Step By Step Construction Of

Orthodontic

Removable Appliance

Lab-work Handout for year 4 students at The

University of Mosul / College of Dentistry.

2018

Authors

:

Dr.Anas Almukhtar

B.D.S., M.Sc. Ph.D Orthodontics

Dr. Ne`am Fakhri Yassin

B.D.S., M.Sc., Ph.D Orthodontics

1

2

List of contents

LAB:1. INTRODUCTION ......................................................... 6

LAB:2. THE PALATAL FINGER SPRING ........................... 11

LAB:3. MODIFIED FINGER SPRING ................................... 17

LAB:4 . Z-SPRING ................................................................... 21

LAB:5 DOUBLE Z-SPRING .................................................. 26

LAB:6. T- SPRING .................................................................. 30

LAB:7. THE BUCCAL CANINE RETRACTOR .................. 34

LAB:8. MODIFIED BUCCAL CANINE RETRACTOR ..... 38

LAB:9. ADAM'S CLASP ........................................................ 42

LAB:10. THE LABIAL ARCH ................................................ 47

LAB:11. THE FITTED LABIAL ARCH . ................................ 51

LAB:12. ROBERT'S RETRACTOR ........................................ 54

LAB:13. ACRYLIC BASE PLATE ….. ................................... 58

3

4

List of figures

. ...................................................... 11

..................................... 16

.................................... 20

. ........................................................... 25

. ................................................... 29

................................................................... 33

.. ........................ 34

........................................................... 46

......................................................... 50

............................................... 53

................................................ 57

............................................................ 63

.. ......................................... 64

5

6

Lab:1. Introduction

.

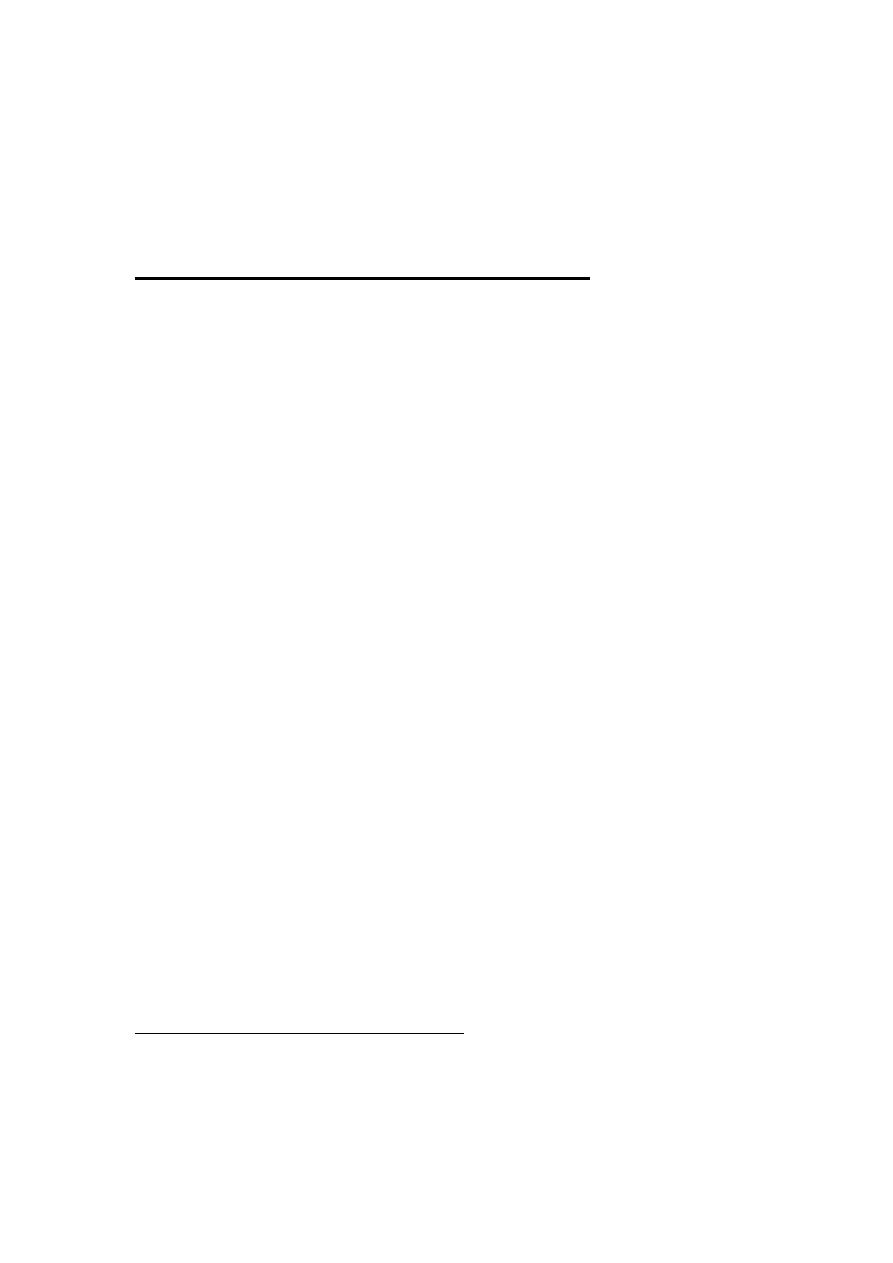

Orthodontic Removable Appliance:

An orthodontic appliance that could be inserted and

removed by the patient.

In general, Removable orthodontic appliances are

considered as an interceptive orthodontic treatment and

is mostly used in mix dentition period. Basically, they

either resolve the treated dental problem or diminish its

severity. Either way, this is definitely beneficial to the

patient. However, this is a patient-dependent protocol

and stability of the appliance in place is vital. The

stability is accomplished mainly by retentive components

(clasps) attached to the appliance. Fulfillment of the

treatment objectives requires a substantial mechanical

concept and designing.

Biomechanics of Tooth movement

When a force is applied to the crown of a tooth, it

will displace slightly within the confines of the

periodontal ligament. This small change in position will

set up areas of tension and compression within the

periodontal ligament. Provided that the force is applied

over a sufficient period of time, remodeling of the socket

will allow the tooth to move farther.

Types of tooth movements:

1. Spontaneous tooth movement: include tooth

movements that occurs spontaneously without

orthodontic force application, An example of this is

7

tipping toward an extraction space or over eruption

of teeth opposite to an extracted tooth.

2. Active tooth movement: these movements which

occur due to application of orthodontic force to the

crown of the tooth. Active tooth movement could be

sub-categorized into the following:

a. Tipping Tooth Movement: When a force is

applied at a single point on the crown trying to

move the tooth, the alveolar bone will resist that

movement which will result in tipping of the tooth

around its center of rotation (about 40% of root

length apically). This means that while the crown

moves in one direction the root apex will move in

the opposite direction.

8

b. Translation (Bodily) Tooth Movement: When all

parts of the tooth move in the same direction for the

same distance. If a tooth is to be moved bodily, a

force couple must be applied to the crown in

conjunction to the original force. This is not

practically applicable with removable appliance

since it is difficult to control the M/F ratio along the

course of tooth movement.

c. Intrusion and Extrusion tooth movement: Is a

translational movement parallel to the long axis of

the tooth.

d. Rotational movements: Rotation of the tooth

around its long axis. To achieve this type of tooth

movement, the application of couple force is

required.

Construction of removable appliance

Removable appliances are made in dental laboratories.

However, learning the basic construction techniques is

essential to master the various applications and mode of

action of each of the components.

Components of removable appliance:

1. Active components: The active components are used

for the application of orthodontic force to the teeth

and are made mainly from stainless steel wires and

Screws and elastics are also used in removable

appliance but less frequent. An example is the Z

spring.

9

2. Retentive components: Those components that are

used to provide resistance of the dislodgement of the

appliance from the mouth. For example of that are

different types of clasps labial bows.

3. Acrylic base plate: Is the basic frame to which all

active and retentive components are attached directly

or indirectly. In addition to its function as the main

frame it also plays an impotent role as an active

component. for example when modified as an anterior

bite plate to treat deep bite cases, also considered as

an impotent retentive component as its adaptation to

the palate and the engagement to the palatal undercuts

of the molars and premolars will increase the retention

of the appliance.

Essential construction tools

For the vast majority of removable appliances the

usual set of instruments and materials are composed of:

1. Orthodontic pliers and cutters

Orthodontic pliers

These are used for all wire bending. The ends are

firm, tapered, with one round end and the other

pyramidal or 2 rounded in section, and meet only at the

tips. The beaks meet only at the tips so that they are

separated about O.6 mm at the base when the pliers are

closed. This makes the beaks of the Universal pliers

parallel when gripping the wire.

Tow famous pliers of this type are:

a) Angle pliers (coil forming pliers): with one cone-

shaped beak and one pyramidal beak.

10

b) Adams pliers (universal pliers): with two

pyramidal beaks.

Orthodontic wire cutters

The diagonal type of wire cutter is used and must have

hardened blades.

2. Stainless steel wire;

These are used to make the active and retentive

components. they can be classified according to its

hardness to:

Extra-hard

Hard (used in removable appliances)

Soft

The wires gauge range between 0.3-1.5 mm; in

removable appliances we use 0.5 - 0.7 mm hard stainless

steel wire.

3. Acrylic:

This is used for construction of the frame or the body of

removable appliance that carry the active and passive

springs. Chemical cure, light cure or hot cure acrylic

could be used. Colures and additives are preferable.

4. Patient’s dental cast model:

A pair of dental cast model (upper and lower arches) for

the patient should be present when constructing the

removable appliance. These are necessary for treatment

plan and construction of the appliance.

