• GYPSUM MATERIAL

Dr. Raied Al-Attar2016-2017

3th lecture

• GYPSUM MATERIALA number of gypsum products are used in dentistry as adjunct to dental operation. Various types of gypsum products are used to form molds and casts on which dental prosthesis and restoration are constructed

• Impression material

• Casts and dies

• Mounting cast to articulator

• Molds for processing dental polymers

• Gypsum-bonded investment

• Bite registration (centric jaw relation record)

Properties of ideal gypsum product

• Dimensional stability no expansion or contraction during and after setting• High compressive strength

• Good surface hardness

• Reproduce the fine details

• Produce smooth surface

• Resonable setting time

• Compatible with the impression material

• Can be disinfected without damaging the surface

3

Classification of gypsum

• Impression plaster (Type I) composed of plaster of paris

rarely used replaced by hydrocolloids and elastomers uses1-final impression in compelet denture construction

2-bite registrition matrial

3-for making impressions for maxillofacial prosthesis

4

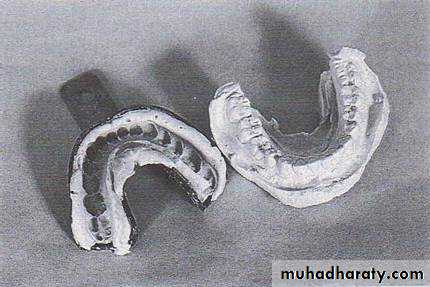

Impression (negative replica), poured into gypsum to make a cast (positive replica

• B Model plaster (Type II) .(beta hemihydrate) : used for

Diagnostic cast constructionArticulation of stone cast

Flasking procedure for acrylic dentures (cast end)

The mix produces a weak cast compared to dental stone. It’s available is fast and regular sets.

5

6

Plaster

PlasterFlask

C Dental stone (Type III): (alpha hemihydrate)used for making

Full or partial denture modelsOrthodontic models

Flasking procedure for acrylic dentures (teeth end)

It requires less water,

stronger than plaster

7

Dental stone casts

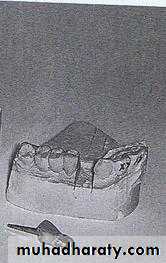

D Dental stone, high strength (Type IV):

die stone used in fabricating wax patterns of cast restorations (crown &bridge)Implants

Precision attachments work

Often colored pink or green

Almost 2 times stronger than type III stone

8

Die stone used in the fabrication of cast crown restoration

E High strength, high expansion dental stone (Type V)

Colored blue or greenMost costly of all gypsum materials

Lowest W:P ratio, higher compressive strength

The need for higher expansion (0.1%) was to compensate for the solidification shrinkage of some alloys used as base metals used for dental casting

9

• Methods of productionGypsum products are produced by partial dehydration of mineral gypsum. Which is calcium sulfate DI – hydrate ( Ca So4.2H2o). They are supplied as powder when mixed with water they form slurry or paste, which set to form a rigid mass.

• PLASTER

• When the gypsum is heated in open container to 110 – 120 C, it gives part of its water to form plaster which is Ca So4.1/2 H 2O

• Ca So4.2H2o------------ Ca So4.1/2 H2o

• The crystal of plaster are irregular in shape and porous and called Beta

10

• STONEChemically stone is the same as plaster that is Ca So4.1/2 H2o but it is made by heating gypsum in wet condition under super heat steam to 125 C. the crystals are dense and regular and have prismatic shape.They are called alpha particles.

DIE STONE

It is produced by boiling gypsum with Ca Cl2 (calcium chloride). The crystal are also dens, regular and have prismatic shape, alpha.

11

SETTING REACTION

When mixing any type of gypsum product (plaster or stone or die stone) with water, they are converted back to gypsum and set to hard mass. The probable sequence is as follows:A. plaster or stone or die stone (Ca So4.1/2 H2o) dissolves in water and it react with water to form gypsum (CaSo4.2H2o).

B. gypsum is less soluble in water and the solution become super- saturated (unstable condition).

C. gypsum crystallize, allowing more particles to dissolve and form gypsum. This will continue until all the particles have been converted to gypsum (Ca So4.2H2o). each crystal as it forms become nucleus for crystallization.

Ca So4.1/2 H2o +H2o …………. Ca So4.2H2O + HEAT (exothermic reaction)

12

Manipulation

Selection: based on the desired properties and dental application. e.g.:For a diagnostic cast, plaster can be used.

For a working cast, strength and accuracy is required, dental stone is the gypsum of choice

Working models for cast restorations require die stone

13

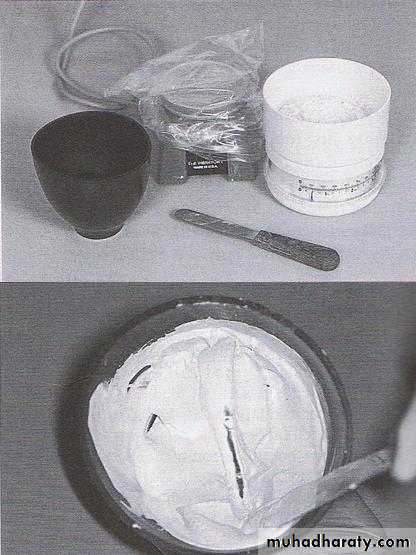

Mixing

The powder is mixed with water at a certain ratio according to the type of gypsum product.W/P ratio for plaster is 0.5 that mean 50 ml of water for 100 gm of plaster powder.

W/P ratio for stone 0.3 .

W/P ratio for die stone 0.2.

The difference in the W/P ratio is due to difference in the bulk volume of powder. Proportioning (W:P ratio)Golden rule: Manufacturer instructions should always be followed.

