• Designation: C 702 – 98

• American Association State Highway and Transportation Officials Standard: T 248• Standard Practice for Reducing Samples of Aggregate to Testing Size1

• 1. Significance and Use

• This practice provides procedures for reducing the large sample obtained in the field or produced in the laboratory to a convenient size for conducting a number of tests to describe the material and measure its quality in a manner that the smaller test sample portion is most likely to be a representation of the larger sample, and thus of the total supply.• 2. Selection of Method

• 2.1 Fine Aggregate—Reduce the size of samples of fine aggregate that are drier than the saturated-surface-dry condition using a mechanical splitter according to Method A. Reduce the size of samples having free moisture on the particle surfaces by quartering according to Method B, or by treating as a miniature stockpile as described in Method C.• 2.1.1 If the use of Method B or Method C is desired, and the sample does not have free moisture on the particle surfaces, moisten the sample to obtain free moisture on the particle surfaces, mix thoroughly, and then reduce the sample size.

• 2.1.2 If use of Method A is desired and the sample has free moisture on the particle surfaces, dry the sample to at least the saturated-surface-dry condition, and then reduce the sample size.

• 2.2 Coarse Aggregates and Mixtures of Coarse and Fine Aggregates—Reduce the sample using a mechanical splitter in accordance with Method A (preferred method) or by quartering in accordance with Method B. The miniature stockpile Method C is not permitted for coarse aggregates or mixtures of coarse and fine aggregates.

• Size of particles(mm)

• Size of particles (in)• Minimum weight of sample

• ≥ 25

• ≥ 1.0

• 50

• 5< max. agg<25

• 3/16<Max.agg<1.0

• 25

• <5

• <3/16

• 13

• Weight of sampling

• METHOD A—MECHANICAL SPLITTER

• 3. Apparatus

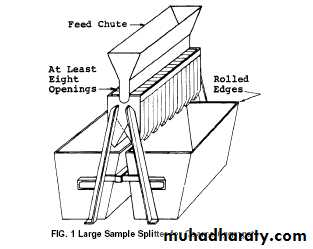

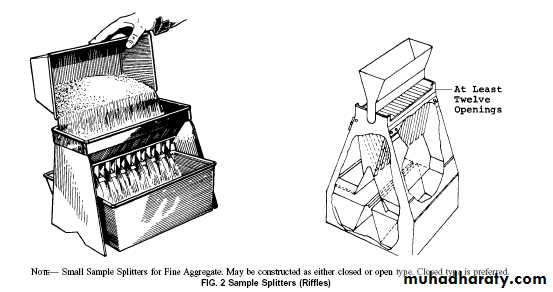

• 3.1 Sample Splitter—Sample splitters shall have an even number of equal width chutes, but not less than a total of eight for coarse aggregate, or twelve for fine aggregate, which discharge alternately to each side of the splitter. For coarse aggregate and mixed aggregate, the minimum width of the individual chutes shall be approximately 50 % larger than the largest particles in the sample to be split. For dry fine aggregate in which the sample will pass the 9.5-mm (3⁄8-in.) sieve , a splitter having chutes 12.5 to 20 mm wide shall be used. The splitter shall be equipped with two receptacles to hold the two halves of the sample following splitting. It shall also be equipped with a straight edged pan. The splitter and accessory equipment shall be so designed that the sample will flow smoothly without restriction or loss of material (see Fig. 1 and Fig. 2).

• METHOD B—QUARTERING

• 5. Apparatus• 5.1 Apparatus shall consist of a shovel, or trowel; a broom or brush; and a canvas blanket approximately 2 by 2.5 m.

• 6. Procedure

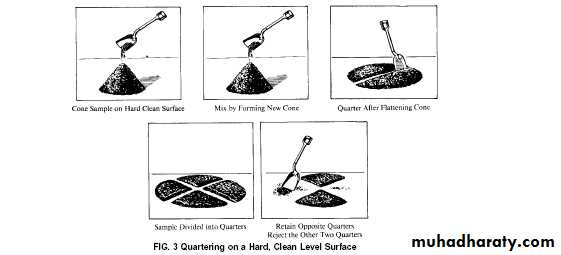

• 6.1.1 Place the original sample on a hard, clean, level surface where there will be neither loss of material nor the accidental addition of foreign material. Mix the material by turning the entire sample over three times. With the last turning, shovel the entire sample into a conical pile. Carefully flatten the conical pile to a uniform thickness and diameter by pressing down the apex with a shovel. The diameter should be approximately four to eight times the thickness. Divide the flattened mass into four equal quarters with a shovel or trowel and remove two diagonally opposite quarters, including all fine material, and brush the cleared spaces clean.

Successively mix and quarter the remaining material until the sample is reduced to the desired size (Fig. 3).

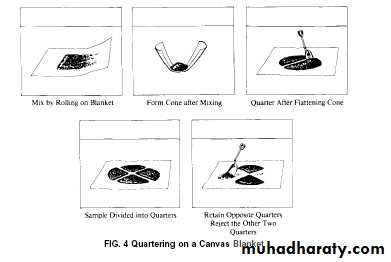

6.1.2 As an alternative to the procedure described in 6.1.1, when the floor surface is uneven, place the field sample on a canvas blanket and mix with a shovel as described in 6.1.1, or by alternately lifting each corner of the canvas and pulling it over the sample toward the diagonally opposite corner causing the material to be rolled. Flatten the pile as described in 6.1.1. Divide the sample as described in 6.1.1, or if the surface beneath the blanket is uneven, insert a stick or pipe beneath the blanket and under the center of the pile, then lift both ends of the stick, dividing the sample into two equal parts. Remove the stick leaving a fold of the blanket between the divided portions. Insert the stick under the center of the pile at right angles to the first division and again lift both ends of the stick, dividing the sample into four equal parts. Remove two diagonally opposite quarters, being careful to clean the fines from the blanket. Successively mix and quarter the remaining material until the sample is reduced to the desired size (Fig. 4).

• METHOD C—MINIATURE STOCKPILE SAMPLING

• (DAMP FINE AGGREGATE ONLY)• 7. Apparatus

• 7.1 Apparatus shall consist of a straight-edged scoop, shovel, or trowel for mixing the aggregate, and either a small sampling, small scoop, or spoon for sampling.

• 8. Procedure

• 8.1 Place the original sample of damp fine aggregate on a hard clean, level surface where there will be neither loss of material nor the accidental addition of foreign material. Mix the material thoroughly by turning the entire sample over three times. With the last turning, shovel the entire sample into a conical pile. If desired, flatten the conical pile to a uniform thickness and diameter by pressing down the apex with a shovel so that each quarter sector of the resulting pile will contain the material originally in it.

Obtain a sample for each test by selecting at least five increments of material at random locations from the miniature stockpile, using any of the sampling devices described in 7.1.