11

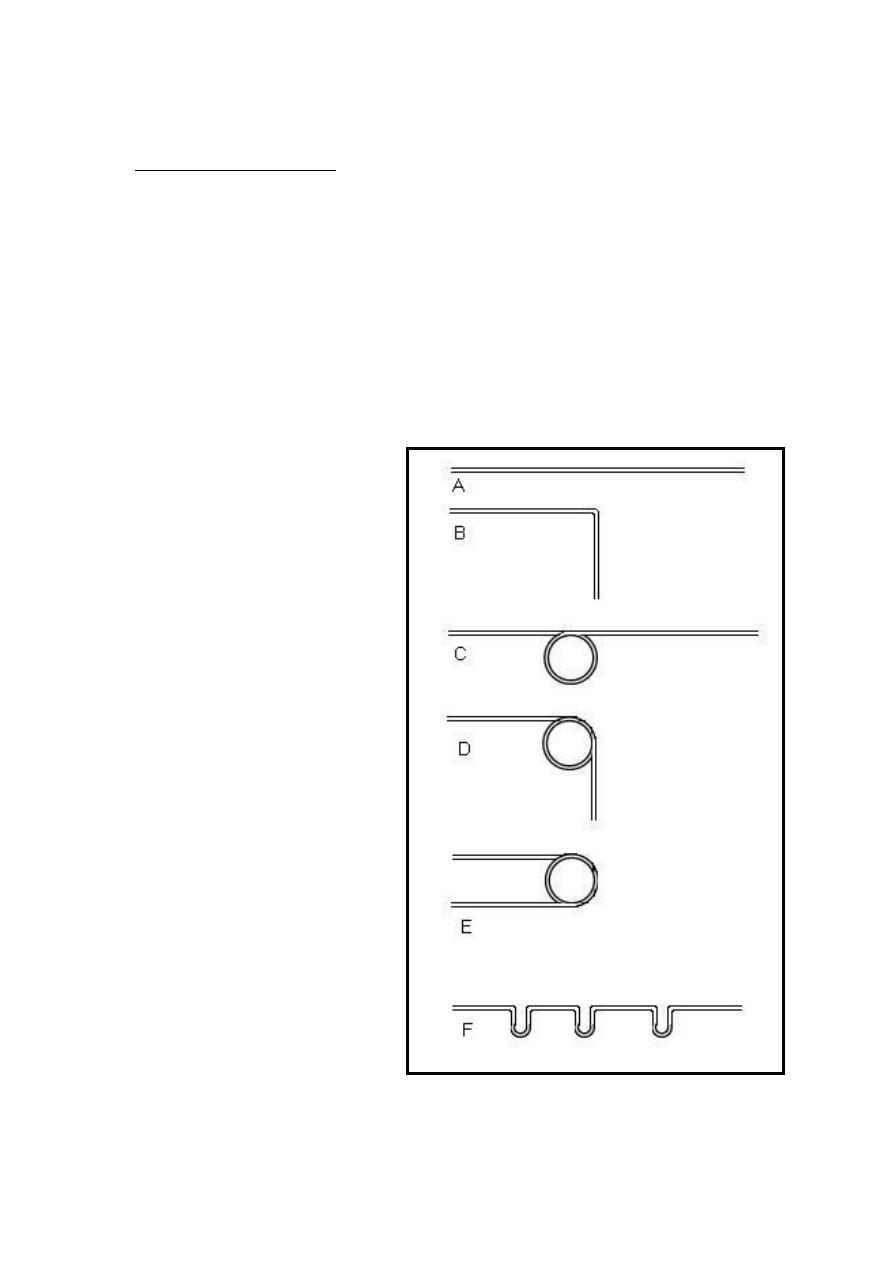

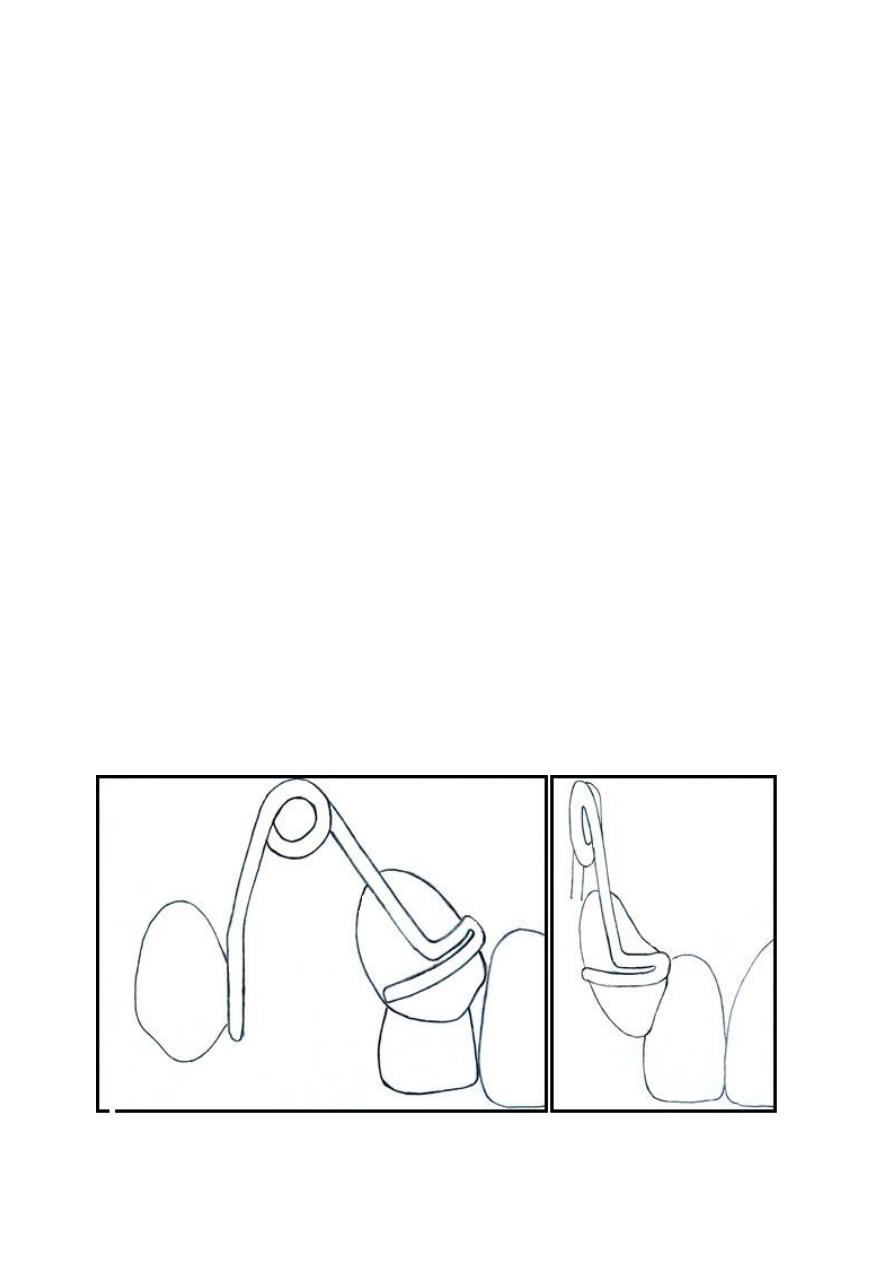

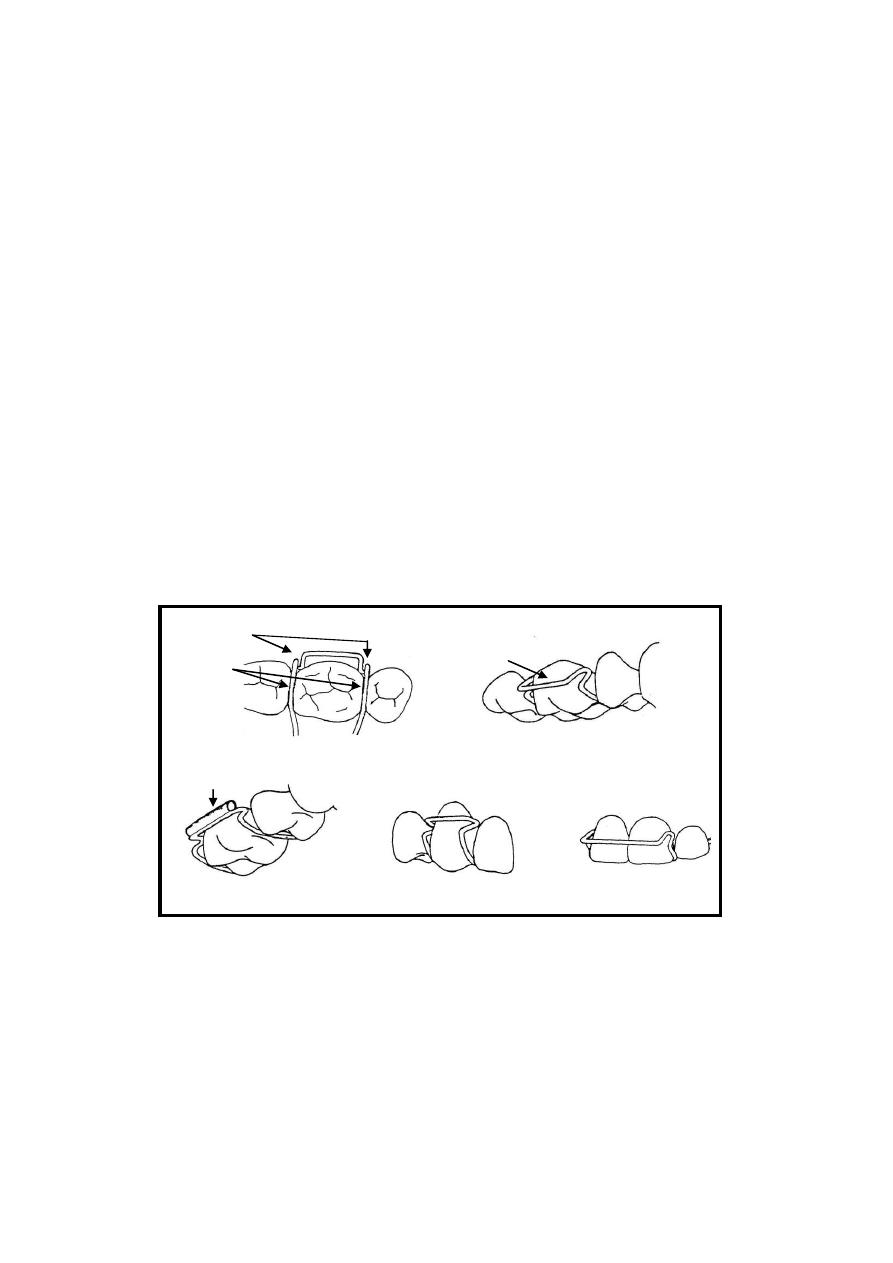

Manual training:

The students are instructed to make the following shapes

(Figure: 1) using 0.6 or 0.7 stainless steel wire.

Meanwhile instructions about the correct pliers grasping,

wire bending and cutting are being given.

Those shapes will introduce the student to the manual

skill of wire bending and help him/her to manage future

wire works accurately.

Figure

1 the students are

instructed to make the shapes

of : A. Straight wire piece;

B. 90 degree angle; C.

Straight wire with coil; D. 90

degree angle with coil; E.

Full turn coil; F. three well

aligned vertical loops on the

same wire.

12

Lab:2.

The palatal finger spring

Description and design

The simplest form of this spring is a strait piece of

wire embedded at one end in the acrylic base plate. The

usual wire diameter is 0.5 mm or occasionally 0.6 mm. a

coil is incorporated near the point of insertion into the

acrylic, this increase the length of the wire and stores

activation energy, thus, it will help delivering a light

force over a longer range of action (figure:2A). The coil

should be made as large as possible 3- 4mm . It is placed

so that when activated it is tightened (the coil is placed

on the side away from the desired tooth movement).

A coil spring of this design will usually be about 2

cm in length from the point of force application to the

insertion into the acrylic. The position of the coil

(distance from the tooth) is most important as it influence

course of action in which the spring works.

Indications:

It is commonly used to move any tooth mesially or

distally along the dental arch

Advantages:

1. Simple design

2. Provide light pressure

3. Well tolerated by the patient

4. Several springs can be added if required

Disadvantages:

- The palatal finger spring can not move teeth in

labial or palatal directions.

13

Step by step construction of finger spring

1. With a sharp pencil, sketch the design of the wire on

the cast model according to the (description and

design) mentioned above.

2. Cut a (5cm) of ( 0.5mm) round stainless steel wire

3. straighten off the wire piece

4. Make a very small loop ( as small as possible) at one

end of the wire and then bend it to be ( 90° )to the

spring long axes. This will be the tooth end of the

spring and will help tooth engagement and prevent

injury from sharp wire terminal.

5. Adapt the wire on the cast model so that the tooth end

is fit on the tooth side opposite to the direction of the

desired tooth movement and the spring long axes is

perpendicular on the direction of tooth movement.

Then measure about (*15 mm) from the tooth end of

the wire and put a mark on the wire.

6. Hold the wire on the mark. The round beak of the plier

should be held away from the operator and from the

first bend made on the wire,( keep in mined that the

coil will always be away from the direction of the

desired tooth movement). Start rolling over the wire

around the round beak of the pliers until forming a

complete coil, and the wire continues in the same

direction.

7. Make sure that the coil will be above the tooth end

(active arm) of the spring. This is a critical point of the

wire design since it will keep the active arm close to

the palate.

Please note that this section is for training purpose only and the

construction steps are not required in any written or verbal exam.

14

8. Re-adapt the spring on the cast model and check the

following points:

a) The spring fits on the side of the tooth away from

the direction of tooth movement

b) The coil is on the side away from the direction of

tooth movement

c) The coil is above the active arm

9. Leave about (4mm) from the coil end and mark the

wire. This is the point where the wire will start to be

embedded in the acrylic.

10. About (2mm) after this point, make a (45°) bend on

the round beak of the pliers and start a 2 to 3 ( zigzag )

bends that is the retentive part of the wire which will

provide the mechanical retention of the spring in the

acrylic base-plate.

11. Cut the excess of the wire and adapt it on the cast

model with piece of soft wax. and check the fallowing

points:

a) The length of the spring is about 2 cm from the

tooth end to the point of insertion into the acrylic.

b) The retentive zigzag does not cross the midline to

the opposite side.

15

Boxing, Open spring and Wire guard:

These are three designs of the acrylic base plate

around the finger spring. Boxing (figure:2B) is designed

to provide the freedom of movement of the active arm

and coil inside an acrylic chamber built in the base-plate.

Open spring (figure:2C) is designed to completely

remove the acrylic of the base-plate from the path of the

movement and leave the active arm and the coil free

without protection. Wire guard is the addition of a

stainless steel wire be incorporate in the open spring

design to prevent distortion of the spring during wearing

and activation. This could be from the tongue side or

occasionally from palatal side too. It could also be used

with the boxing design palatally for the same reason.

Those three designs will be discussed thoroughly in base

plate construction labs.

Activation

It is widely believed that for a single rooted tooth a

force of 30 to 50 g is enough to produce orthodontic

tooth movement with minimal tipping. A tension gauge

could be used to measure the force; however the usual

activation is roughly one third to one half of a unit (the

mesio-distal dimension of the tooth). This is about 3-5

mm. Over activated springs may be harmful to the tooth

producing pain and discomfort to the patient (figure:2).

The palatal finger spring is activated by gentile

opining of the coil with the use of angle pliers the old

position of the tooth end of the spring (before activation)

is marked on the base plate to be compared to the new

position (after activation).

16

A B

C D

Figure

2 the palatal finger spring. A: palatal figure spring design ; B: boxing with wire guard ;

C: open spring ; D: activated finger spring.

17

Lab:3.

Modified finger spring

One of the modifications to the palatal finger spring

is the modified finger spring. it differs from the original

one in four main points: Its action is applied labially

rather than palatally; It crosses the occlusal surface; The

direction of force is vertical and it needs an attachment

(usually orthodontic bracket ) on the labial surface of the

tooth in order to apply its action ( figure 3).

The gauge of the wire is 0.5mm or 0.6mm, a loop is

incorporate in the wire design to increase the length of

the wire and its range of action.

Indications:

For extrusion for ectopic or high buccally erupted teeth

Advantages:

1. Simple design

2. Suitable range of action

Disadvantages:

3. Can not be boxed or guarded.

4. Subjected to distortion.

5. Trauma to the vestibular soft tissues.

Step by step construction

1. On the plaster model, sketch the wire design on the

labial gingiva (figure 3). The end of the active arm

Please note that this section is for training purpose only and the

construction steps are not required in any written or verbal exam.

18

usually located at the mesial margin of the target

tooth and extended distally passing over the tooth to

be moved in addition to two teeth behind. This will

be about 3 mm above the gingival margin. At that

point a small loop 3-4mm in diameter is constructed

by which the wire will change its direction

occlusally, crossing the occlusal surface at the

embrasure between the teeth and rolling over to the

palatal side of the arch where the spring ends by a

retentive zigzag form.

2. Cut about 7 cm of 0.5 mm round stainless steel wire

3. Straighten the wire piece

4. Start to form a very small loop at one end of the wire,

this will be the end of the active arm of the spring

and will prevent injury to the adjacent soft tissue

5. Adapt the wire to the curvature of the alveolar arch.

Fit the wire in position and put a mark on the distal

margin of the third tooth (according to the design

drawing).

6. Hold the wire with the pliers 2 mm behind the mark

point and start to form a 3-4mm loop. The direction

of the loop is always away from the tooth to be

moved (that’s mean the coil will try to open while it

is in action).

7. The coil will not take a complete turn and the wire

leaves the coil at aright angle to the direction of the

active arm and will be directed occlusally.

8. Fit the wire in position and check the following

points:

a. The length of the active arm is appropriate.

b. The lop is above the active arm.

19

c. The wire is adapted to the alveolar mucosa (

1mm away from mucosal surface).

d. The active arm runs 2-3 mm above the gingival

margin.

9. After the necessary correction have been made, Fit

the wire in position and put a mark on the occclusal

end of the embrasure where the wire will pass above

the occlusal surface of the teeth. And use the round

beak of the angle pliers to make a sharp turn to the

palatal side of the dental arch.

10. Adapt the wire on the palatal surface of the teeth

and mucosa

11. Start to make a retentive zigzag bends starting at

the point about 2mm after the lingual gingival margin

where the acrylic base plate will be located, and then

cut the excess wire.

12. Fit the wire in position and check the fallowing:

a. The wire does not interfere occlusally with the

opposing arch.

b. The spring does not cross the midline

c. The loop does not interfere with the vestibular

tissues.

13. Now to finish the spring a small bend is made on

the active arm

(about 10 degrees) at the distal margin of the targeted

tooth gingivally. This bend will ensure correct

direction of the applied force during the course of

action.

Activation:

Activation of the modified finger spring is made by

opining the coil so that the active arm will be about 3

20

mm occlusally to the passive position (figure: 3B). This

will deliver force of about 20-30g which is enough for

extrusion movement.

