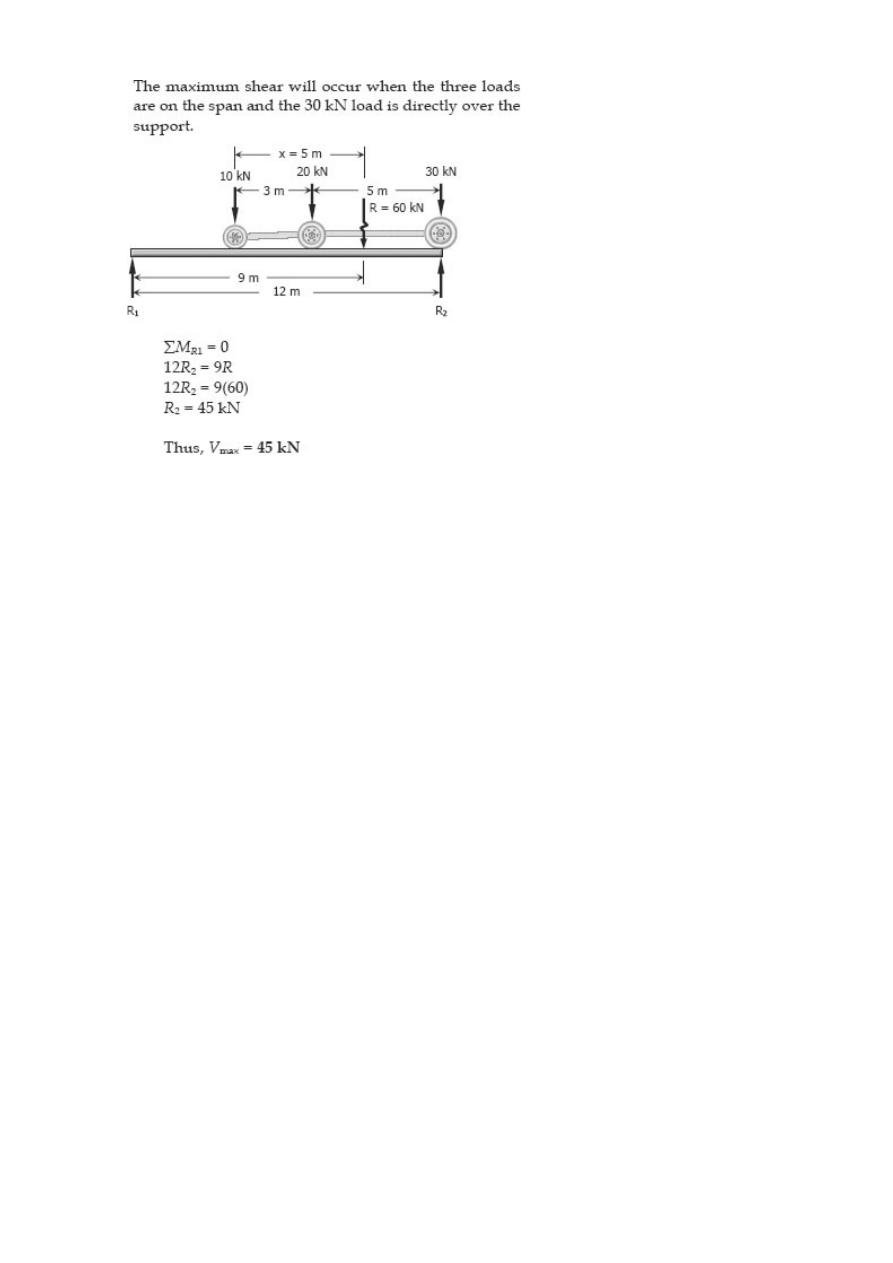

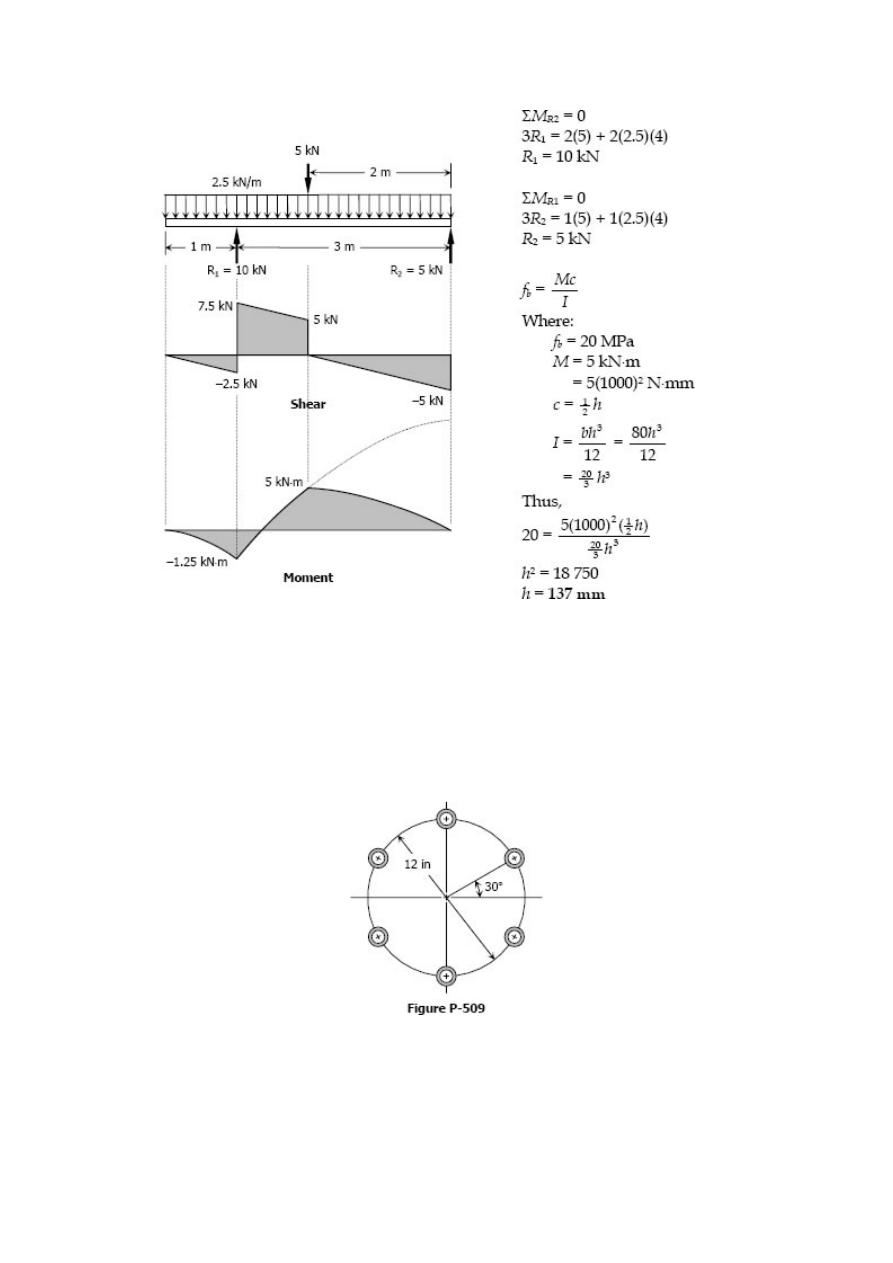