Variations in W:P ratio affect the set materials’ properties such as strength and accuracy.

Too much water the mix will be runny, the model will be weaker.

Too little water difficult to mix, chance to get bubbles inside the mixture.

14

• Manually the water is measured and put in a clean rubber bowel then the powder is stiffed on it gradually, allow the powder to settle then mix clean spatula for 1min. until creamy mix is obtained.

15

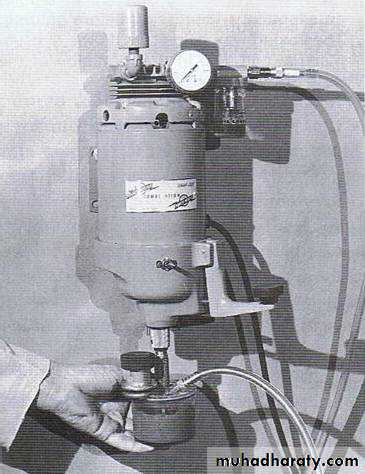

Mechanical (also used with vacuum)

16

• SETTING TIME

Setting time is the time from the beginning of mixing the powder with water until the material hardens.• This time may be measured by GILMORE NEEDLE APPARATUS or by VICAT APPARATUS, in which needle of different weight and thickness is used . penetration of these needles being measured at various times during setting.

working time

• Measured from start of mixing to the point where the consistency no longer acceptable for the product intended purpose

• Initial setting time:

time elapsed from the start of mix until loss of gloss (8-10 minutes)

6-10 minutes of working time are available to pour the gypsum.

17

Final setting time:

is reached when the materials can be safely handled, the gypsum is cool (exothermic reaction is over).Setting expansion: Results from crystal growth during setting. Can be decreased by the addition of potassium sulfate, sodium chloride, borax.

18

FACTORS EFFECTING THE SETTING TIME

W/P ratioThe more water is used for mixing , the fewer nuclei there will be per unit , consequently the setting will be prolonged.

Fineness

The finer the particle size of the hemi hydrate, the faster the mix will harden. The rate of solution of the hemi hydrate , will be increased , also the gypsum nuclei will be more numerous and therefore a more rapid rate of crystallization will occur.

Mixing

The longer and the more rapidly the plaster is mixed , the shorter is the setting time. When the powder is brought into contact with water, some gypsum crystals will be formed .As mixing begins, more particles will be exposed to water and thus form more crystals at the same time the crystals are broken up by mixing and they are distributed through out the mixture and result in the formation of more nuclei for crystallization, thus the setting time is decreased.

Temperature

• There is little change if the setting time between 0-50 C but if the temp. Exceeds 50 c the setting time will be retarded . As the temp. Approaches 100 c , NO SETTING WILL TAKE PLACE.Impurities

• If the manufacture add it to gypsum, the setting time will be shortened because of the increase in the potential nuclei for crystallization.

Retarders and Accelerators

• The addition of accelerators and retards are the most effective and practical for the control of the setting time.

20

Retarder

is the chemical material added to the gypsum product to increase the setting time, ex Glue borax , and gum Arabic. It will reduce the dissolution of hemi hydrate and might deposit on the nuclei of crystallization and effectively reduce the rate of crystallization so retarded the setting time .Accelerator

is the chemical material added to the gypsum product powder to decrease the setting time, ex. sodium chloride and potassium sulfate in certain concentration. These salts increase the rate of dissolution the hemi hydrate and thus the saturation of the solution accrue more rapidly and the gypsum formation

DIMENTIONAL CHANGES ON SETTING (SETTING EXPANSION)

Regardless of the type of gypsum product, an expansion of the mass can be detected during the change from the hemi hydrated to the dihydrated after mixing with water. This expansion could be explained on the basis of the mechanism of crystallization.

There is an outward growth of crystals from nuclei of crystallization, as a result of growth , there is an enlarglement and there is interception in the direction of the growth the impinging crystals. If the process is repeated by thousand of the crystals during growth , it is possible that the outward stress or thrust could produce an expansion of the mass. The final structure immediately after setting is composed of interlocking crystals between which are micro pores and pores containing excess water. On drying the excess water is lost and total empty space is greatly increased.

Factors affecting the setting expansion

1. W/P ratioThe higher the w/p ratio, the less the expansion because of fewer nuclei of crystallization per unit volume are present than the thicker mixes and since it can be assumed that the space between the nuclei will be greater in such case, it follows that there will be less growth interaction of dihydrate crystals with less out ward thrust.

2. Addition of chemicals (accelerators and retarders)

Both will reduce the setting expansion. The reduction of the expansion is due to initial rate of crystallization is so rapid that subsequent growth is resisted with accelerators. For the retarders, the crystalline form may be changed and the crystals may become thick and short so the thrusting between the crystals is reduced so the expansion is reduced.

HYGROSCOPIC EXPANSION

If the setting process is allowed to Occure under water the setting expansion may be more double in magnitude , this is called hygroscopic expansion. This increased expansion is due to additional growth of crystal permitted and not to any difference in the chemical reaction. water fills pores and increases volume

It’s recommended to separate the cast from impression after 1 hour.

Strength increases 2-3 times after 24 hours

STRENGTH

The strength of gypsum produced is generally expressed in term of compressive strength although tensile strength is also considered.Factors effecting the strength :

1. w/p ratio

2.drying

3. mixing

4. chemicals

5. porosity

The strength of gypsum increase rapidly as the material hardens after the initial setting . The excess water present in the set mass affect the strength ; therefore , there is wet strength and dry strength. The wet strength is when there is water left in the mass. The dry strength is that when excess water has been dried in air or in oven in warm temperature.The Dry strength may be two times more than wet.

Drying period compressive strength kg/cm2

2h 98

8h 119

24h 238