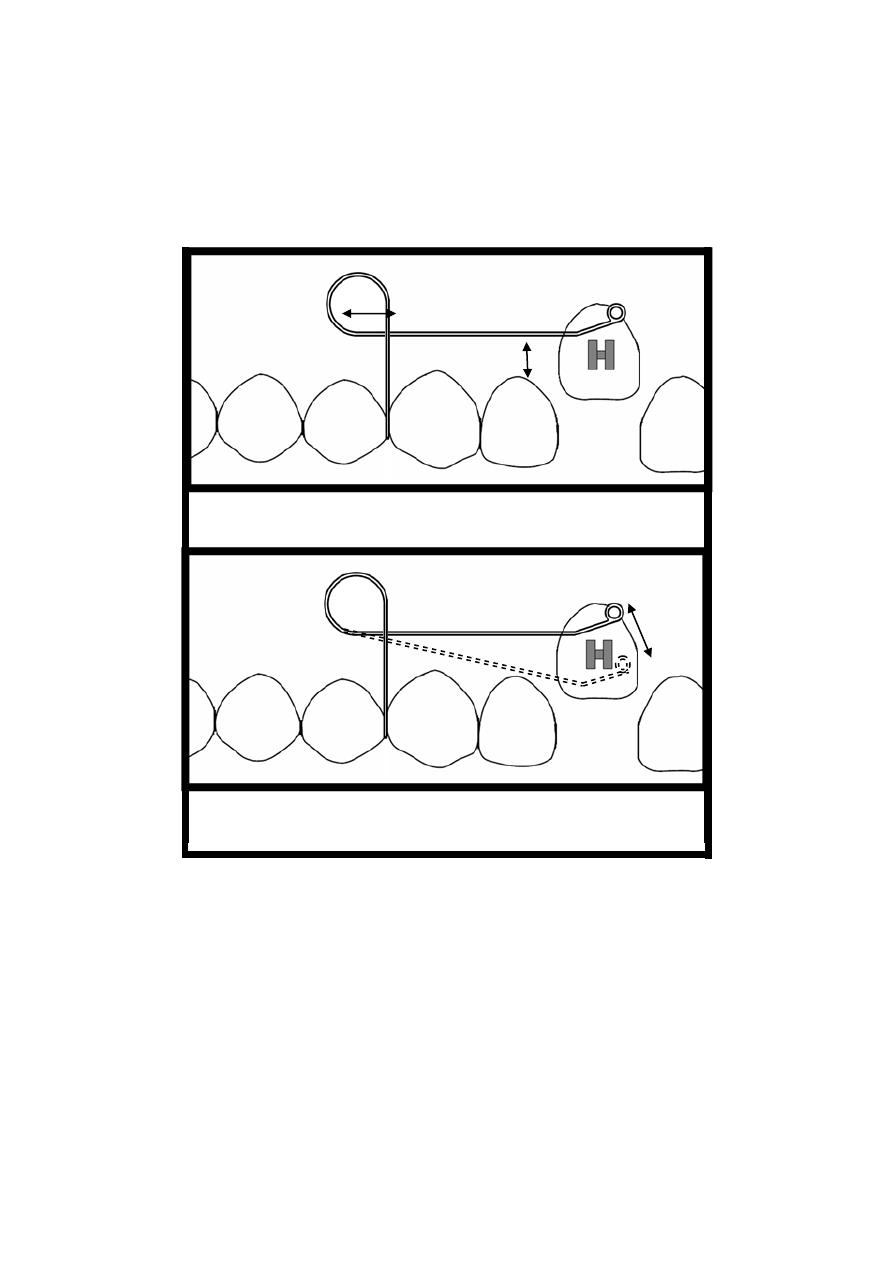

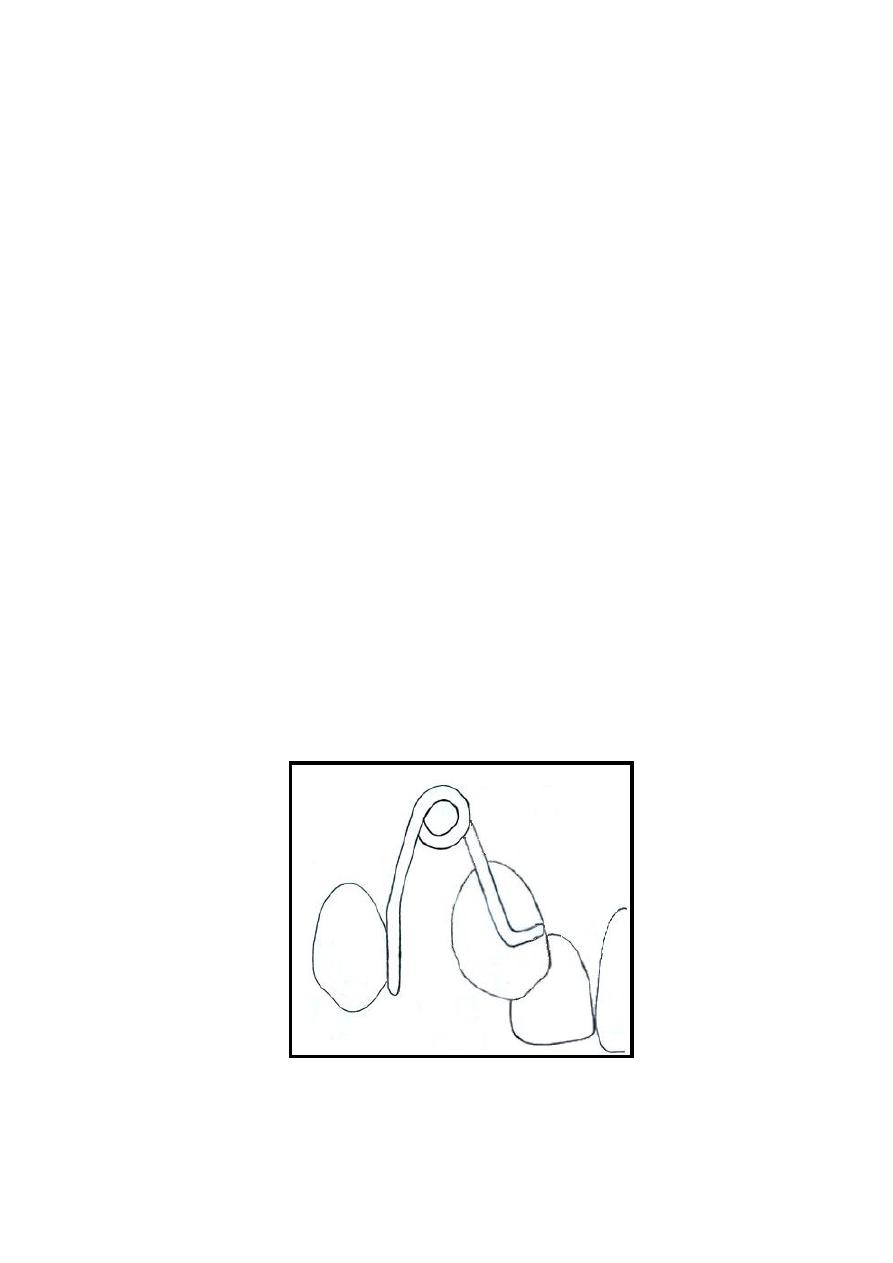

. A

B

3-4 mm

2-3 mm

3 mm

Figure

3 The modified finger spring( Basic design .A:basic design; B: Activation

21

Lab:4 . Z-Spring ( double cantilever)

This is a variant of the palatal finger spring and the

commonest type in this group.

Description:

The spring is bent into the shape of the letter ' Z '

with two coils each is (2 mm) in diameter. It should be

constructed with the spring compressed. The presence

of two coils makes it possible for the active end of the

spring to be activated in a straight line perpendicular

to the dental arch.

Indications

:

1. Correction of single palatally Positioned anterior

tooth.

2. Correction of simple rotation ( not more than 45° )

when combined with active labial arch to produce a

couple force.

Advantages

:

1. The spring is compact and may be narrowed to

small teeth such as lateral incisors.

2. The force is delivered in a straight line due to the

presence of two coils.

3. The spring could be boxed and distortion is not

common.

Disadvantages:

1. Not suitable for posterior teeth.

2. If the spring is made very small it can produce an

excessive force during activation.

22

3. The reactionary force from the cingulum tends to

displace the anterior part of the appliance, good

anterior retention is therefore essential.

4. May produce some intrusive force.

Step by step construction procedure:

1. Start sketching the design of the spring on the

palatal surface of the cast model. The spring name is

self explanatory as it will take the shape of the letter (

Z ) (figure: 4A). The spring is confined to the mesio-

distal dimension of the tooth to be moved. starting at

the mesial border of the tooth, draw a straight line 2-3

mm above the palatal gingival margin crossing the

tooth to the distal side, at that point a coil of 2 mm in

diameter is placed, make sure it will be confined to the

tooth borders, then continue the line in reverse

direction gingival to the coil till the mesial side of the

tooth, at that point another coil of the same dimension

is placed, also make sure that the spring is confined to

the mesio-distal dimension of the tooth, now continue

the line back in reverse direction gingival to the coil

passing about 2 mm ( nearly at the middle of the tooth

dimension where a sharp turn is made to change the

direction posteriorly , the line then continues straight

about 6 mm then start 2 to 3 zigzag retention form.

2. Take a (5 cm) piece of a (0.5mm) stainless steel wire

and straighten it.

3. Start by making a small loop ( as small as possible) at

one of the wires ends, this will be the active end of the

wire.

Please note that this section is for training purpose only and the

construction steps are not required in any written or verbal exam.

23

4. assuming that the z-spring is mad for the upper left

permanent incisor, put the wire on the palatal surface

of the tooth with the small loop is pointing mesially

and mark the point at the distal margin of the tooth.

5. Hold the wire about (1 mm ) before the mark point and

start forming the loop. The size of the loop is very

small in that the wire must be held at the very end of

the pliers beaks, makes sure that the coil is above the

active arm ( the wire end) this will facilitate the correct

direction of the applied force, make a complete turn

heading backward mesially.

6. Re-fit the wire in position and mark the mesial end of

the tooth (the mesial and distal end represents the

largest mesio-distal dimension of the tooth).

7. Repeat the coil just the same as the previous one except

that the coil here is above the remaining wire, this will

facilitate easier adaptation of the spring to the

curvature of the palate. Complete the turn so that the

remaining wire is pointed distally again. Make sure

that the two coils are at the same plain.

8. Re-fit the wire in position according to the sketching

and mark the wire about (2 mm) away from the second

coil (nearly at the meddle of the mesio-distal

dimension of the tooth).

9. Hold the wire just before the mark point and make a

90° bend (on the round beak) at the same plain with the

coils. This will leave the remaining wire pointing

backward.

10. Leave about (6 mm) and start a retentive zigzag

bends, then cut the remaining wire.

11. If the coils are loose and were opened during

construction, squeeze the spring i.e. close the coils to

24

the maximum is mandatory since it will increase the

range of action during the active treatment.

12. Now the spring is completed in shape but is parallel

on the tooth surface and not useful. The active part of

the spring must apply the force perpendicular to the

tooth long axes (figure 4B). This is made by a rounded

bend at the start of the (6mm) straight area of the

spring wire just after the 90 degrees bend; the direction

of the bend is toward the palatal surface which will

elevate the coils to be perpendicular to the tooth long

axes. This bend could be combined with the 90 degree

bend to produce the desired orientation.

13. Be aware that the tooth long axes is not the palatal

surface of the tooth, it is represented on the cast model

by an imaginary line passing between the labial and the

palatal tooth surface.

14. the spring is then boxed with wax ( same as in

finger spring ) and ready for the construction of the

acrylic base plate

25

Activation:

There are two methods for the activation of Z-spring

a. By opining the first coil or the second coil alone, it will

produce force at one side of the tooth which will try to

rotate it.

b. By opining both of the coils which is practically done

by gentile pulling of the active arm to produce

elongation of the spring about (2-3 mm). This is quite

enough for tipping movement and keeping the active

arm parallel to the tooth surface which will produce

equal force on both sides of the tooth.

A B

Figure

4 The Z spring A:Z- spring positioned on the lateral incisor ; B: the z-spring is

positioned perpendicular to the tooth long axes.

26

Lab:5 Double Z-Spring

.

This spring is simply tow Z-springs joined by their

active arms.

Description:

The spring is bent into the shape of two ' Z '

facing each other (figure:5) with four coils each one is

(2 mm) in diameter. It should be constructed with the

spring compressed and the presence of two coils on

each side of the spring makes it possible for the active

end of the spring to deliver the force in a straight

perpendicular to the dental arch.

Indications

:

1. Correction of up to four palatally Positioned anterior

teeth.

2. Correction of simple rotation ( not more than 45° )

when combined with active labial arch to produce a

couple force.

Advantages

:

1. The force is delivered in a straight line due to the

presence of four coils.

2. The spring could be boxed and distortion is not

common.

3. Used for correction of more than one tooth, (2-4)

anterior teeth at the same time.

Disadvantages:

1. Not suitable for posterior teeth,

27

2. If the spring is made very small it can produce an

excessive force during activation.

3. The reactionary force from the cingulum tends to

displace the anterior part of the appliance, good

anterior retention is therefore essential.

4. May produce some intrusive force.

Step by step construction procedure:

1. Assuming that the double Z-spring is made for the two

upper permanent central incisors, sketch the design of

the spring on the palatal surface of the cast model as

shown in (figure:5) . The spring will take the shape of

two (Z) facing each other and joining by their active

arms with four coils of 2mm in diameter.

2. Take a (15 cm) piece of a (0.5mm) stainless steel wire

and straighten it.

3. Put the wire on the palatal surface of the teeth with and

mark two points one on each side at the distal margins

of the teeth.

4. Hold the wire about (1 mm) before the mark points and

start forming the loop from each side. The size of the

loop is very small (2mm) so the wire must be held at

the very end of the pliers beaks, make sure that the

coils are above the active arm as this will facilitate the

correct direction of the applied force, make a complete

turn heading backward mesially from both sides.

5. Re-fit the wire in position, the active arm (which is the

segment of the wire between the two coils) must have a

slight curvature representing the normal arch form.

Please note that this section is for training purpose only and the

construction steps are not required in any written or verbal exam.

.

28

6. Mark the mid-point between the two centrals, let the

mark appear on both the right and the left ends of the

wire.

7. Repeat the coil from each side just the same as the

previous one except that the coil here is under the wire

(the short piece of wire between the first and second

coil from each side), this will facilitate easier

adaptation of the spring to the curvature of the palate.

Complete the turn so that the remaining wire is

pointing distally from each coil and heading away from

each other. Make sure that the four coils are at the

same plain.

8. Re-fit the wire in position according to the drawing and

mark the wire about (2 mm) away from the coils at

each of the two ends (nearly at the middle of the

mesio-distal dimension of the tooth).

9. Hold the wire just before the mark point and make a

90° bend (on the round beak) at the same plain with the

coils. This will leave the remaining wire pointing

backward to the palate.

10. Now leave about (6 mm) and start a retentive zigzag

bends then cut the remaining wire.

11. I case the coils are loose and opened during

construction, squeezing of the spring i.e. closing the

coils to the maximum is mandatory since it will

increase the range of action during the active treatment.

12. Now the spring is completed in shape but is adapted

on the tooth surface and not useful. The active part of

the spring must apply the force perpendicular to the

tooth long axes. This is made by a rounded bend at the

(6mm) straight area of the spring wire just after the 90

degrees bend, the direction of the bend is toward the

palatal surface which will elevate the coils to be

29

perpendicular to the tooth long axes. This bend could

be combined with the 90 degree bend to produce the

desired orientation.

13. The spring is then boxed with wax ( same as in Z-

spring spring ) and ready for the construction of the

acrylic base plate

Activation:

Activation of the double Z-spring is made By

opining both of the coils on each side which is

practically done by gently pulling of the active arm

from the right and left side to produce elongation of

the spring about ( 2-3 mm ). This amount is quite

enough for tipping movement. Pulling the same

amount from the right and left side will keep the active

arm parallel to teeth surface which will produce equal

force on both sides.

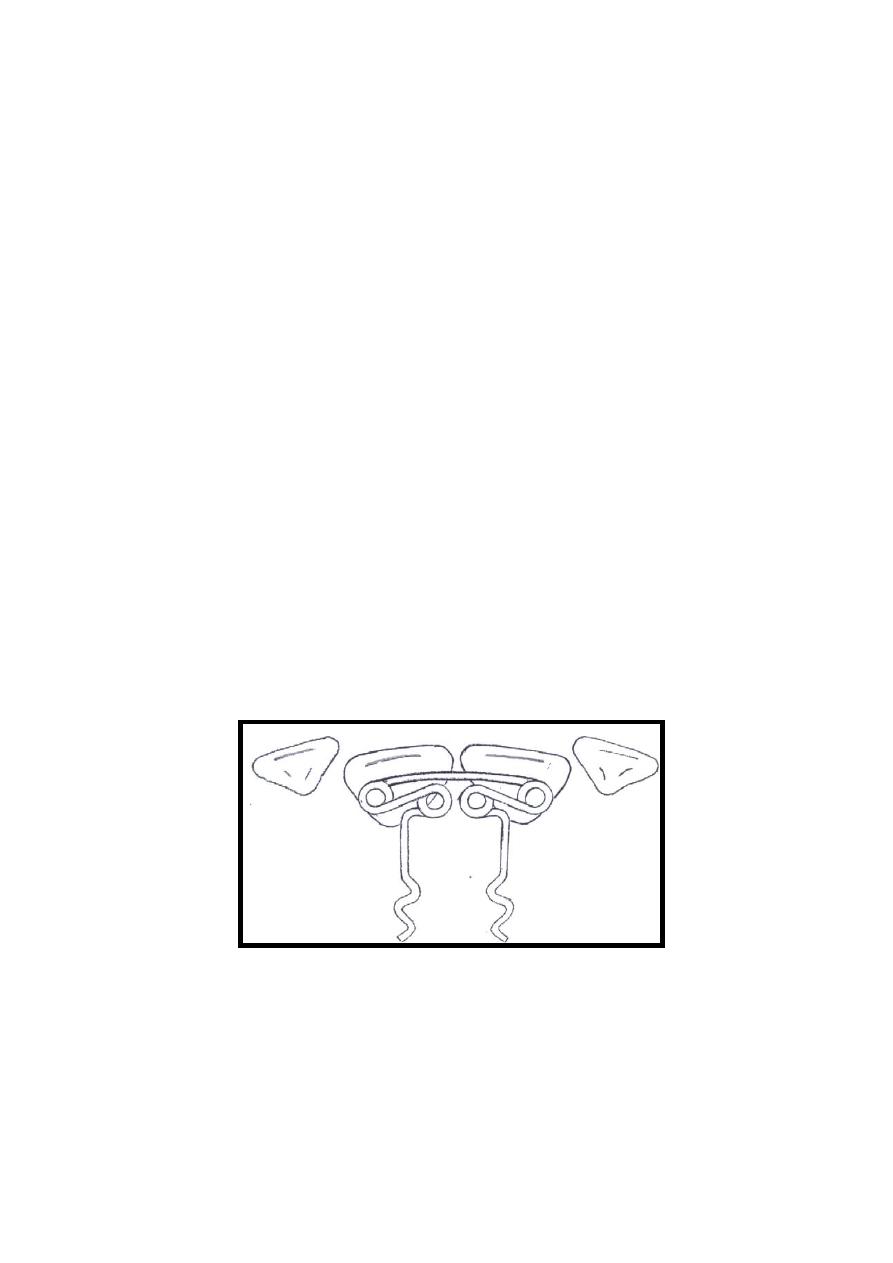

Figure

5 Double Z- spring positioned on the central incisors, note that the

active arm has a slight curvature representing the normal dental arch curve.