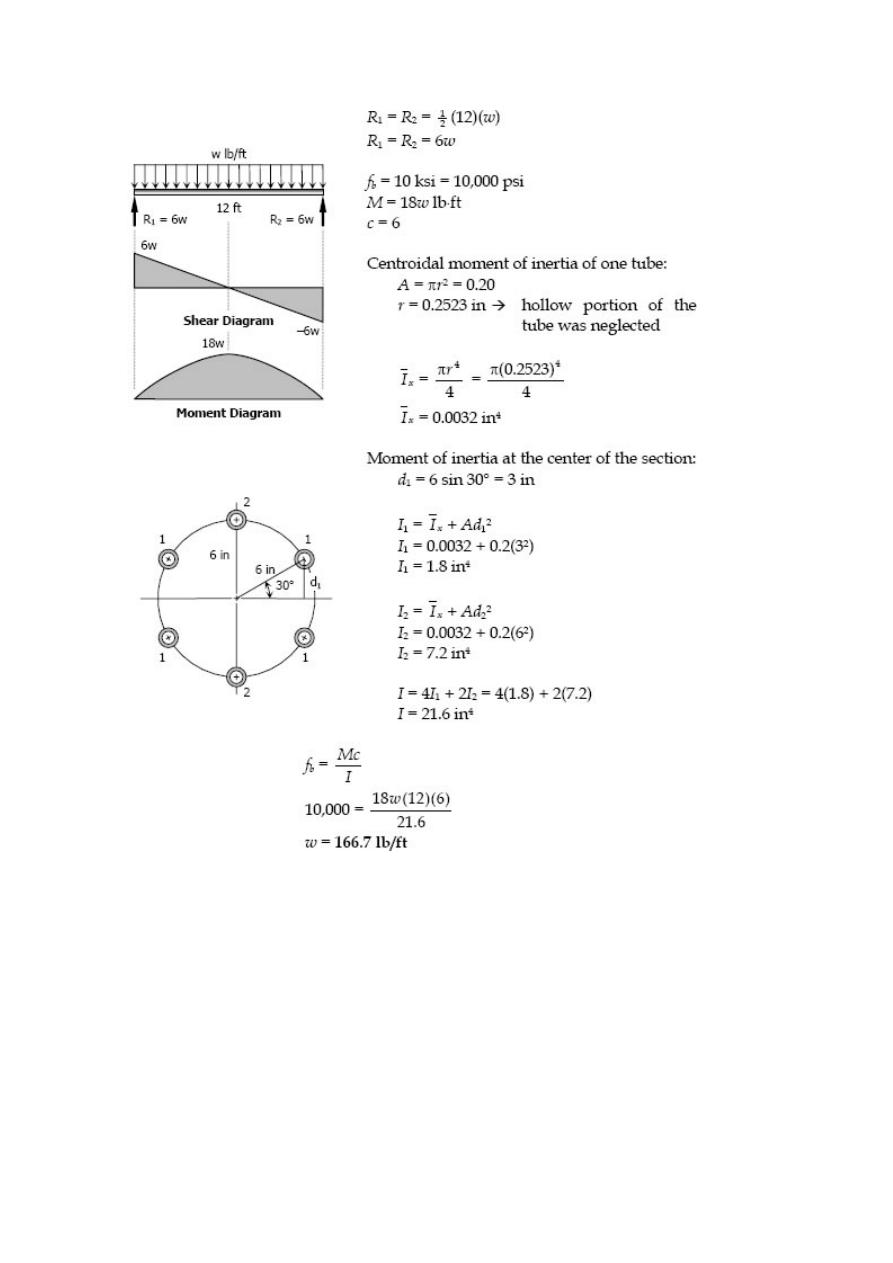