30

Lab:6. T- Spring .

Description:

The name is self explanatory as the spring take

the shape of the letter (T). Both ends embedded into

the base plate and the T shape span rests on the palatal

surface of the tooth to be moved (figure:6). The

addition of extra u shape loops half way up the spring

increase its flexibility and provides spare wire for its

extension during tooth movement.

Indications

:

1. Suitable to provide buccal movement of posterior

teeth.

2. Occasionally used on the anterior teeth since it will

produce an inevitable intrusive force during action.

Advantages

:

1. Highly unlikely to catch on the buccal surface of

posterior teeth during insertion.

2. It occupies only a small space and can be used on a

premolar concurrently with other movements such as

canine retraction.

3. Could be boxed or guarded.

Disadvantages:

1. When used for anterior teeth, a considerable amount

of intrusive force is delivered.

2. It has a small range of activation.

31

Step by step construction procedure:

1. Two important points must be kept in mined during

the construction of this spring:

a. All the bends and loops must be at the SAME

PLANE

b. SYMETRY between the right and left side is

of a primary importance.

2. Sketch the design of the wire on the palatal surface as

shown in (figure 6)

3. Take a (5 cm) piece of 0.5mm stainless steel wire

(0.6mm for molars) and start straighten it.

4. Put the wire on the palatal surface of the tooth and

mark two points one on each side at the mesial and

distal embrasure around the tooth.

5. Hold the wire about (1 mm ) before the mark points

and start forming the U shape loop from each side.

The size of the loop is very small (2mm) so the wire

must be held at the very end of the pliers beaks, the

loops are incomplete ( U shape) and the wire only

turn to the opposite side from each end heading

backward toward each other from both sides.

6. Put the spring on the occlusal surface of the tooth, the

active arm (which is the piece of the wire including

the two loops must have the same mesio-distal width

of the tooth.

7. Now mark the mid point between the two loops , let

the mark appear on both the right and the left ends of

the wire

8. Then make a sharp turn (on the round beak of the

pliers) about (1mm) ahead to the mark point from

Please note that this section is for training purpose only and the

construction steps are not required in any written or verbal exam.

32

each side so that the two wire ends will extend

parallel to each other heading away from the T span

with (0.5 to 1 mm) between them ( figure 6).

9. Now the spring resembles the desired T shape and

you can make the retentive zigzag form about 6 mm

away from the loops. If additional loops is to be

added then the following additional steps are taken.

10. Mark a point about 3-4mm down the first loop and

let the mark appear on both sides of the wire.

11. Hold the wire with the ends of the beaks and make a

90 degree bend on each of the two sides of the wire

ends so that the two ends run apart from each other.

Make sure that all the bends and loops used in the

construction of this loop must be at the same plain.

12. Hold the wire at the ends of the pliers beaks and

start making another (U) shape loops on each side

then follow the same steps of the first loop.

13. Unlike previous springs, this one lie parallel to the

palatal tooth surface. The active arm touches the

tooth on the gingival third of the palatal surface and

the spring has a slight curvature keeping it away from

the palatal soft tissue.

14. The spring is then boxed with wax ( same as in Z-

spring spring ) and ready for the construction of the

acrylic base plate

33

Activation:

Activation of the T-spring is made by gentile

pulling of the spring away from the base-plate toward

the tooth about 2-3mm Which is quite enough for

tipping movement. To compensate for the positional

change during the progress of the treatment, opening

the coils by gentile pulling of the active arm from the

right and left side to will produce elongation of the

spring about (1-2 mm ) and

Figure

6 T- spring positioned on the second

premolar (occlusal view)

34

Lab:7. The Buccal Canine Retractor

.

Description:

The buccal canine retractor is composed of a

posterior arm which emerges palatally from the acrylic

base plate and crosses the occlusal line up into the

vestibule to support a coil from which the (L) shaped

active arm (Singh 2007) is extended on the middle of the

crown (mesio-distally) and curved to engage the crown

mesially (figure:7), It is usually made of 0.7mm wire.

The coil must be 3-5 mm in diameter and situated

roughly on the line representing the centre of the

extracted first premolar space. Care must be taken for the

coil not to interfere with the vestibular tissues, for that

reason the coil must be in position no less than 2 mm

short from the sulcus depth. The end of the active arm is

preferred to have a small loop to prevent injury during

insertion.

Figure

7 The buccal canine retractor.

35

Indications:

It is typically indicated in situation where the canine

overlaps the lateral incisor labially.

Advantages:

1- Offers good control on the canine during distal

movement.

2- Prevent unwanted buccal movement.

4- It generally displaces the appliance less than palatal

spring does.

5- Well accepted by adults because it is unnecessary to

use clasping or labial bow on the anterior teeth.

Disadvantages:

1- Because of the heavy gauge of the wire, excessive

force can be easily exerted on the canine during

retraction.

2- It can cause trauma to the vestibular tissues.

Step by step construction procedure:

1- Sketch the design on the cast according to the

description.

2- Cut about 8cm of 0.7mm stainless steel wire and

straighten it.

3- Place the wire on the buccal surface of the canine

and horizontally at a mid-point of the crown

(occluso-gingivally) and construct a rounded curve

Please note that this section is for training purpose only and the

construction steps are not required in any written or verbal exam.

36

that extends mesially adapted to the tooth surface

ending at the farthest point that could be reached on

the mesial surface of the canine.

4- On the point at the buccal midline of the crown

(mesio-distally) mark a point where a (90) degrees

bend will be placed to redirect the wire apically.

This will form the (L) shape feature of the active

arm. The active arm will extend up to the vestibule

along the tooth long access.

5- With a permanent marker, put a mark on the wire at

the position about 2 mm shorter to the sulcus depth.

6- Hold the wire 2 mm shorter that the mark point and

start to make a loop of about 3-5 mm in diameter,

note that the active arm should always be under the

coil.

7- Complete the turn of the coil so that the remaining

wire is directed back downward.

8- Now put the wire in position and adjust the

remaining wire to point to the embrasure between

the first and the second premolar while the active

arm still fitted on the mesial border of the canine.

9- Mark the point at the interdental space near the

gingival margin on the remaining wire piece where a

light bend is made to direct the wire piece vertically

at the mesial occlusal margin of the second

premolar.

10-

Mark the wire at the occlusal level. Hold the

wire from the marked point and make a sharp bend

palatally.

11-

Now put the wire in position again and mark

the palatal occlusal margin of the premolar where

another bend is to be made to adapt the wire on the

palatal surface

37

12-

While the wire passes on the palate, a zigzag or

a hook form is made for retention. This retention

form is very important since the spring in its action

tends to rotate in the acrylic which might cause

loosening of the spring attachment and loss of.

13-

Cut the remaining wire and put the spring in

position then start to adapt the spring so that it will

be about 1mm away from the buccal and palatal soft

tissue.

14-

Now check for the fallowing points while the

spring in position:

a) The coil is 2mm away from the vestibule

b) The spring is 1mm away from the soft tissue.

c) If the first premolar already extracted, make sure

that the wire passes mesial to the second premolar

and with the occlusal level to avoid interference

with the retracted canine.

d) Check if there is interference with the opposite

arch in occlusion.

Activation:

Activation of the canine retractor is made by closing

the coil so that the active arm move about 3mm

posteriorly.

38

Lab:8. The Modified Buccal Canine

Retractor

Many modifications have been made on the buccal

canine retractor to enhance the control over the retracted

canine. One important modification to the canine

retractor is that made to the end of the active arm in order

to increase the control during retraction, facilitate light

extrusion force and to enable the palatal movement of the

canine at the end of the retraction using the same spring.

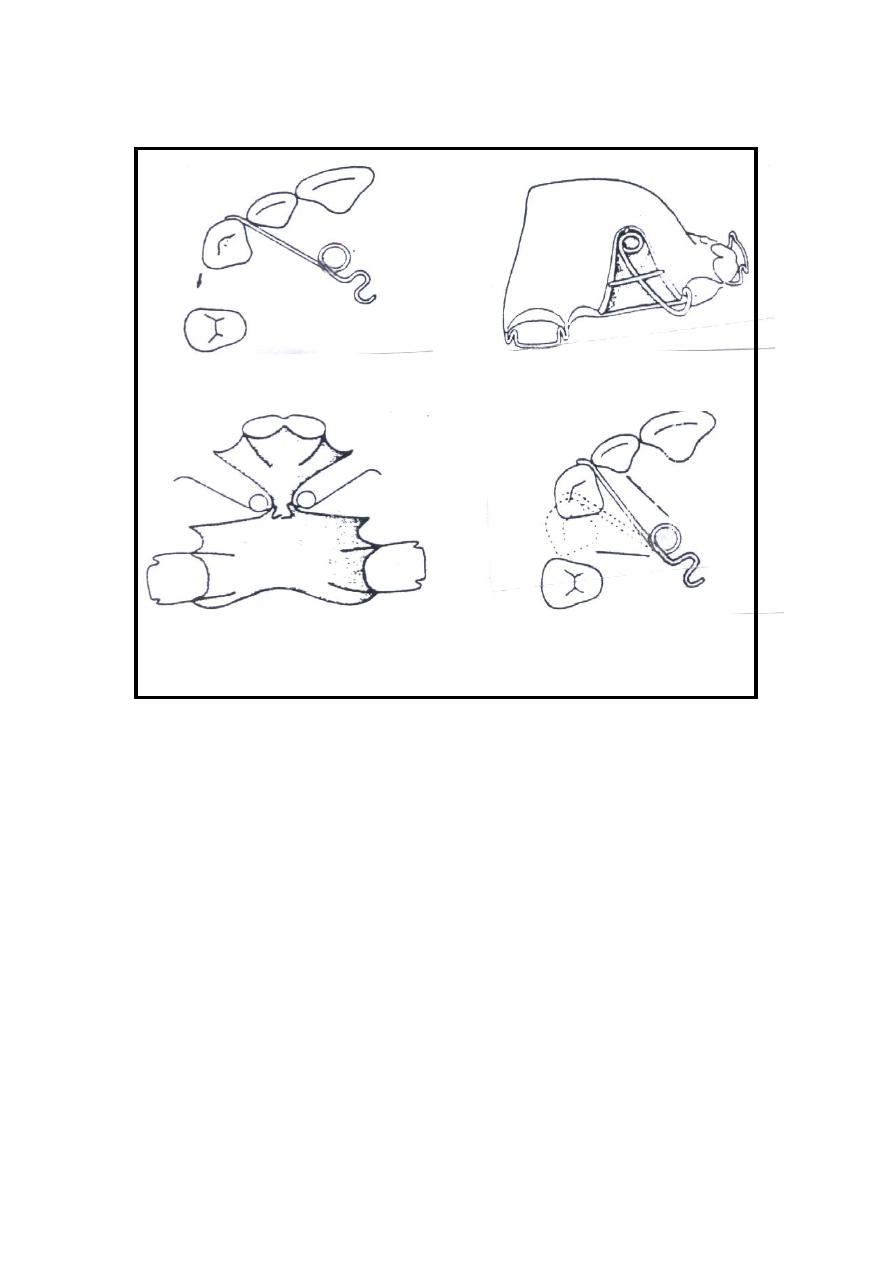

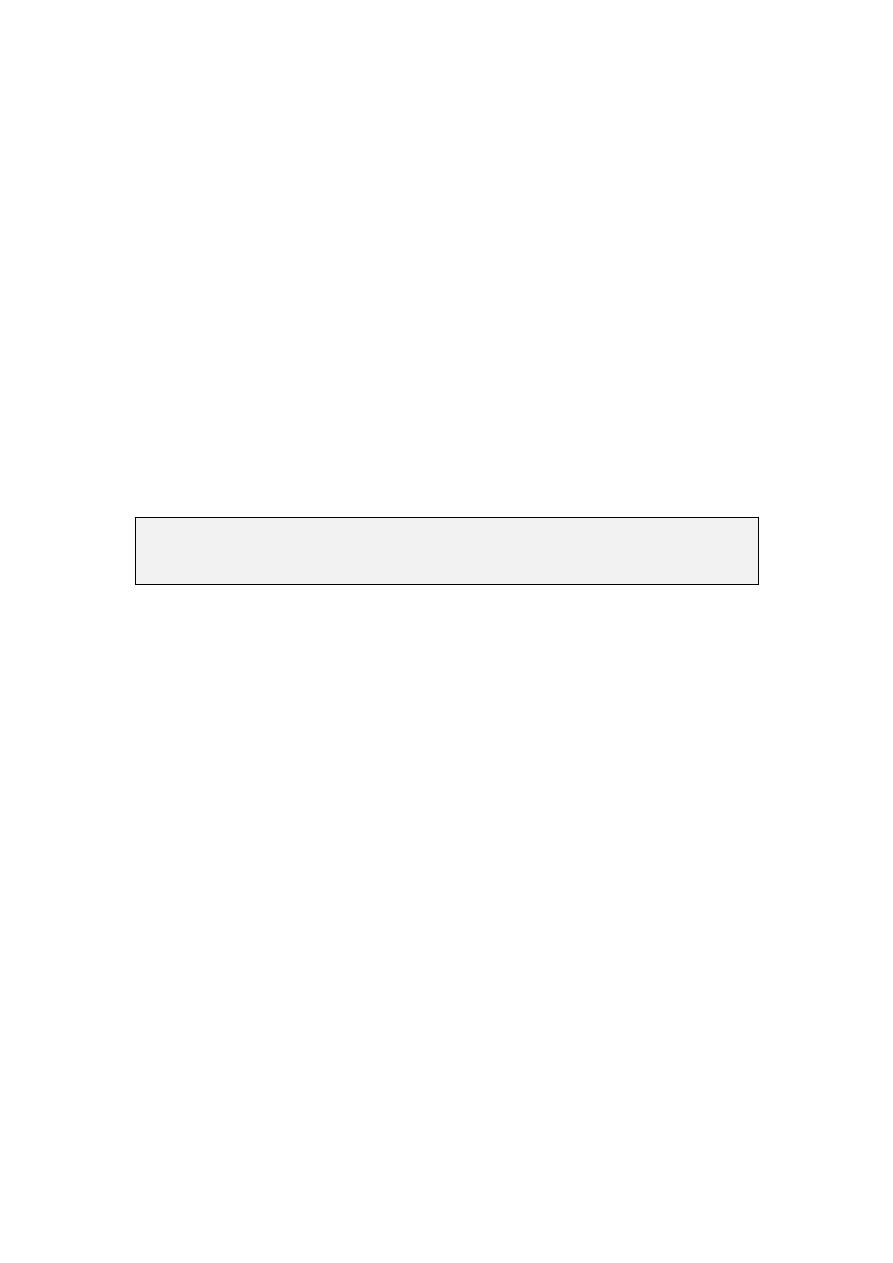

Description:

Generally, the spring has the same form and shape

of the buccal canine retractor also the active arm is

situated at the middle of the crown (mesio-distally). The

head (the end of the active arm) which is modified to

have an extension mesially and distally, which is adapted

on the labial surface of the canine and curved to partially

cover the mesial surface and extended to engage the

distal surface so as to make an excellent control over the

canine (figure 8:A and B).