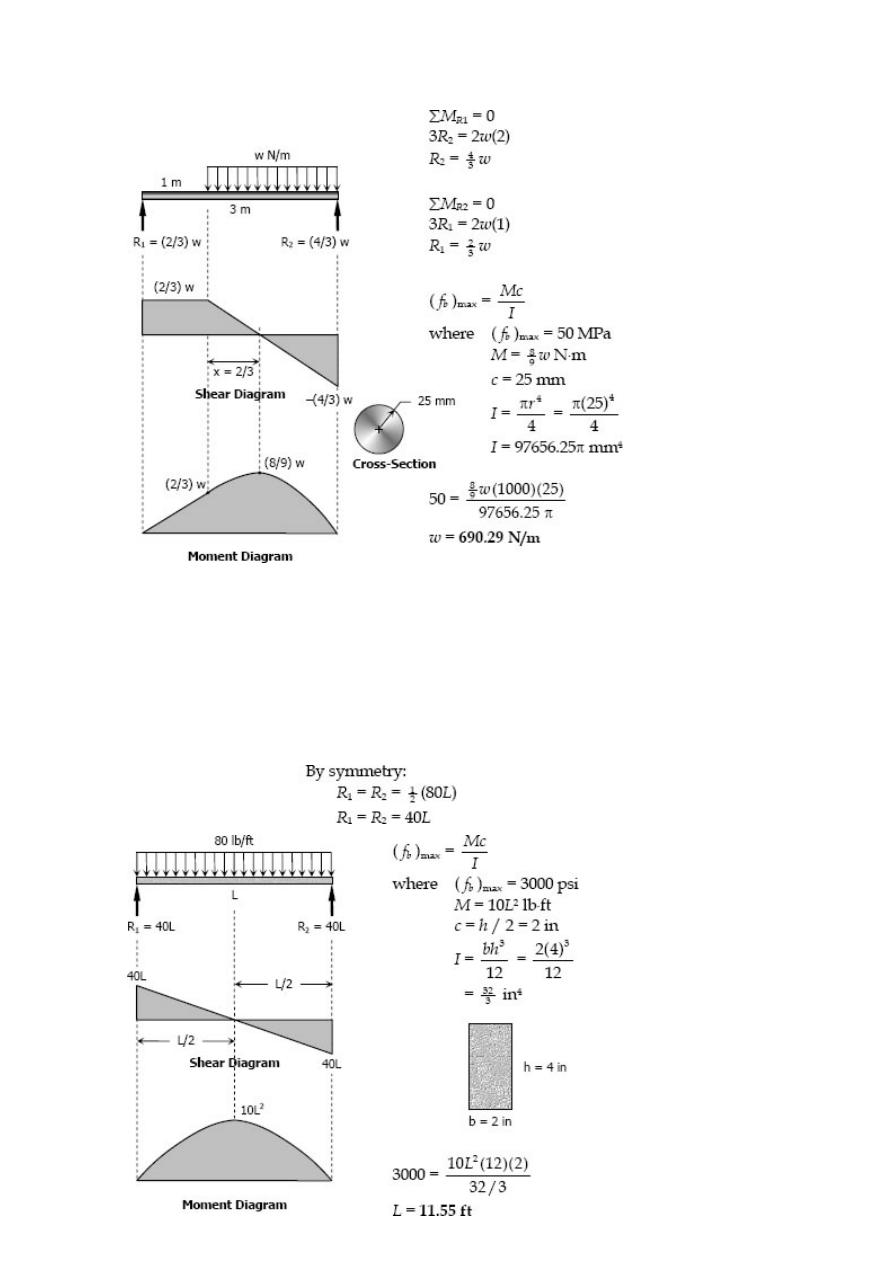

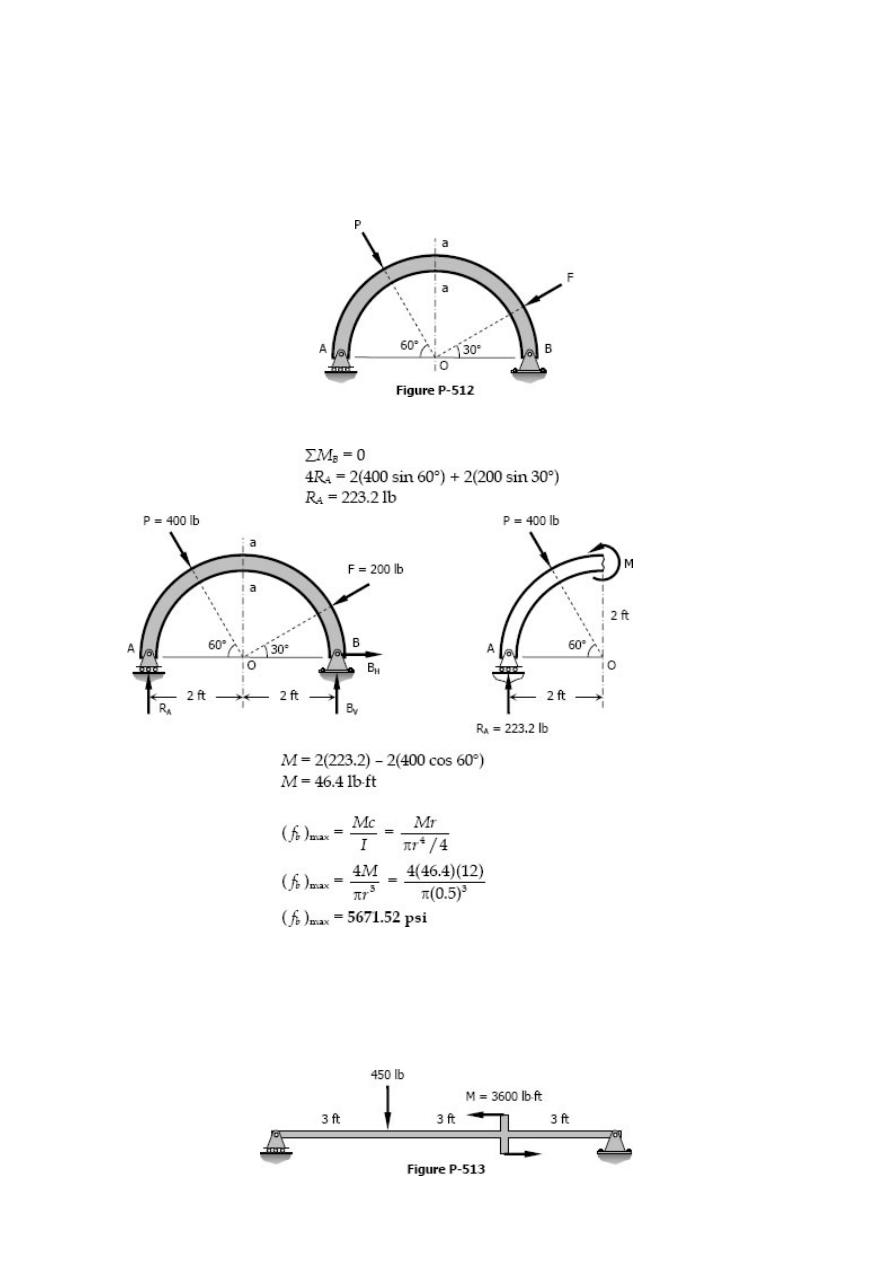

Beams and girders such as in a bridge or an overhead crane are subject to moving