Figure

8 Modified Buccal Canine Retractor. A:Side view ; B: Anterior view

39

Indications:

1. Where the canine overlaps the lateral incisor labially.

2. Buccally erupted canine which is situated out of the

dental arch and need to be moved palatally

3. Partially erupted and high positioned canine.

Advantages:

1. Offers an excellent control on the canine during distal

movement.

2. Enables extrusion and palatal movement of the canine

at the end of the treatment with out the need for

modification that might cause corruption of the spring.

3. It generally displaces the appliance less than palatal

spring does.

4. Well accepted by adults because it is quite unnecessary

to use clasping and labial bow on the anterior teeth

Disadvantages:

1- Because of the heavy gauge of the wire, excessive

force can be easily exerted on the canine during

retraction.

2- It can cause trauma to the vestibular tissues.

Step by step construction procedure:

1- Sketch the design n the cast according to the

description.

2- Cut about 10cm of 0.7mm stainless steel wire and

straighten it

A

B

Please note that this section is for training purpose only and the

construction steps are not required in any written or verbal exam.

40

3- put the wire on the labial surface of the canine so that

the tip of the wire fit at the distal border of the canine

just under the distal contact point and put a mark about

2mm anterior to the mesial border of the canines.

4- Hold the wire at the mark point and form a loop which

leaves the remaining wire pointing distally. Now hold

the wire from the bottom of the U shape loop and bend

it to a right angle to make a small ledge that will adapt

to and catch the mesial surface of the canine when the

spring is in position. The horizontal part at the end of

the wire must also be adapted on the labial surface.

5- Put the wire in position and mark the point at the

centre of the crown where a sharp bend is to be made

upward to the vestibule parallel to the long axes of the

tooth.

5- With a permanent marker, put a mark on the wire at

the position about 2 mm shorter to the sulcus depth.

6- Hold the wire 2 mm shorter that the mark point and

start to make a loop of about 3-5 mm in diameter, note

that the active arm should always be under the coil.

7- Complete the turn of the coil so that the remaining

wire is directed back downward.

8- Now put the wire in position and adjust the remaining

wire to point to the embrasure between the first and

the second premolar while the active arm is still fitted

on the mesial border of the canine.

9- Mark the point at the interdental space near the

gingival margin on the remaining wire piece where a

light bend is made to direct the wire piece vertically at

the mesial occlusal margin of the second premolar.

10- Mark the wire at the occlusal surface. Hold the wire

from the marked point and make a sharp bend

palatally.

41

11- Re-position the wire and mark the palatal occlusal

margin of the premolar where another bend is to be

made to adapt the wire on the palatal surface

12- While the wire passes on the palate, a zigzag or a

hook form is made for retention. This retention form is

very important since the spring in its action tends to

rotate in the acrylic which might cause loosening of

the spring attachment and loss of action if it is not

properly made.

13- Cut the remaining wire and put the spring in position

then start to adapt the spring so that it will be about

1mm away from the buccal and palatal soft tissue.

14- Now check for the fallowing points while the spring

in position:

a- The coil is 2mm away from the vestibule.

b- The spring is 1mm away from the soft tissue.

c- If the first premolar already extracted, check if the

wire passes mesial to the second premolar with the

occlusal level to avoid interference with the retracted

canine

d- Check if there is interference with the opposite arch

in occlusion.

Activation:

Activation of the canine retractor is made by closing

the coil so that the active arm moved about 3mm

posteriorly.

42

Lab:9.

Adam's Clasp .

Also named as the arrowhead clasp. It was designed

By Adam's in 1970 and since then it is the most

commonly used clasp to provide retention for removable

appliances. The clasp is constructed in 0.7mm wire and

most commonly used on permanent first molars but can

be used for almost any tooth.

A partially erupted molar which has less than 4 mm of

crown generally gives poor retention. However, Adam's

clasp needs only 0.25mm of undercut to provide an

acceptable retention which is usually available at the

mesio-buccal and the disto-buccal undercuts. In case the

crown was not fully erupted, the clasp's arrowhead will

push the gingival margin aside and engage the undercuts

when inserted in patient's mouth; a gentle trimming of

the gingival line on the cast model is feasible. When the

molar is not available for retention, Adam's clasp can be

modified to involve two adjacent premolars or two

centrals; In this case 0.6mm wire is preferred.

Components:

1- The active parts

a. The arrow heads: Two small U shape loops act as

two fingers engaging the mesial and distal

undercuts.

b. The bridge: A horizontal piece of wire joining the

two arrow heads and about 2-3mm away form the

buccal tooth surface making roughly 45 degree

angle with the long axes of the crown.

43

c. The tags: The extension of the arrow heads on each

side which crosses the occlusal surface to the

lingual side.

2- The retentive part

Extends from the ends of the tags down to the

gingival margin and continue on both sides passing

about 10 mm along the palatal or lingual soft tissue

( must be 1mm away from the surface). This ends

by a small hook shape loops to increase retention of

the clasp.

Advantages:

1- A relatively shallow undercut is sufficient for

providing an acceptable retention.

2- The bridge of Adam's clasp provides an excellent grip

used for insertion and removal of the appliance.

3- Auxiliary springs, hooks and tubes for extra oral

extensions could be soldered to the bridge.

4-

The design has no sharp edges that may injure the soft

tissues

.

5- The original design can be modified to suit anterior

teeth.

Disadvantages:

1- The labially inclined anterior teeth make it difficult

for the arrow heads to engage the undercut at the

labial surface.

2- The point where hooks or tubes are soldered on the

bridge will be weakened and fracture is common at

that point.

3- Adam’s clasp needs pair of undercuts (at the

mesiobuccal and distobuccal embrasures of the tooth),

if one of them is occupied by a spring, it will be

44

difficult to incorporate two wires at the same

embrasure.

4- Crossing the occlusal surface at two places increases

the chance for occlusal interference.

Indications:

1- Most common for retention of removable

appliance.

2- Shallow undercuts.

3- Partially erupted molars.

4- Premolars and anterior teeth (after modification).

Step by step construction of Adam's clasp:

1- Sketch the design on the permanent molar. Starting

buccally by a descending vertical lines from the

tips of the mesiobuccal and distobuccal cusps down

to the gingival margin then join the two lines by a

transverse line at the junction between the gingival

and middle third of the crown. The drawing is now

is similar to the English letter ( H ) (figure: 9 )

2- If the tooth is partially erupted, carve a small piece

of the gingival margin about 1-2 mm at the mesial

and distal corners of the crown just behind the lines

sketched on the crown.

3- Now cut about 10cm of 0.7 mm wire and straighten

it.

4- Hold the wire by hands and adapt it on the

horizontal line of the (H) shape figure on the crown

and keep the tooth at the centre of the wire piece,

Please note that this section is for training purpose only and the

construction steps are not required in any written or verbal exam.

45

mark two points on the wire at the positions of the

vertical lines.

5- Start wire bending by making a 90 degree bend at

both points resulting into an angled U shape. The

small wire span between the two bends will be the

bridge.

6- Mark the wire at 2mm away from the first bend on

both side, hold the wire with the pliers from the

marked point and make a small U shape loop

(around 1mm internal diameter) at the tip of the

round beak of the pliers. This will result in a two

small U shape loops each of them heading away

from the other, those are the clasp’s arrowhead.

7- Using the pliers hold the U shape loop on each side

and twist it to be at 45 degree angle to the bridge in

the horizontal plane and adapt it on the under cuts

of the molar, make any necessary adjustments so

that the arrowheads fits onto the undercuts.

8- From each side, and roughly at the same level of the

bridge hold the wire with the pliers and make a

sharp bent 70-90 degrees toward the tooth contacts

(Sandhya 2008). This will push the bridge away

from the malar crown. Then another bent bend must

be made at about 2mm away from the first bend that

will direct the wire toward the occlusal surface.

NOTE that these two bends could be combined in

one bend based on tooth anatomy and position.

9- Now fit the wire in position and check the

extensions of the wire on the occlusal surface, make

the necessary adjustment to adapt the two wire

pieces at the embrasure interdentally.

10-

While the clasp is in position, mark the wire at

the lingual margins of the crown and make a sharp

46

bend down gingivally. Let the wire extend about

10mm on the gingival surface then a small hook

shape bend may be made for retention of the clasp

in the acrylic.

11-

Now fit the upper and lower arches together in

occlusion and check for occlusal interference, any

error must be corrected.

12-

For the finished Adam's clasp the following

points must be checked

a. The arrowheads engage the undercuts

b. The bridge is about 2 mm away from the tooth

surface

c. No occlusal interference with the opposite arch

v

Tube soldered to

the bridge

Adam's

clasp

arrowh

eads

Ta

gs

The

bridge

Tu

be

Adam's clasp on

premolar

Adam's clasp on

centrals

Figure

9 Adam’s Clasp

47

Lab:10.

The Labial Arch

.

Since it was first designed by Charles Hawley in the

1920s the labial arch has been widely used in

construction of removable appliances for both active and

passive purposes despite its relatively deficient aesthetic

appearance.

Description:

Howley labial arch is constructed with 0.7mm wire

gauge and that rigid wire give it the chance to share in

retentive and active treatment and resist distortion that

might be resulted from the relatively long and

complicated design

,

The basic design is composed of a horizontal wire

piece extended on the labial surface of the four incisors,

joined by vertical loops from both sides and extended to

about 3mm short than the labial vestibular depth, then

crossed the occlusal surface distal to the canine and

extended on the palatal soft tissue, ended by hooks for

retention.

Indications:

1- As an active component

a. Retraction of the anterior segment (four incisors)

and treatment of minor anterior irregularities.

b. Share with the Z and Double Z springs to produce

couple forces for correction of simple anterior teeth

rotations.

48

2. As passive component

a. Stabilization of the corrected malocclusions when

used as a retainer after active orthodontic treatment.

b. Provide anterior retention and stability of the

removable appliance.

c. Act as a splint for the anterior segment to increase

the anchorage of the removable appliance during

active treatment.

Advantages:

1. It is useful to produce force on single or group of teeth

and at the same time give retention of the appliance.

2. The same appliance used to correct malalignment of

teeth will continue to retain their corrected positions.

Disadvantages:

1. It has relatively poor aesthetic appearance as it appears

on the labial surface of the incisors makes it

unacceptable by some patients.

2. Skill is required for adaptation of the bow and in the

same time to prevent the wire from traumatizing the

soft tissues.

3. Care must be taken during activation of the labial arch

as a small activation might produce a very large force.

4. Subjected to distortion when it mistakenly used by

patient to insert and dislodge the appliance.

49

Step By Step construction:

1.

Sketch the design on the cast as shown in (figure:10).

2.

Take about 15 cm of 0.7mm wire. DO NOT straighten

it as the curve of the wire is useful to produce a

uniform anterior bow.

3.

Put the wire on the labial surface of the anterior

segment so that the centre of the wire piece fits against

the midline between the central incisors and

horizontally at the junction between the middle and

gingival third of the crown.

4.

Mark two points one on each side of the anterior

segment at the distal border of the lateral incisor.

5.

Using the pliers, hold the wire from one of the marked

points and make a sharp 90 degree angle bend, repeat

the procedure for both points so that the curved arch

form span between the two bends fits to the dental ach

while the wire pieces from both sides head toward the

vestibule.

6.

Now re adapt the wire in position and put a mark at

both sides bout 7mm shorter than the vestibule depth,

this will leave roughly 3mm of vestibular clearance

after forming the loops. Grab the wire from the

marked point and start to form a U shape loop directed

away from the bow, the diameter of the U shape loops

must be no less than 5mm.

7.

Put the wire in position. Make any necessary

adjustments to maintain the U shape loops in the

buccal vestibule vertically and horizontally so as to

have 1-2mm clearance from the soft tissue.

Please note that this section is for training purpose only and the

construction steps are not required in any written or verbal exam.

50

8.

After that, mark the wire at the embrasure between the

canine and the first premolar and bend the wire from

that point palatally.

9.

Palatally, the wire pass about 10mm ending with a

small hook to provide retention in the acrylic, make

sure that the wire must be 1-2mm away from the soft

tissue.

Activation:

The flexibility of the labial arch is highly dependent

on the length of the U shape loops, while it is relatively

resilient in the vertical direction; it is very hard in the

horizontal direction, only 1mm activation is quite enough

to produce movement of the four incisors.

Activation of the labial arch during retraction of

anterior teeth is done from the U shape loops by closing

the loops so that the arch will move 1mm palatally, the

activation must not exceed that because it will produce

excessive force on the centrals. Care must be taken not to

distort the bow or traumatize the soft vestibular tissue

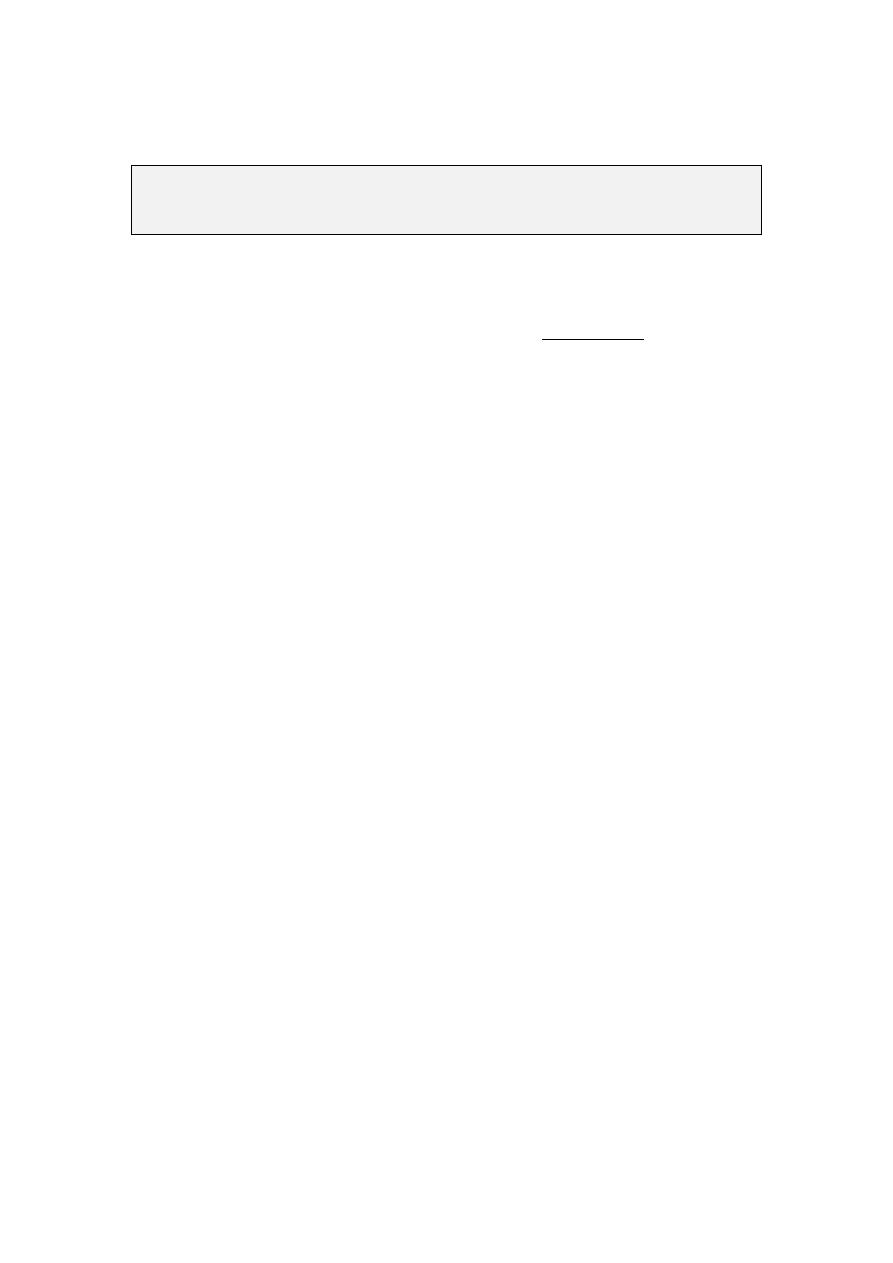

Figure

10 Labial Arch , Anterior view

51

Lab:11.

The Fitted Labial arch

.

When the anterior teeth are proclined so that neither

the Adam's clasp nor the labial arch was suitable, anterior

retention is provided by a modification that combines

both. This was named fitted labial arch.

The basic design is composed of a horizontal wire

span fitted on labial surface at the junction between the

incisal and middle third of the incisors and extended over

two or four incisors ending from both sides by a small 2-

3mm U shape loops directed gingivally. The wire then

passes from both sides to cross the occlusal surface to the

lingual side ending by a hook-like bends for retention in

the acrylic.

Indications:

1. Proclined anterior teeth.

2. Anterior retention is required where labial arch is

not suitable. An example for that is the use of

unilateral canine retractor.

Advantages:

1. Simple in construction and adaptation.

2. Provide good retention of the appliance anteriorly

Disadvantages:

1. Poor aesthetic as it approaches the incisal margin.

2. May interfere with the opposite arch during

occlusion.

52

Step by step construction:

1. Sketch the design on the cast according to the

description above.

2. Make the necessary wire bending to adapt the wire

horizontally on the labial surface so that it will

fallow the curvature of the incisors and mark it

about 4mm short to the distal end of the incisors

from both sides.

3. Now hold the wire from the marked point and make

a sharp 90 degree angle bend, repeat the bend for

the other side.

4. Hold the wire with the pliers beaks near the first

bend and start forming a U shape loop and repeat

the procedure for the other side. The diameter of the

loops should be about 2-3mm so that the resulted

wire will fit to the dimensions of the involved teeth.

5. Re position the wire and make any necessary

adjustment so that the wire fits against the labial

surface of the incisors, place marks on the wire from

both sides at the incisal margin where a sharp bend

will turn the wire direction down to the palatal or

lingual surface.

6.

The wire from both sides must be extended about

one cm on the palatal soft tissue ending by retentive

hooks

.

Activation or tightening of the wire:

Please note that this section is for training purpose only and the

construction steps are not required in any written or verbal exam.

53

The fitted labial arch provide retention through the

horizontal bow which is fitted exactly on the labial

surface of the incisors, tightening of the bow is made

through the adjustment of the U shape loops that

makes the bow tighter on the labial surface.

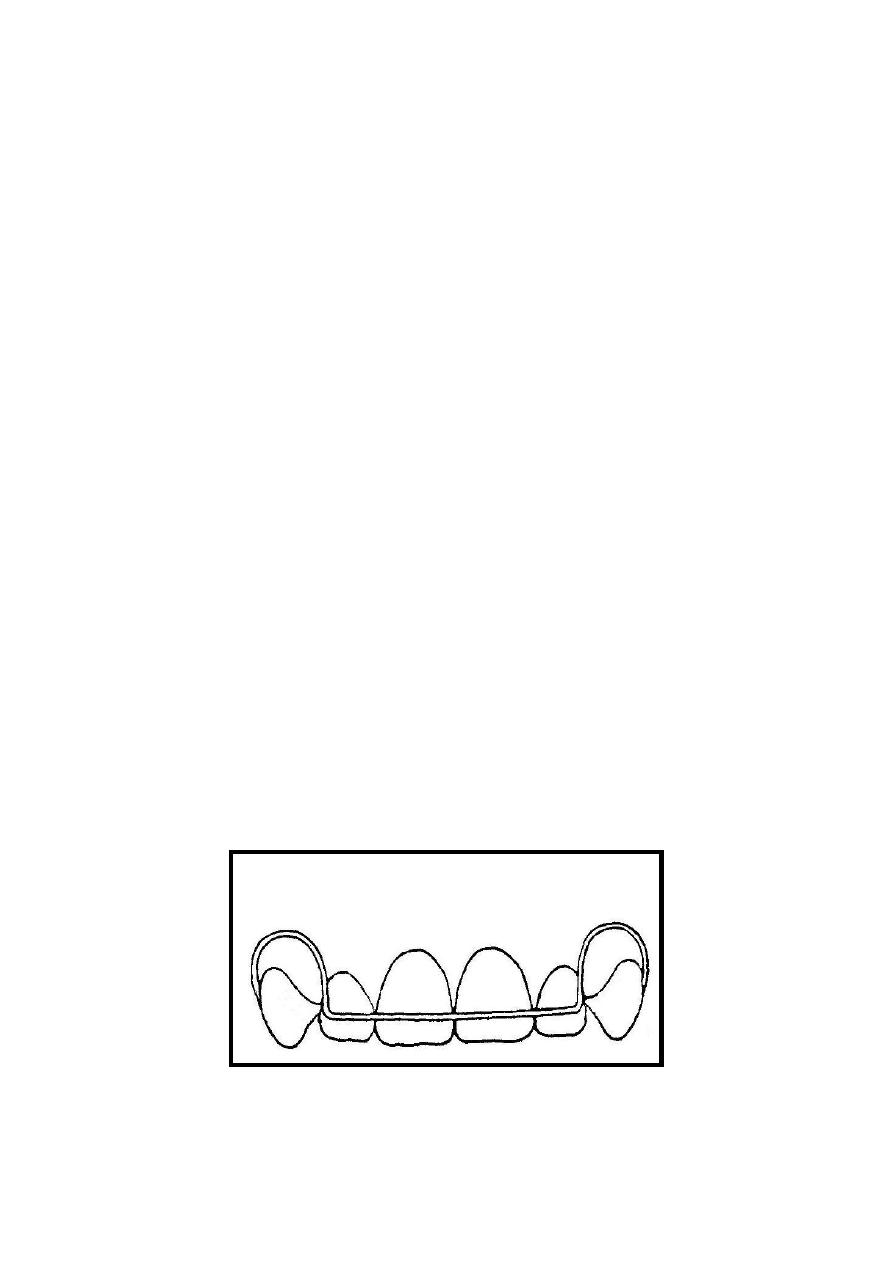

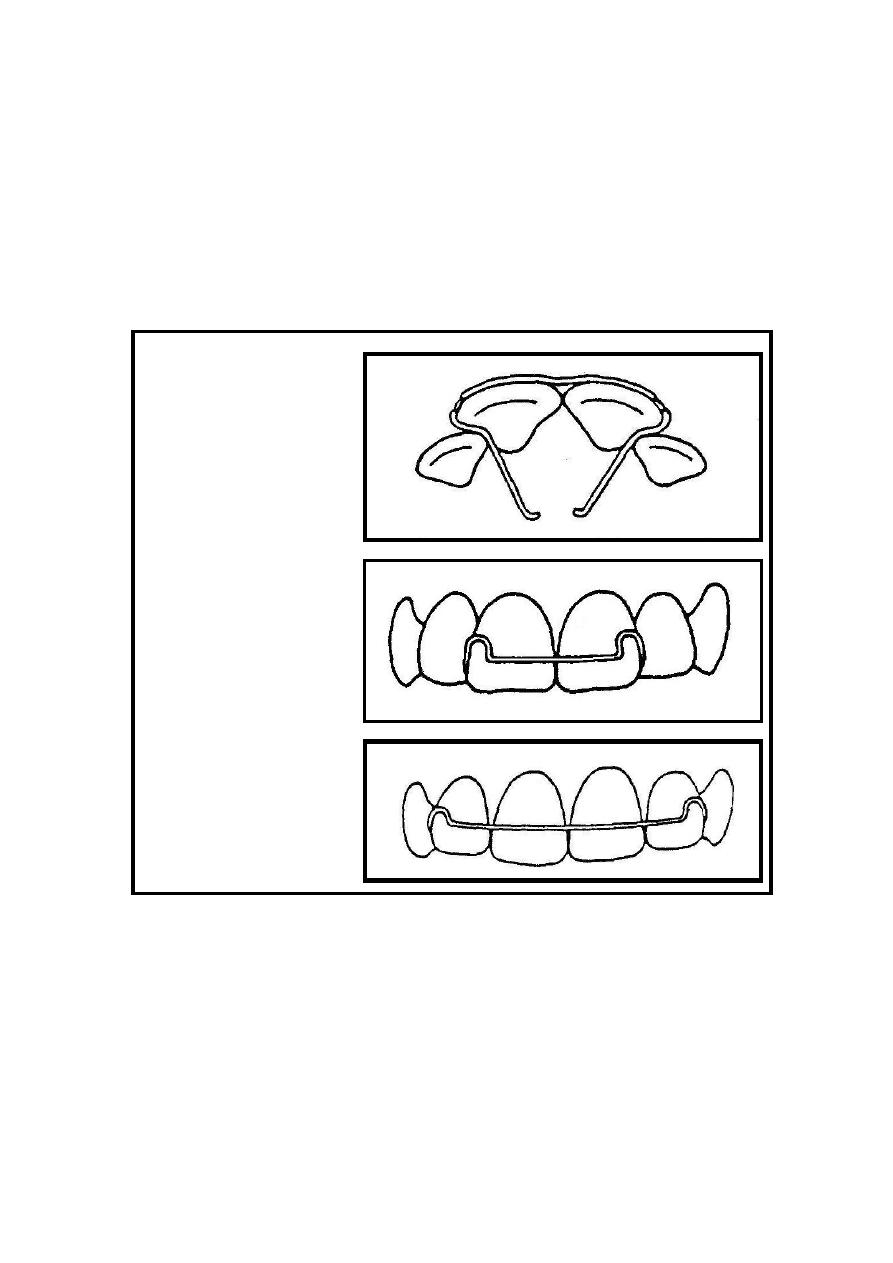

A:

Occlusal view of the fitted

labial wire, note the closely

fitted addaptation of the

wire on the labial surface of

the incisos.

B:

Short Fitted labial wire

involves the two central

incisors only.

C 3:

Long fitted wire involves

the four incisors

Figure

11 Fitted labial arch

54

Lab: 12. Robert's retractor .

.

This is a flexible bow constructed with 0.5 mm

stainless steel wire. It is composed of a bow which

extended on the labial surface of the four incisors. The

bow takes the shape of an ideal arch form despite the

irregularities of the anterior teeth as they will be gathered

when retracted. At both ends a sharp bend will direct the

wire gingivally where it will form a 3-5 mm coil not less

than 3mm shorter than the full depth of the vestibule.

The coil Then changes the redirected of the wire

occlusally where it will cross the occlusal surface distal

to the canine and turn onto the palatal surface.

Robert's retractor is highly flexible in all its parts

except at the part from the coil to the acrylic base plate

where it will be shielded by a 0.5mm stainless steel tube

to support the structure of the flexible bow.

In this lab and only for training purpose the full

design will be constructed with 0.7mm wire which is

believed to be much easier in construction and

adaptation.

Indications:

1. Retraction of anterior segment

2. correction of spacing or minor irregularities

Advantages:

1. This spring produces a light force and easily

adjustable.

55

2. Because it swings backward and downward it will

not slide gingivally on the anterior teeth when

retracted.

Disadvantages:

1. If the supporting arms are not correctly positioned

the sulcus may be traumatized

2. In case of breakage major re construction will be

required.

Step by Step construction:

1. Sketch the design on the cast model as shown in

(figure 12).

2.

Take about 15 cm of 0.5mm (0.7mm for training

only). Don’t straighten it as the curve of the wire is

useful to produce a uniform anterior bow.

3.

Place the wire on the labial surface of the anterior

segment so that the centre of the wire piece fit

against the midline between the central incisors and

vertically at the junction between the middle and

gingival third of the crown.

4.

Adjust the wire by your hands to make an anterior

bow that simulate the normal arch form of the

patient. Despite the irregularities of the anterior

teeth, the bow must be a uniform arch.

5.

Mark two points one on each side of the anterior

segment at the distal border of the lateral incisor.

Please note that this section is for training purpose only and the

construction steps are not required in any written or verbal exam.

56

6. Hold the wire with the pliers from one of the

marked points and make a sharp 90 degree angle

bend, repeat the procedure for both points so that

the bow extends horizontally on the labial surface of

the incisors while the wire pieces from both sides

head toward the vestibule.

7. Now re adapt the wire in position and place a mark

at both sides bout 7mm shorter than the vestibule

depth, grab the wire from the marked point and start

to form a 3-5mm coil, note that the active arm (near

to the bow) must be under the coil.

8. Re-position the wire and make any necessary

adjustment to maintain the coils in the curvature of

the dental arch vertically and horizontally.

9. Inset the wire from both sides into a stainless steel

tube which will extend from the coil to the acrylic

Base plate in the finished appliance (this step will

not be done with 0.7 wire only for training).

10.

After that, mark the wire (the tube) at the

embrasure between the canine and the first premolar

and bend it from that point Palatally.

11.

On the palate, the wire pass about 10mm ended

with a small hook to provide retention in the acrylic,

make sure that the wire in must be 1-2mm away

from the soft tissue.

Activation:

This

bow is light and flexible. An adjustment of

about 3mm is suitable but the site of adjustment is very

important because if the wire is activated at the point

where it emerges from the supporting tube (a sight of

stress concentration) it will often fracture. The bow is

57

adjusted by bending in the vertical limb below the coil.

As the incisors retracted the bow swings downward and

backwards and the level of the horizontal part will need

adjustment.

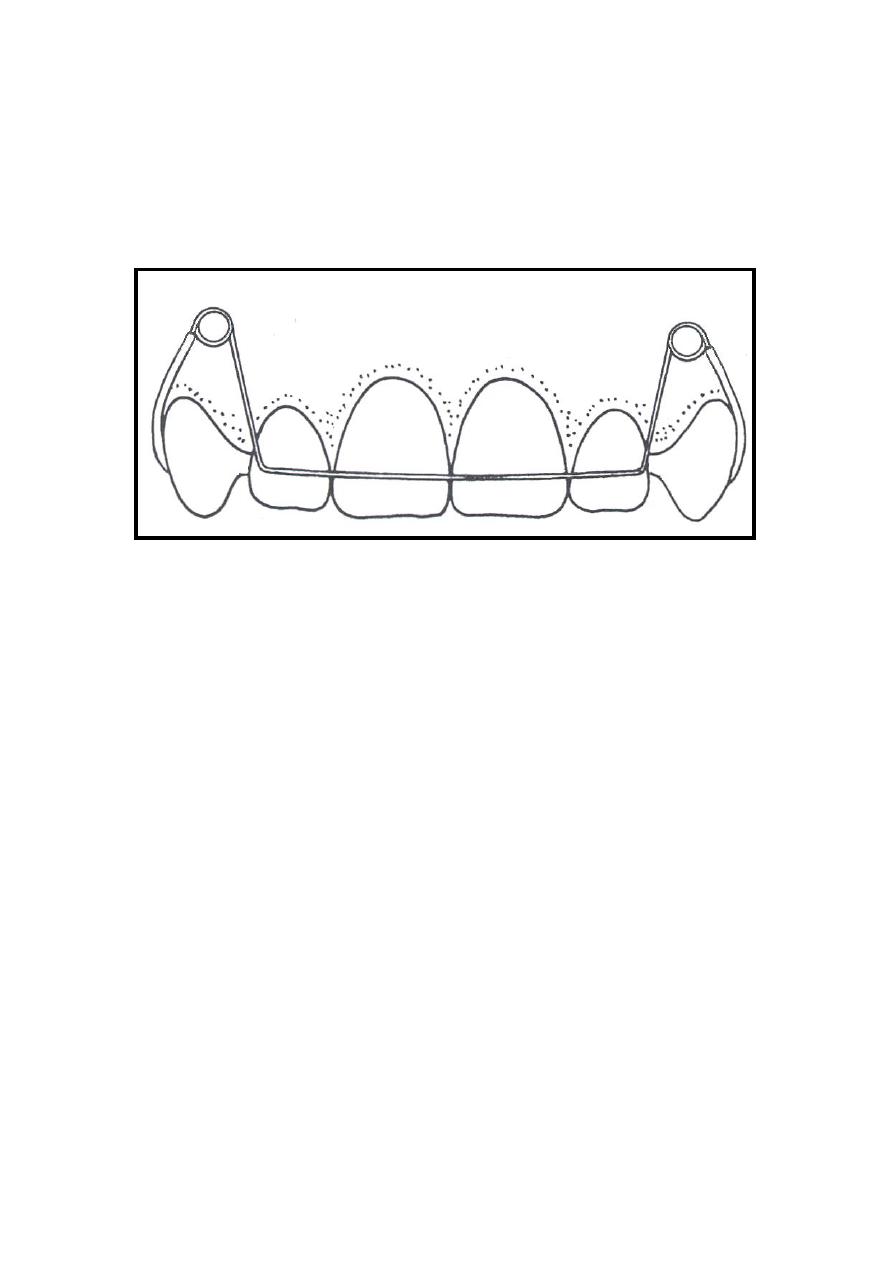

Figure

12 Robert Retractor, Front view

58

Lab: 13 .

Acrylic base plate .

The acrylic base plate constitutes the body of the

removable appliance. It has thee functions:

1. Act as the foundation into which the retaining clasps

and active components of the appliance are

embedded, such as springs and screws.

2. Contribute to the anchorage during the course of

active tooth movement. This might be achieved

though the close fit of the acrylic to the palatal

surface of the teeth and palate.

3.

It could be extended to form bite planes to

disengage the occlusion or produce overbite

reduction

.

Design:

The design of the acrylic base plate depend on the

case to be treated, each case may have deferent

modifications according to the components to be

incorporated into the design. But there are general points

that must be considered during the construction of the

acrylic base plate:

1. Several types of acrylic materials could be used for

construction of the base plate, but chemical cured

acrylic resin is commonly used since it is economic

and less labor intensive.

2. The base plate needs to be thick enough to carry the

retentive and the active components, but should be as

thin as possible to avoid discomfort to the patient,

ideally, this should be as thick as a sheet of modeling

wax (2-3)mm.

59

3. The base plate should normally cover most of the hard

palate, finishing just distal to the first molars.

4. It should fit closely to the palate and around the teeth

that are not to be moved, extends up to one third of the

crown length. Whereas the teeth being moved should

have enough clearance around to move freely.

5. The clasps or springs retentive parts should be

embedded in the acrylic, exposure of the wire may

cause future dislodgement or malfunction of the

springs and clasps.

Modifications to the Acrylic base plate:

The design of the base plate may be modified to

accommodate springs as in boxing , add an active

extensions as in Bite planes , or to accommodate

expansion screws to the basic design.

1- bite planes

The acrylic may be thickened palatal to upper

incisors to form the anterior bite plane or may be

extended on the occlusal surface of the posterior teeth

to form a posterior bite plane.

a- Anterior bite plane

The principal use of the anterior bite plane is for the

reduction of the overbite. This occurs primarily by

alteration of the rate of eruption of the posterior teeth

relative to the lower anterior. Several points must be

considered during the construction of the anterior bite

plane:

60

1. Vertically, the acrylic should be as high as that

when the lower anterior teeth are in contact with the

acrylic bite plane the premolars are separated by 2-

3mm.

2. The posterior limit of the anterior bite plane should

extend just sufficiently to engage the lower incisors.

3. The anterior bite plane should be made with the

occlusal surface parallel to the occlusal plane.

Inclined

bite

planes

may

cause

unwanted

movements. However this may be required in some

cases.

4. Adjustment of the bite plane may be done by

addition of acrylic which may be lost due to

occlusal wear between visits.

5. If the lower incisors are irregular, adjustment of the

bite plane surface is needed to provide contact with

at least 3 lower incisors, then few visits later

leveling of the occlusal plane is possible to lower

anterior level.

b- Posterior bite plane

It is occasionally necessary to extend the base plate to

cover the occlusal surfaces of the posterior teeth

bilaterally to open the bite and so relief the incisal or

cuspal lock while an anterior cross bite or a bucco-

lingual abnormality is being corrected.

Few points must be considered during the

construction of posterior bite plane:

1.

The posterior bite plane should be thick

enough just to disengage the interlocking of the

anterior teeth and permit correction of cross bite.

61

2.

The posterior bite plane should extend on the

first molar and premolars and should be faceted to

accommodate the cusps of the opposing teeth.

3.

It must be simultaneously in contact in both

sides, any correction must be made using articulating

paper.

4.

The mandible must be at a centric relation, this

is achieved by putting a piece of modeling wax on the

occlusal surface of the molars and premolars and

instruct the patient to close in centric relation to the

desired height. Then transfer the wax records with the

upper and lower cast to the articulator.

5.

It is important that the (tags) which is the parts

of the clasp that crosses the occlusal surface must be

free from acrylic of the bite plane, presence of acrylic

surrounding the wire may cause limitation of the

flexibility of the wire. This achieved by covering the

wires with wax before applying acrylic.

62

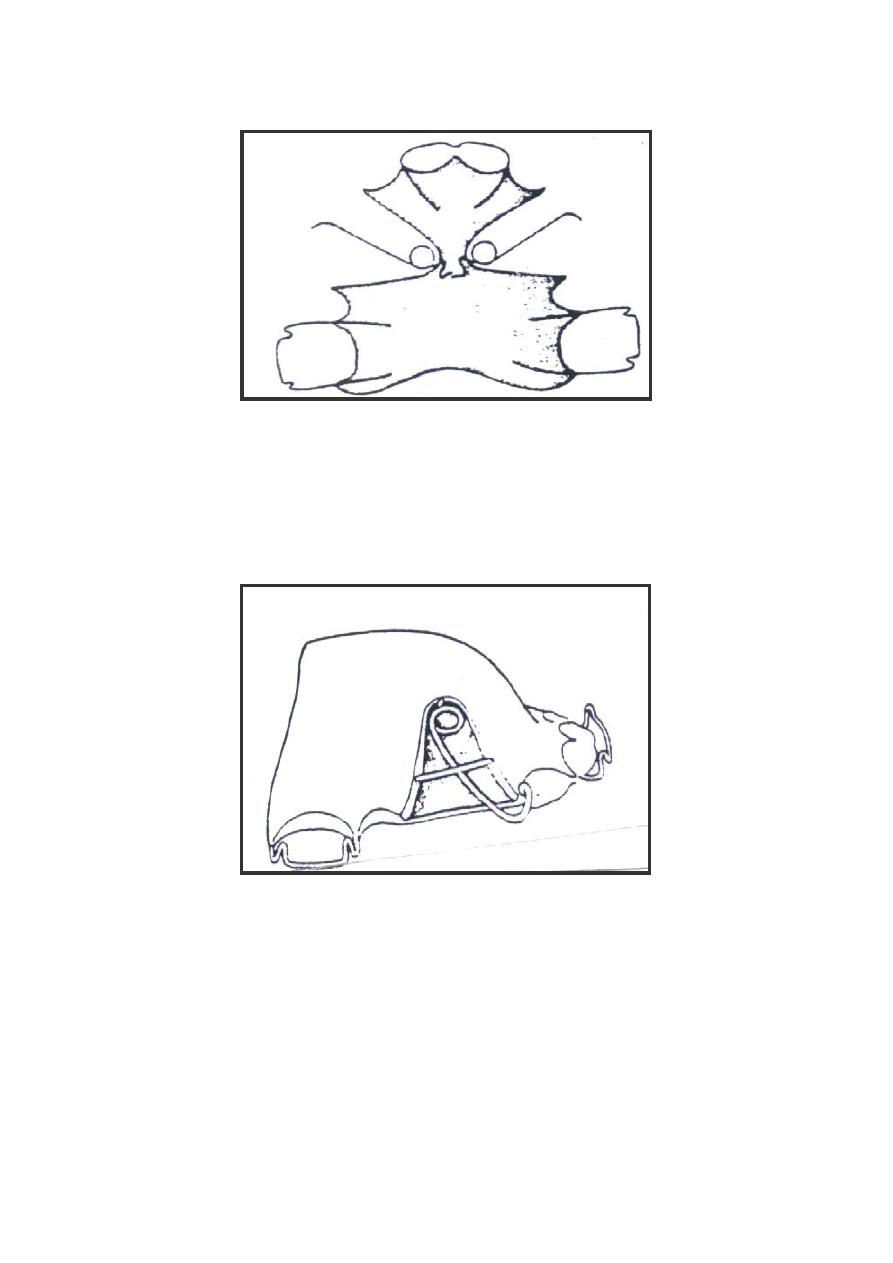

2 Boxing, Open spring and Wire guard:

Those are three designs of the acrylic base plate

around the palatal springs. Boxing (Figure 14) is to

make the active arm and the coil free to move inside

an acrylic chamber built into the base-plate, while

open spring (Figure 13) is to completely remove the

acrylic of the base-plate from the path of the

movement and leave the active arm and the coil free

without protection, the guard wire (figure 14) may

be incorporate in the open spring design to prevent

distortion of the spring during wearing and activation,

it could be added from the tongue side or occasionally

from both sides, it may also be used with the boxing

design palatally for the same reason.

Boxing is made by covering the entire spring with

wax except at the retentive part. The wax must also

cover the area at which future activations may occur

so that the spring will move freely along its range of

action. The acrylic base plate material should then

cover the palatal surface including the boxed spring

with the same thickness which will form a bulge or

elevation at the area of boxing. Then after the acrylic

is set, a hot water bath will eliminate the wax leaving

the spring to move in an acrylic chamber attached

only at its retentive part with the acrylic.

Open spring and guard wire are made in the same

manner except that the acrylic will not cover the

boxed area but leave it opened with out acrylic or

crossed by a piece of wire to protect the spring in

case of guard wire (Figure:13) .

63

Figure

13 Open spring

Figure

14 Combined Boxing and Wire guard

64

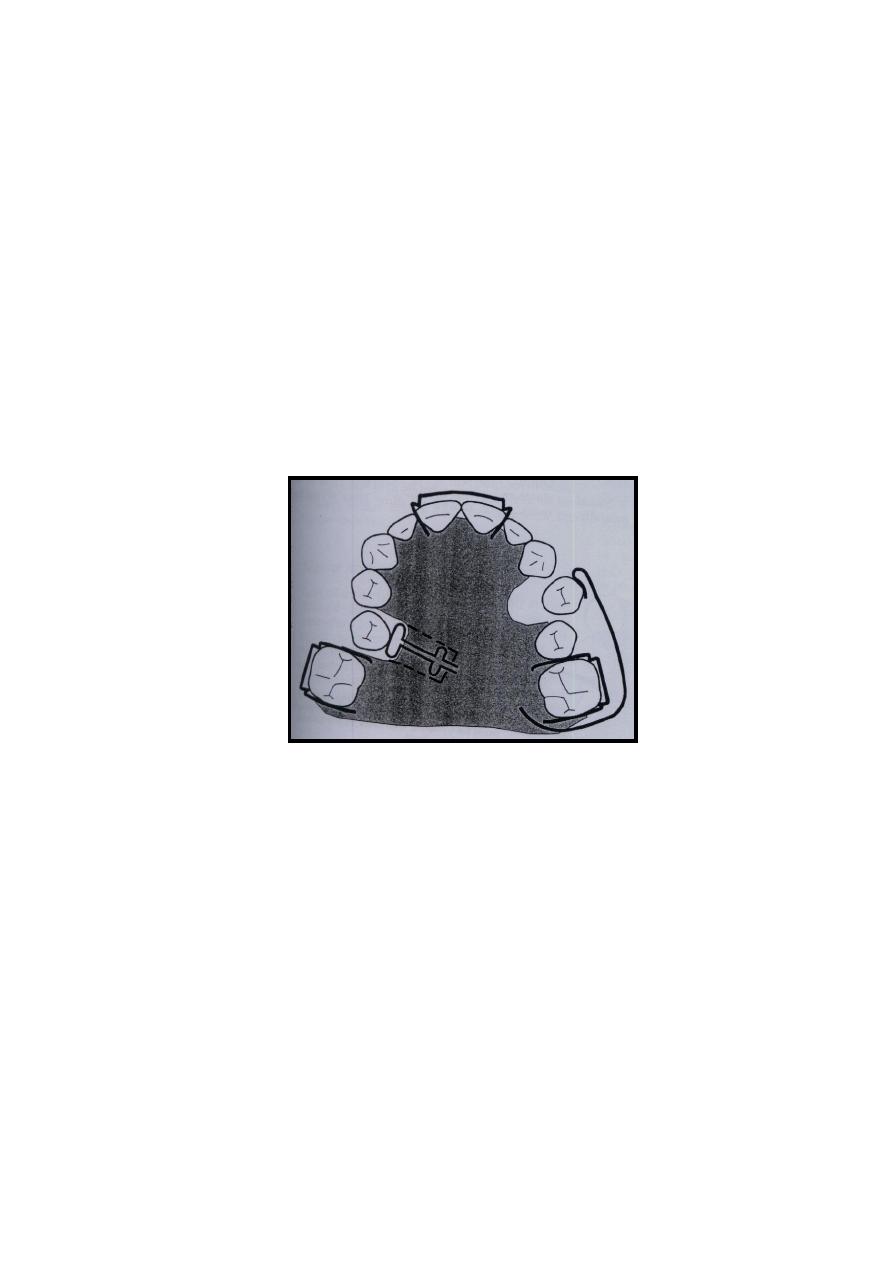

Lab:14.

Orthodontic Screws

3 Orthodontic Screws

An alternative method of providing orthodontic

force is to use expansion screw as an integral part of

the removable appliance (Figure 15). The screw

normally transmits its force by means of acrylic,

which comes in contact with the teeth. Many types of

screw are commercially available for use in removable

appliance (one dimension, two dimensions , fan shape,

etc…), the type of the screw is specific for each case

and have to meat the requirements of an Adequate

travel, Stability and minimal bulk.

Description:

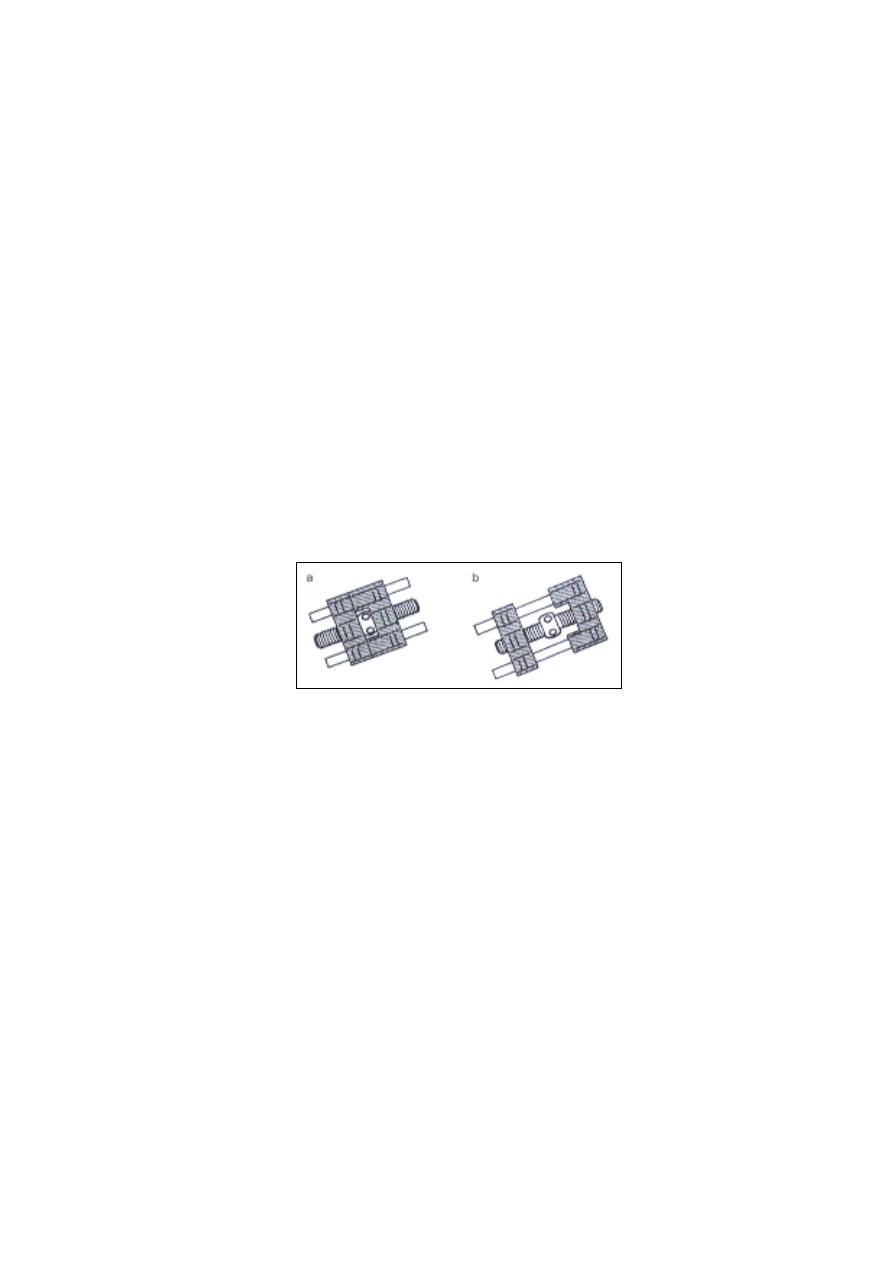

Screws are produce by a number of manufacturers and

a wide range of sizes and shapes are available.

Typically, the design has a central threaded screw,

each end of which engages into a small metal or

plastic block. One of this blocks caries two guide

wires which lie parallel to the screw and pass through

holes in the opposing block. The centre of the screw is

enlarged into a small boss into which four radially

positioned holes are visible. A small wire key is

supplied and activation is made by insertion of the key

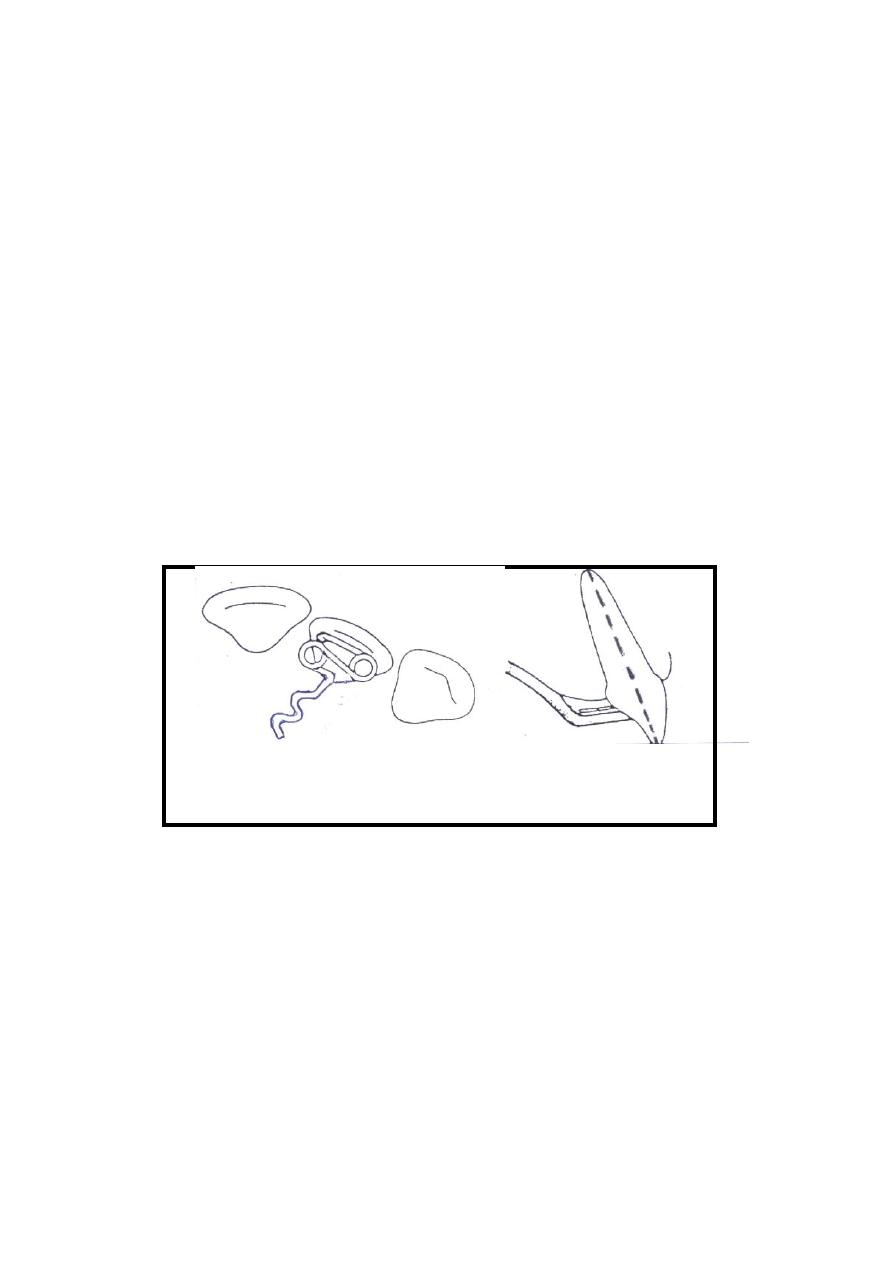

Figure

15 Orthodontic Screws. A: 2sides; B: One Side.

65

into one of these holes and turned like a capstan

through 90 degree until it touches the guide. For

further activations the procedure must be repeated

with the key inserted into the next hole.

Uses:

Screws are recommended only in those few

situations where spring will be unsatisfactory.

Nevertheless, there are certain situations in which

screws are very useful, for example

1. Expansion

It is some times necessary to increase the width

of the upper dental arch or to correct a unilateral cross

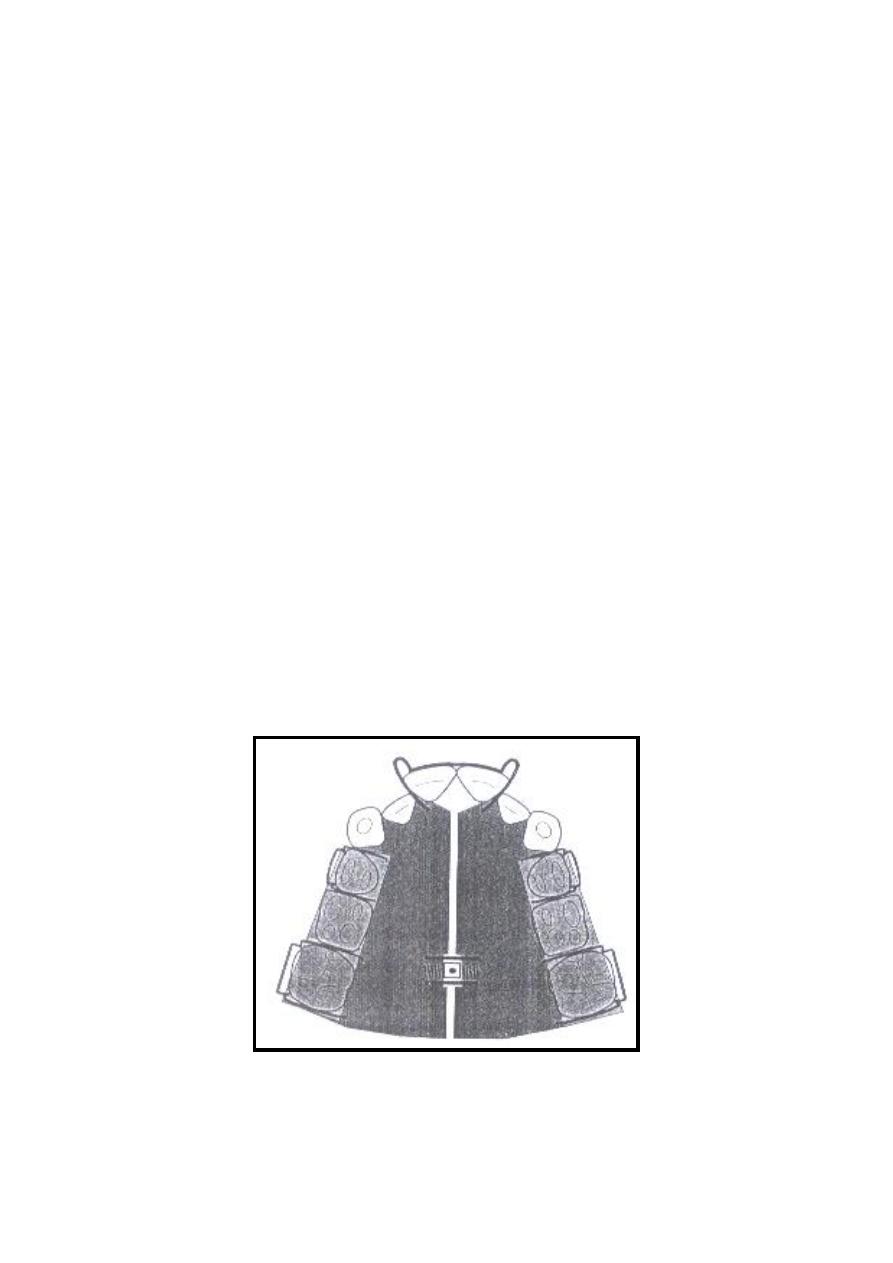

bite .Symmetrical widening of the upper arch could be

achieved by removable appliance with suitable design

containing four Adam's clasps on permanent molars

and premolars. In this case the screw should be placed

horizontally on the midline of the palate. In addition

to a shallow posterior bite planes to prevent secondary

lower arch widening (Figure 16).

Figure

16 Orthodontic Screw at the midline used for expansion

66

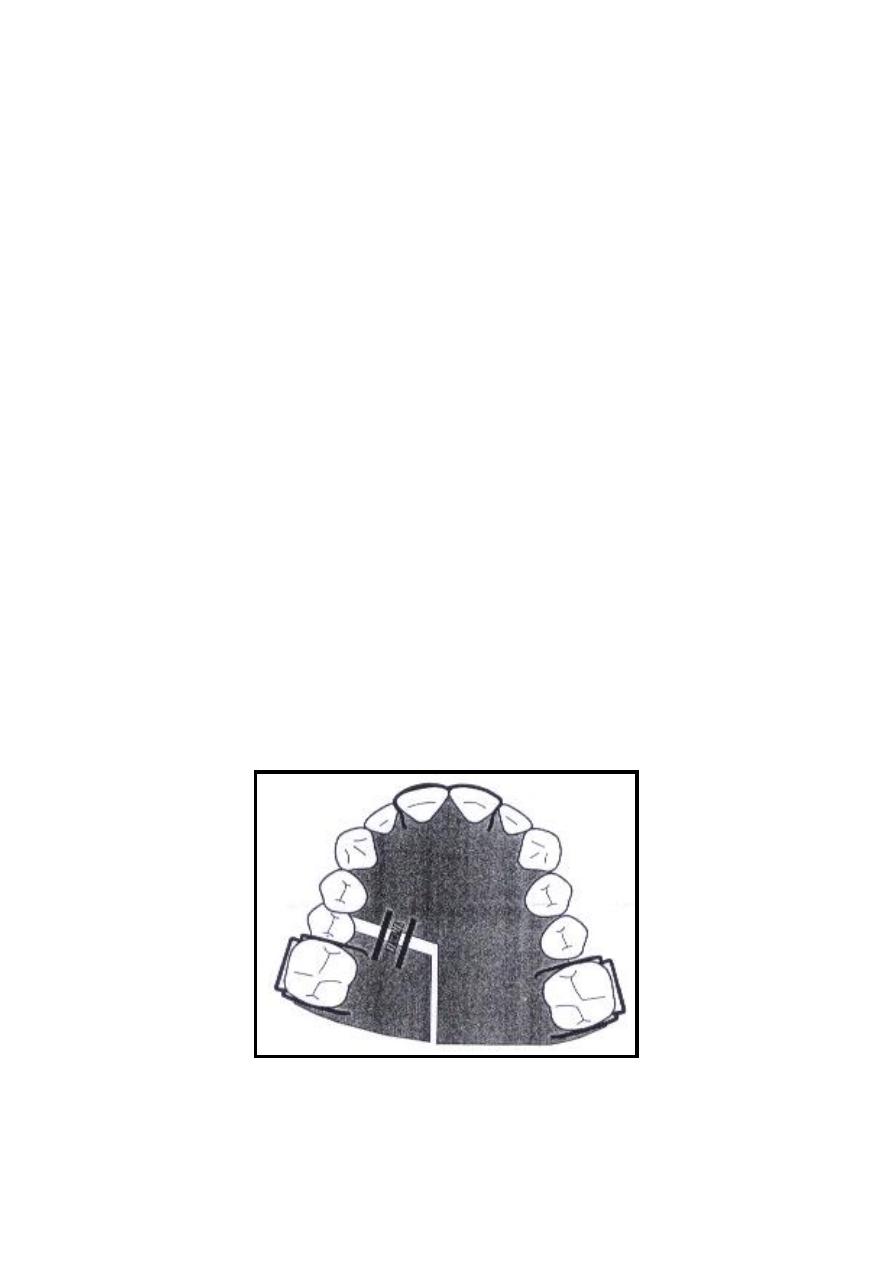

2. Distal movement:

Distal movement of molars could be achieved by a

removable appliance carrying bilateral screws which

will deliver distally directed force to the molars.

Careful positioning of the screws will be necessary in

accordance with the three dimensional orientations of

the arch. A version with a screw only one side of the

appliance is also useful in a situation for example if

unilateral distalization of molar (Figure 17).

Positioning:

Although clasps and springs accept minor

adjustment to correct faulty positioning, screws can

only be corrected by cutting out the screw from the

acrylic and re-fabricate it. It is therefore very

important to accurately position the screw in the

three dimensions during construction.

Figure

17 Orthodontic Screw at one side of the arch used

for distal movement.

67

Disadvantages

1. Most important is the bulky appliance that will

cause discomfort to the patient.

2. over activation may cause difficulties in appliance

incretion and will gradually lose its fitness

3. Full cooperation of the patient is required since

relapse is quick and may elongate treatment time.

Adjustments:

Activation of the screw is done by inserting the key

wire into one of the activation holes and turn the screw

to the direction that will open the screw until the key

touches the guide bars ( the direction is usually

marked by an arrow on the screw), this will make

quarter turn. Farther activation means to repeat the

previous work. Activations are done by the patient

once or twice a week, each quarter turn will provide a

0.25mm opining that means about 1.5-2mm per month

which is considered a reasonable amount of tooth

movement.

68

References:

Sandhya, S.L., 2008. Orthodontic Removable Appliance

2nd ed., Jaypee.

Singh, G., 2007. Textbook of Orthodontics 2nd ed.,

Jaypee.